Poster template 1314

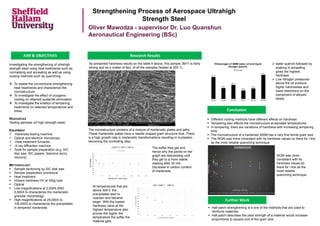

- 1. Strengthening Process of Aerospace Ultrahigh Strength Steel Oliver Mawodza - supervisor Dr. Luo Quanshun Aeronautical Engineering (BSc) AIM & OBJECTIVES Investigating the strengthening of ultrahigh strength steel using heat treatments such as normalising and annealing as well as using cooling methods such as quenching. To repeat the conventional strengthening heat treatments and characterize the microstructure. To investigate the effect of cryogenic cooling on retained austenite elimination. To investigate the kinetics of tempering treatments on selected temperatures and times. RESOURCES Testing samples (of high strength steel) EQUIPMENT -Hardness testing machine Optical and electron microscopy -Heat treatment furnaces -X-ray diffraction machine Tools for sample preparation (e.g. SIC disc saw, SIC papers, diamond slurry microns) METHODOLOGY Sample sectioning by SIC disk saw Sample preparation procedure Heat treatment Vickers hardness HV at 30kg load Optical Low-magnifications at 2,000X AND 5,000X to characterize the martensitic granular morphology: High-magnifications at 25,000X to 100,000X to characterize the precipitates in tempered martensite Research Results Further Work Conclusion As presented hardness results on the table 4 above, this sample 3M11 is fairly strong and as a matter of fact, of all the samples heated at 300 ◦C, The microstructure contains of a mixture of martensitic plates and laths. These martensitic plates have a needle shaped grain structure look. There is a high growth rate in martensitic transformations resulting in nucleation becoming the controlling step. 500 520 540 560 580 600 620 640 660 680 700 0 50 100 150 200 250 300 350 HV/KG/MM2 TEMPERING TIMES (MIN) (300◦C) 3M11-3M18 HV(average) The softer they get and hence why the points on the graph are descending until they get to a more stable reading after 30 min. Decrease in carbon content of martensite. 681.2 655.4 662.8 649.8 654.6 686.2 3M-WQ 3M-OQ 3M-ACN 3M-AC 3M-OQN 3M-WQN HV(average) of 300M water, oil and liquid nitrogen quench. HV(average) water quench followed by soaking in annealing gives the highest hardness Low nitrogen pressures above the oil produce higher hardnesses and lower distortions on the component of alloyed steels Different cooling methods have different effects on hardness Tempering also effects the microstructure at elevated temperatures In tempering, there are variations of hardness with increasing tempering time The microstructure of a hardened 300M has a very fine ferrite grain size The WQN was more consistent with its hardness values so there for I tick as the most reliable quenching technique. Hall-patch strengthening is a one of the methods that are used to reinforce materials Hall-patch describes the yield strength of a material would increase proportional to square-root of the grain size. WQN was more consistent with its hardness values so there for I tick as the most reliable quenching technique. 400 420 440 460 480 500 520 540 560 580 600 0 10 20 30 40 50 60 70 HV/KG/MM2 TEMPERING TIME 500◦(3M71 - 3M74) At temperatures that are above 500◦C the precipitates start to coarsen and became larger. With the lowest hardness value at the highest temperature also proves the higher the temperature the softer the material gets