ANSI Pump 811 Brochure

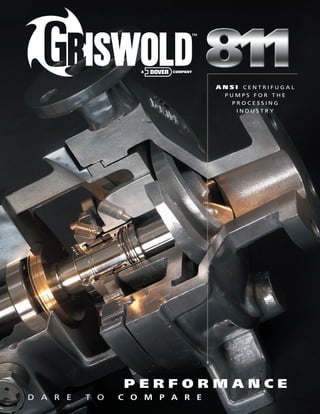

- 1. anSI Centrifugal PumPs for the ProCessing inDustry Performance D a r e t o C o m p a r e

- 2. Griswold m o v e Y o u r Griswold: what drives your pump anythinG but selection process? standard In a rapidly changing world market, there’s no longer room the griswold Pump Com- for making business decisions based on convention or costly pany is no newcomer to old relationships. Every angle must be scrutinized to give your pumps. With product lines are all ANSI production process the edge needed to survive economic vola- dating back over 70 years, pumps the same? tility and polarized competition. you’ll find a wealth of In 1977, the American National Maximizing production and minimizing costs are as much func- industry knowledge and Standards Institute (ANSI) estab- tions of equipment performance as initial and long-term costs experience behind every lished manufacturing criteria for of operating and maintaining equipment. Most importantly, griswold product. at our centrifugal pumps to ensure that you must minimize the time and financial losses caused by facility in grand terrace, dimensional, material composition production failures. As a result, pump specification must meet California, we manufac- and safety specifications meet the even more demanding criteria than ANSI compliance: ture a variety of pumps, demanding needs of the chemi- including ansi, end suction centrifugals, self-priming cal processing industry. Mandatory design features, such as self-ven- 1 proven track record of performance 2 and submersible/vertical tilation, foot mounting, center- extended equipment life turbines. With hundreds of line discharge and back pullout, 3 thousands of pump instal- reduced initial cost and became the industry’s assurance lations worldwide and our total cost of ownership that complying pumps met produc- international distribution 4 tion and safety needs. network, griswold serves Speed and ease of repair a broad range of chemi- Even though ANSI compliance or replacement cal process, industrial and would seem to level the playing Dare to compare your ANSI pump. In a world where you need municipal applications, field for pump specification, your every advantage—we’re confident you’ll choose Griswold. including: choices are actually far more com- plex. The fact is that many brands pulp and paper just meet the minimal requirements of this standard. And while other Chemical brands may offer similar features petrochemical and performance, you may experi- ence inflated cost, delayed delivery, oil and gas and deflated service. In a market textile where all ANSI pumps seem the same, dare to compare. breweries Grain processing Food processing poultry processing automotive pharmaceutical Steel food processing Semiconductor Water treatment power generation chemical P a g e 2

- 3. ANsi PumPs p r o C e S S t o a h I g h e r S t a n D a r D 2 page 8–11 Compare 811 4 4 other page 4–13 extended brands Compare equipment life: 811 4 Exceeding standard ANSI con- struction requirements, the Model other oil & gas speed and ease brands 811 includes several additions that are critical to long-term reli- of replacement: able function. To start, our superior 1 When meeting your production open impeller and seal chambers quota is compromised, each day are designed to facilitate corro- waiting for repairs can mean page 4–7 sive and erosive substance trans- significant losses in revenue Compare port, heat regulation and routine (another factor in your true cost 811 4 maintenance. The 811’s range of enhanced power frames and of ownership). The Griswold 811 proven track and our extensive inventory of other rigid base plates combine the lat- parts are 100% interchange- record of brands est technology with the highest performance: able with hundreds of thou- quality construction to minimize sands of other anSI pumps the effects of work forces and currently in use. With stock- The Griswold 811 ANSI line shaft deflection, optimize cooling ing distributors from coast-to- offers the best pumps you’ll and further simplify the installa- coast and throughout the world, find on the market. Engineered tion and maintenance process. backed by Griswold’s 36-hour for exceptional performance All told, you can expect the 811 ship commitment (next day on and maximum flexibility, our pump series to continue per- parts), and NO premium charge 811 models go the mile in the forming long after other ANSIs for expedited shipment, you can harshest and most difficult fluid wear out or break down. be up and going before you may processing applications. Gris- wold’s 811 centrifugal pump even get a response call from not only meets ANSI standards our competition! 3 for chemical processing, it was And with our dedication to cus- among the first pump designs tomer service, reduced response to comply with these standards page 4–13 times and engineering support, in the 1970s. Almost 30 years of Compare Griswold stands ready to help proven performance has enabled Griswold to focus on enhancing 811 4 improve your process, increase your productivity, lower your our ANSI pump features and reduced initial costs and reduce your stress. other support offerings to surpass the & total cost brands industry standard and exceed our of ownership: customers’ expectations. You may have heard that the ini- tial cost of your pump and parts plays a minor role in your total cost of ownership. NOT TRUE! semiconductor With Griswold’s 811, you get identical quality and longevity pharmaceutical as the best-known brands—at textile a lower initial price. Factor in our low cost on parts, and your long- term savings are even greater! This translates into your LOWEST total cost of ownership. P a g e 3

