Collecting Economic Data in Power Quality Survey

- 1. POWERQUALITY Briefing Paper David Chapman Copper Development Association UK Roman Targosz European Copper Institute November 2009 Collecting Economic Data in Power Quality Survey

- 2. Power Quality 2 www.leonardo-energy.org About Study Committee 4 I. ECONOMIC FRAMEWORK FOR POWER QUALITY 7 BASIC ECONOMIC CONCEPTS OF POWER QUALITY 7 1. The importance of power quality 7 2. Common PQ phenomena 9 3. Response of equipment to PQ events 12 4. Economic consequences 14 II. METHODOLOGY FOR COLLECTING POWER QUALITY ECONOMIC DATA 17 1. Introduction 17 2. Data collection 18 2a. Direct Economical Analysis 23 2b. Indirect Economical Analysis 23 III. APPROACH FOR END-USERS 26 A. Process interruption 27 A 1. Work in progress 27 A 2. Labour 29 A 3. Process slow down 30 A 4. Process restart 32 A 5. Equipment 32 A 6. Other cost 33 A 7. Savings 34 A 8. Total process interruption cost 35 B. PQ phenomena cost 35 B 1. Non-interrupting voltage dips 35 B 2. Harmonics (current and voltage) 36 B 3. Surges and transients 42 B 4. Voltage fluctuations and flicker 43 B 5. Unbalance 46 B 6. Earthing and EMC 49

- 3. Collecting Economic Data in Power Quality Survey 3 www.leonardo-energy.org C. Cost of postponed PQ effects 50 C 1. Cost of ageing of equipment in power networks 50 C 2. Mis-operation cost 56 D. Conclusions 57 IV. STRUCTURING THE DATA COLLECTION PROCESS 59 A. Taxonomy 59 A1. Critical sectors 59 A2. Cost categories 61 A3. Cost types - Operating consequences 61 A4. PQ phenomena 62 A5. Equipment: 62 A6. PQ consequences 63 A7. Solutions 64 B. Executing data collection process – end user perspective 65 V. APPENDIX A EFFECTIVENESS OF PQ SOLUTIONS 69 VI. APPENDIX B COMPONENTS & PROCESS FLOW OF ECONOMIC DATA COLLECTION 73 VII. APPENDIX C INTERNATIONAL EXAMPLES OF PQ COST SURVEYS 75 I. Interruptions 75 II. Dips 82 VIII. BIBLIOGRAPHY 87 IX. ACKNOWLEDGEMENTS 88

- 4. Power Quality 4 www.leonardo-energy.org About Study Committee CIGRE-CIRED-UIE Joint Working Group (JWG) “Economic Framework for Power Quality”. JWG C4.107 has been established in CIGRE, in conjunction with CIRED and UIE, with the purpose to study and analyse economics related to power quality. The JWG initiated work in 2006. Rationale: Various independent studies have been undertaken by utilities, manufacturers, consultants, regulators, and research organisations, to estimate the cost of power quality problems to the power systems and their customers. A good understanding of the basis for determining these costs is important in assessing appropriate interventions (either by the power network operators or by the customer themselves). The purpose of the group is to study and analyse economics related to power quality. http://pqeconomics.webexone.com The scope of the JWG is: • Review and document the economic implications of the power quality parameters: voltage dips, short interruptions, and voltage waveform quality. • Review and document methods of assessing these costs that have been used to date, including aspects such as: ∗ Direct and indirect costs to customers (e.g. production losses and plant damage). ∗ Energy losses associated with poor power quality. ∗ Cost of energy not supplied

- 5. Collecting Economic Data in Power Quality Survey 5 www.leonardo-energy.org • Methods of collecting customer costs. • Actual customer costs collected to date for various industry sectors. • Propose a standardized method of collecting the above information, based on the experience of various international studies. • Recommend a methodology of using this data to cost and motivate power quality interventions on the power system or within the customer plant. • Provide indicative costs for specific industry sectors, where possible. Long interruptions are not considered as part of the scope of this Group, as this has been extensively addressed by the previous Cigré study committee 38 - (published as TB 191) in 2001. (can be purchased from http://www.e-cigre.org/Order/select.asp?ID=192) Time schedule: Initiation of the JWG: 2006; Final deliverables: end 2009. The group works under framework of CIGRE Committtee C4. The Mission of SC C4 is to facilitate and promote the progress of engineering and the international exchange of information and knowledge in the field of System Technical Performance. To add value to this information and knowledge by means of synthesizing state-of-the-art practices and developing recommendations". http://www.cigre-c4.org/home.asp Another CIGRE-CIRED-UIE C4.110 Joint Working Group “Voltage Dip Immunity of Equipment Used in Installations” works on technical aspects

- 6. Power Quality 6 www.leonardo-energy.org of voltage dips. The work scope is providing industry with guidance on what measures to take in ensuring that their plant is not adversely affected by voltage dips. http://www.jwgc4-110.org/l Both authors contribute to the collaborative work of JWG C4.107 Group. This report describes authors view on economic data collection. As introduction the general information about the Group framework is provided in the report The results of the C4.107 study will be published in form of the report, which is expected by end of 2009.

- 7. Collecting Economic Data in Power Quality Survey 7 www.leonardo-energy.org I. ECONOMIC FRAMEWORK FOR POWER QUALITY BASIC ECONOMIC CONCEPTS OF POWER QUALITY 1. The importance of power quality ‘Power Quality’ (PQ) is the term generically used to describe the extent to which the electrical energy available at the point of use is compatible with the needs of the load equipment connected at that point. The effects of a lack of compatibility are termed ‘PQ problems’ or ‘PQ issues’. Compatibility is a two-sided equation as the characteristics of both the electrical power supply AND the load equipment are important variables. There are many parameters for which compatibility is necessary, including supply voltage level, voltage stability, waveform distortion due to harmonics and interharmonics, voltage unbalance between the phases and long and short-term availability of the supply. When there is a lack of compatibility, end user equipment may cease to function, operate erratically or incorrectly, may operate outside its normal envelope at reduced efficiency or in such a way that its operating life is reduced. The situation is further complicated by the fact that many PQ issues are caused by the operation (or mis-operation) of end-use equipment that is connected to the network. Electrical and electronic equipment rarely operates in isolation. Even the simplest of commercial operations requires the interoperation of several items of equipment – the use of a personal computer usually requires the aid of some communications equipment, a network and a printer, for example. In other words, the failure of one piece of equipment usually results in the failure of a process that may or may not affect other processes. Regardless, however, when process equipment ceases

- 8. Power Quality 8 www.leonardo-energy.org operation, the result is financial loss. Depending on factors such as the nature of the business, the organisation of the work flow (whether continuous processing or batch production) and the value of the product, this loss may range from the trivially small to the extremely large. There are two obvious approaches to ensuring 100% compatibility between electric power supply and end use loads: either design and construct a perfect electric power delivery grid, or make all end-use devices perfectly tolerant of common PQ issues. Unfortunately, for a number of reasons, neither of these approaches represents the economic optimum. Firstly, some loads are relatively insensitive to many PQ phenomena while being rather sensitive to others. Incandescent lighting is insensitive to harmonic distortion, but overly sensitive – in combination with the human response - to flicker caused by small, cyclic, voltage disturbances. On the other hand, electronic equipment is not disturbed by the scale of voltage instability that causes flicker while it is very sensitive to voltage dips and to higher levels of harmonic voltage distortion. Making every supply suitable for every load would be expensive and is unnecessary. Secondly, although the cost of designing and manufacturing any individual piece of equipment to be ‘immune’ is not large, that cost is multiplied by the total number of pieces of equipment in use and represents a very large economic burden on consumers. Thirdly, the option of building a very robust, very clean, system would be extremely high and it would be very difficult, if not impossible, to guarantee a minimum performance level at all points of common coupling. In the near future, increased penetration of distributed generation will make this even more difficult as generation is added at medium and low voltage levels. Lastly, many PQ issues arise within the consumer’s premises, due to the characteristics of the installed equipment, sub- optimal installation of equipment and cabling, poor electromagnetic compatibility (EMC) performance of earthing systems, etc, so perfection at the point of common coupling is no guarantee of perfection at the point of use.

