Hazop steps

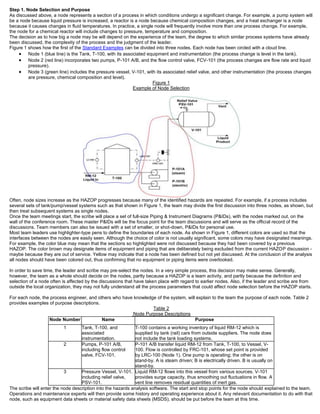

- 1. Step 1. Node Selection and Purpose As discussed above, a node represents a section of a process in which conditions undergo a significant change. For example, a pump system will be a node because liquid pressure is increased, a reactor is a node because chemical composition changes, and a heat exchanger is a node because it causes changes in fluid temperatures. In practice, a single node will frequently involve more than one process change. For example, the node for a chemical reactor will include changes to pressure, temperature and composition. The decision as to how big a node may be will depend on the experience of the team, the degree to which similar process systems have already been discussed, the complexity of the process and the judgment of the leader. Figure 1 shows how the first of the Standard Examples can be divided into three nodes. Each node has been circled with a cloud line. Node 1 (blue line) is the Tank, T-100, with its associated equipment and instrumentation (the process change is level in the tank). Node 2 (red line) incorporates two pumps, P-101 A/B, and the flow control valve, FCV-101 (the process changes are flow rate and liquid pressure). Node 3 (green line) includes the pressure vessel, V-101, with its associated relief valve, and other instrumentation (the process changes are pressure, chemical composition and level). Figure 1 Example of Node Selection Often, node sizes increase as the HAZOP progresses because many of the identified hazards are repeated. For example, if a process includes several sets of tank/pump/vessel systems such as that shown in Figure 1, the team may divide the first discussion into three nodes, as shown, but then treat subsequent systems as single nodes. Once the team meetings start, the scribe will place a set of full-size Piping & Instrument Diagrams (P&IDs), with the nodes marked out, on the wall of the conference room. These master P&IDs will be the focus point for the team discussions and will serve as the official record of the discussions. Team members can also be issued with a set of smaller, or shot-down, P&IDs for personal use. Most team leaders use highlighter-type pens to define the boundaries of each node. As shown in Figure 1, different colors are used so that the interfaces between the nodes are easily seen. Although the choice of color is not usually significant, some colors may have designated meanings. For example, the color blue may mean that the sections so highlighted were not discussed because they had been covered by a previous HAZOP. The color brown may designate items of equipment and piping that are deliberately being excluded from the current HAZOP discussion - maybe because they are out of service. Yellow may indicate that a node has been defined but not yet discussed. At the conclusion of the analysis all nodes should have been colored out, thus confirming that no equipment or piping items were overlooked. In order to save time, the leader and scribe may pre-select the nodes. In a very simple process, this decision may make sense. Generally, however, the team as a whole should decide on the nodes, partly because a HAZOP is a team activity, and partly because the definition and selection of a node often is affected by the discussions that have taken place with regard to earlier nodes. Also, if the leader and scribe are from outside the local organization, they may not fully understand all the process parameters that could affect node selection before the HAZOP starts. For each node, the process engineer, and others who have knowledge of the system, will explain to the team the purpose of each node. Table 2 provides examples of purpose descriptions. Table 2 Node Purpose Descriptions Node Number Name Purpose 1 Tank, T-100, and T-100 contains a working inventory of liquid RM-12 which is associated supplied by tank (rail) cars from outside suppliers. The node does instrumentation. not include the tank loading systems. 2 Pumps, P-101 A/B, P-101 A/B transfer liquid RM-12 from Tank, T-100, to Vessel, V- including flow control 100. Flow is controlled by FRC-101, whose set point is provided valve, FCV-101. by LRC-100 (Node 1). One pump is operating; the other is on stand-by. A is steam driven; B is electrically driven. B is usually on stand-by. 3 Pressure Vessel, V-101, Liquid RM-12 flows into this vessel from various sources. V-101 including relief valve, provides surge capacity, thus smoothing out fluctuations in flow. A PSV-101. vent line removes residual quantities of inert gas. The scribe will enter the node description into the hazards analysis software. The start and stop points for the node should explained to the team. Operations and maintenance experts will then provide some history and operating experience about it. Any relevant documentation to do with that node, such as equipment data sheets or material safety data sheets (MSDS), should be put before the team at this time.

