Controlling Wrinkle Pattern Thin Metal Polymer Films

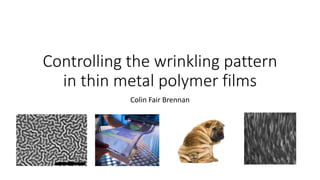

- 1. Controlling the wrinkling pattern in thin metal polymer films Colin Fair Brennan

- 2. Overview • Motivation – Why wrinkles? • Background theory • Experimental methods • Results • Conclusions and potential work • Acknowledgments

- 3. Motivation • Wrinkles – Why are they important? What can you do with them? • There’s a number of applications • SERS / Flexible electronics / Controlled wettability • And more…

- 4. Surface Enhanced Raman Spectroscopy (SERS) • Extremely sensitive molecular fingerprinting technique – single molecules Number of applications through forensics, healthcare and diagnostics

- 6. Controlled Wettability • Wettability due to roughness

- 7. Theory • Why do wrinkles form? And how can you control them? • It all comes down to Energy. Patterns are formed to reduce the overall free energy of the system.

- 8. Theory • Controlling the wrinkles – What affects the wavelength? 𝜆 = 2𝜋ℎ 𝐸𝑓 3𝐸𝑠 1 3 𝜆 = 𝜋ℎ 𝑓 2 1 − 2𝑣 3 1 − 𝑣 1 − 𝑣 𝑓 2 𝐸𝑓 𝜇∞ 𝐻 𝐻𝑓 1 4 • Elastic properties – Young’s modulus • Polymer / Capping layer thickness

- 9. Experimental Methods • Polymer Solution • Deposition – Spin coating / Sputtering • Thermal Treatment • Microscopy – AFM, White light interferometer, Optical

- 10. Deposition Solid Substrate (Si) Polymer (PMMA) Thin metal film Polymer Deposition Thin Metal Film Deposition • Spin Coating • Sputtering

- 11. Atomic Force Microscopy (AFM) • To measure polymer thickness

- 12. Optical Microscopy • Wrinkle analysis

- 14. Results • Effects of… • Polymer thickness • Capping layer thickness • Thermal treatment time

- 15. Polymer thickness • Images A – D increasing the polymer thickness

- 16. Capping layer thickness 10.8nm AuPd λ = 5.153µm 20.9nm AuPd λ = 1.92µm

- 17. Thermal treatment time 5.2nm Cr 7.2nm Cr Wrinkle wavelengths decrease in time though not substantially! Thermal treatment time was increased by twenty minutes from A to B for both samples. A) λ = 3.125 µm B) λ = 2.14 µm A) λ = 3.09 µm B) λ = 3.02 µm

- 18. Conclusions • The overall aim of the study was achieved and from the results some clear trends appeared • By increasing the polymer thickness, there was an increase in wrinkle wavelength • With an increase in the metallic capping layer thickness there was a decrease in wrinkle wavelength • Increasing the time for thermal treatment did decrease the wrinkle wavelength, however not substantially.

- 19. Future Work • Examine the effects of wavelength for both reflectivity and contact angle. • To examine further the effects of thermal treatment time and also to examine varying the temperature of thermal treatment. • To use the wavelengths as a means of measuring the Young’s modulus of different materials. • To use the system to create functional surfaces (i.e. controlled wettability etc.)

- 20. Acknowledgments • A very big thank you to my two supervisors Dr. George Amarandei and Dr. Izabela Naydenova. • Thank you to the FOCAS institute for facilitating our needs to carry out these projects. • Thank you also to the DIT School of Physics.

- 21. Thank you for listening Any questions???