HSE Management Plan

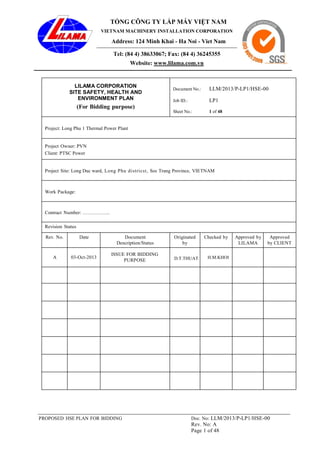

- 1. TỔNG CÔNG TY LẮP MÁY VIỆT NAM VIETNAM MACHINERY INSTALLATION CORPORATION Address: 124 Minh Khai - Ha Noi - Viet Nam Tel: (84 4) 38633067; Fax: (84 4) 36245355 Website: www.lilama.com.vn LILAMA CORPORATION SITE SAFETY, HEALTH AND ENVIRONMENT PLAN (For Bidding purpose) Document No.: LLM/2013/P-LP1/HSE-00 Job ID.: LP1 Sheet No.: 1 of 48 Project: Long Phu 1 Thermal Power Plant Project Owner: PVN Client: PTSC Power Project Site: Long Duc ward, Long Phu districst, Soc Trang Province, VIETNAM Work Package: Contract Number: …………….. Revision Status Rev. No. Date A 03-Oct-2013 Document Description/Status ISSUE FOR BIDDING PURPOSE PROPOSED HSE PLAN FOR BIDDING Originated by D.T.THUAT Checked by Approved by LILAMA Approved by CLIENT H.M.KHOI Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 1 of 48

- 2. Contents 1. Purpose 2. Health, Safety & Environment Projection Policy 3. Safety Control Organization and Responsibility 3.1. Safety Control Organization 3.2. Responsibility 4. Safety, Health and Environment Implementation 4.1. Safety, Health and Environment Committee 4.2. Education and Induction 4.3. Zero Accident Movement (ZAM) 4.5. Weekly Safety Assembly 4.6. Notice of Accident 5. Health/ First Aid 5.1. Medical Center 5.2. First Aid Boxes 5.3. Record Keeping 5.4. Physical Qualification of Workers 6. Emergency Plan 6.1. General 6.2. Fire procedure 6.3. Site Evacuation 6.4. Emergency Communications/alarms 6.5. First Aid Center Function in emergencies 6.6. Site Emergency Reporting Procedure 7. Workplace Environment 7.1. General Requirement 7.2. Sanitation 7.3. House Keeping 7.4. Waste Disposal/ Rubbish Collection & Handling 7.5. Noise 7.6. Working Times/ Overtime Working 8. Personal Protective Apparatus & Safety Equipment 8.1. General 8.2. Safety Helmet 8.3. Respiratory Protection 8.4. Hearing Protection 8.5. Safety nets 8.6. Safety Shoes 8.7. Safety Goggles 8.8. Safety Belts 8.9. Safety Gloves PROPOSED HSE PLAN FOR BIDDING 6 7 11 12 14 18 Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 2 of 48

- 3. 8.10. Clothing/ Uniform 9. Equipment Inspections/ Tagging 9.1. General 9.2. Crane Inspections and Testing 9.3. Vehicle Inspections General 9.4. Tools and Equipment Inspection 9.5. Site Inspections of Tools and Equipment 10. Electrical Safety Procedures 10.1. Electrical Distribution 10.2. Temporary Electrical Wiring 10.3. Electrical Personnel/ Training/ Emergency 10.4. Electrical Wire and Apparatus 11. Fire Prevention and Protections 11.1. Fire Prevention 11.2. Fire Protection 12. Traffic Rules and Regulations 12.1. General 12.2. Vehicle Testing and Permits 12.3. Vehicle Parking 12.4. Traffic Rules 13. Safe Work Practices 13.1. Platforms and Scaffolds 13.2. Hand Tools and Power Tools 13.3. Ladders 13.4. Floor and Wall Openings 13.5. Manual Lifting and Carrying 13.6. Mechanized Equipment 13.7. Compressed Air and Gases 13.9. Forklifts 13.9. Cranes 13.10. Rigging, Hoisting and Jacking 13.11. Critical and Heavy Lift 13.12. Signals, Signal Persons, Signs and Tags 13.13. Material Handling and Storage 13.14. Welding and Cutting 13.15. Steel Erection 13.16. Chemicals/ Hazardous Materials 13.17. Painting, Coating and Spraying 13.18. Grinding Wire and Buffing Wheels 13.19. Shop Work Machinery and Equipment 13.20. Temporary Electrical Wiring Works PROPOSED HSE PLAN FOR BIDDING 23 24 27 29 32 Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 3 of 48

- 4. 14. 15. 16. 17. 13.21. Excavation 13.22. Demolition 13.23. Blasting and Explosives (to do at a later date) 13.24. Hot Work Procedures (to do at a later date) Safety Control System 14.1. Safety Inspections 14.2. Accident Analysis 14.3. Reporting 14.4. Safety Plan Review Motivation and Incentive Schemes (to be prepared later) General Rules and Regulations for all personnel Penalties for safety violations/ failure to comply PROPOSED HSE PLAN FOR BIDDING 49 51 52 Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 4 of 48

- 5. SITE HEALTH AND SAFETY PLAN The following Contractor's Health and Safety Plan is a preliminary document and may be amended from time to time as required. The Health and Safety Plan contains the minimum requirements the Contractor to observe in this respect whilst carrying out the Construction Works. Safety is of primary importance and the Contractor are fully responsible for the health and safety of his work force at all times. 1. PURPOSE This plan is a guide to promote among all staffs and all workers the importance of safety accident prevention. The rate of accident needs to be controlled and kept to a minimum to avoid the wastage of manpower and resources, and also to prevent physical and mental anguish for the construction period of Long Phu 1 Thermal Power Project. In case accident occurs, first-aid facilities and first-aid staffs should be available to minimize the loss or damage due to personnel injuries. First-aid staffs should be trained persons with effective ability to assume such job. 2. HEALTH, SAFETY & ENVIRONMENT (HSE) PROTECTION POLICY We LILAMA Corporation (“LILAMA”), are committed to achieving Health, Safety and Environment (HSE) excellence. This is a responsibility of management and employees in all function. We will strive to provide a safe and healthy working environment and to avoid adverse impact and injury to the environment and the communities in which we do business. The duties and responsibilities of various personnel are laid down to ensure participation by everyone with the safety consciousness in prevention of accidents. To systematize the safety procedures of the Company, the following is set forth as fundamental Safety Policy. During work execution the contents of this Policy will be modified/amended and revised according to site situation and for improvement of safety. The requirements of the Contract and relevant Vietnamese local rules and regulations shall be met in each case. 3. SAFETY CONTROL ORGANIZATION AND RESPONSIBILITY 3.1. Safety control organization (Will be submitted later) 3.2. Responsibility A. Site manager’s responsibility The objective of the Site Manager is to constantly work towards: 1) Maintaining a safe and healthy working environment. 2) To establish and promote practices and procedures to prevent accident and injuries. 3) To observe all safety regulation allotted out by the company. 4) To establish a safety committee. 5) To upgrade standards and control. 6) To execute Zero Accident Movement (ZAM) B. Section chief’s responsibility 1) To maintain safe working conditions and practices for all employees. 2) To maintain good housekeeping in the section. 3) To ensure adequate personal protective equipment in accordance with safety rules and regulations. 4) To ensure all safety rules and regulations complied with and explained to employees in his section and subcontractors under his control. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 5 of 48