- 4. Griswold f e a t u r e F o r f e a t u r e m C h a l l e enGineered labyrinth seals standard: ductile iron frame adapters: for flexibility INPRO® oil seals keep outside contaminants from lubrication media, significantly extending Ductile Iron construction provides & durability bearing life. Standard in bronze. Carbon-filled Teflon® and magnetic face seals optional. strength and safety. Precision- machined fits accurately align The Model 811 is available in a wide the liquid end to the power end. range of sizes, capacities and materials mountinG frame flanGe: Large openings simplify installation to fit virtually any process fluid applica- Machined to accommodate C-face motor adapters. and maintenance. Includes jacking tion. With over 30 selections and mul- bolts to facilitate disassembly. tiple design options, we’ve got your extra larGe capacity application covered—for abrasive and powder-coated oil sump: corrosive substances, and capacities Maximized oil capacity delivers improved ranging from 4 through 4000 gallons heat transfer and oil temperature, greatly per minute. extending bearing life. Designed to accommodate optional fin coolers for Griswold maintains strict quality higher temperature applications. assurance programs to ensure that Impenetrable fusion bonded our entire product line is manufac- epoxy coating on interior tured to the highest standard for surface extends quality, engineered tolerances: cleanliness and longevity of the lubricating oil. • Our American-engineered invest- ment and no-bake casting processes produce smooth, superior surface finishes for consistent and reliable performance. • A metallurgist-controlled anneal- ing process assures the maximum durability and product life available on the market. • CNC (computer numerically con- trolled) machining equipment guarantees consistency for all parts. • All power frames are assembled and inventoried in our Clean Room to keep sensitive bearings and internal components contaminant-free. external clearance adjustment: For maintaining original flow, pressure and efficiency, minimizing energy con- sumption and repairs, and extending Mean-Time-Between-Repair (MTBR). heavy-duty shaft & bearinGs: Engineered to minimize vibration and shaft deflection, less than 0.002 inch per ANSI B73.1, optimizing pump life. Sleeved and solid shaft available in a variety of materials. Bearings sized for 10-year life under tough operating conditions. maGnetic drain pluG: oversized siGht Glass: Collects damaging metal- One-inch bulls eye reflective sight glass lic contaminants away from facilitates monitoring oil level and condition, the bearings. critical to bearing life. Bottle oiler optional. P a g e 4