- 9. Collecting Economic Data in Power Quality Survey 9 www.leonardo-energy.org 2. Common PQ phenomena Figure 1: Classification of PQ phenomena PQ phenomena are well documented elsewhere; the following paragraphs give a brief description of the most economically disruptive phenomena. • Voltage dips A voltage dip is a short-term reduction in voltage. It is specified in terms of duration and magnitude of retained voltage. Voltage dips are the result of increased voltage drop in the system caused by increased current flow, either as the result of the addition of a large load, for example the starting current of a large motor, or due to a fault current. Those caused by large loads are generally localised, often within the same installation, while those due to network fault currents can be widely distributed and affect a large number of consumers. The characteristics of network dips - magnitude and duration - depend on many factors, including the voltage level at which the fault is located, the response time of the protective devices, the degree of network meshing, the number and configuration of transformers, etc. Most fault-induced dips are caused by single-phase or 90% 100% 110% 1 s 1 min 1 h voltage swells voltage dips short interruptions long interruptions 10% vvvoltage changes and fluctuations duration of disturbance rmsvoltageaspercentageofnominal

- 10. Power Quality 10 www.leonardo-energy.org two-phase (phase to phase) faults. Because three-phase faults are less common than single- and two-phase faults, simultaneous dips in all three phases are also less likely. • Voltage fluctuations The primary cause of voltage fluctuations is the time variability of the reactive power component of fluctuating loads such as, for example, arc furnaces, rolling mill drives, main winders, etc. In general, these loads have a high rate of change of power with respect to the short-circuit capacity at the point of connection to the supply. The magnitude of the fluctuations is often such that the supply voltage remains within the permitted voltage tolerance band but the cyclic nature of the variation, combined with the characteristics of tungsten lamps and the response of the human eye and brain, lead to a sensation of flicker. Flicker is an impression of unsteadiness of illumination that can cause loss of concentration, headaches and, in some cases, epileptic fits. • Harmonic distortion Harmonic frequencies are integral multiples of the fundamental supply frequency. Current harmonics are generated within the system and in consumer loads by the non-linear behaviour of magnetic materials, rectifiers and electronic converters. Although harmonic frequencies have always been present in the electricity system, the increase in the number of items of equipment using electronic power control in recent years has led to increased levels. Voltage harmonics are created by harmonic currents as they flow through system impedances. Non-linear loads draw harmonic currents from the supply, so producing a corresponding harmonic voltage drop in the impedance of the supply network. As a

- 11. Collecting Economic Data in Power Quality Survey 11 www.leonardo-energy.org result all consumers see harmonic voltage distortion on the supply voltage. Standards have been introduced to limit the emission of harmonic current by individual items of equipment and by installations in an attempt to limit the overall level of harmonic distortion on supply networks. Fortunately, the design of networks tends to mitigate some of the effects of harmonic load current – delta transformer windings sink the third and ninth harmonic currents emitted by single-phase loads, for example. Electronic converters also introduce other frequencies into the supply, known as interharmonics. So far, the magnitude of interharmonic voltages is small. • Unbalance A three-phase supply system is said to be balanced if the three-phase voltages and current have the same amplitude and are separated by 120 degrees with respect to each other. If either of these conditions is not met, the system is said to be unbalanced. Unbalanced supply voltage usually arises because of unequal loading of the phases at the low voltage level where most of the loads are single phase. Other causes are the asymmetry of the distribution system and the connection of large non- three-phase loads, such as railway connections and arc furnaces. • Transients Transient disturbances are high frequency events with durations much less than one cycle of the fundamental supply frequency. Causes include switching or lightning strikes on the network and switching of reactive loads on the consumer’s site or nearby sites. Transients can have magnitudes of several thousand volts and so can cause serious damage to both the installation and the equipment connected to it. Non-damaging transients can cause severe disruption due to data corruption.

- 12. Power Quality 12 www.leonardo-energy.org 3. Response of equipment to PQ events • Data processing and communications equipment This type of equipment operates internally from a low voltage dc supply derived from the ac supply by a rectifier and electronic converter. It is insensitive to moderate levels of harmonic distortion and can be made immune to most transients, but it is sensitive to voltage dips. When the supply voltage drops during a dip, the amount of energy delivered to the load is reduced. The ability of the equipment to ‘ride through’ the dip depends on the amount of stored energy available from the internal power supply capacitor and the instantaneous energy requirement of the device. A personal computer (PC) will have a better ride through capability while processing than it would have while writing to an optical drive, for example. IT equipment dip performance is described by curves such as the Computer and Business Equipment Manufacturers Association (CBEMA) curve and its more modern replacement, the Information Technology Industry Council (ITIC) curve. These curves show the safe operational envelope of the equipment on a nominal voltage/time plot. If the duration and retained voltage during a dip lie above the boundary, the equipment is likely to continue to operate normally. In reality, these curves simply specify typical equipment performance; they do not imply that the equipment will survive the dips that typically occur on the network.

- 13. Collecting Economic Data in Power Quality Survey 13 www.leonardo-energy.org • Variable speed drives Variable speed drives (VSD) use an electronic converter to produce a variable frequency motor drive voltage from the fixed supply frequency. Using VSDs is much more energy efficient than using belts and gearboxes to change speed or using throttle valves to control fluid flows. They are used extensively in industrial processing, materials handling and building management. During a dip the amount of energy supplied by the electrical system is reduced and may be below that required by the process, resulting in loss of control. Since motor controlled processes rarely operate in isolation, this can result in loss of synchronisation with other parts of the process and uncoordinated shut down. VSDs usually include a number of measures to protect the electronics and the motor from abnormal conditions, such as under voltage or loss of a phase voltage, that may trigger shut down in the event of a dip. VSDs draw harmonic currents from the supply. Many drives are designed to minimise or eliminate these currents. VSDs are not affected by normal levels of harmonic distortion. • Lighting Any change in supply voltage magnitude may cause a change in the luminous flux or spectral distribution of a light source. Incandescent light sources are particularly sensitive, as the luminous flux is approximately proportional to the cube of the applied voltage. They are susceptible to ‘flicker’, which is a subjective visual impression of unsteadiness of a light’s flux, when its luminance or spectral distribution

- 14. Power Quality 14 www.leonardo-energy.org fluctuates with time. The human eye-brain response to variation of luminous flux produces fatigue and loss of concentration for relatively small variations in light intensity at frequencies of about 2 to 20 Hz. Gas discharge lighting is less sensitive to traditional flicker, partly because it is often electronically controlled, but is affected by a flicker effect due to jitter caused by voltage variation due to interharmonic voltage distortion. Gas discharge lighting is sensitive to dips: if a dip is deep enough to extinguish the discharge, a hot lamp may not re-strike when the voltage returns to normal. • Solenoid operated contactors Solenoid operated contactors and relays are used in large numbers in process control systems and they are particularly sensitive to voltage dips. ‘Hardened’ devices are available, but are relatively rarely used. • Transformers Transformers are affected by harmonic currents. Part of the load loss of a transformer is due to eddy current losses in the windings – usually around 5 to 8% of the loss is due to eddy currents and the remainder due to conductor resistance. Eddy current losses are proportional to the square of frequency so harmonic currents have a serious effect on the heat generated within the transformer, leading to higher operating temperatures and significant reduction in transformer lifetime. 4. Economic consequences From the descriptions of equipment responses it is apparent that the economic consequences of poor PQ fall into three categories: • Complete or partial loss of one or more processes (e.g. loss of

