Regenerative turbine pump application, design, and features

•

4 gefällt mir•1,888 views

A regenerative turbine pump varies from the more familiar centrifugal pump mostly in the design of its impeller. This design difference makes the regenerative turbine pump uniquely suited for low NPSH (Net Positive Suction Head) applications, among others. Regenerative turbine pumps can safely pump liquids close to the boiling point without the detriment of cavitation, and the pump design is suitable for handling highly unstable liquids.

Melden

Teilen

Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

Cell imbalance can cause negative effects such as early stopping of the battery charging and discharging process which can reduce its capacity. In the previous active balancing research, the energy used for the balancing process was taken from the cell or battery pack, resulting in drop of electric vehicle driving range. In this paper, a cell charger based battery balancing system is proposed with a reduction in the number of switches. The use of a cell charger aims to increase the usable energy of the battery pack, since the energy used for the balancing process is taken directly from the grid. The use of fewer switches aims to reduce the cost and space used on the battery management system (BMS) hardware. The charger used for the balancing process has a maximum current of 3 A and a maximum voltage of 3.65 V while the number of switches used is n+5 for n batteries. A 15S1P 200 Ah LiFePO4 battery pack consists of 15 cells used for testing purpose. The test results show that the time needed to equalize the 15 cell battery voltage reaches 6 hours from the difference between the highest and lowest battery cell voltages of 145.1 mV to 15.1 mV.Active battery balancing system for electric vehicles based on cell charger

Active battery balancing system for electric vehicles based on cell chargerInternational Journal of Power Electronics and Drive Systems

Weitere ähnliche Inhalte

Was ist angesagt?

Cell imbalance can cause negative effects such as early stopping of the battery charging and discharging process which can reduce its capacity. In the previous active balancing research, the energy used for the balancing process was taken from the cell or battery pack, resulting in drop of electric vehicle driving range. In this paper, a cell charger based battery balancing system is proposed with a reduction in the number of switches. The use of a cell charger aims to increase the usable energy of the battery pack, since the energy used for the balancing process is taken directly from the grid. The use of fewer switches aims to reduce the cost and space used on the battery management system (BMS) hardware. The charger used for the balancing process has a maximum current of 3 A and a maximum voltage of 3.65 V while the number of switches used is n+5 for n batteries. A 15S1P 200 Ah LiFePO4 battery pack consists of 15 cells used for testing purpose. The test results show that the time needed to equalize the 15 cell battery voltage reaches 6 hours from the difference between the highest and lowest battery cell voltages of 145.1 mV to 15.1 mV.Active battery balancing system for electric vehicles based on cell charger

Active battery balancing system for electric vehicles based on cell chargerInternational Journal of Power Electronics and Drive Systems

Was ist angesagt? (20)

Supercapacitors and Battery power management for Hybrid Vehicle Applications ...

Supercapacitors and Battery power management for Hybrid Vehicle Applications ...

“SEMINAR REPORT ON SOLAR ASSISTED VAPOUR ADSORPTION REFRIGERATION SYSTEM”

“SEMINAR REPORT ON SOLAR ASSISTED VAPOUR ADSORPTION REFRIGERATION SYSTEM”

Active battery balancing system for electric vehicles based on cell charger

Active battery balancing system for electric vehicles based on cell charger

Andere mochten auch

Andere mochten auch (17)

Design and testing of disc type hybrid turbine pump

Design and testing of disc type hybrid turbine pump

P.P.T on water distribution system by Manish Pandey

P.P.T on water distribution system by Manish Pandey

Ähnlich wie Regenerative turbine pump application, design, and features

Ähnlich wie Regenerative turbine pump application, design, and features (20)

Introduction to Pumps , Compressors,Fans & Blowers.pdf

Introduction to Pumps , Compressors,Fans & Blowers.pdf

INTRODUCTION TO PUMPS, COMPRESSORS, FANS & BLOWERS.pdf

INTRODUCTION TO PUMPS, COMPRESSORS, FANS & BLOWERS.pdf

ch2 pumps this pdf is more help full as the reference

ch2 pumps this pdf is more help full as the reference

Basics Concepts of Operation, Maintenance, and Troubleshooting of a Centrifug...

Basics Concepts of Operation, Maintenance, and Troubleshooting of a Centrifug...