- 6. 5) To rectify all unsafe conditions and hazards when required by Safety Manager. C. Site engineer/FOREMAN/supervisor’s responsibility 1) To enforce all safety rules and regulations. 2) To investigate accidents and near misses with Safety Manager. 3) To ensure that all persons working under him are trained on safe and proper working procedures. 4) To inspect his working areas, tools and equipment frequently 5) To conduct section’s regular safety meetings at work sites 6) To take stop-work action against any person working unsafely 7) To rectify hazards pointed out by Safety Manager or safety personnel 8) To maintain good housekeeping in his work areas D. Safety manager’s responsibility 1) Formulating, administrating and making necessary changes in this HSE plan. 2) Submitting directly to the Site Manager regular monthly, weekly or daily reports on the status of safety. 3) Acting in advisory capacity on all matters pertaining to safety as required for the guidance of management. 4) Maintaining the accident record system, making necessary reports, personal investigations of fatal or serious accidents, securing Site Engineer/Supervisor’s accident reports and checking corrective actions. 5) Coordinating safety work with first aid. 6) Making personal inspections for purpose of discovering and correcting unsafe conditions or unsafe work practices before they cause accidents. 7) Maintaining outside professional contracts to exchange information with others and to keep this HSE plan up-to-date. 8) Making certain the laws, ordinances or orders bearing on industrial safety. 9) Securing necessary help or advice from the minister of labor, insurance companies, and other concerned parties relating to safety or health. 10) Controlling or supervising fire-fighting activities. 11) Checking whether safety equipment used by plant personnel is acceptable. 12) Executing Zero Accident Movement E. Sub-contractor’s responsibility (if any). 1) To ensure that all the respective agents and employees conform to the contents of this HSE plan. 2) To supply employees with appropriate safety equipment and appliances when working. 3) To attend Contractor’s safety meetings, when called upon, and to conduct safety meetings for all his employees. 4) To rectify unsafe conditions and hazards when required by Contractor’s Safety Manager and/or his staff. 5) To maintain good house keeping 6) Report all accidents to the Contractor’s Safety Manager or his staff immediately. 7) To seek first aid for all injuries, however slight, at the first aid station 8) To be entirely responsible for the implementation of safety measures and full compliance with regulations of his company in respect of both himself and all his employees PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 6 of 48

- 7. 9) Should accept this HSE plan and perform the work accordingly. In case a subcontractor wants to apply his own safety plan the plan should be reviewed and approved by the Contractor’s Safety Manager. F. Employee’s responsibility 1) To obey all company’s safety regulations to prevent himself and his colleagues from injuries. 2) To report all unsafe acts and conditions to his supervisor or his foreman immediately. 3) To report all accidents to his supervisor or his foreman immediately. 4) To seek advice from his supervisor a) When an unusual situation develops which may appear wrong to him. b) When he does not know how to do a job. c) When he does not understand the instruction. 5) To wear all personal protective equipment such as safety helmet, safety shoes and other equipment required by the work condition. 6) To maintain good housekeeping in the work area. 7) Not to create unsafe conditions. 8) To rectify any hazard or unsafe condition found at his area of work. 4. SAFETY, HEALTH AND ENVIRONMENT IMPLEMENTATION 4.1. Safety, health and environment committee Chairman : Site Manager Other Members: Safety Manager, Representatives for workers, Representatives for Subcontractors (if any), Representative for Owners. It is required that at least companies on the project send workers and supervisors to represent the Subcontractors. Frequency : Monthly Function : - Establishing a monthly execution plan - Conduct monthly safety audits - Review the accident statistics for the month - Guidance and confirmation of safety rules/regulations - Safety control issues and solutions - Make amendments and revisions to this HSE Plan The minutes of this committee will be submitted to CLIENT (The general agenda format is to be developed later). 4.2. Education and induction A. New-comer employee education 1) Object : General Safety Induction for all Lilama Personnel 2) Time : One day before commencing work on the project site 3) Duration : From 1 to 3 hours 4) Instructor : Safety Manager and/or Safety Induction Officer 5) Contents : Explanation of safety and health rules, regulations. Explanation of works, specific site conditions and penalties Samples of correct safety equipment to be on display PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 7 of 48

- 8. Workers to fill out personal information slips and acknowledge undertaking the course. 6) Identification (“Photo ID”) Badge for site access will be issued by Client’s Safety Department after completion of the site specific induction. B. Specific employee education and certification 1) Object: To give more detailed induction to certain new site employees, whose jobs are considered generally more hazardous, i.e. welders/ riggers/ scaffold erectors/ electricians/working inside tanks, vessels, steam generators, etc. 2) Time: Once in quarter of the year. 3) Instructor : Safety Manager/ Safety Induction Officer/ Contractor Specialty Supervisor 4) Contents : Dangerous factor of each work process Correct use of facilities, equipment & material Use of safety equipment and protection materials C. Regular education 1) Object : To reinforce safety issues for all site employees 2) Time: Daily 10 minutes before work starts during “Pre start meeting”, especially when a major phase of construction work starts. 3) Instructor : Safety Manager/ Safety Induction Officer/ Section chief 4) Contents : Dangerous factor of each work process Safety/ health performance and accident prevention. Example of accidents & prevention of industrial disaster Correct use of facilities, equipment & material Improvement of work circumstances & prevention of occupational disease Use of safety equipment and protection materials Zero accident movement Other items about site safety control. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 8 of 48

- 9. D. PRE-START meeting 1) Object: Explanation of works for the day and familiarization of dangerous area and confirmation of safety before work such as the wearing of safety & protection equipment. 2) Duration : Short time (i.e. 10 minutes) before work start 3) Instructor : Site Engineer/ Supervisor or Sub-contractor’s Engineer/ Safety Officer 4) Contents : Personal protective clothing House keeping Fire prevention/Fire fighting Safe welding and cutting Scaffolding Power tools Safe electrical installation Lighting Ladders Safe material storage Manual lifting Working with cranes Excavations Falls Chemicals Noise Intoxicants/ drugs First aid Sanitation and Hygiene Disposal and Handling of waste E. Special safety training 1) Object : Specific Safety training for Workers to be in service for specific tasks that are considered as dangerous work 2) Period & Time : Before work start (Required time will be decided by Safety Manager Subject to work condition) 3) Instructor : Safety Manager/ Safety Induction Officer/ Contractor Specialty Supervisor (e.g. Rigging supervisor/ Heavy Lift supervisor) 4) Contents: Work procedure, characteristic of work, potential risk of hazard, safety requirement and emergency measures. 4.3. Zero accident movement (“ZAM”) A. Purpose As a part of practical safety program to promote autonomous movement for prevention of hazard and to encourage a hazard prevention consciousness for all employees and workers, we wish to execute this program so called “Zero Accident Movement” so that the accident ratios might be reduced or zero eventually. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 9 of 48

- 10. B. Enforcement principle 1) Notice a start of zero accident movement to all employees and head office safety management post 2) Before starting ZAM, construct safety management organization and possess a basic standard safe device, and educate safety to all employee and worker 3) Establishing target time for zero accident and note the start dates of ZAM to every employees and workers. 4) To execute ZAM systemically and efficiently, each section & subcontractor shall establish their target time for zero accident, check their execution status, records any proposal for ZAM on the daily basic. Safety Officer record their zero accident time in total. 5) After achieving the first target time for ZAM, continue the ZAM to double, triple and continuously toward to reach the best record. 6) When a hazard demand recuperation over 4 days, the achieved time of ZAM so far is invalid and new time record shall be resumed 4.4. WEEKLY TOOLBOX MEETING The safety assembly will be held on a weekly basic. All staff from the contractor and subcontractors shall attend: The purposes are: Convey a safety message Safety status and activities for the previous month Planned safety activities and other related information for this month Demonstrate general safety skills such as use of fire extinguisher Award for personnel or sub-contractor who achieved the best safety performance during previous month 4.5. Notice of accident A. All accidents and dangerous occurrences arising out of and in the course of employment must be reported by the supervisor to the Safety Manager, Client’s Project Safety Department , at the time of its occurrence or at latest before the end of the day’s work B. A formal accident notice form must subsequently be submitted to the Safety Manager within twenty-four (24) hours following the accident, for him to conduct the necessary investigations. Accident Notification and Witness forms are in the appendix. C. An accident with any of the consequences listed below shall be immediately reported to the Safety Manager or Safety Officer. These accidents will be investigated in depth to identify all causes and to recommend hazard control measures. Except for rescue and emergency measures, the accident scene shall not be disturbed until it has been released by Safety Manager’s instruction. The consequences requiring an in depth investigation are: 1) Fatal injury 2) Any accident requiring hospitalization of the victim 3) Any incident involving electricity/ electric shock 4) Five or more persons admitted to a hospital due to same disease 5. HEALTH/FIRST-AID 5.1. On Site Medical center An onsite Medical Centre (SOS Clinic) is provided by Client and run on site by SOS All persons will report here for help PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 10 of 48