- 15. Collecting Economic Data in Power Quality Survey 15 www.leonardo-energy.org control following a dip) • Poor long term productivity or product quality (e.g. as a result of operator fatigue due to flicker) • Increased costs due to reduction of equipment lifetime, resulting in premature failure (e.g. overheating of transformers due to harmonics). These consequences take effect over very different time scales. A process failure, triggered by a PQ event such as a dip, has immediate consequences followed by a period of recovery during which further costs may be incurred. It is relatively easy to identify the costs that result from a single event or to predict what the costs might be. Continuous or prolonged conditions, such as flicker, can reduce long term productivity. If the problem is prolonged and widespread, the business may become uncompetitive and may require additional borrowing to sustain it. Premature failure of equipment will usually result in process failure with similar consequences to those caused by single PQ events. The difference is that the causes are in the past and were unrecognised, suggesting that predicting these costs is difficult unless a survey procedure is put in place. Depending on the type of operation in question, the economic consequences may range from trivial to catastrophic. The user can take several approaches: • Do nothing, and suffer the consequences • Take responsibility by adding mitigation equipment or hardening measures within the installation

- 16. Power Quality 16 www.leonardo-energy.org • Working with a supplier to improve the level of PQ by local measures specifically for, but external to, the installation • Negotiate with a supplier for a guarantee of a defined level of PQ, along the lines of an insurance policy. ‘Doing nothing’ – business as usual - is only viable for those enterprises that use batch processing for manufacturing and data handling. Process interruptions are limited in their impact and be relatively easily mitigated by, for example, reorganising work schedules. The economic consequences are not zero, but may be acceptable to the business. In every other case the first steps in analysing the economic impact of PQ on a particular organisation, or part of an organisation, include: • obtaining thorough and continuing measurements of relevant PQ parameters • logging of process failures and their costs and relating their occurrence to PQ events • assessing the likely failure modes and failure rates of processes and items of equipment, bearing in mind the different time scales involved • considering options for redesigning processes to reduce interdependence and reduce the risk of cascading failures • investigating options for hardening process equipment against PQ events and conditions.

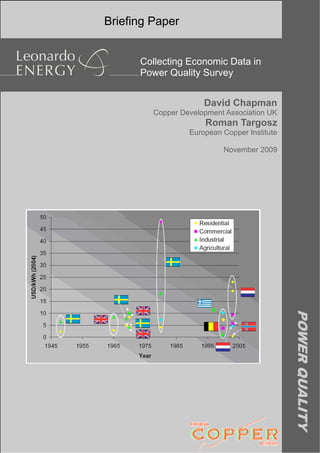

- 17. Collecting Economic Data in Power Quality Survey 17 www.leonardo-energy.org II. METHODOLOGY FOR COLLECTING POWER QUALITY ECONOMIC DATA 1. Introduction Interruptions exceeding 1 minute (IEEE) or 3 minutes (EN 50160:1999) are classified as ‘continuity and reliability of supply’ issues rather than ‘power quality’ issues. More than ten years ago, long interruptions were considered the only practically measurable consequence of the deterioration of the quality of the power supply. Nowadays, although long interruptions remain the more damaging events for some sectors (such as residential, agriculture and general commerce), most sectors experience much greater losses due to voltage quality problems. Voltage dips and short electrical power interruptions are common power quality issues and are major contributors to financial losses of modern industrial and commercial end users. Although individually not as detrimental as long duration outages, voltage dips and short interruptions occur much more frequently. Most often, economic losses are incurred when the disturbances cause nuisance tripping of sensitive equipment, which in turn leads to a halt in manufacturing or other business processes. For large industrial and commercial customers, the annual consequences of process disruption due to voltage disturbances can reach millions of dollars. The potential economic impact of PQ issues on customers’ operations can be assessed by considering: • the predicted level of PQ disturbances and their severity • analysis of the sensitivity of operations on the site to PQ disturbances • historical data relating to the impact of PQ disturbances.

- 18. Power Quality 18 www.leonardo-energy.org The first two steps of this procedure are described below for the case of voltage dips: The evaluation of the impact of voltage dips at a particular site in the network requires fault-analysis followed by voltage dip analysis. In fault analysis, various types of faults (symmetrical and asymmetrical) are simulated at numerous locations throughout the system network and the corresponding expected voltage magnitudes and durations (assuming 100% reliable primary protection, i.e. the duration of voltage dips is determined by the primary protection settings) are determined at various network buses. The subsequent voltage dip analysis is performed for the point-of-common -coupling (PCC) of interest. The frequency of dips of specified dip magnitude and duration over a period of interest is determined by associating the fault analysis result with the historical fault performance (fault per km per year) of all network buses, overhead lines and underground cables. This information is generally available from historic data obtained from long term monitoring at representative locations in the network. In order to determine whether the equipment will be affected by, or will ride-through, a dip of specified magnitude and duration, the expected voltage dips are compared with the sensitivity of process equipment connected at a given bus. This procedure requires the preparation of a chart showing both the dip performance for a particular bus in the system and the responses of the customer equipment to these voltage dips. Precise information relating the equipment response to voltage dips is required, which may be obtained from the equipment manufacturer or by testing. Since the testing of each and every piece of equipment is neither justifiable nor possible, sensitive industrial equipment is classified into

- 19. Collecting Economic Data in Power Quality Survey 19 www.leonardo-energy.org categories and testing performed on a suitable number of items of equipment selected at random from each category. However, even though the equipment may belong to the same equipment category, it might not exhibit the same sensitivity to voltage dips making it difficult to develop a single standard defining the sensitivity of process equipment. In addition, most processes rely on many pieces of equipment and may be disrupted by the tripping of any, or even one, of them depending on their interconnections and interdependencies. Therefore, for any assessment of financial losses incurred in a customer facility due to voltage dips, the precise counting of process trips, rather than individual equipment trips, is essential. The equipment sensitivity to voltage dips is usually expressed only in terms of the magnitude and duration of voltage dip. For this purpose, the rectangular voltage-tolerance curve (as shown in the figure below) can be used. It indicates that a voltage dip deeper than the specified voltage magnitude threshold (Vmin) and longer than the specified duration threshold (Tcrit) will cause malfunction (or trip) of the equipment. However, in practice, most of the equipment, e.g. motor-contactors and household electronics items would have non-rectangular voltage-tolerance characteristics. Two parameters, which may be detrimental to sensitivity of some of the industrial equipment (though to a lesser extent than voltage dip magnitude and duration) such as motor-contactors, are the point-on- wave of dip initiation and the phase-shift during the dip. Figure 2: Equipment Voltage-Tolerance Curve

- 20. Power Quality 20 www.leonardo-energy.org The probabilistic assessment of the number of process trips incorporates the uncertainty coupled with the equipment sensitivity as well as the uncertainty associated with possible connections of various items of equipment involved in an industrial process. 2. Data collection The methodology for the collection of economic data on the consequences of PQ is presented below. Once this data has been collected, it will remain valid until a significant change takes place, such as the provision of new or modernised production facilities, or the installation of PQ immunisation measures. The precise approach will depend on business activity sector, type of disturbance, PQ phenomena under consideration and required level of assessment accuracy. Both end users and electricity suppliers are affected. For the end user, deciding which data to collect requires a detailed understanding of the production processes and identification of the most significant cost categories. Some costs, such as contractual penalties, loss of reputation, brand damage and loss of strategic customers, occur over a long time period. For an accurate result, it is important to include the financial savings - such as reduced energy costs, raw materials and staff resources – as well as the financial costs of an interruption. Historical information on, for example, site turnover, profitability, asset value and capital cost, electricity bill, electrical system maintenance cost, past investments in PQ mitigation, etc., will be helpful to extend the practical use and analysis of the data. Non-financial data, such as employment levels, working time system, electrical system configurations, power and energy quantities and loading, are necessary to complete some calculations and to benchmark the impact of PQ on site activity. The ultimate objective of economic data collection is preparation of the basis

