INVENTORY PLANNING

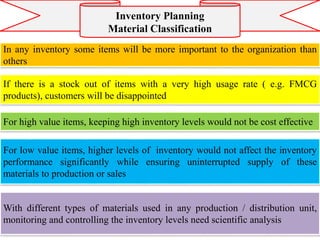

- 1. In any inventory some items will be more important to the organization than others If there is a stock out of items with a very high usage rate ( e.g. FMCG products), customers will be disappointed Inventory Planning Material Classification For high value items, keeping high inventory levels would not be cost effective For low value items, higher levels of inventory would not affect the inventory performance significantly while ensuring uninterrupted supply of these materials to production or sales With different types of materials used in any production / distribution unit, monitoring and controlling the inventory levels need scientific analysis

- 2. Inventory Planning Methods of Classification There are different ways of classifying material. Some of the major ones include: Type of requirement Frequency of procurement Standard or stock items Physical or chemical nature Cost Type of requirement One way of classifying materials is whether they are used for direct (i.e.; go into the products being manufactured) or used indirectly for supporting the production process. As an example, for a car manufacturer, the steering wheel assembly could be classified as direct material. Oil, used to lubricate the factory conveyor belt would be classified as indirect material.

- 3. Inventory Planning Observation on Materials In a computer, A large proportion of the total costs is made up of small number of high value components like CPU A large number of components like mouse, connectors, cables, key board, etc constitute a smaller proportion of the total cost

- 4. Inventory Planning 80:20 Rule, The Pareto Principle The Pareto principle (also known as the 80-20 rule, the law of the vital few) states that, for many events, roughly 80% of the results come from 20% of the efforts Based on these observations he formulated the pareto principle

- 5. Inventory Planning Observation on Materials It takes 20% effort to complete the first 80% of a project, the remaining 20% work takes 80% effort

- 6. Inventory Planning Pareto Rule in Inventory Typically,80% of an operations sales are accounted for by only 20% of all stocked item types. The relationship can be used to classify the different types of items kept in an inventory by their usage value ABC inventory control allows inventory managers to concentrate their efforts on controlling the more significant items of stock

- 7. The pareto rule has been applied to this classification called ABC, with a slight improvisation Inventory Planning ABC Classification

- 8. Inventory Planning ABC Analysis Let us refer to the table above Class A items constitute approximately 10% of the number of items in inventory, and their value typically ranges from 70-80% of the total value of inventory. Class B ranges from between 11-20% of the items in inventory, and their value ranges from between 10-20% of the total inventory value. The last category, Class C make up 70-80% of the items in inventory, and their value is only between 5-10% of the total inventory value. By clearly identifying the high value of A class items this allows purchase managers to focus their efforts on areas which will have the maximum impact to the organization

- 9. The graph shows how the Pareto Analysis or ABC Analysis can be depicted pictorially Inventory Planning ABC Analysis On the X-axis we have the cumulative percentage of items. On the Y-axis we have the cumulative percentage of use by value. As can be seen from the graph, a few items contribute to a high percentage of usage by value and there are many items which are the ‘C’ class items which contribute only to a small percentage of usage by value. The ABC analysis puts items into categories that show the amount of effort worth spending on inventory control 20% of inventory items need 80% of the attention while the remaining 80% of items need only 20% of the attention

- 11. Inventory Planning Classify Items The first step in ABC analysis is to classify all inventory items as either A,B,C Calculate value for each item: Cost x Annual demand Rank items according to their annual value (descending order) Classify 10% as A items 20% as B items 70% as C Items These classification will not be exact, but they have been found to be close to the actual occurrence

- 12. Inventory Planning ‘A’ Class Items The next step is to determine the level of inventory control for each classification Class ‘A’ Items require tight inventory control as they represent a large percentage of the total value of inventory .These levels should be as low as possible, with minimum safety stocks They require accurate forecasts and detailed record keeping They also need appropriate inventory control system and cost effective procedure to determine order quantities In addition, close attention should be given to purchasing policies and procedures of class ‘A’ item

- 13. Inventory Planning ‘B’ & ‘C’ Class Items ‘B’ and ‘C’ items require less stringent inventory control Since carrying cost are usually lower for ‘C’ Items, higher inventory levels can sometimes be maintained with larger safety stocks It may not be necessary to control ‘C’ items beyond simple observation

- 15. Inventory Planning ABC Classification Example

- 16. Inventory Planning Application of ABC Analysis

- 17. Inventory Planning XYZ Classification Many enterprises need to manage their inventory based on the movement of goods or more precisely, the demand For some items, it is easier to forecast demand than for some others The XYZ analysis helps manage inventory based on the fluctuation of demand for some product

- 18. Inventory Planning XYZ Classification Many enterprises need to manage their inventory based on the movement of goods or more precisely the demand X Classification Material requirement is predictable and hence should be stocked in adequate quantities The requirement fluctuate only slightly around a constant level so that the demand can be accurately

- 19. Y Classification Inventory Planning XYZ Classification

- 20. Inventory Planning XYZ Classification Completely irregular consumption Z Classification These materials are not used regularly The usage can strongly fluctuate or occur sporadically In these cases, you can often observe periods with no consumption at all Forecast is extremely demanding and very difficult It is useful to further subdivide the ‘Z’ materials into ‘Z1’ and ‘Z2’ materials, the letter being used even less regularly than ‘Z1’ Materials This enables you to trigger detailed counteractive measures for particularly critical materials

- 24. Inventory Planning Single Period Inventory Analysis Purchase managers sometime face a special situation, That of one time inventory purchases or purchases for a single period. This is referred to as the “Newsboy Model” Along with specialized equipment (Usually expensive),Spare parts are to be purchased Examples In Industry The provision store or supermarket must decide how many loaves of bread to order for each day During the festival season, the sweet shop must decide how much of sweets to make in such situations, a technique called marginal analysis is used

- 25. Material classification plays an important role in managing different inventory items The treatment required to monitor and control varies from item group to item group and hence classification based on value or movement or any other criteria helps in ensuring supply as per demand at economical cost The choice of classification (ABC OR XYZ) depends on the industry segment FMCG / Retail / Distribution industries may be use XYZ Classification Electronics manufacturing units may be use ABC Inventory Planning Summary