Radial and axial thrust in centrifugal pump and Methods use to balance them

Radial and axial thrust in centrifugal pump and Methods use to balance them

Mehr von Mountain States Engineering and Controls

Mehr von Mountain States Engineering and Controls (20)

Breathing Air Purifiers for Commercial and Industrial Use

Breathing Air Purifiers for Commercial and Industrial Use

Trunnion Mount Ball Valves For Industrial Pipelines

Trunnion Mount Ball Valves For Industrial Pipelines

Integrated control valve, sensors, actuator, and controller

Integrated control valve, sensors, actuator, and controller

Three Piece Ball Valves Available With Metal Seats

Three Piece Ball Valves Available With Metal Seats

Trunnion mounted ball valves for industrial applications

Trunnion mounted ball valves for industrial applications

Kürzlich hochgeladen

From customer value engagements to hands-on production support, our Services span across every stage of our customers digital transformation journey, to help ensure that every customer is successful in their adoption of our solutions.

• Implementation, Upgrade, Migration, and Maintenance Services

• On-Premises and On-Cloud

• COTS Training Services; On-Site and Virtual

• Software Support Services; Legacy and 3DEXPERIENCE

• Value Engagement & Blueprinting

• Specialized Consulting and Support Services

• Customized Training Services

• Automation and Configuration Services

• Technical Resource Augmentation Services

• Project Management

• Know-how Training (mentoring) and Resource AugmentationNavigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...Arindam Chakraborty, Ph.D., P.E. (CA, TX)

Welcome to the April edition of WIPAC Monthly, the magazine brought to you by Water Industry Process Automation & Control.

In this month's edition, along with the latest news from the industry we have articles on:

The use of artificial intelligence and self-service platforms to improve water sustainability

A feature article on measuring wastewater spills

An article on the National Underground Asset Register

Have a good month,

OliverWater Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024Water Industry Process Automation & Control

Kürzlich hochgeladen (20)

Design For Accessibility: Getting it right from the start

Design For Accessibility: Getting it right from the start

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Block diagram reduction techniques in control systems.ppt

Block diagram reduction techniques in control systems.ppt

Regenerative turbine pump application, design, and features

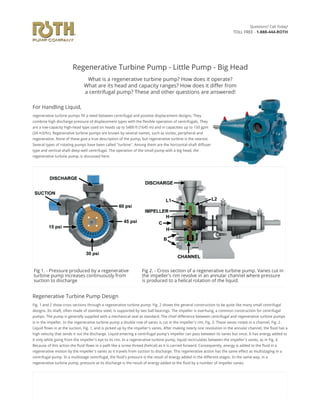

- 1. Regenerative Turbine Pump - Little Pump - Big Head What is a regenerative turbine pump? How does it operate? What are its head and capacity ranges? How does it di䑁䫠er from a centrifugal pump? These and other questions are answered! For Handling Liquid, regenerative turbine pumps fill a need between centrifugal and positive displacement designs. They combine high discharge pressure of displacement types with the flexible operation of centrifugals. They are a low-capacity high-head type used on heads up to 5400 ft (1645 m) and in capacities up to 150 gpm (34 m3/hr). Regenerative turbine pumps are known by several names, such as vortex, peripheral and regenerative. None of these give a true description of the pump, but regenerative turbine is the nearest. Several types of rotating pumps have been called "turbine". Among them are the horizontal-shaft diffuser type and vertical-shaft deep-well centrifugal. The operation of the small pump with a big head, the regenerative turbine pump, is discussed here. Fig 1. - Pressure produced by a regenerative turbine pump increases continuously from suction to discharge Fig 2. - Cross section of a regenerative turbine pump. Vanes cut in the impeller's rim revolve in an annular channel where pressure is produced to a helical rotation of the liquid. Regenerative Turbine Pump Design Fig. 1 and 2 show cross sections through a regenerative turbine pump. Fig. 2 shows the general construction to be quite like many small centrifugal designs. Its shaft, often made of stainless steel, is supported by two ball bearings. The impeller is overhung, a common construction for centrifugal pumps. The pump is generally supplied with a mechanical seal as standard. The chief difference between centrifugal and regenerative turbine pumps is in the impeller. In the regenerative turbine pump a double row of vanes is cut in the impeller's rim, Fig. 3. These vanes rotate in a channel, Fig. 2. Liquid flows in at the suction, Fig. 1, and is picked up by the impeller's vanes. After making nearly one revolution in the annular channel, the fluid has a high velocity that sends it out the discharge. Liquid entering a centrifugal pump's impeller can pass between its vanes but once. It has energy added to it only while going from the impeller's eye to its rim. In a regenerative turbine pump, liquid recirculates between the impeller's vanes, as in Fig. 4. Because of this action the fluid flows in a path like a screw thread (helical) as it is carried forward. Consequently, energy is added to the fluid in a regenerative motion by the impeller's vanes as it travels from suction to discharge. This regenerative action has the same effect as multistaging in a centrifugal pump. In a multistage centrifugal, the fluid's pressure is the result of energy added in the different stages. In the same way, in a regenerative turbine pump, pressure at its discharge is the result of energy added to the fluid by a number of impeller vanes. Questions? Call Today! TOLL FREE - 1-888-444-ROTH