- 11. 5.2. First aid boxes 1) First aid boxes will be provided at the main office of LILAMA, First-aid center, and in several locations within the main construction site, carried by all Subcontractors' medical staffs. 2) Client medical center will have on standby a more substantial first aid kit, including stretcher for serious medical emergencies when the medical center staffs are called out to attend. 3) Safety Manager will periodically inspect all first aid boxes to ensure that they are properly equipped. 5.3. Record keeping 1) Client medical center staff will keep a record of all persons who receive treatment in the medical center. This record will include; Name of person, company, ID No., treatment received, cause of accident/ illness, location of accident, medicines issued, further treatment required, ambulance use, hospitalization, and any time off work. 2) All records to be passed to Safety Manager weekly. 3) Subcontractors first aid/ medical staff(s) will be required to submit a weekly report of any accident victims that they treat that do not go to main medical center 5.4. Physical qualifications of employees 1) All persons shall be physical qualified for performing the duties to which they are assigned. Some factors to be considered in making work assignments are strength, endurance, agility, coordination, and visual and hearing acuity. 2) Employees shall not use or be under the influence of alcohol, narcotics, intoxicants or similar mind altering substances while on duty. Employees found to be under the influence of/consuming these substances will be immediately removed from working site. 3) Operators of any equipment or vehicle must be able to read and understand the sign, signals, and operating instruction in use. 4) All persons working with explosives shall be in good physical condition and be able to understand and give written and oral orders 5) All staff and workers are required to inform Safety Department of medical conditions from which they suffer. This information is to be passed to Safety Department during induction. This may include, but is not limited to the following: diabetes, color blindness, partial deafness, allergies to medicines, etc. 6. EMERGENCY PLANS 6.1. GENERAL 1) The emergency communication system shall be established and poster at the convenient access-ways, in all site offices, in all security towers / gates, medical center, in order for speedy rescue of the accident victims, timely communication with local fire brigade office, prompt response from first aid staff, and the soonest possible evacuation of the workforce if necessary in a serious emergency. 2) In an emergency situation such as safety accident, the first observer shall report it to Safety Officer or any persons in reporting line as soon as possible. 3) The person who receives the report shall first start rescue activity and report to Safety Manager or any person in reporting line. 4) First finders name and ID No. shall be recorded for future use by Safety Department for investigation. 5) Site Facilities are available for use in case of Emergency PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 11 of 48

- 12. 6.2. FIRE PROCEDURE The best procedure for any fire, is “ DO NOT LET IT START”, failing that, the best means of dealing with any fire is to put it out as soon as possible and stop it from speeding. On seeing any fire personnel shall. Small fire: Inform others in the surrounding area- to call safety/ security officers Find the nearest fire extinguishers/ water bucket and attempt to put the fire out, if it is safe to do so. And they are competent and confident to do so If unable to contain/ control the fire inform the nearest safety officer/ security office the call the fire brigade. Make sure all personnel are clear of the fire area and that no one is trapped. Major fire: Inform others in the area to leave immediately. Inform the nearest supervisor/engineer/ safety officer/ security officer to call fire brigade, and sound the alarm. Make sure all personnel are clear of the fire area and no one is trapped. The first finder/ supervisor shall stay in the vicinity if it is the safe to do so, to direct emergency service personnel. Report to the designated meeting point and wait until the all clear is given. 6.3. SITE EVACUATION (as per Client’s Procedures) 6.4. EMERGENCY COMMUNICATIONS/ ALARMS The main types of emergency for emergency communication on the project will be: 1.Telephone. 2. Two way radio (walkie-talkie) 3. Alarm Siren. 4. Voice. 1) An emergency telephone numbers list will be developed and posted at all site offices, all gate posts, first aid station and passed to all Project staff with Mobile phone. 2) A list of all frequencies/ channels in use on the project will be developed and issued to all project staff/ security guards/ first aid staff/ safety officers and all Subcontractors. There will be a dedicated frequency for safety staff/ emergencies, which any person with a radio can use to inform Safety Department of Safety Problem, emergency situations, and accidents. First aid station radio will be permanently set to this frequency. 3) An alarm siren shall be established for sounding alarms for site evacuation, fire alarm, explosion/ gas leak, start work/ stop work times. 4) The oldest and most reliable form of emergency communication is voice. Someone sees a problem/ accident / emergency - they must personally inform the nearest security guard, safety officer, supervisor, Contractor staff member. If there is a language problem, take the person and show them the problem. 6.5. FIRST AID CENTRE FUNCTION IN EMERGENCIES The function of the first aid centre in any emergencies is to provide first aid services to any person injured; this will include coordinating the operation of the Client ambulance, providing first aid treatment in the first instance on the site and Client medical center, and communicating with the safety department. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 12 of 48

- 13. 6.6. SITE EMERGENCY REPORT SEQUENCE CONTRACTOR Site Manager Safety Manager Chief Medical Officer LONG PHU 1 CLIENT’s Project Manager Local authority Contractor and/ Engineer/ Supervisor/ Safety officer/ Gate security First Aid Officer First Finder 7. WORKPLACE ENVIRONMENT 7.1. GENERAL REQUIREMENTS 1) Ventilation shall be provided where possible, to remove dusts and poisonous gas in the areas where such pollutants are produced. 2) The working environment shall be free from the causes of such symptoms as muscle spasms, nausea and skin irritation. 3) The working area shall be maintained clean by Contractor and/or Sub-contractors' labourers to prevent disease caused by dirty condition. 4) Maintaining good housekeeping for the clean work environment. 5) Protecting the workers from noise exceeding specified limit. 6) Ensuring all necessary warning and advisory signs are placed. 7.2. SANITATION A. WATER 1) Drinking water for site workers will be available on site and will be sign posted “WATER FOR DRINKING” in both Vietnamese and English PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 13 of 48

- 14. The service water will be provided in working area and Subcontractor’s office area with signboard “ CAUTION-WATER UNFIT FOR DRINKING, WASHING OR COOKING” in both Vietnamese and English B. TOILETS 1) Toilet facilities shall be provided in each construction job site. Under temporary field conditions, provisions shall be made to assure not less than one toilet facility in available. 2) Toilet shall be so constructed that the occupants shall be protected against weather and falling objects. All cracks shall be sealed and the door shall be tight-fitting, adequate ventilation also shall be provided. 3) Short term temporary toilets may be of simple construction with a toilet pit, providing, some lime and a thin layer of soil is added daily, plus good ventilation is provided. 4) Long term temporary toilets shall be completely portable, fully enclosed, with removal waste bowls. Waste shall be transferred by suitable means to a central septic for primary treatment before discharge to drainage channel. C. TEMPORARY FACILITIES 1) Temporary facilities such as offices, workshops, warehouses and Subcontractor containers shall be built in the word site with good ventilation, well lighted, and maintained in a clean, orderly manner. All temporary building shall be a safe distance away from any hazards, especially fuel storage areas. 2) Temporary facilities will be equipped with fire extinguishers, that are fully charge, serviceable, and located in prominent position 3) All temporary offices, stores, camps of any kind must have rubbish/ waste bin with cover. Such bins will be emptied at least once a week. 4) All temporary officers/ containers/ stores/ warehouses must have the company name clearly displayed in a prominent position. D. FIRST AID 1) At the start of major work, arrangements shall be made for medical facilities and nurse to be available for prompt attention to the injured and consultation on occupational health. 2) The main first aid center shall be located in the project office. There shall be at least one nurse on duty whenever works are being carried out on the project. 3) The safety manager shall check the contents of the first aid kids periodically when or is in process to ensure that expended items are replaced. 2) 7.3. HOUSE KEEPING 1) All stairways, passageways, gangways, and access ways shall be kept free of materials, supplies, and obstructions at all times. This applies especially to access- ways / working platforms on scaffolding. 2) Loose or light material shall not be stored or left on roofs or floors that are not closed in, unless it is securely tied down. 3) Tools, materials, extension cords, hoses or debris shall not cause tripping or other hazard. 4) Tools, materials, and equipment subject to displacement or falling shall be adequately secured. 5) Empty bags having contained lime, cement, and other dust - producing material shall be removed daily. This also applies to other dusty waste, such as insulation off-cuts. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 14 of 48