- 2. All control valves have a fail position. In the event of a power failure and/or loss of instrument air, the valve's spring operator will cause the valve to fail open, fail closed, or remain in its current position. These failure modes should be identified. During the course of the HAZOP (probably while discussing 'High Flow' or 'No Flow') the team can discuss if the valve's fail position is what it should be. An analysis of this type is particularly valuable if more than one accident scenario has to be considered, and if the different scenarios call for different valve positions. Once the node is defined and described, the team discusses deviations from design or operating intent following the steps shown in Table 1. Step 2. Process Guideword / Safe Limits A HAZOP looks at deviations from design or safe process conditions, so the first decision is to select the process parameters that are germane to the facility under discussion. Generally the following parameters will be used: Flow Rate; Flow Quantity (for batch operations); Pressure; Temperature; Level (when vessels and tanks are a part of the node); Composition; and Phase. It will often be found that two parameters are related to one another. For example, the deviation of "high temperature" can create "high pressure". Which of these parameters the team chooses to focus on is not usually all that important. The parameters listed above can be supplemented with more specialized parameters, such as viscosity, color, surface tension and density. These secondary parameters will not generally be needed since they are dependent on the first set. For example, the density of a liquid is likely to be a function of temperature and composition. Therefore the discussions to do with temperature and composition deviations will incorporate any concerns to do with density. The safe limit values for each guideword should be established wherever possible. Step 3. Identification of Hazards and their Causes Once the nodes have been defined, and the safe operating limits identified, the hazards are determined. A hazard is a deviation outside the safe operating limit that is identified through the use of deviation guidewords. The most commonly used deviation guidewords are: High (More / Too Much); Low (Less / Too Little / Not Enough); No; Reverse; Misdirected; and Wrong (Other Than). Some teams use the term "Loss of Containment" as a guideword. Given that the ultimate purpose of a process safety program is to make sure that hazardous materials remain confined in the pipes, tanks, and vessels that they are intended to be in, it could be argued that all process deviations can ultimately result in "Loss of Containment", and so there is no need to handle this term separately. For example, high temperature in a reactor is not, in and of itself, a hazard; it becomes a hazard only if it generates a pressure so high that containment is lost (exacerbated by weakening of pressure vessel walls at the higher temperature). Similarly, high flow is not usually a hazard except that it may lead to a tank being filled too rapidly, thus generating a high level scenario, which then can lead to "Loss of Containment" due to overflow of the tank. Another example would be "Wrong Composition" in T-101 that can lead to loss of containment if the seal on P-101A fails. Most of the discussion to do with events and their causes will be associated with the node itself. For example, a leak from a pump may be caused by a seal leak at that pump. However, the team should always be looking for causes from other areas of the plant. For example, if a new chemical is inadvertently introduced into the system at another location, that chemical could cause the seal to leak. If the consequence of a hazard has an effect on another node the team leader and scribe should postpone the relevant discussion until that node is reached by the team. The actual guideword selected depends on team preference and company tradition. For example, the word "more" is used in traditional HAZOPs to describe an excess of some parameter. However, many teams prefer to use the word "high". An even better term is "too much" because it implies an undesirable situation - the parameter in question has gone outside its safe limit range. After all, high flow is often a good thing because it suggests that the facility is making more product and more money. Table 3 shows potential hazards for two of the variables: level in T-100, and flow from T-100 to V-101. Table 3 Hazard Causes Node Process Deviation Causes Variable 1 Level High 1. High flow into T-100 2. Failure of the T-100 level control system. 3. P-101A and B both stop. Low 1. Low flow into T-100. 2. Failure of the T-100 level control system ... ... ... 2 Flow High 1. Failure of level control system in T-100. 2. Pump overspeed. Low/No 1. Failure of level control system in T-100. 2. Pump mechanical problems. Reverse 1. Pump failure (with check valve failure). Some hazards can have more than one cause. For example, High Level in T-100 is shown in Table 3 to have three potential causes: 1. High flow into the tank; 2. Failure of the level control system of the tank; and 3. Pumps P-101 A/B stop.