- 2. Fig. 3 - Regenerative turbine pump's impeller showing radial vanes on each side of its rim Fig. 4 - As impeller carries it forward, 䐺uid circulates between the vanes as shown Flow in the Impeller Recirculation of liquid between the vanes of a regenerative turbine pump occurs a number of times between suction and discharge. The path of fluid travel can be thought of as an extended helical spring bent in a circle until its ends nearly touch. When the pump operates under low heads, space between the helical coils increases. On high heads the helix closes. That is, the fluid circulates more times in its travel from suction to discharge. Regenerative Pump Construction In Fig. 2 the pump has a vertical split case. By removing bolts B, cover C and liner L1 can be taken off to inspect or remove the impeller. To keep liquid flow small from high to low-pressure areas in the pump, the impeller has close clearance between liners L1 and L2. Pressure on the Impeller About one-half discharge pressure exists around the impeller's hub, which is the pressure on the mechanical seal. Holes H through the impeller prevent unbalanced pressures on it and end thrust on the bearings. A small bypass flow also occurs across the sealing surfaces between the discharge and suction, Fig. 1. Wear on these sealing surfaces increases the clearances and the bypass flow. The same thing happens at the sealing rings of centrifugal pumps. This wear reduces pump capacity greatly when operating at a high head. Most failures of regenerative turbine pumps are caused by this wear at the sealing surfaces. A study of the causes of wear belongs in a separate article where it can be discussed at length. However to prevent serious wear, don't let the impeller touch liners L1 and L2, Fig. 2 and be sure pumped liquid is free of abrasive material. Roth regenerative turbine pumps with patented self-centering impellers greatly reduce the wear problem. Discharge Pressure A regenerative turbine pump can develop several times the discharge pressure of a centrifugal type having equal impeller diameter and speed. This pressure increases rim as indicated in Fig. 1. Fig. 5 - Power needed to drive a medium-head centrifugal pump decreases as the discharge head increases as indicated by the horsepower and head-capacity curves Pump Operation

- 3. Related Products REGENERATIVE PUMPS PRODUCT LINES Roth Pump offers a variety of of both chemical & industrial pumps for improving the operation and efficiency of commercial systems Chemical Pumps Overview of available regenerative turbine chemical pumps Industrial Pumps Overview of available industrial regenerative turbine pumps Power required to drive a centrifugal pump decreases as operating head increases, as indicated by the horsepower curve, Fig. 5. At 24 gpm, total head is 30 ft, point A, and power about 0.6 hp, point B. If we throttle the pump to reduce its capacity to 6 gpm, head increases to 36 ft, point C, and power drops to about 0.35 hp, point D. Fig. 6 shows how a comparable regenerative turbine pump performs. At 24 gpm its discharge head is about 55 ft, point E and requires about 0.7 hp to drive it, point F. If we throttle the pump down to 6 gpm its head goes to 124 ft, point G, and its power to 1.4 hp, point H. So, select the driving motor for the highest head the turbine pump will have to develop. Fig. 6 - If a regenerative turbine pump is throttled to reduce its output, discharge pressure and power input increase Test Curves The curves, Figures 5 and 6 are from tests. The centrifugal pump had a 6-in. impeller and the regenerative turbine a 4.25-in. impeller, each running 1750 rpm. Fig. 6 shows the high head obtained with a small diameter impeller. It also shows the pump's wide operating range. This range is desirable on many applications where the head may vary greatly or is hard to find. In Fig. 5, the centrifugal pump operates most efficiently at 30-ft head and 24- gpm. The regenerative turbine pump develops 55-ft head at 24 gpm. If the head increased 5 or 6 ft, the centrifugal pump could not discharge. On the turbine pump this increase in head would cause only a slight decrease in capacity with a small increase in power. Power for a regenerative turbine pump reaches a maximum at shutoff where it is the lowest on a centrifugal pump. So regenerative turbine pumps should not be operated against a closed discharge, unless a pressure relief valve is used. Install a pressure gauge on the pump's discharge, observe the manufacturer's pressure limits and you'll increase the pump's life. Download the PDF version of Regenerative Turbine Pump - Little Pump - Big Head