- 15. 6) Protruding nails in scrap boards, planks, and timbers shall be removed, hammered in, or bent over flush with the wood unless placed in containers or trucks for removal. All second-hand timber delivered to site must have nails treated as above. Nails that are removed must not be left on the ground; they must be placed in suitable container. Such work is responsibilities of all workers of Contractor or Sub-contractors. 7) The scrap and debris shall be cleared from work areas, passageways, and stairs in and around buildings, storage yards, warehouses and other structures. 8) All sharp waste i.e. broken glass, sheet metal off-cuts, must be placed in metal drums. Accumulation of such debris on the ground is not permitted. 9) All storage areas and the construction site shall be kept free from the accumulation of combustible materials. Grass shall be kept down. Contractor and/or his sub-contractor shall establish a regular patrol for cleanup of the area. 10) Rubbish, brush, long grass, or other combustible material shall be kept out from areas where flammable and combustible liquids are stored, handled, or processed. 11) Accumulation of flammable and combustible liquids on floors, etc., is prohibited. All spills of flammable and combustible liquids shall be cleaned up immediately. 12) Safety Manager will inspect the work area daily for adequate housekeeping and record unsatisfactory finding on the "Site Safety Inspection Record". 13) All litter, food scraps, paper, cigarette packets, food packaging, cardboard etc. must be placed in rubbish bins. These bins must be provided at every office and container and store, and be provided with lid to prevent windblown debris. 14) Vermin (rats, mice, insects) will be controlled primarily by the strict control of eating anywhere within the construction site, the use of bins with lids, the frequent removal of rubbish to control / eradicate any infestations that occur, using approved sprays / poisons etc. 15) Control of dust from construction activity and traffic will be controlled by the regular use of water trucks to spray sufficient water to keep the ground damp if any. 7.4. WASTE MATERIAL DISPOSAL/RUBBISH COLLECTION& HANDLING 1) All waste material and rubbish shall be disposed to the designated place (will be determined later) by the Main Contractor & / or his Subcontractor. 2) Waste material will be treated according to CLIENT’s requirements. 3) All vehicles carting waste material from the site to designated place must have covers over the load, and the Subcontractor concerned must immediately clean up any spillage of waste material on both site roads and public roads. 4) For both security and safety purpose, rubbish removal will not be permitted at night. This will discourage the practice of placing valuable goods on the bottom and covering with rubbish, to easily pass through security gates. 5) All scrap lumber, waste material, and rubbish shall be collected and stored in piles or containers for removal. 6) Garbage shall be collected in dustbins placed in several points at site and disposal daily. 7) All rubbish bins will have lids to prevent litter being blown about by the wind, and to stop vermin getting into the bins. 8) All rubbish/waste / excess material must be removed from the site by Subcontractor / Contractor waste removal Subcontractor by vehicle. There will be no scavenging of waste by workers or locals at any place on the project site. Workers are not allowed to leave the site carrying any kind of rubbish / waste. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 15 of 48

- 16. 9) Oils, chemicals and other industrial wastes shall be collected at differently appointed places and disposed to the designed place in accordance with approved regulations and Client Site Environment Policy 10) The dumping of waste oils / toxic chemical in site drainage system is strictly prohibited. Any Subcontractor found disposing of waste materials in this way will be required to clean the entire area. 7.5. NOISE 1) In all cases where the noise levels exceed specified limits, a continuing and effective protection program shall be administered. 2) When the sound pressure level in a working area is too much high, personal ear protection equipment such as earplugs or earmuffs shall be worn. 3) Noise hazardous areas will be marked with caution signs indicating both the presence of hazardous noise levels and the necessity of ear protection device. 7.6. WORKING TIMES / OVERTIME WORKING The following will be the normal working times for the project: comply with the provisions of CLIENT. In conjunction with these times the following operating procedure will apply: 1. During the times when the workers entry gate is opened, all workers will have to use this gate, they will not gain entry through any other gate – workers will be required to pass through in single file, presenting their ID cards, and being checked for items such as safety helmet, safety shoes, company uniform, no food, no alcohol, and carrying no goods or equipment. 2. Any ways are carried out after 5 PM will need to be requested in advance, by submitting an Overtime Work request (OTW Request) sheet. This sheet must be submitted before 3 PM on the way in which the over time will be worked, and will include the following details: Company name, locations and nature of works, number of workers, name of person in charge / supervisor, planned duration of work and any requirements for inspections / tests by Contractor Staff, Overtime Work Request sheets. 3. OTW request sheets must be passed to CLIENT to which the work is applicable, who in turn will pass a copy of the sheet to safety department. 4. Copies of approved Overtime Request Sheets will be passed to gate security, and only those companies that have requested to work and been approved will be permitted entry. 5. Note that works at each dark place, at night need sufficient lighting. This includes deliveries, concrete works, bar bending, any work activity. Works will not proceed unless there is ample light for working safety. For dangerous and critical works at night, an inspection must be carried out by Safety department during the day, for assessing the nature of hazard, to determine whether overtime request will be granted. 6. Overtime works include any work activity, plus material deliveries to the main site. Preparation and workshop activities in the contractor lay down area do not require a request for overtime, however all works must be carried out safety , day or night and unsafe work practice or conditions will not be tolerated by Safety Department at any time of day, on any part of the project. 8. PERSONAL PROTECTIVE APPARATUS & SAFETY EQUIPMENT 8.1. GENERAL 1) Personal protective devices shall be used as a minimum by everyone whenever on site. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 16 of 48

- 17. 2) Personal working on electrical distribution systems shall be provided with lineman's belts, insulating gloves, insulating hoods, insulating blankets, insulating line hose, and hot line tools as necessary, which shall be tested and maintained in safe condition. 3) Electric welding, gas welding, cutting blazing pressure and fusion welding, and operations shall require goggles, face masks, shields, or helmet, suitable to the type of work. 4) Persons handling rough, sharp-edged, abrasive materials or where the work subjects the hands to lacerations, punctures, burns, or bruises shall use gloves. 8.2. SAFETY HELMET 1) Each person on site shall wear approved safety helmets when on the project site. Exclusions to this are within offices and fully enclosed vehicles/ equipment. 2) Hard hat usage will include the entire construction site, basically anywhere that work is being carried out, supervised, or inspected- helmets must be worn. There are no exceptions made for visitors/ operators outside their cabins, office staff, and senior management. 3) Holes must not be made in safety hats as these lessen the ability to withstand impact. 4) Safety hats should not be painted as solvents in some paints could cause them to become brittle. 5) All helmets must have the company name and/ or logo that the wearer works for to be marked clearly visible on the helmet. Loose fittings / broken / substandard helmets will be confiscated and the worker will not be permitted on the site. 8.3. RESPIRATORY PROTECTION Before any work commences that requires respiratory protection, a confined space inspection must be requested and carried out by CONTRACTOR Safety Department in conjunction with Client Safety Department. Simply wearing respiratory equipment is not sufficient to protect against many on the dangers associated with working with gases and vapors. 1) When respiratory protective equipment is required, only the specified equipment shall be use, wore correctly, maintained properly and stored in the correct manner. 2) Only approved respiratory protective devices shall be provided and used to protect against exposure to hazardous atmospheres containing dusts, fibers, fumes, mists, gases, vapors, other contaminants, atmospheres deficient in oxygen, or otherwise considered immediately dangerous to life or health. 3) Respiratory devices using compressed oxygen, liquid air, liquid oxygen, or mixed gases are prohibited unless approved prior to use. 4) When sufficient ventilation cannot be obtained without blocking access, such as listed below, shall be performed with general mechanical ventilation, air-line respiratory or local exhaust ventilation sufficient to reduce welding fumes and smoke to safe limits. Local exhaust ventilation will consist of movable hoods placed near the work to remove smoke and fumes at the source. a) Zinc-bearing of filler metals coated with zinc-bearing materials (galvanized) b) Cadmium bearing metals of metals coated with cadmium-bearing materials. c) Chromium bearing metals or metals coated with Chromium-bearing materials. d) Metals coated with mercury-bearing materials. etc 8.4. HEARING PROTECTION Workers in area's with generally high noise levels, working with power tools that produce excessive noise, working with loud equipment should wear hearing protection. Hearing protection can be in the form of earmuffs (cover the ear), or ear plugs (inserted into the ear PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 17 of 48