- 21. Collecting Economic Data in Power Quality Survey 21 www.leonardo-energy.org for the analysis of PQ investment. Data can be collected either at particular time intervals, most practically annually (or on a pro rata annual basis when the frequency of disturbances is less than once per year), or on a cost per event basis, particularly in cases where the PQ disturbance and its consequences are well defined and occur over a short time scale. The first method, periodic collection, may apply to flicker, most harmonic and unbalance impacts, EMC and earthing related problems. The second method, cost per event, is best used to assess impact of, for example, voltage dips, surges and transients and to calculate the financial consequence of process interruption. Electricity suppliers are responsible for the delivery of electrical energy at a particular PQ level, usually defined or implied by a contract with end user. Apart from the consequences of non-compliance to contract, they also suffer the loss of revenue for energy not supplied when end users’ activities are disrupted by a PQ related stoppage. The capital and operating expenses of any mitigation equipment and PQ improvement measures are the elements of the Power Network Operators costs. Most often, economic losses are incurred when disturbances cause nuisance tripping of sensitive equipment, which in turn halts manufacturing or other business processes. For large industrial and commercial customers, the consequence of process disruption can reach millions of dollars. Realising the potential magnitude of losses due to voltage dips and short interruptions, more and more industrial and commercial customers have started to seek protection, both technical and contractual, from the impact of these disturbances. The most common approach is to install mitigation

- 22. Power Quality 22 www.leonardo-energy.org devices (sometimes known as ‘custom power’) to isolate processes from disruptive events. The alternative approach is to contract for a higher quality of supply by means of a power quality contract with the electrical utility. However, regardless of which option is preferred, the investment must be economically justifiable. Power quality problems other than voltage dips are much less studied in practice. There are only a few examples of documented costs of harmonics, unbalance, surges, transients or problems related to earthing. The reasons for investigating the cost of PQ are: • to build awareness of the potential magnitude of PQ costs which may affect the productivity of the company • while statistics and previous experiences are helpful, no two companies, even when operating in the same sector, will be equally vulnerable to PQ disturbances • as PQ becomes subject to contract between a user and a supplier, the cost of PQ needs to be quantified to establish the so-called ‘Willingness to Pay’ as is a measure of a value of improved PQ for which the user is going to pay a premium • in case of failure caused by a PQ event for which the supplier is contractually liable, the amount of compensation will need to be determined. A previous cost survey will help to establish the methodology, allowing a prompt and accurate determination of the amount. • awareness of the cost of PQ will help to minimise it. Once their potential contribution is recognised, many small and simple incremental improvements are possible without significant investment.

- 23. Collecting Economic Data in Power Quality Survey 23 www.leonardo-energy.org 2a. Direct Economical Analysis Some of the data collected may be the historic or post mortem analysis of the consequences of a PQ problem. This data will be a valuable source of information, provided that the methodology was correct and adequate. However, subsequent changes and improvements in the organisation of the company may have a significant effect on the applicability of this data for the direct economic analysis presented in this report. The data collection process must address the issue of seasonality, i.e. the extent to which the cost of PQ depends on the time when it was incurred. Many businesses have a seasonal cycle, so the effects on costs and profitability depend heavily on the timing of an interruption with respect to the business cycle. In terms of immediate effects, the timing may determine the necessity of evacuation of staff, customers or neighbours and the ability to make up lost production to meet the market demand cycle. This publication is primarily about ‘raw’ economic data collection. Such data provides highly accurate and reliable information which may be further used to perform analysis for investment in PQ mitigation measures. However, indirect methods exist to map the economic PQ consequences in a company, for example, by industry sector, annual turnover, annual energy consumption (or unused energy due to outage) and/or peak load. The PQ impact assessment in such cases is limited to voltage dips and interruptions. 2b. Indirect Economical Analysis When the information required for economic analysis is not available, indirect economic analysis is the only option to estimate the financial losses due to power quality disturbances. Common ways of indirect

- 24. Power Quality 24 www.leonardo-energy.org analysis include the customer willingness to pay and customer willingness to accept methods and estimation of the cost from the size and value of mitigation solutions. Customer’s Willingness to Pay and Willingness to Accept The customer’s willingness to pay (WTP) method has been used in several studies to obtain the costs of power supply interruptions. Usually, customers are given several hypothetical outage scenarios and asked to assess the amount of money that they would be willing to pay in order to avoid each of them. In terms of power quality, customers are asked to assess their willingness to pay for different levels of power quality improvements. Though the WTP method may not be as technical as the analytical approaches, it reflects the value customers place on electricity supply and power quality. However, one should anticipate that the amount that a customer is willing to pay will be lower than the actual financial damage likely to be caused by the power quality disturbance. This is because an economical benefit could only be achieved if the financial damage due to power interruption is more than the amount paid to avoid the damage. Therefore, from the customers’ point of view, the WTP amount will always be less than the actual damage due to power quality disturbances. The WTP method makes sense only when customers understand the damaging effects of power supply interruption on their processes. Usually, the effects of total power interruption are more apparent and well-known. However, the effects of other power quality disturbances, such as voltage dips that cause partial disruption of processes, are not straightforward. In most cases, customers do not know the financial damages due to power quality disturbances, and therefore cannot place an accurate WTP value on them.

- 25. Collecting Economic Data in Power Quality Survey 25 www.leonardo-energy.org In the customer’s willingness to accept (WTA) method, electricity users are given various imaginary outage scenarios and asked to estimate the amount of compensation that they would be willing to accept for each of them. The WTA and WTP methods are similar in that they each require customers to place a monetary value on hypothetical outage scenarios. However, in most cases, the WTA method gives substantially larger values compared to the WTP method. The reason behind this is that customers consider the electricity supply as a social right rather than a market commodity and expect to be compensated if it is absent. It is recommended that the two methods are used together to produce upper and lower limits for power interruption costs. Both WTP and WTA methods are heavily dependent upon the customer’s subjectivity in placing a value on power quality costs, and may be influenced by other considerations, such as their perception of electricity supply, their knowledge of power quality disturbances and their ability to pay. Cost Estimation from Historical Events Over the years, numerous surveys have been carried out around the world to gather information regarding financial losses of various industrial, agricultural, commercial and even residential customers. By reviewing the studies to date, the financial loss information can be gathered and aggregated to represent different customer types and sizes and can be conveniently used to estimate PQ related costs of a particular customer. To obtain realistic cost estimation from historical events, one would have to use historical values from the customer type that best resembles the customer of concern, ideally obtained from customers of similar nature and size, and within the same geographical region. Unfortunately, information gathered from historical events is still insufficient to meet

- 26. Power Quality 26 www.leonardo-energy.org these requirements. Most studies produced cost values for total power interruption, but without considering the impact of other power quality disturbances. Some produced cost values for voltage dips but have yet to determine cost values for different severity levels of voltage dips. Overall, cost estimates from historical events without considering the customer’s equipment and process sensitivities will not produce accurate financial loss values. III. APPROACH FOR END-USERS For all PQ consequences, the methods to be followed can be of two types: deterministic or probabilistic. Deterministic methods are appropriate when all the items of the analysis, from the operating conditions of the system to the discount rate value, are known with reasonable certainty, which is the case for analysis performed on existing systems whose operating conditions are repeatable and well defined. Probabilistic methods are needed when some of the problem variables are affected by uncertainties, such as for systems in design or under construction and where expansion of an existing system is being planned. However, technicians are often involved in estimating the future costs of operation of existing systems when both cash flows and operating conditions of the system vary over a range and thus introduce a degree of uncertainty. There are basically two approaches in the process of collection of direct PQ costs; either driven by consequences (see Appendix - Taxonomy F) or disturbances - PQ phenomena (see Appendix – Taxonomy D). The proposed methodology suggests unification of the data collection as process interruption cost (sometimes also referred to as production outage cost) for all kinds of disturbances. Other costs which cannot be attributed to process interruption (as an immediate effect) are proposed to be collected on a case by case basis for each PQ phenomena or as