- 5. model desiGN e n G e S a n y C o m p e t I t I v e b r a n D extra-heavy casinGs: Class 150 pumps incorporate Class 300 wall thickness as standard, extend- optImIze ing reliability and casing life under severe corrosive/erosive conditions: your pump • Top centerline, self-venting discharge for air handling replacement • Back pull-out to simplify maintenance process • Rigid casing feet prevent pipe load misalignment and promote Challenge your existing equip- seal /casing life ment quality, delivery and costs • Discharge connection for pressure gauge or seal bypass with griswold’s ready-to-ship flush connection standard on Ductile Iron and Stainless inventory of 811 pumps and Steel casings parts. our high-quality, ansi- • Class 150 FF standard for positive sealing. Optional Class compliant pumps and wearing 150 RF 300 FF/RF available parts will interchange quickly • Casing drain standard in Ductile Iron and Stainless and seamlessly with a variety Steel for simplified maintenance. of ansi pump models and brands–without piping, base- plate or coupling changes. all at a significant cost savings! fully open impeller: factor in our no premIum With double the wear area of enclosed models, the 811 impeller offers superior 36-hr ShIp CommItment handling of solids, corrosives and abrasives. on pumps and neXt-DaY Back pump-out vanes reduce hydraulic ShIppInG on parts, and you’ll loads and seal chamber pressure. save money, simplify order- ing, reduce inventory and expedite line repair. W I t h : pumpS: 4 Ductile Iron pumps 4 Stainless Steel pumps I n t e r C h a n G e a b l e 4 alloy 20 pumps sealinG flexibility: 4 CD4mCu pumps Wide range of sealing options coupled with seal chambers and stuffing boxes partS: selected for service condition to improve lubrication and heat dissipation of seal 4 bearings & seals faces, maximizing pump uptime. 4 Cases contained 4 Impellers casinG Gasket: Provides positive sealing at casing 4 power frames joint to prevent “blow out” of liquids and to facilitate disassembly. 4 Shafts & sleeves 4 Stuffing boxes InterchangeabIlIty G u I D e 4 all other parts for anSI pumps All 811 parts, from end to end, are 100% interchangeable with many ANSI pumps. Ask for our 56-page Parts Guide—your tool for cross-referencing Griswold 811 to comparable pumps by size and part number! P a g e 5

- 6. Griswolda n S I p r o C e S S p u m p S D e S I G n e D lf F o r l increased capability for reduced volumes Standard ANSI pumps (with expanding style volute casing) are not designed for low flow, high head applications: the excessive radial loads and shaft vibration experienced can shorten bearing and seal life. Griswold’s Model 811lF series is designed with a circular concentric casing in conjunction with a radial vane impeller to reduce those excessive radial loads and minimize shaft deflection, thus extending MTBPM. 1 circular concentric volute casinG: The fully machined concentric volute reduces excessive radial loads experienced in low flow, high head appli- cations. Shaft vibration and deflection is minimized, extending bearing and mechanical seal life. Class 150 raised face flanges are standard with the Model 811lF series for positive sealing. Class 300 raised face flanges are available as an option. 2 low flow radial vane impeller: Griswold’s radial vane impellers are specially designed to reduce the thrust load and seal chamber pressure normally associated with low flow applications. When operating in reduced volume conditions, the low flow impeller’s vanes provide better hydraulic control than tra- ditional ANSI impellers. Balance holes reduce both axial thrust and seal chamber pressure, extending bearing and seal life. P a g e 6

- 7. for low flows o W f l o W S e r v I c e S. 3 ft. 1000 300 900 270 811LF performance: 800 LF 3x11/2 – 13 @3560 RPM 240 With a traditional ANSI pump, throttling or recirculat- 700 total head (60hz) 210 ing flow to attain low flow conditions causes exces- sive radial load and shaft deflection—all of which can 600 result in premature failure to bearings and mechanical 180 seals. 500 Griswold 811lF pumps feature flow capacities as low 150 as 4 GPM, and heads as high as 920’—low flow/high LF 2x1– 10 @3560 RPM head performance you can count on to further extend 120 400 your MTBPM. 300 LF 11/2 x1– 8 90 @3560 RPM 60 200 LF 3x11/2 – 13 @1750 RPM LF 2x1– 10 30 100 @1750 RPM LF 11/2 x1– 8 @1750 RPM 0 0 petrochemical 0 gPm 25 50 75 100 125 150 175 200 225 250 3/ 0 h 5 10 15 20 25 30 35 40 45 50 55 capacity (60hz) SIX 811lf moDelS lF 1 1/2 x 1 – 8 @ 1750 rpm lF 1 1/2 x 1 – 8 @ 3500 rpm lF 2 x 1 – 10 @ 1750 rpm lF 2 x 1 – 10 @ 3500 rpm lF 3 x 11/2 –13 @ 1750 rpm lF 3 x 11/2 –13 @ 3500 rpm 811lf CapaCItIeS 4 4 Gpm to 210 Gpm heads to 920’ retrofittinG: Griswold Model 811lF pumps are ANSI dimensional, so they can be installed without piping or base changes to existing equipment. In fact, since all other parts and features are identical/interchangeable within the entire 811 ANSI line, the 811lF case and impeller can be easily retrofitted to an existing Griswold pump as well as 100,000s of other ANSI pumps already in service! P a g e 7

