Steel Making: Ingot casting defects

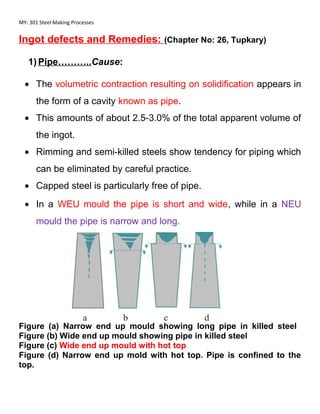

- 1. MY: 301 Steel Making Processes Ingot defects and Remedies: (Chapter No: 26, Tupkary) 1) Pipe………..Cause: • The volumetric contraction resulting on solidification appears in the form of a cavity known as pipe. • This amounts of about 2.5-3.0% of the total apparent volume of the ingot. • Rimming and semi-killed steels show tendency for piping which can be eliminated by careful practice. • Capped steel is particularly free of pipe. • In a WEU mould the pipe is short and wide, while in a NEU mould the pipe is narrow and long. Figure (a) Narrow end up mould showing long pipe in killed steel Figure (b) Wide end up mould showing pipe in killed steel Figure (c) Wide end up mould with hot top Figure (d) Narrow end up mold with hot top. Pipe is confined to the top.

- 2. MY: 301 Steel Making Processes Remedies of pipe formation: • By adopting hot top feeder head. It acts as a reservoir to feed the metal to the main part of the ingot and avoid the formation of pipe. The volume of the hot top is 10-15% higher than ingot volume • Use of exothermic materials in the hot top keeps the metal hot in the top portion and pipe formation can be avoided • Another method = to pour little more metal after partial solidification, but this is not a very common practice.

- 3. MY: 301 Steel Making Processes 2) Columnar Structure: • After the formation of initial chill layer further solidification results in the formation of dendrites which grow along their principal axis perpendicular the mold wall. • It is tree like structure…Dendrites initially grow as primary arms and depending upon the cooling rate, composition and agitation, secondary arms grow outward from the primary arms. Likewise, tertiary arms grow outward from the secondary arms. Figure: Dendritic structure • Their lateral growth is restricted due to the growth of adjoining dendrites giving rise to the elongated crystal. • If the length of these is appreciable it is known as columnar structure.

- 4. MY: 301 Steel Making Processes • Ingot possessing columnar structure tends to crack during rolling. 3) Blow Holes: • The entrapment of gas evolved during solidification of steel produce cavities known as blow holes in all except killed steels. • These are of two types. i. Primary blow holes are elongated or like honeycomb and are located next to the ingot skin. ii. Secondary blow holes are more spherical and are located further in. Remedy: Control of gas evolution during solidification so that blow hole forms only within the ingot skin of adequate thickness.

- 5. MY: 301 Steel Making Processes 4) Segregation: • It is the difference in composition of steel within the ingot than some average composition. Segregation is due to a) Difference in solubility of solute elements in liquid and solid steel i.e. partition coefficient of element in steel. Partition coefficient of solute (K) is defined as The value of K ≤ 1. The solute elements whose K = 1 do not segregate. All elements whose K < 1 tend to segregate. b) Rate of solidification: faster rate of solidification avoids the elements to segregate. The initial chill layer of ingot has practically the same composition as that of liquid steel. Decrease in rate of solidification causes elements to segregate. c) Larger size ingots: are susceptible to segregation than smaller size ones. Larger size ingots require more time for solidification. Remedy: soaking of ingots at high temperature can minimize segregation.

- 6. MY: 301 Steel Making Processes 5) Non-metallic inclusions: • Inclusions are foreign particles that contaminate the metal surface during rolling or other metal forming processes. Common inclusion particles include oxides, sulfides or silicates. Inclusions can be characterized by their shape, size and distribution. • Non metallic inclusions are inorganic oxides, sulphides and nitrides formed by reaction between metal like Fe, Ti, Zr, Mn, Si & Al with non metallic elements like oxygen, nitrogen, sulphur etc...