- 27. Collecting Economic Data in Power Quality Survey 27 www.leonardo-energy.org postponed effects (premature ageing and mis-operation). Cost assessment can be performed using a method of in depth interview with staff responsible for production like internal service or maintenance departments and if possible management staff responsible for site production technology and production cost issues. Furthermore some financial staff assistance might be required. This method was applied in the LPQI PQ cost survey. The survey form can be found at: http://www.leonardo-energy.org/european-power-quality-survey A. Process interruption A1. Work in progress W Work in progress (WIP) lost or wasted due to a process disruption. Material and labour wasted as a consequence of any PQ disturbance - phenomena (2D). (1) where: W1 is the cost of unrecoverable WIP W2 is the cost of reworking recoverable WIP to a usable standard When production and services in progress are partially wasted, W1 describes only that part which cannot be recovered. 21 WWW +=

- 28. Power Quality 28 www.leonardo-energy.org The issue of cost recoverability is absolutely essential to understand and quantify. Irrecoverable means that the (semi-finished) product of an interrupted process will not be repaired, used in a further process or sold as a lower quality product. WIP1 (2) where: M unrecoverable material lost, consisting of purchase price cost plus overhead cost of purchase plus site transportation, less scrap or residual value. E energy cost unrecoverably lost in WIP €/kWh LWIP1 labour cost defined as (3) where the right hand side of equation represents the sum of a number [i] of different processes/operations, each of which consumes [ni] hours of (wasted) labour at an hourly rate [Li] and hourly overheads [Oi] which express hourly depreciation rates of fixed assets or rental cost of equipment owned or used by the company. [Oi], in the simplest case, or where differentiation into processes makes only negligible calculation difference, this will be the number of wasted labour hours multiplied by the cost of labour, including overhead costs. Both M and L are expressed in monetary value. LEMW ++=1 ∑ +×= i iiiWIP OLnL )(1

- 29. Collecting Economic Data in Power Quality Survey 29 www.leonardo-energy.org For that part of the WIP that can be recovered, W2 represents the cost of labour required to complete the product to normal standard. (4) The symbol definitions are analogous to those in (3) As described under the definition of W1, it is crucial to assess how much of WIP can be recovered; during surveys staff may underestimate both W1 and W2. In reality there is often enough spare capacity to allow production to return to normal levels within a reasonably short time, but this may not be the case for time-sensitive or seasonal goods or where fresh or perishable produce is being processed. Establishing W1 and W2 requires an in depth analysis of cost elements. One practical approach would be to monitor production costs for a period following an outage and compare them with costs for a similar period with no outages. The balance between W1 and W2 is sometimes difficult to assess because the decision to reuse or scrap WIP is subjective and may depend on conditions at the time; for example, if raw material were in short supply or on long lead times, WIP would be more likely to be reused. A2. Labour LOUT The cost of lost or idle labour (i.e. the cost of staff who are unable to work) due to a process interruption, starting from the moment of interruption and ending when normal process activity resumes. The symbol definitions are analogous to those used in (3). ∑ +×= 2 222 )(2 i iii OLnW

- 30. Power Quality 30 www.leonardo-energy.org (5) Symbols marked with a prime [’] indicate terms which account for the redeployment of labour to other tasks (not related to the stoppage) or the employment of additional labour to aid recovery of the process. If the staff responsible for the operation or process [i] is completely idle and no additional labour cost will be required to compensate for lost time, the [’] value will be zero. If the staff is redeployed to other tasks which are necessary but are not stoppage related, the difference in the working time, labour and overhead rates are accounted for in the prime terms which would be subtracted from the non-prime elements. If additional labour was required to recover from the stoppage, the prime terms would be added to the non-prime terms. A3. Process slow down This cost subcategory can be used either as a supplementary element to process interruption costs (for example, when a process is restrained by the failure of another, e.g. a bottling process which is slowed down by the failure by one of several product processing lines) or as a specific alternative approach for some sectors - see ‘Appendix: Structuring the data collection process’. In the case of independent use, care must be taken to avoid overlap with other process interruption costs. P If equipment or a process is affected by a power quality disturbance, activity may be reduced, e.g. because only a fraction of parallel processes are operating, operate at a slower rate or some fraction of the product is out of specification. The value should be an estimate per single event ))''(')(( 3 3 3 3 33 3 i i i i ii i OUT OLnOLnL ∑ +×±+×=

- 31. Collecting Economic Data in Power Quality Survey 31 www.leonardo-energy.org (6) where: P1 is the consequential loss caused by the reduction in efficiency below normal due to reduced production due to limitations on capacity or speed, temporarily loss of synchronisation, additional restarts and resets, re-calibration, repair and maintenance and increased defect rate. (7) where: T The annual cost of sales (i.e turnover minus profit). In cases where no raw materials (including energy) are lost, the annual ‘added value’ should be used. If the effect is simply to reduce the efficiency of labour, the annual cost of labour should be used. WT Normal annual working time of organisation. This is average time in a year when company is working, taking account of shift patterns, holidays, etc. n Number of hours for which efficiency is reduced Percentage reduction of level of activity. This is the best assessment of the reduction in performance (as a sole result of PQ disturbance) compared to normal activity from the broadest possible perspective. and 21 PPP += ff T En W T P Δ××=1 ffEΔ

- 32. Power Quality 32 www.leonardo-energy.org P2 The cost of dealing with out-of-specification product by, e.g., repair, rework, recycling or scrapping. Where the under performance of a production process can be calculated more precisely, that method should be preferred. A4. Process restart PR Process restart cost. When a process is interrupted, other ancillary processes, such as heating, cooling, ventilation and filtration, may also trip. These processes must be re-established and verified before the main process can restart, requiring additional time and labour. Some checking procedures, such as cleaning in paper or food production, may also be required. Typical cost items are materials, consumables (calculated directly in monetary units) and labour calculated using equation (3). In cases where the interrupted process is restarted from an independent power supply until normal power supply conditions are restored, all the operating costs of the generating equipment form part of the Process Restart cost. A5. Equipment E Equipment damage. When a process is interrupted the shutdown occurs in a disorderly manner and it is possible that equipment will be damaged as a result. Damage may be instantaneous (e.g. damage by mechanical collision) or incremental (e.g. by overheating due to loss of coolant) leading to shorter equipment life, increased maintenance, etc.

- 33. Collecting Economic Data in Power Quality Survey 33 www.leonardo-energy.org The value should be an estimate per single event: (8) E1 Equipment damage cost consisting of: • cost of equipment and tools damaged beyond repair and scrapped. Scrap or recovered value should be deducted • cost of repair, adjustment and calibration of damaged equipment and tolos • cost of installation of new equipment, parts and tolos • cost of hiring replacement equipment • other indirect costs of equipment damage, e.g. additional costs for backup equipment, extra (compared to normal scenario) cost of additional overhaul in future. This category typically includes transformers, capacitors, motors, cables, contactors, relays, protection and control, computers, lights, tools. and E2 Additional maintenance, repair, material and consumables costs as a consequence of the process interruption. Examples are bearings, pads, fuses, compressed air, water, oil. Value of this cost should be expressed directly in monetary units. A6. Other cost O Other process interruption related, usually indirect, costs: The estimated value per single event in monetary units, including: 21 EEE +=

- 34. Power Quality 34 www.leonardo-energy.org • penalties due to contract non-delivery or late delivery • environmental fines / penalties • cost of evacuation of personnel and equipment (also external) • costs of personnel injury (additional inability to work) • increased insurance rates (equipment, personnel health, liability) • compensation paid out • hidden costs from loss of: ∗ Competitiveness ∗ Reputation ∗ customer satisfaction and, as a consequence, lost opportunity of subsequent revenues ∗ employee tolerance • Other non-specified indirect or direct costs. A7. Savings SS. Savings. Note: It is likely that interrupted operations can save money or defer expenditure. This usually is defined in terms of ‘unused raw materials’, ‘unpaid wages for contracted/temporary staff’ or ‘savings due to reduced energy usage’. Because of idle time resulting from PQ related disruption, some ‘savings’ might be generated. The value of these savings as a consequence of the particular PQ disturbance can be: • savings from unused materials or inventory