- 18. cavity). Some examples of operations that require hearing protection are: Pile driving operations, use of jack hammers, continual use of power saws, angle grinders and concrete hammer drills. 8.5. SAFETY NETS 1) Workers in unguarded work places over water, machinery, dangerous operation or where 7m above the surface shall be protected by safety nets. Nets shall be installed as close under the work surfaces as practical but in no case more than 1.8m below such work surface. Nets shall be hung with sufficient clearance to prevent contact with the surfaces or structures below. 2) It must be emphasized that safety nets are to be used in conjunction with handrails/barricades. They are not the primary means of preventing workers and or objects from falling. Kick-boards on scaffolding, safety harnesses, guard-rails etc., are primary means of preventing falling items. 3) Nets shall be inspected daily for cuts and damage from abrasions, chemicals, or heat. Repairs shall be made before work above work the nets is resumed. 4) Debris shall be removed from safety nets at least daily and combustible materials shall be removed above the net. 5) To prevent small objects from passing though the safety nets, if they are used as overhead protection, fine woven mesh may be added on top of the rope or steel net. 6) For overhead protection where objects can fall from more than 5m, or any hot-works are carried out above, safety net must consist of steel mesh with plywood and metal sheeting. The thickness of both will depend on the height from which objects can fall, the type of objects expected, and the type of area/access covered. 8.6. SAFETY SHOES 1) To prevent injuries to the feet caused by protruding or falling objects, all employees working on Long Phu 1 project sites shall wear fully enclosed steel capped safety footwear. All such footwear must be of a suitable sturdy material to offer protection to the feet and to be worn correctly so that whole foot is encased and protected. (The foot must fit snuggly into the appropriate footwear so that whole foot area is covered/protected) 2) All sub-contract employees shall wear safety shoes with steel-cap or other acceptable safety footwear (steel capped “Gum Boots/wellingtons” etc) as approved by the Client safety Department. 3) *The wearing of slippers is generally prohibited anywhere on the project site. Under no circumstances is any or work or activity to be performed in bare feet. 4) *Personnel involved with rigging, handling heavy materials, operating jack-hammers (heavy air/hydraulic tools), the erection of steel structures etc, must wear properly fitted and appropriate steel capped safety footwear. 5) There are generally no exceptions for everyone on site to be wearing non approved/appropriate safety footy wear. Vehicle operators / security guards / office cleaners etc, must all wear project approved footwear /shoes. *Slippers/sandals etc of any nature will as a rule be forbidden to be worn on the site. 6) There may be controlled exceptions e.g. When working in vessels / places that require strict cleanliness/minimizing contaminates, in which case it would necessary to remove dirty safety footwear and substitute with clean slippers or similar, another identified area is within the confines of the site administration /management complex. *Unless a risk assessment indicates otherwise or exemption is granted from Long Phu 1 projects management. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 18 of 48

- 19. 8.7. SAFETY GOGGLES/GLASSES 1) To prevent eye injuries whilst working on Long Phu 1 sites, all employees engaged in cutting, grinding, using of power tools, chipping, doing oxyacetylene cutting, etc. shall wear safety glasses along with a correctly fitted full face shield in effect giving“Double Eye Protection” as per Client’s Policies and procedures. 2) Contractor shall provide safety goggles/glasses to all employees who are employed on the Long Phu 1 project site as per Client’s PPE standard eye protection, under the following conditions: a) All issued safety goggles/glasses must be maintained in good condition. b) Lenses which have become pitted or scratched are blurred or damaged as a result or normal use shall be replaced. 8.8. SAFETY HARNESS (Full body type) 1) Safety harness fitted with double lanyards (100% constant hook up) must be worn and used in the manner that at all times (1)one lanyard is constantly attached to an independently anchored line or other secure anchor point/rail when; - Working from scaffolds, platforms or other surfaces/structures which do not provide sufficient protection against a fall from height of 1.8m or greater. - Working on any roof with a slope greater than one in four, or on any sloping roof that is wet. - Working within 2m of any unprotected edge where a fall to another level that is greater than 1.8mtr exists. e.g., roofs, excavations, platforms/walkways, tops on vessels /tanks, structures etc) - Being lifted or working from a basket suspended from a crane. Lanyard to be attached to an independent connection of crane wire rope - When working in any elevated work platform basket. 2) Safety harness should be visually inspected for defects prior to each use and return to work supervisor if found defective 3) Hardware for lineman’s body belts, safety traps, and lanyards shall be drop forged or pressed steel and have a corrosive resistive finish and surface shall be smooth and free of sharp edges. 4) All safety harness/ ropes/shackles etc. must be checked and approved by Safety Department as passed fit for purpose before going into service and then all ongoing checks before each use are too made by the suitably competent user or supervisor. 8.9. SAFETY GLOVES 1) Gloves can prevent many injuries when handling rough materials or substances which can cause skin irritation. A general guideline for the type of glove to use when handling various materials are: - Cloth gloves are suitable for protection against dirt, silvers, chafing and abrasion these are satisfactory for light handling job and should not be used for handling rough, sharp or heavy materials. - Rubber, neoprene and vinyl gloves protects against acid, oils, solvents and caustic materials. These should be washed, inside and outside after use and inspected for leaks regularly. - Leather gloves are generally used for heavy-duty works, as they are able to resist sparks, moderated heat, chips and rough objects. Welder use chrome-tanned leather or horsehide gloves. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 19 of 48

- 20. - Heat resistant and thermal gloves should be used when there is the possibility of receiving burns from hot and very cold sources. 2) Gloves contaminated with oil, grease or chemical should not be used. 3) Gauntlet type must not be used when working with moving or rotating machinery and equipment which could cause the gloves to become caught and result in hand injuries. 8.10. CLOTHING-UNIFORM (High- Visibility) Clothing is an important part of personal safety equipment for several reasons. All workers on the project must be supplied with and wear their company uniform with high visibility for entry to the site. - Workers should have the most suitable clothing for the weather conditions and the works to be carried out. This includes wet weather clothing and clothing with allows the workers to conduct their particular work effectively. - Workers who have suitable/comfortable clothing are less likely to have accidents and will be able to work more productively. - It enables contractor to control access to their work areas to their workers only. This is a benefit for safety control and for security purposes. 9. EQUIPMENT INSPECTIONS/ TAGGING 9.1. GENERAL To the ensure no accidents are caused by poor quality/ faulty equipment, all: vehicles, major equipment, electrical tools, gas tools, air tools, electrical distribution equipment, hydraulic tools, hoists, explosive tools and scaffolding/ ladders will be inspected prior to going into service on the project site. Hand tools will not be inspected prior to use, however, the same conditions apply, that is, the tool must be in good condition, and appropriate for the work to be carried out. Hand tools in poor condition, are to be “Tagged out of service” and removed from the job site by safety department during site inspections or as identified by the supervisor or workers. 9.2. CRANE INSPECTIONS AND TESTING All cranes operating on the Long Phu 1 project site must be in good condition. To ensure that all cranes operating on the project are satisfactory and meet the Long Phu 1 projects site standards the safety department will carry out these inspections on all cranes along with Client Safety Department prior to being approved for use The following items will be inspected and must be immediately repaired or replaced if found to be defective or sub-standard if the crane is to remain on site. Unless cranes are inspected and passed, they will not be permitted to work on the project. Crane Inspection sheet –should contain the followings: 1) Engine condition. 2) Hoist condition 3) Boom condition- any defective part to be repaired an re-inspected. This includes bent, broken, missing, and previously poorly repaired members. 4) Hook condition - swivel hook, wire sleeve, bearings. a. main hook and safety latch b. aux. hook and safety latch 5) Out rigger condition - hydraulic ram condition, footing pad condition. 6) Safety switch: a. Over hoist limit switch at boom top should activate when the hook touches the anti tool block PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 20 of 48