- 7. MY: 301 Steel Making Processes Types of non-metallic inclusions: • Oxides FeO, Al2O3, SiO2, MnO, Cr2O3 etc. Al2O3*SiO2, Al2O3*FeO, Cr2O3*FeO, MgO*Al2O3, MnO*SiO2 etc. • Sulfides FeS, MnS, CaS, MgS, Ce2S3 etc. • Oxysulfides MnS*MnO, Al2O3*CaS, FeS*FeO etc. • Carbides Fe3C, WC, Cr3C2, Mn3C, Fe3W3C etc. • Nitrides TiN, AlN, VN, BN etc. • Carbonitrides Titanium carbonitrides, vanadium carbonitrides, niobium carbonitrides etc. • Phosphides Fe3P, Fe2P, Mn5P2 • Depending on the source, from which non-metallic inclusion are derived, they are subdivided into two groups: indigenous and exogenous inclusions.

- 8. MY: 301 Steel Making Processes 1. Indigenous inclusions are formed in liquid, solidified or solid steel as a result of chemical reactions (deoxidation, desulfurization) between the elements dissolved in steel. 2. Exogenous inclusions are derived from external sources such as furnace refractories, ladle lining, mold materials etc. Amount of exogenous inclusions and their influence on the steel properties are insufficient. Distribution of non-metallic inclusions: Besides of the shape of non-metallic inclusions their distribution throughout the steel grain structure is very important factor determining mechanical properties of the steel. 1. Homogeneous distribution of small inclusions is the most desirable type of distribution. In some steels microscopic carbides or nitrides homogeneously distributed in the steel are created by purpose in order to increase the steel strength. 2. Location of inclusions along the grain boundaries is undesirable since this type of distribution weakens the metal. 3. Clusters of inclusions are also unfavorable since they may result in local drop of mechanical properties such as toughness and fatigue strength.

- 9. MY: 301 Steel Making Processes

- 10. MY: 301 Steel Making Processes Solidification of Ingots: (Chapter No. 25, Tupkary) Types of steels • Molten steel contains dissolved gases. During cooling of the steel the solubility of dissolved gases is decreases and the excess come out of solution. (e.g., in liquid steel solubility of oxygen is 0.16% but in solid steel is only 0.003%) • The amount of oxygen in solution and the amount that is expelled as CO is decided by its carbon content, the type and amount of deoxidizer added to steel prior to solidification. • Steel that is fully oxidized by a strong deoxidizer is called Killed Steel. • If the evolution of the gas is appreciable, in other words deoxidation is not fully carried out, it gives appearance of boiling to liquid steel in the mould. This boiling action is termed as Rimming and the steel known as Rimming Steel. • In between violently rimming and killed steel lies the Semi Killed Steel, which is only partially deoxidized such that some gas evolution takes place during later stages of solidification. • The capped steel is only a special variety of rimming steels in which the rimming action is less violent.

- 11. MY: 301 Steel Making Processes Mechanism of Solidification: • Killed steel solidifies in three zones in an ingot. • The metal next to the mould walls and bottom is chilled by the cold mould surfaces. This is a thin layer and is known as chill, shell or skin of an ingot and has a fine equiaxed grains. • The rate of solidification is very high in forming the skin, however the rate of solidification soon slow down. • The mould expands on heating and the skin contracts on solidification; it reduces the rate of heat flow and thereby slows down the cooling of an ingot. • The solidification front moves inwards perpendicular to the mould faces resulting in columnar grains next to the chill. OR • After the formation of initial chill layer further solidification results in the formation of dendrities which row along their principal axis perpendicular to the mould walls. • Their lateral growth is restricted due to the growth of adjoining dendrities giving rise to elongated crystal. If the length of these is appreciable is known as columnar structure

- 12. MY: 301 Steel Making Processes • In general columnar structure does not extend to the centre of the ingot. The central portion solidifies as equiaxed grains of bigger sizes than those in the chill due to slow cooling. • One zone blends into the next gradually. The extent of each zone varies with composition and temperature of liquid steel, mould design and its temperature at the time of teeming.

- 13. MY: 301 Steel Making Processes Segregation: • Segregation means departure from the average composition. • Segregation is the result of the differential solidification characteristic of all liquid solution. • In case of Steel, is an alloy (liquid solution) of S, Si, C, P, Mn etc. in iron and hence is prone to segregate during solidification. • The initial chill layer of the ingot has practically the same composition as that of the steel poured in the mould, i.e. there is no segregation in the chill layer because of vary rapid rate of solidification. • The progressive solidification there after results in solidification of purer phase (rich in iron) while the remaining liquid gets richer in impurity contents. • If the concentration > the average it is called positive segregation. • If the concentration < the average it is called positive segregation.

- 14. MY: 301 Steel Making Processes • It can be minimized by prolonged soaking of ingots before working.