- 35. Collecting Economic Data in Power Quality Survey 35 www.leonardo-energy.org • savings from wages that were not paid • savings on energy bill • other specific savings. A8. Total process interruption cost Finally the process interruption cost for each event are expressed as (9) B. PQ phenomena cost As described above, these costs are collected only if the PQ disturbance does not cause process interruption! B1. Non-interrupting voltage dips When a voltage dip occurs, but no disruption results because the process is protected by the operation of a mitigation device (such as a UPS, voltage restorer or stabiliser), the additional cost of operating this equipment should be included here. This may include any additional maintenance or inspection, but not installation, cost. Where the main supply cannot be quickly restored and backup supply equipment, such as diesel generating sets, take over the supply, the operating costs (e.g. fuel) should be included. It may also happen that voltage dips disturb, but do not halt, the production process; these consequences should be assessed as described under Process Interruption: • Process slow down (6),(7) 76543218 AAAAAAAA −+++++=

- 36. Power Quality 36 www.leonardo-energy.org • Equipment damage (8), particularly E2 B2. Harmonics (current and voltage) The effects of the voltage and current distortion on equipment and components fall into three classes: additional energy losses, premature ageing and mis-operation. The term ‘additional’ means that these losses are superimposed on those normally present at the fundamental frequency. ‘Premature’ refers to the possibility of an increased ageing rate with respect to the nominal service conditions. ‘Mis-operation’ refers to the loss of equipment performance with respect to the normal conditions. Specifically, the effects of harmonic distortion on the electricity supply network are not instantly visible but can have serious consequences in the medium and long term, the most important ones being: • subjecting equipment in both electricity users’ installations and the network to voltages and currents at frequencies for which it was not designed • derating of network equipment, such as cables and overhead lines, due to the additional harmonic load • derating and overheating of transformers, particularly due to saturation effects in the iron core and increased eddy current losses in the windings • premature ageing of network equipment and consumer appliances, due to the exposure of e.g. insulation materials or electronic components to excessive harmonic voltages and currents • additional Joule losses in conductors due to skin effect • neutral conductor overload due to the cumulative effect of currents at harmonic orders of odd multiples of three

- 37. Collecting Economic Data in Power Quality Survey 37 www.leonardo-energy.org • destruction of power factor correction capacitors in customers’ installations due to the amplification of harmonic current by resonance. Harmonics may cause the production process to stop, in which case the PQ cost data are collected as described under Process Interruption. Otherwise, harmonics may still cause PQ costs and the effects may be quantified by using the same approach as above for Non-interrupting voltage dips. Some specific harmonic cost may be: Losses due to complaints with clients The calculation should be based on the cost of labour (salary x person x hours) dedicated to discuss the problem with the client, in addition to the cost for transportation and measuring equipment investment. To calculate extra harmonic losses the following methods may be helpful: Joule losses in aerial and underground power networks This grows with the square of the growth of the harmonic voltage. Extra Joule losses in phase conductors caused by harmonic currents in aerial and underground power networks can be calculated according to the proposed simplified method as follows: (11) euros/year = (kW) x 3 x 10-3 x 8760 (h/year) x E (euros/kWh ) tELIZP n nnlinesinlosses ⋅⋅⋅⋅= ∑ ∞ =2 2 __ 3

- 38. Power Quality 38 www.leonardo-energy.org where: Plosses in lines losses (quantified in euros/year) Zn impedance harm. n (W/km) In averaged current harm. n (A) L total lengths of line (km) E price energy (euros/kWh) T time (h) The total Plosses in lines value of the whole power system is then calculated by addition of partial Plosses in lines values corresponding to different ranges of networks In case of LV lines there are significant additional losses in the neutral conductor caused by harmonic currents being an odd multiple of three times the fundamental frequency. Some studies suggest that this neutral current in downsized neutral conductor may reach levels exceeding phase currents. These losses can only be assessed precisely by measurements in every part of the network. For practical purposes, an approximate figure can be calculated by scaling the network loss at fundamental frequency by the square of total harmonic current distortion and the ratio of the resistive component of network impedance at the prevalent harmonic current spectrum to the resistive component of network impedance at fundamental frequency.

- 39. Collecting Economic Data in Power Quality Survey 39 www.leonardo-energy.org Losses in transformers The most important of these losses is that due to eddy current losses in the winding; it can be very large and consequently most calculation models ignore the other harmonic induced losses. The precise impact of a harmonic current on load loss depends on the harmonic frequency and the way the transformer is designed. In general, the eddy current loss increases by the square of the frequency and the square of the load current. So, if the load current contained 20% fifth harmonic, the eddy current loss due to the harmonic current component would be 5 x 5 x 0.2 x 0.2 multiplied by the eddy current loss at the fundamental frequency – meaning that the eddy current loss would have doubled. In a transformer that is heavily loaded with harmonic currents, the excess loss can cause high temperature at some locations in the windings. This can seriously reduce the life span of the transformer and even cause immediate damage and sometimes fire. Specifically, the procedure of reducing the maximum apparent power transferred by the transformer as a consequence of harmonics, often called de-rating, can be used. To estimate the required de-rating of the transformer, the load's de-rating factor may be calculated. This method, used commonly in Europe, is to estimate by how much a standard transformer should be de-rated so that the total loss on harmonic load does not exceed the fundamental design loss. This de-rating parameter is known as ‘factor K’. The transformer de-rating factor is calculated according to the formula in HD 538.3.S1. The factor K is given by:

- 40. Power Quality 40 www.leonardo-energy.org (12) where: e the eddy current loss at the fundamental frequency divided by the loss due to a DC current equal to the RMS value of the sinusoidal current, both at reference temperature. n the harmonic order I the RMS value of the sinusoidal current including all harmonics given by: (13) In the magnitude of the nth harmonic I1 the magnitude of the fundamental current q exponential constant that is dependent on the type of winding and frequency. Typical values are 1.7 for transformers with round rectangular cross-section conductors in both windings and 1.5 for those with foil low voltage windings. (K-1) represents extra losses due to the harmonic load compared to losses supplying a pure sinusoidal load. The alternative method, proposed by Paola Verde et al in studies on harmonics (equation 14) includes losses generated in transformer core. 5.0 2 2 1 2 1 1 ⎥ ⎥ ⎦ ⎤ ⎢ ⎢ ⎣ ⎡ ⎟ ⎟ ⎠ ⎞ ⎜ ⎜ ⎝ ⎛ ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ + += ∑ = = Nn n nqh I I n I I e e K ( ) 5.0 1 2 1 1 5.0 1 2 ⎥ ⎥ ⎦ ⎤ ⎢ ⎢ ⎣ ⎡ ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ =⎟ ⎠ ⎞ ⎜ ⎝ ⎛ = ∑∑ = = = = Nn n n Nn n n I I III

- 41. Collecting Economic Data in Power Quality Survey 41 www.leonardo-energy.org (14) where: PT losses of transformer due harmonic distortion (kW) PFe fundamental frequency iron losses (kW) Rn equivalent copper loss resistance of transformer at the nth order V1 fundamental component voltage (V) Vn harmonic voltage of order n In harmonic current of order n m exponent with an assumed value m=2 n order of harmonic Calculation of PT individually can be onerous. Instead, a simplified method can be proposed based on the application of a simple algorithm by regrouping transformers according their size. Losses in generators A similar method of calculation to that for transformers can be used. According to ‘Harmonic costs on Distribution Power Systems’ by Roger Bergeron, additional losses in generators and motors due to harmonic components can be calculated using the following algorithm: (15) 6,2 1 2 1 ··3 nV V PRIP m n Fen n nT ∑∑ ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ += ∑= ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ += n n n N Nn V V nV V PPP 2 2 1 2 1 1 1 35

