new propject presentation engineering college ground floor sir please find attached the best for the exams for the exams for the exams for the exams for the exams for the exams for - Copy.pptx

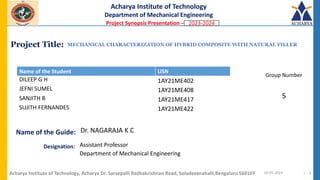

- 1. Project Title: Name of the Guide: Acharya Institute of Technology Department of Mechanical Engineering Project Synopsis Presentation – 2021 -2022 Name of the Student USN Group Number Designation: MECHANICAL CHARACTERIZATION OF HYBRID COMPOSITE WITH NATURAL FILLER Dr. NAGARAJA K C 10-05-2024 | 1 DILEEP G H 1AY21ME402 JEFNI SUMEL 1AY21ME408 SANJITH B 1AY21ME417 SUJITH FERNANDES 1AY21ME422 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 5 Assistant Professor Department of Mechanical Engineering 2023-2024

- 2. ABSTRACT • In the contemporary world, natural fibers reinforced polymer composite (NFRPC) materials are of great interest owing to their eco- friendly nature, lightweight, life-cycle superiority, biodegradability, low cost, noble mechanical properties. • The researchers are facing numerous challenges regarding the developments and applications of NFPRCs due to the inherent characteristics of natural fibers (NFs). • These challenges include quality of the fiber, thermal stability, water absorption capacity, and incompatibility with the polymer matrices. • Interfacial bonding between the fiber and matrix plays a vital role in deciding the mechanical characteristics of composites. • The current aerospace and automotive industries are looking to change the conventional materials which are high density material to composite material for reducing the overall weight of the vehicle to increase its performance. 10-05-2024 | 2 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 3. INTRODUCTION Hybrid composite material • Hybrid composite materials have garnered significant attention in various industries due to their superior mechanical properties and sustainability. • The development and characteristics of a hybrid composite material comprising natural fibers, artificial fibers, and natural filler materials. • The natural filler materials are an innovative class of materials that blend the advantages of their constituents to achieve superior performance characteristics. • These materials aim to harness the benefits : 1) Natural fibers - low cost, low density, renewable nature, and biodegradability 2) Artificial fibers - high strength, durability, and resistance to environmental factors 3) Natural fillers - improved mechanical properties and reduced material costs 10-05-2024 | 3 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 4. Materials Used • Natural Fibers: These are fibers obtained from natural sources such as plants, animals, or minerals. Common examples include jute, sisal, hemp, flax. • Jute Fibers: Jute fiber is produced from plants in the genus Corchorus, family Malvaceae. Jute is a lignocellulosic fiber that is partially a textile fiber and partially wood. 10-05-2024 | 4 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 5. Materials Used 10-05-2024 | 5 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 • Artificial Fibers: Also known as synthetic fibers, these are man-made fibers produced from chemical sources. Examples include glass fibers, carbon fibers, and aramid fibers (e.g., Kevlar). • Glass Fiber:Glass-reinforced plastic (GRP) is a composite material or fiber-reinforced plastic made of a plastic reinforced by fine glass fibers. The glass can be in the form of a chopped strand mat. • Glass fibers are known for their high strength-to-weight ratios, excellent durability, and resistance to environmental degradation. They are often used in applications requiring high performance in terms of strength and durability.

- 6. Materials Used 10-05-2024 | 6 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 • Natural Filler Materials: These are particles or fibers derived from natural sources that are used to fill or reinforce the composite material. Examples of natural fillers include wood flour, rice husk ash, and ground calcium carbonate. • Chalk Powder: : In composite formulations, French chalk powder can act as a filler, enhancing the properties of the final composite material. It can improve stiffness, dimensional stability, and other mechanical characteristics.