- 3. The process and deviation guidewords are organized into a matrix, as shown in Table 4. The shaded boxes in this matrix are to be discussed by the team. The empty boxes (such as "Reverse Phase" and "Misdirected Temperature") are not discussed because they do not have physical meaning. In Table 4, the deviations "Low" and "No" are merged since they often lead to essentially the same discussion. However they should be used separately where appropriate. For example, "Low Level" in a tank may lead to little more than production problems, whereas "No Level" in that tank could create major hazards such as pump cavitation and air ingress into the tank. Table 4 HAZOP Matrix Flow Pressure Temperature Level Composition Phase High Low / No Reverse Misdirected Wrong The choice of terms can vary according to the practice and culture of the facility. For example, some companies use the terms "As Well As" or "Contamination". These are equivalent to the term "Wrong Composition" in Table 4. Sometimes the guideword combination "Reverse Pressure" is us used to cover situations where operating pressures are below ambient. Having determined which node parameters are to be used, the team discusses the hazards associated with each (shaded) square, using the prompt questions shown in Table 5 - which uses the term High Flow for illustration. Table 5 HAZOP Steps - Using "High Flow" as an Example 1. What is the quantitative definition for "High Flow"? (i.e., what is the Safe Upper Limit for flow in this node?). 2. What are the causes of "High Flow"? 3. How would an operator know that "High Flow" is occurring? How is this hazard "announced"? 4. What are the consequences (safety, environmental, economic) of "High Flow"? 5. What safeguards are in place to prevent "High Flow"? 6. What is the predicted frequency with which "High Flow" is expected to occur, both with and without safeguards? 7. What is the risk associated with the hazard just identified (evaluated from a risk matrix)? 8. Does the team have any findings or recommendations? The team will find that many hazards, causes and consequences are similar to one another as the discussion moves from node to node. Teams can sometimes become tangled up when hazards have effects outside the current node. For example, the team may be discussing "Low Level" in Tank, T-101. The cause of low level in the tank may lie within the node itself: a leak through the tank base, for example. However "Low Level" is more likely to be caused by loss of flow of RM-12 into the tank, i.e., the cause is "Low Flow" in an upstream node. Similarly, deviations in the current node can create hazards in other nodes. "Low Level" in T-101 could lead to seal failure of P-101A, which is in the next node. Step 4. "Announcement" of the Hazard The team should ask how each deviation outside the safe limits "announces" itself. Usually high and low alarms are built into the instrumentation associated with critical variables. These alarms tell the operator that an unsafe condition has occurred, or is developing. In the standard example a high level alarm incorporated into LRC-100 would warn the operator of high level in T-100. If the team finds that there is no obvious way for an operator to know that a safe limit has been exceeded, then the hazards analysis will probably recommend the installation of additional instrumentation to provide warnings and alarms. Step 5. Consequences Having identified the hazards, the team should then determine the consequences of those hazards, with and without safeguards in place. Consequences can be safety, environmental or economic. Table 6 illustrates some consequences for the standard example using the hazards listed in Table 3. Table 6 Consequences Node Process Value Consequences Variable 1 Level High 1. Overflow could cause injury to operator in area. 2. Overflow would be contained by secondary containment system � no environmental hazard identified. Low 1. Possible damage to Pump, P-101, impeller, leading to vibration and leak and personal injury. ... ... ... 2 Flow High 1. None identified. Low/No 1. High level in T-100 and/or low level in V-101. Reverse 1. Overflow of T-100. ... ... ... It can be seen from Table 6 that the term "None identified" is entered into the notes when the team was unable to think of a significant consequence associated with that hazard. Use of this term assures readers of the final report that the team did discuss potential consequences, but were unable to come up with issues of significance; they did not simply forget to examine this scenario. Step 6. Identification of Safeguards Some teams choose to list the safeguard-type assumptions that are made during the analysis. Table 7 provides an example of such a list. Table 7 Hazards Analysis Assumptions 1. The facility has been designed and engineered properly based on legal requirements, design/engineering codes, industry standards and good engineering practices. 2. The process will not be operated above design rates. 3. All equipment will be well maintained. 4. Appropriate instrument and control system test procedures will be followed.