- 21. b. Reverse alarm switch - audible noise when crane reversing c. Horn and flashing light, during operation 7) Lifting capacity table should be installed in operators cabin 8) Load indicator in operator box. 9) Boom angle indicator to be installed on side of boom base Following items will be inspected for condition of rigging tackle. 10) For handling of steel structure, sling belts are required to prevent slippage of structure pieces. 11) For lifting of long, heavy or items with specific lifting points - 2 or more wire or sling belts shall be used. 12) For sling belt, specific type of shackle for use with sling must be used. 13) All chain, wire rope, nylon slings to be used must be in good condition, and be accompanied by recent test certificate. 14) All rigging will be inspected every month and register documents will be kept by safety department. 9.3. VEHICLE INSPECTION GENERAL Refer to section on Vehicle testing in section 12.2 and must be approved by Client Safety Department. 9.4. TOOLS AND EQUIPMENT INSPECTIONS All tools (electric, explosive, hydraulic, pneumatic, gas) and equipment, especially for electrical distribution, welding, oxyacetylene cutting, jacking, hoisting, will be inspected by safety department before being allowed to be used on site. 9.5. SITE INSPECTION OF TOOLS AND EQUIPMENT During the daily and weekly safety inspections on site by the safety Department, special attention will be given to: the checking of equipment status, the observation of correct use, (including use of safety gear), the condition of hand tools, and to the condition and use of nonmechanical equipment such as ladders and scaffolding. Any equipment in poor condition will be removed by safety Department or the supervisor. Larger equipment that cannot be easily removed will be shut down if is found to be in poor condition, for example material and personnel hoists, cutting machines. 10. ELECTRICAL SAFETY PROCEDURES 10.1. ELECTRICAL DISTRIBUTION 1. System generally. The system of electrical distribution and control on the project will have the following main component: Transformers. Main Distribution Boards: All electrical supply from the transformers will be through CLIENT. Other Temporary Distribution: Contractor’s electric box, switchboards, tools, welding machines, cables and other temporary distribution connected through an ELCB: All to be inspected by safety department prior to use on site, with periodic re-inspection. 2. Access Controls PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 21 of 48

- 22. A) Transformers Only authorized Contractor electrical section personnel to access transformers. This applies equally to the generators and transfer switches. B) CONTRACTOR distribution Boards: All CONTRACTOR DB’s to be lockable steel cabinet. Keys to be held only by electrical section and safety department. Works to be carried out on the DB, only CONTRACTOR authorized electrical staff. All field Distribution Boards supplying socket outlets shall be fitted with appropriately size 30A RCD/ELCB protection devices All Field Distribution Boards shall be weatherproof. All Field Distribution Board shall be mounted on a stand PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 22 of 48

- 23. 3. Connection Control A) Connection of CONTRACTOR DB’s to LDP Connection prepared by CONTRACTOR electrical section, this include the cable, DB’s, cable termination etc. Before connection, it is requires that inspection by authorized person from electrical section, sign off sheet, and “power on”. B) Connection of equipment /Tools/ Temporary distribution to DB’s. All connection, temporary, testing and checking to be done by approved contractor electrician. All temporary wiring system must be approved prior to “power on”. 4. Record/logs. CONTRACTOR electrical section to maintain and update daily, the list of all connections. All CONTRACTOR DB's to have numbering system for ease of record keeping and repair/ maintenance. All incoming cables to CONTRACTOR DB's must be identified as to which company’s DB/ equipment is connected. Log to be maintained for all connections, disconnections and requests to “power on”. If there are frequent requests to re-close the circuit to a particular DB, or a fault is detected on contractor DB, that DB will be disconnected, and will require connection procedure again after repair. Detailed survey and plans must be made and kept of all buried cable. 5. Electrical wire and apparatus A. General 1) Live parts of wiring or equipment shall be guarded to protect all persons or objects from harm 2) Transformer banks or high voltage equipment shall be protected from unauthorized access. Entrances not under constant observation shall be kept locked. Sign warning of high voltage and prohibiting unauthorized entrance shall be posted at entrances. Metallic enclosures shall be grounded. 3) Gates or doors to enclosures for electrical equipment shall swing outward or provide clearance from installed equipment 4) Electric wire or flexible cord passing through work areas shall be protected from damage by foot traffic, vehicles, sharp corners, projections, pinching and any contact with acids, corrosives or other liquids. 5) Insulation mats or platforms of substantial construction shall be so placed on floors and on the frames of equipment having exposed live parts so that an operator or persons in the vicinity cannot touch such any such part. 6) All circuits shall be protected against overload. 7) When fuses are installed or removed with one or both terminals energized, special tools insulated for the voltage shall be used. 8) Patched, oil soaked, worn or frayed electric cords cables shall not be used. 9) Disconnecting boxes shall be securely fastened to the surface and fitted with covers. 10) Plugs and receptacles shall be kept out of water unless of an approved submersible type. B. Disconnect and over current protection. 1) Switches shall be of the enclosed safety type, within enclosures grounded, and installed so as to minimize the danger of accidental operation. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 23 of 48

- 24. 2) 3) 4) Fuses and circuit breakers shall be of the proper rating for the circuit protected. Switches, circuit breakers, fuse panels, and motor controllers in wet locations or outside shall be in a weatherproof enclosure or cabinet. Over current protection devices must be readily accessible, clearly labeled, not exposed to physical damage and not placed in the vicinity of easily ignitable materials. C. Temporary wiring 1) Temporary wiring shall be guarded, buried, or isolated by elevation to prevent accidental contact by workers or equipment 2) Wires with non-rated weatherproof insulation shall not be enclosed in metal raceways nor used for wiring in tanks, penstocks and tunnels. 3) Wires shall be insulated from their supports. 4) Exposed empty light sockets and broken bulbs shall not be permitted. 5) Nonmetallic sheathed cable may not be used where precluded by the NEC (National Electric Code) a. As portable extension cords. b. Laying on the ground subject to any type of traffic or potential damages c. Where subject to frequent flexing. d. As service entrance cable D. Overhead line 1) Overhead transmission and distribution lines shall be carried on towers and poles that provide at clearances over roadways and structures. 2) Clearances shall be adequate for the movement of vehicles and for the operation of construction equipment 3) Floating plant and associated equipment shall not be sited or placed within 6m of construction equipment 4) Operations adjacent to overhead lines shall not be initiated until coordinated with the utility officials. 5) SIGNS/ MARKERS. All warning signs, danger signs, advisory signs, instruction signs, and the like to be prominently displayed, of reasonable size to allow readability from 5m, have the primary signage in Vietnamese, and secondary in English. All signs must be have Vietnamese. Transformer enclosure to have “No Unauthorized Access” signs, “Danger- HIGH VOLTAGE” signs. Transformer to have clearly displayed “ Danger- HIGH VOLTAGE” signs and “Danger - Electricity” All DB’s (CONTRACTOR and Sub-contractor) to have “Danger - Electricity” signs and “Danger- 400 Volts” (or similar) on the doors. All electrical section mains cable/ DB connection cable in building must be enclosed in conduit, duct and any other approved means. All buried cable must be identified and below surface with tape on the surface with marker posts at a maximum Spacing of 30m and at all junctions and transition points. A monthly inspection to be carried out by electrical section to ensure that any missing pegs are replaced. 6. Electrical equipment inspection. Prior to any electrical section equipment being used on the site, it will be inspected by safety department, and Client safety department. Equipment will be checked for: general PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 24 of 48