- 42. Power Quality 42 www.leonardo-energy.org Where: Pn = total harmonic losses (kW) PN = sinusoidal nominal losses (kW) V1 = fundamental voltage Vn = harmonic voltage of order n Dielectric losses in capacitor banks Losses (kW) in capacitors due to harmonic components can be calculated using the following algorithm: (16) where: Pd1 losses at fundamental frequency (W) Pn losses due to harmonic n component (W) V1 fundamental component voltage (V) Vn harmonic voltage of order n n order of harmonic B3. Surges and transients Most transients arise from the effects of lightning strikes or switching of heavy or reactive loads. Because of the high frequencies involved, they are considerably attenuated as they propagate through the network so 2 1 1 1 ∑ ∞ = ⎟⎟ ⎠ ⎞ ⎜⎜ ⎝ ⎛ = n n dn V V nPP

- 43. Collecting Economic Data in Power Quality Survey 43 www.leonardo-energy.org that those occurring close to the point of interest will be much larger than those originating further away. Protective devices in the network ensure that transients are generally kept to a safe level and most problems arise because the source of the transient is close to, or within, the installation. The damage that results may be instantaneous, such as the catastrophic failure of electrical plant or appliances, or the corruption of data within computers or in network cabling, or it may be progressive with each event doing a little more damage to insulation materials until catastrophic failure of cables or capacitors occurs. The cost of replacing the failed equipment and the cost of the downtime involved must be considered. Surges and transients, even if not halting the production process, may still be responsible for some process and equipment costs. Surge arresters need maintenance to replace activated parts, production equipment, protection equipment and controls need to be checked or reset. This can be addressed by using the process and equipment costs approach. B4. Voltage fluctuations and flicker Voltage fluctuations in the power systems cause a number of harmful effects of technical and ergonomic nature. Both kinds of effects may involve additional costs in the production process. Some selected effects of voltage fluctuation are described below. Also, frequently occurring, irregular operation of contactors and relays should be mentioned, as their economic effects could be damaging. • Electric machines: Voltage fluctuations at the induction motor terminals cause changes in torque and slip; as a consequence they influence technical processes. In the worst cases they may lead to excessive vibrations and therefore to a reduction of mechanical strength and shortening the motor service life. Voltage fluctuations at

- 44. Power Quality 44 www.leonardo-energy.org the terminals of synchronous motors and generators give rise to hunting and premature wear of rotors; they also cause additional torque, changes in power and increase in losses. • Static rectifiers: A change of supply voltage in phase-controlled rectifiers with DC side parameters control usually results in a lower power factor and the generation of non-characteristic harmonics and interharmonics. In the case of a drive braking in inverter mode, it can result in a switching failure, with consequent damage to the system components. • Electrolysers: Equipment lifetime can be reduced and the efficiency processes decreased and there is a risk of increased maintenance and/or repair costs. • Electroheat equipment: Efficiency is reduced – for example, due to a longer melt time with the arc furnace - but it is noticeable only when the magnitude of a voltage fluctuation is significant. • Light sources: A change in the supply voltage magnitude results in change of the luminous flux of a light source, known as flicker. It is a subjective visual impression of unsteadiness of a light flux, whose luminescence or spectral distribution fluctuates with time. The perceived severity of flicker depends on the repetition rate of the voltage fluctutions. Excessive flicker can cause migraine and is responsible in some instances of the so-called ‘sick building syndrome’. The voltage of an electrical network varies continuously as equipment on the network is switched. The voltage variation can be slow or fast, depending on whether it is a cumulative variation of the total load supplied by the grid, or an abrupt variation of a large load. The level of voltage

- 45. Collecting Economic Data in Power Quality Survey 45 www.leonardo-energy.org variations caused by switching of electrical equipment depends on the network impedance. With increasing impedance, the level of voltage variations will increase. Cyclic variation of the voltage creates flicker, a perturbation which affects the lighting equipment and creates a impression of unsteadiness of the visual sensation. Complaints about flicker are usually localised so routine measurement campaigns are not often carried out. On the other hand, the available data confirms that the long term and short term flicker levels are commonly below those that might give rise to complaints. Values in excess of the EN 50160 value do occur, however, especially in remote areas due to the higher supply impedance. Since flicker is very easily observed, diagnostic measurements are easily targeted at affected areas. Given the immediate visibility of the phenomenon and the severe human discomfort that can be caused, each case of complaint must be taken very seriously. In order to prevent flicker becoming a widespread problem, appropriate emission limitation is essential, with due allowance for the cumulative effect across the network levels. To assess the adverse effect of flicker on staff work efficiency, the following approach may be used: F Flicker can cause migraine and can be responsible for so called ‘sick building syndrome’. The flicker sensation is measured as Pst (ten minute measurement period) and Plt (two hour measurement period); a value of 1 indicates that 50% of the population would perceive flicker in a 60W tungsten bulb connected to such a supply. Levels persistently close to or above 1 would be likely to cause

- 46. Power Quality 46 www.leonardo-energy.org some reduction in manpower efficiency especially for visually detailed operations. In such a case the labour cost will be higher by Lex which is defined as nominal labour required to execute the job multiplied by slowdown rate SDR. The indicated value of SDR in some rooms of high flicker emissions values is 0.1 according to a LBNA study[13]. (17) where: Lex is extra labour cost SDR slowdown rate (suggested at 0.1) B5. Unbalance The sensitivity of electrical equipment to unbalance differs from one appliance to another. A short overview of the most common problems is given below: • Induction machines: These are AC asynchronous machines with internally induced rotating magnetic fields. The magnitude is proportional to the amplitude of the direct and/or inverse components. The rotational sense of the field of the inverse component is opposite to the field of the direct component. Hence, in the case of an unbalanced supply, the total rotating magnetic field becomes ‘elliptical’ instead of circular. Induction machines face three kinds of problems due to unbalance. Firstly, the machine cannot produce its full torque as the inversely rotating magnetic field of the negative-sequence system causes a negative braking torque that has to be subtracted from the base torque due to the normal rotating magnetic field. Secondly, the bearings may suffer mechanical SDROLnL i ii iex ×+×= ∑ )(

- 47. Collecting Economic Data in Power Quality Survey 47 www.leonardo-energy.org damage because of induced torque components at double system frequency. Finally, the stator and, especially, the rotor are heated excessively, possibly leading to faster thermal ageing. This heat is caused by induction of significant currents by the fast rotating (in the relative sense) inverse magnetic field, as seen by the rotor, and is also accompanied by vibrations. To be able to deal with this extra heating, the motor must be derated, which may require a machine of a larger power rating to be installed. In general, a fully loaded motor on a 2% unbalance supply is likely to suffer damage. • Synchronous generators: Synchronous generators are AC machines and one application is in local generation such as CHP units. They exhibit phenomena similar to those described for induction machines, but mainly suffer from excess heating. Special care must be devoted to the design of stabilising damper windings on the rotor, where the currents are induced by the indirect and homopolar components. • Capacity of transformers, cables and lines: The capacity of transformers, cables and lines is reduced due to negative-sequence components. The operational limit is in fact determined by the RMS rating of the total current, being partially made up of ‘useless’ non- direct sequence currents as well. This has to be considered when setting trigger points of protection devices, operating on the total current. The maximum capacity can be expressed by a derating factor, to be supplied by the manufacturer, which can be used to select a larger system, capable of handling the load. • Transformers: Transformers subject to negative-sequence voltages transform them in the same way as positive-sequence voltages. The behaviour with respect to homopolar voltages depends on the primary and secondary connections and, more particularly, the

- 48. Power Quality 48 www.leonardo-energy.org presence of a neutral conductor. If, for instance, one side has a three -phase four-wire connection, neutral currents can flow. If at the other side the winding is delta-connected, the homopolar current is transformed into a circulating (and heat-causing) current in the delta. The associated homopolar magnetic flux passes through constructional parts of the transformer causing parasitic losses in parts such as the tank, sometimes requiring an additional derating. • Electronic power converters: These are present in many devices such as adjustable speed drives, PC power supplies, efficient lighting and so on. They can produce additional, uncharacteristic, harmonics although, in general, the total harmonic distortion remains more or less constant. The design of passive filter banks dealing with these harmonics must take this phenomenon into account. The devices discussed above are obviously three-phase loads. Of course, single-phase loads may also be affected by supply voltage variations resulting from unbalance effects. The table below shows typical extra losses from load unbalance as a function of neutral current resulting from unbalance to average phase current. Table 1: Extra losses due to unbalance Ratio of neutral current to average phase current % of additional losses from load unbalance transformers Low voltage lines 0.5 6-8 40-50 1,0 15-20 70-140 1.5 35-50 140-260 2.0 70-90 200-500 3.0 150-200