- 8. Griswold S u p e r I o r c o n S t r u c t I o n. e X t r a o r D I n a r Y P e r f o r m for 1 4 C o m p a r e Increases performance Increases longevity 4 heavy-duty Simplifies 4 castinGs: maintenance • Wide Choice of materials. Your choice of standard stocked materials for Model 811 centrifugal pumps includes Ductile Iron, 316 Stainless Steel, CD4MCu and Alloy 20. Other alloys available. • Superior Casting Finishes. Investment and no-bake casting processes ensure smooth, pre- cise, superior finishes that guarantee consistent, reliable performance. • Controlled Solution annealing. Metallurgists strictly supervise all heat-treating operations to assure maximum corrosion-resistance for all alloys. 2 fully open impeller: C o m p a r e Increases performance 4 • Ideally Suited for Chemical process Industry applications. Because it has two times the area in the critical casing and stuffing box/seal chamber clearances, Griswold’s Open Impeller is far superior to its typical enclosed Increases longevity 4 counterpart. Our open design minimizes concentrated wear by balancing hydraulic axial thrust load and reducing stuffing box pressure. This not only facilitates corrosive, abrasive, solid and stringy fiber handling, but also simpli- Simplifies maintenance 4 fies maintenance, extends life and reduces repair costs. • Self-tightening to reduce leaks and Failures. Our impeller design is further enhanced by threading on the shaft and sealing through a controlled squeeze contained o-ring to eliminate bolt loosening with system changes or high temperatures. Metal-to-metal contact ensures optimal running and transmittal of torque and alignment. Because we eliminate the impeller bolt, we also eliminate corrosion or gasket leakage, ensuring that smooth entrance contour and lower NPSH requirements are realized. • external Clearance adjustment. Peak efficiency is ensured through simple maintenance to account for wear area loss. Adjustment is quick and easy to set at the site with an ordinary open-end wrench–no shims or shop maintenance needed, as with enclosed impellers. The external clearance adjustment moves the impeller forward to reestablish original clearance and hydraulic pressure without disassembly or replacement of wear rings. • back pump-out vanes reduce pressure on the shaft seal and axial thrust on the bearings. Maintenance is further simplified–extending bearing life, seal life and performance. • Investment Cast Impellers. Ultra-smooth, consistently cast investment impellers are standard on Stainless Steel, CD4MCu and Alloy 20, and optional on Ductile Iron pumps. This feature improves hydraulic and mechanical balance, maximizes seal and bearing life and improves efficiency. P a g e 8