- 25. condition, cable and wiring, connections, casing, switches, grounding resistance, suitability for work intended, markings and/or warnings, guards and covers, plugs, etc. If equipment is satisfactory, it will be allowed into the construction site for use. Equipment which fails in the inspection must be repaired or replaced before re-inspection. 10.2. TEMPORARY ELECTRICAL WIRING Generator notes Live parts of wiring or equipment must be guarded to protect all persons or objects from accidental contact. Electric wire and cable passing through work area’s shall be protected from damage by foot traffic, vehicles, sharp corners, projections, pinching and crossing/ acids All electric cord must be doubly insulated. No single of an approved submersible type. Switches, circuit breakers, fuse panels, motor controllers, and the like, in wet conditions or outside shall be in weatherproof cabinets/boxes. Temporary lighting shall be equipped with guards to prevent accidental contact with the bulb, except when the bulb is deeply recessed within a reflector. All connections /splicing/ cable junctions must be made via mechanical means. Twisting wires together and tapping up it strictly prohibited. All neutral bars must be inside electric box. All electric box to have lockable cover, with approved electrical staff in control of the keys. All generators will be connected from the generator earth to the structure being worked on or to the main plant earth grid Where small generators are being used with extensions leads being plugged in directly to the generator these must be fitted with an appropriately sized 30mA RCD/ELCB protection device. All generators shall be fitted with an effective silencer. All generators shall be free of fluid and oil leaks CABLE AND WIRE DETAIL. 1. Mains: All damage of cable must be cleared before buried. Cable markers at max, spacing of 30m, plus junctions and transition points. 2. Temporary Cables/ Wire: Must be well insulated from scaffolding / handrails/ structural steel Must not be lying in water, unless approved marine cable and all connections/ sockets etc., approved submersible type. No electric cable/ wire to be run across vehicle access way. This includes, motorbikes, forklifts, cars, material trolleys, any kind of wheeled vehicles cannot drive over electric cable or wire. 3. Road Crossings. Buried minimum 0.5m for mains. Buried 100-200mm for temporary lines in (steel or PVC pipe) 4. Minimum Cable and Wire requirements: PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 25 of 48

- 26. Minimum requirement for wire is that it be double insulated wire. No single insulated wire, or single wire strands taped together are permitted on the project. All cable for connection of welding machines direct to CONTRACTOR DB's must be proposed prior to connection. All extension leads will be of a heavy duty double insulated flexible cable with a minimum size of 1.5mm2 All extensions leads will be fitted with heavy duty weatherproof plugs with I.P.56 rating. No extension leads will be longer than 30 m in length. All extension leads and plugs will include an earth core. All extension leads shall be kept clear of the ground and run in such a way as to not impede workers access. Layout of CONTRACTOR Distribution Board: To be done later 10.3. ELECTRICAL PERSONNEL All electrical personnel working on the project site must submit for record: their qualification/certificate/training courses undertaken etc, to the safety department. Only approved electricians from CONTRACTOR will be permitted to undertaken any form of electrical wiring, connection, testing. Electrical staff will be identified on their ID cards and on safety helmets, by means of approval stickers. 10.4. ELECTRIC EQUIPMENT. 1) Switching equipment for shutting down the welding machine shall be provided on or near the welding machine. 2) The non- current carrying metal parts of electrically powered welding machines shall be grounded. Grounding circuits, other than by means of the structure, shall be checked to ensure that the circuit between the ground and the equipment to ground has resistance low enough to permit sufficient current to flow to cause the over-current device to interrupt the circuit. The rounding to rotating equipment such as pumps, turbines shall be prohibited. 3) Neither terminal of the welding generator shall be bonded to the frame of the welder when the leads unattended. 4) Cable with splices or repaired insulation within 3m of the holder. 5) Welding supply cables shall not be place near power supply cables or other hightension. 6) Welding leads shall not be permitted to contact metal parts supporting suspended scaffolds. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 26 of 48

- 27. 11. FIRE PREVENTION AND PROTECTION 11.1. FIRE PREVENTION A. General restrictions 1) A survey of the suitable and effectiveness of fire prevention and protection measures and facilities existing at each project or installation shall be made by the Safety manager at least monthly. Records of the survey findings and recommendations shall be retained on file at the project. 2) No Fires are permitted anywhere on the project site. This includes the burning of rubbish, fires for warmth, fires for heating PVC pipes for joining, fires for heating bitumen and other similar products, etc. 3) Smoking is completely prohibited within the project offices and buildings including warehouses. Smoking is permitted within designated areas of contractor offices. 4) Smoking shall be prohibited in all area where flammable, combustible, or similar hazardous materials are stored. 5) All sources of ignition shall be prohibited within 15m of operations which constitute a fire hazard. The area shall be conspicuously posted: NO SMOKING or OPEN FLAME. B. Spacing emergency access 1) Emergency lanes to provide access to all areas shall be established and maintained free of obstruction. 2) At least 3m clearance from buildings or structures shall be maintained for piles of lumber and other combustible materials to be used in the construction. 3) Material shall be piled to minimize the spread of fire internally and to permit access for firefighting or other emergency vehicles 4) Clearance shall be maintained around lights and heating units to prevent ignition of combustible materials. C. Flammable and combustible liquids 1) All sources of ignition shall be prohibited in areas where flammable liquids are stored, handled, and processed. Suitable NO SMOKING OR OPEN FLAME signs shall be posted in all such areas. 2) Flammable or combustible liquids shall not be stored in areas used for exits, stairways, or areas designated as a safe passageway of people. 3) All buildings, rooms, and compartments where flammable liquids are stored, processed or used shall be well ventilated by a gravity or mechanical exhausting system. 4) Drums, barrels, and other flammable liquid containers shall be tightly capped. Safety cans or other portable service containers of flammable liquids shall be painted with name of the contents. 5) Smoking or open flames within 15m where flammable materials are being used or transferred or where equipment is being fueled is prohibited. 6) Workers shall be required to guard carefully against any part of their clothing becoming contaminated with flammable or combustible fluids. Gloves and clothing contaminated with fuels/ combustible fluids shall not be worn and must be taken off the construction site. 11.2. FIRE PROTECTION A. Fire protection PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 27 of 48

- 28. 1) Fire extinguishers shall be suitably placed, distinctly marked, readily accessible, and maintained in a fully charged and operable condition 2) Fire barrels and buckets shall be painted red, marked “For Fire Only". Barrels shall be kept filled at all times. 3) Fire extinguisher equipment shall be provided in each storage area according to the fire hazard present. 4) Every office, warehouse area, storage container must have a minimum of one operational fire extinguisher. B. Fire fighting organizations, training and drilling. 1) Fire fighting organizations shall be provided to assure adequate protection to life and property. 2) Demonstrations and training in fire fighting shall be conducted at intervals to ensure that project personnel are familiar with and are capable of operation of firefighting equipment. 3) Emergency telephone numbers and reporting instructions shall be conspicuously posted, at every gate post and guard station, at the site offices, and at major building entry points. 12. TRAFFICE RULES AND REGULATIONS 12.1. General The aim of this section is to provide a framework for traffic operations on and around the project to ensure there are no accidents involving vehicles &/or personnel. All traffic accidents are preventable, so particular attention will be paid to condition of vehicles and enforcement of rules and regulations. 12.2. Vehicle testing and permits All vehicles on the project site must be approved by Long Phu 1 Project and be road -worthy. All vehicles will be tested before being allowed to work on site. Test will include brakes, exhaust system, indicator lamps, lights, horns and reversing signals. Vehicles that do not comply will not be granted access to the site. It is to be noted that farming vehicles from the surrounding area are not suitable for working on the project or making deliveries to the site. All vehicles in use shall be checked at the beginning of each shift to assure that all parts, equipment, and accessories that affect safe operation are in proper operation condition and free from defects. All defects shall be corrected before the vehicle is placed in service. 12.3. Vehicle parking All workers bikes and motorbikes are to be parked in the designated area (see site layout plan) All project vehicles that are permitted to enter the construction site will be required to make use of designated parking area as they are established, and to ensure no access is blocked. 12.4. Traffic rules 1) Speed limit for all vehicles on the project will as sign posted across the project 2) All construction traffic must give way when entering the public roads. 3) All heavy vehicles are required to have flashing yellow light when operating/moving. 4) All trucks carrying earth/debris/ rubbish on the public roads must have a cover over the load when traveling 5) Spillage of material of the public roads must be immediately cleaned up. 6) Companies involved in cartage of excavated material to and from dump locations must provide water trucks for dust control, and wash down of public roads 7) All drivers/operators must comply with all traffic signs and directions as they move about the site. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 28 of 48

