exp 15.docx

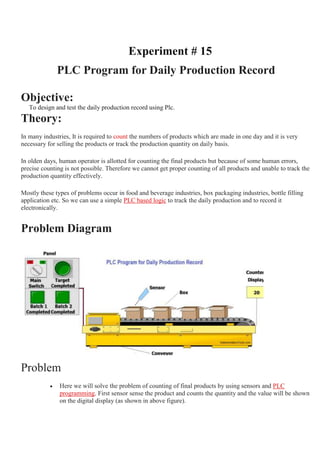

- 1. Experiment # 15 PLC Program for Daily Production Record Objective: To design and test the daily production record using Plc. Theory: In many industries, It is required to count the numbers of products which are made in one day and it is very necessary for selling the products or track the production quantity on daily basis. In olden days, human operator is allotted for counting the final products but because of some human errors, precise counting is not possible. Therefore we cannot get proper counting of all products and unable to track the production quantity effectively. Mostly these types of problems occur in food and beverage industries, box packaging industries, bottle filling application etc. So we can use a simple PLC based logic to track the daily production and to record it electronically. Problem Diagram Problem Here we will solve the problem of counting of final products by using sensors and PLC programming. First sensor sense the product and counts the quantity and the value will be shown on the digital display (as shown in above figure).

- 2. For easy explanation, we will consider one simple example of empty box counting system. In this system empty boxes are travelling form first process to second process (say one place to another). Sensor is used for counting the empty boxes. So when sensor will detect empty box then display will start , say starts count from 1 and this is done by simple logic. Every 24 hours / after one day, we can reset the counter value by using RESET button. Here we will consider two batches of production for easy explanation. And also we have considered two batches completion indications for operator for each batch which will display on the Local Panel. By PLC logic we will implement the desired logic. So when any batch will be completed then indication lamp will be ON as per PLC program. Once production target will be completed, display counter can be reset by using RESET button. List of Inputs/Outputs Inputs List Box detector Sensor : I0.0 Reset : I0.1 Main SWITCH : I0.2 Outputs List Target completed : Q0.0 Batch 1 completed : Q0.1 Batch 2 completed : Q0.2 PLC Ladder diagram for Daily Production Record

- 3. Network 1 : In Network 1 we used Main SWITCH (I0.2) to start the system/batch and we used NO contact of box detector sensor (I0.0) in series. Here we considered one UP counter so when box detector sensor (I0.0) detects the box then counter will starts counting. Here also we have taken target completed output (Q0.0) for target completion indication for the operator indication on the panel. By pressing RESET button (I0.1) operator can RESET the old production record. Counter operation is used to count the products, in which RESET (I0.1) used for reset the production record. And Preset value (PV) is 20 products. Counter value (CV) is MW2 indicates the actual number of products detected by sensor & this value will be used in the following rungs to track the batch status. Network 2 : In Network 2 we used batch1 logic from counter block output CV. Here we used comparator for counting 10 boxes for batch 1 and when it will be completed then batch 1 completed lamp (Q0.1) will ON. In this add equal to equal comparator in which input is (MW2) and for 10 products. Network 3 : In network 3 we used batch 1 logic from counter block output CV. Here we used comparator for counting 20 boxes for batch 2 and when it will be completed then batch 2 competed lamp (Q0.2) will ON

- 4. And this way we can decide that how many products and batches are produced.

- 5. Outputs:

- 6. CONCLUSION: Activity Name Exp # 15 Group No. Student Roll No. No. C L O P L O Domain + Taxonomy Criteria Awarded Score (out of 4 for each cell) 1 3 5 P3 An ability to Select and apply appropriate techniques, resources, and modern technology and IT tools, including prediction and modelling, to broadly-defined Engineering Technology problems, with an understanding of the limitations. - - - - - - - - - Total