- 9. or the loNG ruN m a n c e . e X C e p t I o n a l e n d u r a n c e. 3 seal chambers & sealinG flexibility: Our quality seal chambers are engineered to provide optimum seal environment for heat dissipation, solids, entrapped air and vapor. Oversized seal chambers increase radial clear- ance between the mechanical seal and seal chamber, as well as provide better circulation of liquid to and from the seal faces, preventing failure of the shaft seal. A variety of flush plans are available for additional lubrication and cooling of the seal faces. 5-year Whole Pump Warranty. all 811 pumps are backed by a 5-Year Standard bore large bore tapered bore unconditional guarantee against defects in material and workmanship. 4 Services utilizing packing or Most services including those Services up to 10% solids or Services mechanical seals. For mild with solids greater than 10%. those containing entrained air fluid at ambient tempera- Increased radial clearance or vapors. For lower seal face tures. between seal & chamber for temperatures, self venting & improved liquid circulation, draining. Circulates solids & lubrication & cooling. vapors away from seal faces. Sealing Flexibility Packing Most Services Not Available Not Available Single Seal/No Flush Not Recommended Not Recommended Services with Solids up to 10% Single Seal/With Mild, Most Services including All Services with Flush Clear Fluids Solids above 10% Solids up to 10% Seal SeleCtIon Conventional Double Zero Leakage Zero Leakage Not Seal with Seal Plan Applications Applications Available 4 Single Inside Seal: For non to moderately corrosive Cartridge Double Zero Leakage Zero Leakage Zero Leakage liquids, moderate abrasives and Seal with Seal Plan Applications Applications Applications liquids with good lubrication qualities. 4 Conventional Double Seal: For liquids that are incompat- ible with single seals, cavitation 4 or low flow situations. Meets environmental regulations for toxic, hazardous, abrasive and Single corrosive substances. Inside Seal 4 Single Cartridge Seal: con- For same applications as seals to fit Conventional ventional single seals, allow- ing simplified seal setting and any application: Double Seal Single maintenance. 4 Double Cartridge Seal: con- For same applications as Cartridge Seals, Component Seals & Conventional Cartridge Seal ventional double seals, allow- packing. With Griswold’s broad selection of seals, you ing simplified seal setting and Double can accommodate most any fluid and temperature for Cartridge Seal maintenance. demanding chemical, petroleum, pharmaceutical and general industry applications. Our engineers can recom- 4 Double Gas barrierregula- Meets environmental Seal: Double Gas mend the best seal to maximize your application and barrier Seal tions for toxic or hazardous materials. For use when seal pot system life–including cartridge or component, single or external flush is not desirable or double, inside or outside, balance or unbalanced or when compatible seal flush seals or conventional packing. liquid is not available. P a g e 9

- 10. Griswold S u p e r I o r c o n S t r u c t I o n. e X t r a o r D I n a r Y P e r f o for 5 4 C o m p a r e Increases performance Increases longevity 4 enhanced 4 power frames: Simplifies maintenance • Inpro® labyrinth oil Seals. Our • Improved Strength & rigidity. high-quality oil seals keep outside The superior tensile strength of both environmental contaminants from our cast and ductile iron makes Gris- entering your lubrication media, wold power frames not only stron- greatly extending bearing life– ger than the competition’s (as much available standard in bronze, and as 33%), but also more rigid—and optional in Carbon-filled Teflon® or better equipped to withstand magnetic seal face. forces and moments experienced • magnetic Drain plug. Our drain • large Sight Glass. Our one-inch in today’s process applications. (see plug is designed to magnetically bulls eye sight glass simplifies oil chart next page) collect damaging metallic contami- level and conditions monitoring, • heavy-Duty Shaft & bearings. nants away from the bearings. critical to bearing life. Our shaft is engineered for heavy- • monitoring locations. Each • large oil Sump & oversized Fill duty loads and for minimum vibra- power frame is machined with 4 plug. Increased oil capacity maxi- tion and deflection at seal faces (less condition-monitoring sites to facili- mizes heat transfer for reduced oil than 0.002 inches per ANSI B73.1), tate consistent checking of vibration temperature. Our extra large 1/2” extending bearing and seal life. and temperature. NPT oil fill plug further simplifies the Using only the highest-quality bear- • Clean room assembly. All sizes lubrication process. Designed to ings further optimizes the 811’s per- of our power frames are assembled accommodate optional fin coolers for formance and reliability. Both shaft in Griswold’s climate controlled, higher temperature applications. and bearings are rated for 10-year sealed, clean room which filters out average life under tough operating • powder Coated oil Sump lining. airborne dirt and debris that might conditions. Standard hook-type Griswold utilizes a “Fusion Bonded otherwise contaminate sensitive sleeved design meets ANSI shaft Epoxy Coating” on the interior sur- bearings and internal components. deflection standards and provides face of the power frame to provide We also inventory all finished power ease of maintenance. Solid shaft an impenetrable barrier between frames and associated components design available for more demand- the iron frame and oil, enhancing in this ultra clean environment to ing applications. Both are available the long-term quality and cleanli- ensure the most reliable power in a variety of materials. ness of the lubricating oil. frame you can buy. • hook-type replaceable Shaft Sleeve. The 811’s hook-type shaft sleeve is free to expand with tempera- ture changes and promotes renewal of the sealing surface without bearing and shaft disassembly. P a g e 1 0