- 29. 8) 9) 10) 11) 12) 13) 14) 15) 16) 17) At night all excavations must have flashing yellow lights around the perimeter, at a maximum spacing of 10m. Vehicles with cabin for one operator are to only have one person in the cabin. Riding on vehicles is prohibited unless the vehicle designed for transporting people, i.e. no riding in the back of tracks, standing on the foot plate of forklift, etc.) No seat no ride, seat belts where fitted must be worn Pedestrian traffic has right of way over all vehicular traffic. Vehicles without lights will not be permitted to operate at night. No exceptions Farm vehicles are not allowed on site All vehicle operators are required to wear shoes and to have a safety helmet with them. Operators outside their vehicles must wear safety helmets. All vehicles should be switched off whilst being refueled and strictly no smoking is allowed within 15m of that vehicle. Traffic signs apply to all vehicles: including cranes, concrete trucks, motorbikes, company cars, forklifts, bikes, delivery trucks, and excavators. All heavy equipment, large cranes, piling, heavy earthmoving equipment etc, must only travel around the site when accompanied by a signal man on foot to keep the area around the equipment clear and prevent collisions or escorted by an approved vehicle escort. 13. SAFE WORK PRACTICES 13.1 Platforms and Scaffolds A. General; SCAFF TAG SYSTEM WILL BE USED. 1) Scaffold platforms shall be kept free of grease, mud or any other material or material/equipment which will render them unsafe or hazardous to persons using them. 2) Where walkways and work surfaces are slippery, abrasive material shall be used to assure safe footing. 3) The width of all scaffolds, runway, and platforms shall be determined by the purpose, but in no case they shall be less than 45cm 4) Employees on the ramps, scaffolds, roofs, floors, or other working surfaces from which they may fall 1.8m or more or working over water, machinery or dangerous operations shall be protected by guardrails with intermediate rail or catch platforms or temporary floors or safety nets or safety belts. 5) All planking or platforms shall butt together (not overlap on top of each other creating a trip hazard) and be supported below each side of abutment with scaffold tube be overlapped (minimum 20cm) and secured from movement. 6) Scaffolding will be inspected weekly by competent person and signed off on reverse of Scafftag as fit for purpose; safety department will also constantly monitor these structures. B. Standard guardrail 1) A standard railing shall consist of top rail, intermediate rail, and posts, and shall have a vertical height of approximately above 0.9m from upper surface of top rail to floor, platform, runway, or ramp level. The top rail shall be smooth-surfaced throughout the length of the railing. 2) Posts and top and intermediate railings for pipe railings shall be at least 1 & 1/2 inches nominal diameter with posts spaced not more than 2.4m on center. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 29 of 48

- 30. 3) Other types, and arrangements of railing construction are acceptable provided they meet the following conditions: 4) A smooth- surfaced top rail at the height above floor, platform, runway, or ramp level of approximately 0.9m 5) Strength to withstand at least 200 pounds top rail pressure with a minimum deflection. 6) Protection between top rail and floor, platform, runway, ramp, or stair treads, equivalent at least to that of that afforded by standard intermediate rail. 7) Elimination of overhang or rail ends unless such overhang does not constitute a hazard. C. Material scaffolds and tower. 1) All such equipment shall be erected in accordance with manufacturer’s specifications and the load limits as recommended by the manufacture shall not be exceeded. 2) Extreme caution shall be taken where metal scaffolds are used in the vicinity of energized electrical circuits. 3) All metal scaffolds shall be plumb and level. 4) The sections of metal shall be securely connected. 5) All braces shall be securely fastened. 6) Planking shall be created at both ends to prevent movement. 7) Work platforms shall be securely fastened to the scaffolds. 8) All wheels and casters on rollers shall have a positive locking device, securely fastened to prevent accidental movement 9) The force necessary to move mobile scaffolds shall be applied as close to the base as practical and provision shall be made to stabilize the tower during movement from location to another. 10) Freestanding mobile scaffolds working platform heights shall not exceed three times the smallest base dimension. 11) No person shall be allowed to ride on manually propelled scaffolds. 12) Where ramps are used a minimum width of 1.2m for personnel and 3.6m for equipment shall be provided. Guardrails shall be provided on all personnel ramps. 13.2 Hand tools and power tools A. General. 1) Tools having defects that will impair their strength or render them unsafe shall be removed from service 2) When work is being performed overhead, tools not in use shall be secured or placed in holders. 3) Throwing tools or materials from one location to another, form one person to another, or dropping them to lower levels, shall not be permitted. 4) Only non-sparking tools shall be used in locations where sources of ignition may a fire or explosion. 5) Power tools shall be inspected, tested and determined to be in safe operation condition prior to use. 6) Loose and frayed clothing, loose long hair, dangling jewelry, shall not be worn while working with any power tool or machine. B. Power saw. 1) 2) Circular saws shall be equipped with guards that automatically and completely enclose the cutting edges, splitters, and anti-kickback devices. Cracked, bent, or damaged blades shall be destroyed. PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 30 of 48

- 31. 3) 4) Power saws shall not be left running unattended. Each hand-fed crosscut table saw shall have a spreader to prevent the material from squeezing the saw or being thrown back on the operator. C. Wood working machinery 1) A brush shall be provided for the removal for sawdust, chips, and shavings on all wood working machinery 2) Blades of planers and jointers shall be fully guarded and cylindrical heads with throats in the cylinder. 3) A push-stick, block or other safe means shall be used on all operations close to highspeed cutting edges. 4) The use of cracked, bent, or otherwise defective parts such as saw blades, cutters, and knives is prohibited. 13.3 Ladders 1) All ladders must be visually inspected prior to use. 2) Portable metal ladders shall not be used for electrical work or where they may contact electrical conductors. 3) No one shall use a straight or extension ladder unless the ladder is provided with safety feet and is held, tied or otherwise made secure to prevent slipping or falling 4) Ladders shall not be used over machines with exposed moving parts, unless it is held by s second person, or the top securely lashed. 5) To prevent slipping and breaking, straight and extension ladders shall be placed with the feet approximately one fourth of the ladder’s extended length from the wall or object against which the top is resting; when this position is not possible, the ladder shall be another unless the top is securely lashed. 6) The person shall face ladder and use both hands for support when ascending or descending. A person’s feet shall never be placed higher than the third rung from the top of the ladder, unless the ladder is placed against a structure which affords a support that can be used for holding onto with the hands, such as a substation structure, pole, or other similar structure. 7) When working on a ladder where the top cannot be lashed or otherwise secured the reaching distance shall not exceed one arm’s length to either side. 8) A stepladder shall be used in the open position. It shall be opened fully and locked. Personnel shall not stand on the top board of any stepladder. 9) Wires, cables or ropes being installed or removed shall not be attached to ladders or personnel working on them. 10) The use of ladders with broken or missing rungs or steps, broken or split side rails, or other faulty construction is prohibited 11) Job-made Ladders a) All wood used to construct job-made ladders shall be thoroughly seasoned, straight grained, and free from knots, decay, and other defects. b) Job-made ladders shall be constructed for the intended used. If the ladder is to provide the only mean of access or exit from a working area for 25 or more personnel, or simultaneous two-way traffic is expected, a double cleat ladder shall be installed. c) Double cleat ladders shall not exceed 7 meter in length. d) Single cleat ladders shall not exceed 9 meter in length. 13.4 Floor and wall openings PROPOSED HSE PLAN FOR BIDDING Doc. No: LLM/2013/P-LP1/HSE-00 Rev. No: A Page 31 of 48