- 49. Collecting Economic Data in Power Quality Survey 49 www.leonardo-energy.org The calculation of the economical effect of unbalance should be carried out by assessing the cost of the consequences described above and/or the cost of measures provided to mitigate them, most practically on annual basis. B6. Earthing and EMC The use of a combined protective earth and neutral (PEN) conductor, as used in a TN-C system, is not compatible with the principles of good design. The primary purpose of the protective conductor is to provide a path for fault currents, leakage currents (at the fundamental frequency) and the high frequency noise currents that arise from, for example, switched mode power supplies via radio frequency interference (RFI) filters and second to be a voltage reference for signal interfaces. In a TN-C system neutral currents - including third harmonics - and earth currents mix in neutral conductors, protective conductors and connected metalwork. The magnitude of leakage currents varies around the installation. Since the earth leakage current originates mainly from single-phase equipment on each of the three phases, balanced components of the fundamental from each phase will tend to cancel, so that the current in the protective conductor may increase or decrease as circuits are combined along a distribution system. The worst of these conditions are often encountered in single-phase, final circuits supplying ICT equipment. Leakage currents are harmless while flowing to earth, but can easily reach lethal levels if the connection fails. As microelectronic devices have developed they have become more sensitive. Operating voltages and the energy required to switch logic states have reduced; the immunity to voltage noise has generally

- 50. Power Quality 50 www.leonardo-energy.org decreased making these systems more sensitive to noise. The effect of these trends has been offset by improvements in the system design to improve noise immunity. These measures include the use of differential interfaces and better software design that includes the use of error detecting and correcting protocols on networks. These techniques are very effective, but reduce network throughput by sending redundant (error control) data and requiring re-transmission of failed data packets. As the electrical noise increases, the error rate increases, and throughput decreases until useful communication ceases completely. To the user it appears as if the system has suddenly failed, whereas in fact it has merely degraded to the extent that the available recovery mechanisms can no longer cope. If the electrical noise can be reduced to a low enough level, the error rate will also reduce and data transmission will again be possible. High noise levels reduce throughput by requiring repeat transmission and further reduce efficiency. Clearly, network efficiency is related to data processing efficiency, which is related to business efficiency. As with many things, efficiency is worst when the need is greatest and when the network is busy. Consequently, reducing the level of electrical noise in the data processing environment is crucial to increasing efficiency. Despite the most serious economic consequences of lethal levels of leakage currents, the cost of data loss, data corruption and cost of mitigation should be assessed, most practically on an annual basis Finally all PQ phenomena related costs can be expressed as: (18)654321 BBBBBBB +++++=

- 51. Collecting Economic Data in Power Quality Survey 51 www.leonardo-energy.org C. Cost of postponed PQ effects C1. Cost of ageing of equipment in power networks Electrical power system components are subjected to different service stresses (electrical, thermal, mechanical), which can lead to degradation or ageing of electrical insulation - an irreversible process, resulting in failure of the component. For insulation in MV/LV power systems electrical and thermal stresses (i.e voltage and temperature) are, in general, the most significant. Moreover, the interaction between electrical and thermal stresses can lead to a further increase of electrothermal ageing rate with respect to the effect of these stresses applied separately, referred to as stress synergism. The ageing rate can be accelerated by the increase of electrical and thermal stress levels (with respect to the nominal service conditions), due, for example, to voltage and current harmonics. Similar effects may result from other disturbances such as unbalance or overvoltages. When harmonic distortion is present, the equipment and component models can take into account only thermal stress, leading to Arrhenius law based models, or can also take electrical stresses into account, leading to more complex life models. Assuming that the useful life of an insulated device is determined by thermal degradation of the insulation materials, the rate of degradation can be represented by the well-known reaction rate equation of Arrhenius when the absolute temperature of the materials is constant. From the Arrhenius relationship, it has been demonstrated that the thermal loss of life of the k-th component in a time period Tc characterised by different operating conditions, each at given temperature and of given duration, can be expressed as the summation of relative losses of life: t kLΔ

- 52. Power Quality 52 www.leonardo-energy.org , (18) where q is the number of operating conditions during Tc; ti,k is the duration of operating condition of the k-th component at constant temperature qi,k; finally is the useful life of the kth component at temperature qI,k, obtained from Arrhenius model. The temperature of each component qi,k can be determined by considering the heat balance relationships, in which the losses at the fundamental and at the harmonics are the forcing terms. When both thermal and electrical stresses have to be taken into account, the procedure is similar, but the life models to be used in relation to 4.18 change for the electrothermal model. The relative loss of life of the MV/LV power system component in the time period Tc, , can be again expressed as the summation of fractional losses of life: (19) where is the life that the component would experience if constant values of electric and thermal stresses a n d w e r e continuously applied until failure. In the literature, electrothermal models that explicitly account for the effects of voltage and current harmonics for the most common equipment and components of MV and LV systems can be found. The reduction of equipment useful life can be quantified in economic terms. The calculation can be based on the thermal condition (determination of temperature rise due to harmonic Joule losses) of equipment. Several ( )k,iθΛ Let kΔ ( )ii ,EL θ iE iθ ( ) = = ∑ ⎥ ⎥ ⎦ ⎤ ⎢ ⎢ ⎣ ⎡q 1i k,i k,it k t L θΛ Δ ( )∑ ⎥ ⎦ ⎤ ⎢ ⎣ ⎡q 1i ii i k et ,EL t L = = θ Δ

- 53. Collecting Economic Data in Power Quality Survey 53 www.leonardo-energy.org formulas have been proposed for evaluating loss of equipment life, considering the operating rather than the nominal conditions. The operating temperature rise of the hottest point ( ) at operating condition is evaluated by the following formula: (20) where : = expected temperature rise of the hottest point under normal operating conditions = temperature rise of the hottest point caused by harmonics content = operating power = harmonics content = Expected life span under polluted harmonics conditions = Expected life span under nominal conditions = Expected life span under operating conditions There could be more loss of life at operating conditions than at rated conditions because the life expectancy will be greater than Network operators could lose more money in reduction of equipment useful life in harmonics conditions when their e q u i p m e n t i s operating below their nominal rating. To determine the economic impact, the actual cost for the future replacement of the equipment is needed . The time, t, used should be chosen according to the normal lifetime of the equipment type: hTΔ O O h h T P P T Δ⋅≈Δ OTΔ hTΔ OP hP ht Nt Ot Ot Nt ( )⎭ ⎬ ⎫ ⎩ ⎨ ⎧ Δ+ Δ ⎟ ⎠ ⎞ ⎜ ⎝ ⎛ − ⋅= hOO h TTT T K E Oh ett

- 54. Power Quality 54 www.leonardo-energy.org (21) This is modified in the following form: (22) where: is present value of future equipment replaced in sinusoidal (and balanced) conditions is actual cost for replacing the equipment is expected life span of the actual equipment The same formula is used to calculate the present cost for buying new equipment in years representing the expected lifespan under harmonics condition. (23) where: is present cost for buying new equipment in years representing the expected life span under harmonic (or other responsible PQ disturbance) condition is expected life span of the actual equipment under harmonics condition ∑ ++ +×− = = n t t t tctb ir eCC PV 0 )]1)(1[( )1()( O O t t E E ir eC PV )]1)(1[( )1( ++ +× = EC EPV Ot ht EhPV ht ht h h t t E Eh ir eC PV )]1)(1[( )1( ++ +× =