- 11. or the loNG ruN r m a n c e . e X C e p t I o n a l e n d u r a n c e. griswold’s StANdArd features StAck 6 4 up! C o m p a r e Increases performance Increases longevity 4 power frame 4 Competition griswold Simplifies upGrade: maintenance Power frame • 811 l. The 811 is offered in a larger frame that is ideal standard in high-load applications or when conditions push the feature power frame beyond ANSI limits. The 811 L features Comparison: an oversized rotating assembly and higher radial and magnetic thrust load carrying bearings. Duplex angular contact YeS no pulp & paper Drain plug bearings insure zero end play for improved sealing and maximum mechanical seal life. Whether pumping viscous Inpro® liquids or high specific gravity liquids, fluctuating process YeS no lab Seals conditions, or pumping high heads or low flows, our 811 L power frame guarantees maximum pump life in epoxy Coated your toughest applications. YeS no Interior Clean room YeS no assembly Cast Iron 7 tensile 30000 20000 Strength lbs lbs 4 C o m p a r e Increases mtX, ltX & performance XltX Frames heavy duty Increases longevity 4 Ductile Iron c-face motor Simplifies 4 tensile Strength 65000 lbs 60000 lbs adapter: maintenance StX Frames • optional C-Face adapter. Our C-Face motor adapter bolts directly to the precision machined fit on the power frame. Register fits on both ends of the adapter lock in a standard C-Face motor, guaranteeing both parallel and angular alignment. This quick, yet precision installation minimizes time spent aligning shaft couplings, and eliminates seal and bearing replacements caused by misalignment. Best of all, our C-Face adapters—like the rest of our parts— are directly interchangeable with most ANSI pumps! P a g e 1 1

- 12. Griswold suP Extensive W e ’ v e Comprehensive Support optIoNS Griswold offers a broad range of options and upgrades to at griswold, our commitment to your success extends way tailor the 811’s handling and performance to meet virtu- beyond our top-of-the-line prod- ally any fluid processing application. You can rely on our ucts. We’ve structured our staff, engineering staff to assist you in configuring pump size, systems and inventory to deliver material and components to best suit your specific plant and processing requirements. 1 consistent high-level solutions for meeting your most critical equip- ment and emergency delivery needs. We pride ourselves in pro- Compare viding What you need, When you need it, and the ConfiDenCe 811 4 and reliability to make your baseplate job easier. mountinG other brands systems 1 enGineerinG & customer support Griswold offers a complete range of pre-engineered rigid base- plates designed to reduce stress • equipment Selection: our and vibration as well as extend 2 application engineers utilize MTBPM, thus ensuring long- the latest software to identify term durability. Our wide selec- the optimum pump for your tion of metallic and non-metallic application, as well as compo- Compare baseplates provides flexibility in nent and seal specifications. selecting the best base to fit your 811 4 • technical Support: our engi- operating needs and budget. hiGh & low neering staff stands ready to Bases include a fully enclosed steel temperature other brands answer any questions regard- coupling guard as standard, with capability ing performance and repair. optional non-sparking coupling guard available. • heat Jacket: Clamps on to the our state-of-the-art test center is available for a number of cer- casing to manage heat trans- Fabricated fer. Easy to install or remove tified performance tests, either Steel base for servicing. witnessed or non-witnessed, (enhanced fabricated and conforms to hydraulic steel base also • Jacketed Seal Chamber: available) institute standards. Maintains temperature con- trol for heating or cooling of sealing environment. • bearing Frame Finned Cooler: Directly cools oil to lower bearing temperature. Recom- mended for temperatures over 350 degrees. certified Composite testing base engineering support Composite Foundation base P a g e 1 2

