LSB Symposium

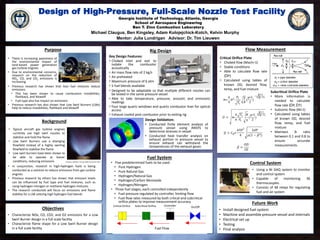

- 1. Georgia Institute of Technology, Atlanta, Georgia School of Aerospace Engineering Ben T. Zinn Combustion Laboratory Design of High-Pressure, Full-Scale Nozzle Test Facility Michael Claugus, Ben Kingsley, Adam Kolojejchick-Kotch, Kelvin Murphy Purpose Background • Typical aircraft gas turbine engines currently use high swirl nozzles to stabilize and hold the flame • Low Swirl Burners use a diverging flowfield instead of a highly swirling flowfield to stabilize the flame • Low swirl burners have been shown to be able to operate at leaner conditions, reducing emissions Rig Design • In conjunction, research in high-hydrogen fuels is being conducted as a solution to reduce emissions from gas turbine engines • Previous research by others has shown that emission levels can be influenced by fuel type and fuel mixtures, such as using hydrogen-nitrogen or methane-hydrogen mixtures • The research conducted will focus on emissions and flame stability for a LSB utilizing high hydrogen fuel blends • Characterize NOx, CO, CO2, and O2 emissions for a Low Swirl Burner design in a full scale facility • Characterize flame shape for a Low Swirl Burner design in a full scale facility Objectives Critical Orifice Plate • Choked flow (Mach=1) • Stable conditions • Able to calculate flow rate (DP) • Calculated using tables of known OD, desired flow, temp, and fuel mixture Subcritical Orifice Plate • More information is needed to calculate flow rate (DP, DT) • Subsonic flow (M<1) • Calculated using tables of known OD, desired flow, temp, and fuel mixture • Maintain b ratio between 0.1 and 0.8 to ensure accurate measurements Fuel Flow Critical Orifice Subcritical Orifice Controller On/Off Future Work Fuel System • There is increasing awareness of the environmental impact of land-based power generation gas turbine engines • Due to environmental concerns, research on the reduction of NOx, CO, and CO2 emissions is increasing • Previous research has shown that lean fuel mixtures reduce emissions • This has been shown to cause combustion instabilities, flashback, and blowoff • Fuel type also has impact on emissions • Previous research has also shown that Low Swirl Burners (LSBs) help to reduce instabilities, flashback and blowoff • Designed to be adaptable so that multiple different nozzles can be tested in the same pressure vessel • Able to take temperature, pressure, acoustic and emissions readings • Four large quartz windows and quartz combustor liner for optical access • Exhaust cooled post combustor prior to exiting rig Key Design Features: • Choked inlet and exit to isolate the combustor acoustically • Air mass flow rate of 2 kg/s • Air preheated • Maximum pressure of 6 atm • 5 fuel blends available Design Validation: • Conducted finite element analysis of pressure vessel using ANSYS to determine stresses in vessel • Conducted heat transfer analysis on exhaust portion in pressure vessel to ensure exhaust can withstand the temperatures of the exhaust gases • Five predetermined fuels to be used: • Pure Hydrogen • Pure Natural Gas • Hydrogen/Natural Gas • Hydrogen/Carbon Monoxide • Hydrogen/Nitrogen • Three fuel stages, each controlled independently • Fuel pressure regulated by controller, limiting flow • Fuel flow rates measured by both critical and subcritical orifice plates to improve measurement accuracy Flow Measurement • Install designed fuel system • Machine and assemble pressure vessel and internals • Electrical set up • Testing • Final analysis Control System • Using a NI DAQ system to monitor and control system • Capable of monitoring 36 thermocouples • Consists of 48 relays for regulating fuel and air system Mentor: Julia Lundrigan Advisor: Dr. Tim Lieuwen Courtesy: Littlejohn, Cheng, Noble & Lieuwen 2010

- 2. • With the increasing awareness of the negative environmental impact of gas turbine engines and power plant emissions, research on the reduction of NOx, CO, and CO2 emissions using novel combustor configurations and fuel mixtures is essential. One known manner in which emissions from gas turbine engines and power plants can be reduced is be operating at lean conditions where the equivalence ratio (ratio of fuel to air) is low and thus there is more air going through the combustor than is necessary to burn all of the fuel. Lean combustion systems, however, are prone to combustion instabilities (acoustic and pressure fluctuations), flashback (the flame propagates upstream), and blowoff (the flame leaves the combustor), which are all extremely detrimental to the system. Additionally, these effects are worse with high H2 fuels which are most alternative fuels. • One manner in which these challenges can be overcome is by utilizing low swirl burner (LSB) configurations. Typical aircraft gas turbine engines currently use high swirl combustors to stabilize and hold the flame. However, previous research has shown that LSBs can hold a flame during a large range of operating conditions, including very lean conditions. The ability to operate at these extremely lean conditions ultimately assists with reduced emissions as well as reduced fuel consumption. In addition to utilizing LSBs, investigations into alternative fuels is also being conducted as a solution to the challenges of greenhouse gas emissions from gas turbine engines. Previous research by others has shown that emission levels can be influenced by fuel type and fuel mixtures, such as using hydrogen-nitrogen or methane-hydrogen mixtures. • The purpose of this research is to conduct high speed chemiluminescence flame imaging and NOx, CO, and CO2 emissions measurements on novel low swirl burner designs for direct application in industrial gas turbines. For alternative fuels, the manner in which the flame is stabilized using vortex breakdown in high swirl combustors can lead to increased flashback issues. High speed chemiluminescence allows for direct observation and analysis of the flame. For these experiments specifically, broad spectrum and narrow spectrum images will be taken. Narrow spectrum images will focus on the CH* band at 430 nm to ascertain the location of the flame front; OH* will be used for high hydrogen tests. The research conducted will be on a full scale combustor using single nozzle designs based on tests performed by another student in the Ben T. Zinn Combustion Laboratory. The combustor will be run at high pressures and preheat temperatures to further simulate a real gas turbine engine environment. This research has direct application to power gas turbines as well as indirect application to aircraft gas turbine engines. • 1. To characterize NOx, CO, CO2, and O2 emissions for a Low Swirl Burner design in a full scale facility. To achieve this it will be necessary to utilize multiple fuel mixtures to ensure the results represent a range of conditions the combustor would experience in real world application. This will require testing using methane only, as well as multiple methane and hydrogen mixtures. In order to simulate a full scale combustor environment, the combustor will be operated at 8atm with air preheated to 600°F and flow velocities to match real world engine conditions. • 2. To characterize flame shape for a Low Swirl Burner design in a full scale facility. as stated in the previous objective, to achieve this it will be necessary to utilize multiple fuel mixtures to ensure the results represent a range of conditions the combustor would experience in real world application. Additionally, a high resolution CCD camera will be used to take time-average broad spectrum and narrow spectrum images. Narrow spectrum images will focus on the CH* band at 430 nm to ascertain the location of the flame front. This will allow for further characterization of the LSB design.