- 4. 5. Alarm and shutdown set points will not be set out of range or disconnected to avoid nuisance trips or other problems. 6. Control valve bypasses will not be used unless the control valve is blocked out. 7. Rupture disks will be monitored. 8. If a double relief valve system is used, at least one will always be in service when the facility is operating. 9. Relief device bypasses, vents and drains not normally opened during operation will remain closed. 10. Pressure safety relief valves will not open except on demand. 11. Inadvertent opening or closing of locked/car sealed valves or blinds during maintenance is not addressed. Step 7. Predicted Frequency of Occurrence of the Hazard -1 Estimated frequency values for each hazard are generally stated in terms of events per year, or yr . Sometimes they are in units of events per mission or events per batch operation. Table 8 provides some estimated frequency values for the hazards in the standard example. Table 8 Sample Frequencies Node Process Variable Deviation Frequency Frequency without with safeguards -1 safeguards yr -1 yr 1 Level High 0.1 0.01 Low 0.5 0.05 ... ... ... 2 Flow High 0.05 0.01 Low/No 1.0 1.0 Reverse 0.01 0.01 ... ... ... -1 Taking the deviation "High Level" in T-101 as an example, the anticipated frequency of this event is 0.1 yr , or once in ten years. If credit is taken for the safeguard (high level alarm on LRC-101) and the probability of this alarm failing is say 0.1, then the anticipated frequency of high level -1 drops to 0.01 yr , or once in a hundred years. If a hazard has more than one cause, a frequency for each can be provided in the same way as was done for consequences in Table 6. The full hazard / cause / consequence / frequency layout can be structured as shown in Table 9. Table 9 Example of Hazard Frequencies Hazard Cause Consequence Frequency Risk # # # 1 1.1 1.1 1.1 1.1 1.2 1.2 1.2 1.2 2 2.1 2.1 2.1 2.1 3 3.1 3.1 3.1 3.1 3.2 3.2 3.2 3.2 3.3 3.3 3.3 3.3 Hazard #1 could be, say, "High Level in Tank, T-100". The first cause for this hazard (#1.1) is "High Flow into T-100". The consequence associated with this failure is "Overflow of tank leading to operator injury". The predicted frequency of this event, taking credit for safeguards, is -1 once in a hundred years, or 0.01 yr . The second cause (#1.2) for Hazard #1 is the failure of LRC-101, the T-100 level control system. In this case the consequence (#1.2) may be a small spill from the tank that is handled by the drain system, thus avoiding an environmental problem. The predicted frequency for this event (#1.2) is once in twenty years. Step 8. Risk Rank Once the hazards have been identified, and their causes, consequences and frequencies discussed, the team should risk rank each identified hazard scenario. If a risk matrix is used the estimated risk values for the two scenarios are 'B' and 'C' respectively. Formal risk ranking can help reduce the number of findings. Hazards analysis teams have a tendency to be conservative and to generate a recommendation for every identified hazard without a great deal of scrutiny. Formalizing the risk helps cut out those recommendations that are really not justifiable. Step 9. Findings Those hazards that have a risk level above the facility's acceptable risk level generate a finding which will then become a recommendation. Findings and their associated information should be summarized and presented in an overview form as illustrated in Table 10. Generally, findings are listed in the order in which they were created. The order in which the findings are listed is not significant in terms of risk level or follow-up priority. Table 10 Presentation of Findings Finding Node Finding Risk Suggested Drawings / Number Rank Recommendations Documents During the course of a long HAZOP, the team may find that certain findings are repeating themselves. For example, it may be that all centrifugal pumps of a certain type have an unusually high rate of seal failure. In such cases the team should develop generic findings and recommendations. Step 10. Next Process Guideword / Node Having completed the discussion to do with a process guideword, the team moves on to the next guideword, or to the next node if all of the guidewords have been discussed until the HAZOP is concluded.