- 13. uPerior solutioNs G o t Y o u c o v e r e d Comprehensive 4 Support Compare 811 4 2 inventory optimization lubrication other brands the griswold staff, along with options our stocking distributors, can review your pumps and parts 811 power ends accommodate usage to recommend upgrades all lubrication systems, including and optimize your on-site flood oil, oil mist and grease lubri- inventory, minimizing stocking cation. Our power ends are pre- hassles and your long-term oper- drilled for all lubrication methods ating costs. because we offer and can be easily converted in the identical features, interchange- field without modification. ability and quality as hundreds of thousands of pumps and parts worldwide, at 30-40% savings , we can improve your existing process and reduce your total cost of ownership. 3 Compare 811 4 5 seal flush other brands 3 plans expedited We offer all ANSI B73.1 seal delivery flush and cooling plans to con- 36-hour Ship commitment trol emission levels, improve on entire pumps, next-day lubrication and cooling of the special surface Shipping on parts: seal faces, and reduce down- preparation time. Ask us to assist you in griswold offers the quickest selecting the best plan. Griswold offers a variety of delivery response in the industry. Compare optional surface preparation 811 4 When your production quota is processes for extended corrosion on the line, each day of down- protection and contaminant-free other time waiting on a repair can pumping: brands mean several hundred thousand • electro polishing dollars of revenue, unfulfilled • passivation critical shipments, and lost jobs. factor those statistics into your • hard metal Coatings total costs of ownership! main- • Fusion bonded, epoxy taining an extensive inventory Coated power end at our headquarters and stock- • Special paint Systems ing distributors, we can make this commitment—or better— without the additional premi- ums our competitors charge. 3 6-h o u r S h I p p I n G C o m m I t m e n t ! (NEXT DAY ON PARTS) P a g e 1 3

- 14. PerformANce & capacity – 2850 rPm (50hz) 3500 3/ 0 h 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 0 Gpm 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 Ft. 2850 Ft. 300 1000 700 210 280 rpm 900 600 180 260 240 800 500 160 220 total head – 3500 rPm (60hz) 700 total head – 2850 rPm (50hz) LF 3x11/2 –13 PerformANce curve 180 600 3x11/2 –13 400 120 LF 2x1–10 500 3x2–13 140 300 400 2x 80 1–10 100 3x11/2 –10 6x4 –10G 300 4x3–13 200 LF 11/2 x1– 8 3x2–10 4x3–10 3x 60 200 11/2 x1– 8 11/2 3x2–8 40 –8 4x3–8G 100 100 11/2 x1 3x11/2 3x2–6 –6 –6 20 0 0 0 0 0 Gpm 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 3/ 0 h20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 capacity – 3500 rPm (60hz) capacity – 1450 rPm (50hz) 3/ 1750 0 h 20 40 60 100 150 200 300 400 500 Ft. 0 Gpm 100 200 300 400 600 800 1000 1200 1600 2000 2400 Ft. 1450 300 90 200 60 rpm 85 270 55 80 6x4–17 180 75 PerformANce 240 160 50 curve 70 65 210 45 total head – 1450 rPm (50hz) total head – 1750 rPm (60hz) LF 3x11/2 – 13 8x6–15 140 60 40 55 180 10x8–15G 120 35 50 45 150 100 30 40 120 3x11/2 –13 3x2–13 4x3–13 6x4–13 8x6–13 25 80 LF 2x1– 10 35 10x8 –13 30 100 20 2x 1– 60 10 3x11/2 80 –10 3x2–10 4x3–10 6x4 –10H 6x4 –10G LF 11/2 x1– 8 20 H 60 10 3– 40 1 2 x1– 8 1/ 4x3 –8 4x 10 3x1 1/ 2 3x2–8 40 –8 4x3–8G 10 11/2 x1 3x11/2 20 –6 –6 3x2–6 20 0 0 0 0 0 Gpm 100 200 300 400 600 800 1000 1200 1600 2000 2400 2800 3200 3600 3/ 0 h 20 40 50 75 100 150 200 250 300 400 500 600 700 800 capacity – 1750 rPm (60hz) P a g e 1 4