Vcs Breton 2009

•

4 gefällt mir•820 views

With VCS machine tool precision can be increased

Melden

Teilen

Melden

Teilen

Empfohlen

Empfohlen

Weitere ähnliche Inhalte

Ähnlich wie Vcs Breton 2009

Ähnlich wie Vcs Breton 2009 (20)

STUDY OF FIVE-AXIS COMMERCIAL SOFTWARE POST-PROCESSOR CONVERSION APPLIED TO A...

STUDY OF FIVE-AXIS COMMERCIAL SOFTWARE POST-PROCESSOR CONVERSION APPLIED TO A...

The research of 6-DOF flight simulator washout filter Control Method

The research of 6-DOF flight simulator washout filter Control Method

Optimal and Pid Controller for Controlling Camera's Position InUnmanned Aeria...

Optimal and Pid Controller for Controlling Camera's Position InUnmanned Aeria...

Experiment to determine a method for effortless static calibration of the ine...

Experiment to determine a method for effortless static calibration of the ine...

Mehr von Breton SpA

Mehr von Breton SpA (20)

24 reasons to choose Breton Shapemill 5 axis machining centre

24 reasons to choose Breton Shapemill 5 axis machining centre

Kürzlich hochgeladen

Kürzlich hochgeladen (20)

Strategies for Landing an Oracle DBA Job as a Fresher

Strategies for Landing an Oracle DBA Job as a Fresher

ICT role in 21st century education and its challenges

ICT role in 21st century education and its challenges

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

DEV meet-up UiPath Document Understanding May 7 2024 Amsterdam

DEV meet-up UiPath Document Understanding May 7 2024 Amsterdam

Apidays New York 2024 - Accelerating FinTech Innovation by Vasa Krishnan, Fin...

Apidays New York 2024 - Accelerating FinTech Innovation by Vasa Krishnan, Fin...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

Apidays New York 2024 - Passkeys: Developing APIs to enable passwordless auth...

Apidays New York 2024 - Passkeys: Developing APIs to enable passwordless auth...

Cloud Frontiers: A Deep Dive into Serverless Spatial Data and FME

Cloud Frontiers: A Deep Dive into Serverless Spatial Data and FME

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

Apidays New York 2024 - Scaling API-first by Ian Reasor and Radu Cotescu, Adobe

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

How to Troubleshoot Apps for the Modern Connected Worker

How to Troubleshoot Apps for the Modern Connected Worker

Emergent Methods: Multi-lingual narrative tracking in the news - real-time ex...

Emergent Methods: Multi-lingual narrative tracking in the news - real-time ex...

Modular Monolith - a Practical Alternative to Microservices @ Devoxx UK 2024

Modular Monolith - a Practical Alternative to Microservices @ Devoxx UK 2024

Why Teams call analytics are critical to your entire business

Why Teams call analytics are critical to your entire business

Vcs Breton 2009

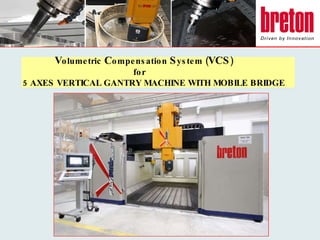

- 1. V olumetric C ompensation S ystem ( VCS ) for 5 AXES VERTICAL GANTRY MACHINE WITH MOBILE BRIDGE

- 9. Step 2 VCS File From the geometric errors measured, the Renishaw Software directly generate the data file in VCS format to introduce in the Siemens 840D Control HOW to USE VCS SYSTEM // VCS-Format //----------- // [HEADER] MACHINE_PRODUCER = BRETON MACHINE_TYPE = FLYMILL 2T MACHINE_NUMBER = 0 CONTROL_PRODUCER = SIEMENS CONTROL_TYPE = 840D CONTROL_NUMBER = 0 CONTROL_SOFTWARE_VERSION = 6.5.39 CUSTOMER = RENISHAW OPERATOR = REICHLE DATE = 080129 TEMPERATURE = 23 COMMENT = komplett YTY] AXIS_LENGTH [L_U] = 2000 INTERVAL [L_U] = 200 REF_POS_X [L_U] = 1233 REF_POS_Z [L_U] = -683.5 MEAS_TOOL_Y [L_U] = 170 MEAS_TOOL_Z [L_U] = 110 DEVIATION [D_U] GRIDPOINTS = { 0.0 -1.9 200.0 -2.4 400.0 -4.15 600.0 -5 800.0 -6.9 1000.0 -9 1200.0 -8.4

- 10. VCS Compile Cycle installed Activate Sinumerik VCS functionality to compensate for the geometric machine error VCS file Measurements Step 3 CNC CNC Machine model HOW VCS SYSTEM WORKS

- 11. Verification of VCS Improvement by Diagonal Measurament HOW VCS SYSTEM WORKS Step 4 4 3 2 1 Y Z X

- 12. Qualitative Example of Volumetric errors before VCS activation

- 13. Qualitative Example of Volumetric errors with VCS compensation

- 14. DAILY VCS UTILISATION During the daily working operations VCS System taking the feedback from the machine, evaluate for each point of the trajectory the compensation to introduce, to have at the tool tip the maximum positioning and orientation precision. The VCS System don’t compensate the temperature variation errors. To have the maximum precision from VCS System the machine must be calibrated at least once in each season With Renishaw calibration system the calibration time is very reduced VCS system can’t be intended as a substitute fro a good mechanical design and build.