Power metallurgy

•Als PPTX, PDF herunterladen•

0 gefällt mir•100 views

poster making on Power Metallurgy

Melden

Teilen

Melden

Teilen

Empfohlen

Weitere ähnliche Inhalte

Was ist angesagt?

Was ist angesagt? (20)

Manufacturing of bearing through powder metallurgy

Manufacturing of bearing through powder metallurgy

Powder Metallurgy METZ (Comet 14 wining presentation organized by MES-Metallu...

Powder Metallurgy METZ (Comet 14 wining presentation organized by MES-Metallu...

Ähnlich wie Power metallurgy

Ähnlich wie Power metallurgy (20)

Mehr von Samarth Sojitra

Mehr von Samarth Sojitra (7)

Kürzlich hochgeladen

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Indian Girls Waiting For You To Fuck

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...Call Girls in Nagpur High Profile

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Girls Waiting For You To Fuck

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...Call Girls in Nagpur High Profile

Kürzlich hochgeladen (20)

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...

Booking open Available Pune Call Girls Pargaon 6297143586 Call Hot Indian Gi...

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Roadmap to Membership of RICS - Pathways and Routes

Roadmap to Membership of RICS - Pathways and Routes

Call for Papers - International Journal of Intelligent Systems and Applicatio...

Call for Papers - International Journal of Intelligent Systems and Applicatio...

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Power metallurgy

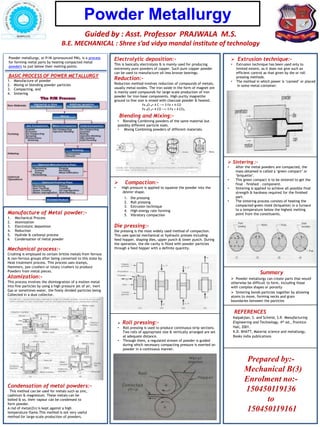

- 1. Blending and Mixing Powder Metallurgy Guided by : Asst. Professor PRAJWALA M.S. B.E. MECHANICAL : Shree s’ad vidya mandal institute of technology Powder metallurgy, or P/M (pronounced PM), is a process for forming metal parts by heating compacted metal powders to just below their melting points. BASIC PROCESS OF POWER METALLURGY 1. Manufacture of powder 2. Mixing or blending powder particles 3. Compacting, and 4. Sintering Manufacture of Metal powder:- 1. Mechanical Process 2. Atomization 3. Electrolytic deposition 4. Reduction 5. Hydride & carbonyl process 6. Condensation of metal powder Mechanical process:- Crushing is employed to certain brittle metals from ferrous & non-ferrous groups after being converted to this state by Heat treatment process. This process uses stamps, Hammers, jaw crushers or rotary crushers to produce Powders from metal pieces. Atomization:- This process involves the disintegration of a molten metal Into fine particles by using a high pressure jet of air, inert Gas or sometimes water, the finely divided particles being Collected in a dust collector. Condensation of metal powders:- This method can be used for metals such as zinc, cadmium & magnesium. These metals can be boiled & so, their vapour can be condensed to form powder. A rod of metal(Zn) is kept against a high temperature flame.This method is not very useful method for large-scale production of powders. Electrolytic deposition:- This is basically electrolysis & is mainly used for producing extremely pure powders of copper. Such pure copper powder can be used to manufacture oil-less bronze bearings. Reduction:- Reduction method involves reduction of compounds of metals, usually metal-oxides. The iron oxide in the form of magnet ore is mainly used compounds for large-scale production of iron powder for iron-base components. High-purity magnetite ground to fine size is mixed with charcoal powder & heated. Fe ₃O ₄+ 4 C ⟶ 3 Fe + 4 CO Fe ₃O ₄+ 4 CO ⟶ 3 Fe + 4 CO₂ Blending and Mixing:- • Blending Combining powders of the same material but possibly different particle sizes. • Mixing Combining powders of different materials. Compaction:- • High pressure is applied to squeeze the powder into the desirer shape. 1. Die pressing 2. Roll pressing 3. Extrusion technique 4. High energy rate forming 5. Vibratory compaction Die pressing:- Die pressing is the most widely used method of compaction. This uses special mechanical or hydraulic presses including feed hopper, shaping dies, upper punch & lower punch. During the operation, the die cavity is filled with powder particles through a feed hopper with a definite quantity. Roll pressing:- • Roll pressing is used to produce continuous strip sections. Two rolls of appropriate size & vertically arranged are set at adequate distance. • Through them, a regulated stream of powder is guided during which necessary compacting pressure is exerted on powder in a continuous manner. Extrusion technique:- • Extrusion technique has been used only to limited extent, as it does not give such an efficient control as that given by die or roll pressing methods. • The method in which power is ‘canned’ or placed in some metal container. Sintering :- • After the metal powders are compacted, the mass obtained is called a ‘green compact’ or ‘briquette’. • This green compact is to be sintered to get the final – finished – component. • Sintering is applied to achieve all possible final strength & hardness required for the finished part. • The sintering process consists of heating the compacted green mold (briquette) in a furnace to a temperature below the highest melting point from the constituents. Summary Powder metallurgy can create parts that would otherwise be difficult to form, including those with complex shapes or porosity Sintering bonds particles together by allowing atoms to move, forming necks and grain boundaries between the particles REFERENCES Kalpakjian, S. and Schmid, S.R. Manufacturing Engineering and Technology, 4th ed., Prentice Hall, 2001. K.D. BHATT, Material science and metallurgy, Books india publications Prepared by:- Mechanical B(3) Enrolment no:- 150450119136 to 150450119161