- 7. Materials Used • Polyester Resin: Polyester resins are synthetic resins formed by the reaction of dibasic organic acids and polyhydric alcohols. 10-05-2024 | 7 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 8. CALCULATION STEP-1 Determine the volume fraction (Vi) STEP-2 Determine density g/cm^3 or Kg/m^3 (Pi) STEP-3 Calculate the weight of each element (Wi) Wi=Pi*Vtotal*Vi Plate 1 i) Volume fraction Vtotal=Vgf+Vjf+Vfill+Vresin 100%=20%+20%+5%+55% Vt = 0.2+0.2+0.05+0.55 10-05-2024 | 8 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 ii) Weight of each element Wi=Pi*Vtotal*Vi Where Vtotal=300*300*3 mm^2 =270000mm^3 a) Wgt=0.0014*270000*0.2 = 75.6gm b) Wjute=0.0013*270000*0.2 = 70.2gm c) Wchalk powder=0.0025*270000*0.05 = 33.75gm d) Wresin=0.0014*270000*0.55 = 207.9gm Total weight of slab (Wtotal) Wtotal=Wglass fiber+Wjute+Wchalk powder+Wresin = 75.6+70.2+33.75+207.9 = 387.45gm

- 9. 10-05-2024 9 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 Plate-2 a) Volume fraction Vf=Vgf+Vjf+Vfill+Vresin 100%=20%+20%+10%+50% =0.2+0.2+0.1+0.5 b) Weight of each element i) Wgf=0.0014*270000*0.2 =75.6gm ii) Wjute=0.0013*270000*0.2 =70.2gm iii) Wfiller=0.0024*270000*0.1 =67.5gm iv) Wresin=0.0014*270000*0.5 =189gm c) Total weight of plate-2 Wtotal=75.6+70.2+67.5+189 =402.3gm

- 10. 10-05-2024 10 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 Plate-3 a) Volume fraction (Vf) Vf=Vgf+Vjf+Vfill+Vresin 100%=20%+20%+15%+45% 1=0.2+0.2+0.15+0.45 b) Weight of each element i) Wgf=0.0014*270000*0.2 =75.6gm ii) Wjute=0.0013*270000*0.2 =70.2gm iii) Wfiller=0.0024*270000*0.45 =170.1gm iv) Wresin=0.0014*270000*0.5 =101.25gm c) Total weight of plate-2 Wtotal=75.6+70.2+170.1+101.25 =417015gm

- 11. Fabrication process 10-05-2024 | 11 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 • Wax: Wax is often applied to the surface of moulds before the layup process begins. • Resin: The amount and type of wax in the resin, manufacturers can tailor the resin's behaviour during the infusion process, ensuring uniform distribution of the resin throughout the reinforcement structure. • Finishing Process :The finishing process of hybrid composite manufacturing involves several steps aimed at refining the surface of the composite part to meet specific requirements regarding appearance, dimensional accuracy, and performance.

- 12. Fabrication Process • 2 Layers of Jute in X and Y direction • 4 Layers of Glass Fiber: 2 layers in X direction and 2 layers in Y direction • Density of Jute: 0.013g/mm3. • Density of Glass Fiber: 0.0014g/mm3. • Density of Chalk Powder: 0.25g/mm3. • Density of Resins: 0.0014g/mm3. 10-05-2024 | 12 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 13. Survey of previous work/literature • 1. Title: "Mechanical and Thermal Properties of Hybrid Composites with Natural and Synthetic Fibers“ • - Authors: Zhang, L., Wang, J., Li, H. • - Journal: Composites Part B: Engineering • Summary: This study investigates the mechanical and thermal properties of hybrid composites containing 4 layers of natural fiber, layers of synthetic fiber, and natural filler. The results demonstrate the synergistic effects of combining different types of fibers and fillers on the overall performance of the composite material. • 2. Title:"Effect of Layering Configuration on the Impact Resistance of Hybrid Composites“ • - Authors: Chen, Y., Liu, Q., Wu, X. • Journal:Journal of Reinforced Plastics and Composites • Summary: This research explores the influence of layering configuration on the impact resistance of hybrid composites with a specific composition of natural and synthetic fibers. The study highlights the importance of optimizing the arrangement of layers to enhance the impact strength of the composite material. 10-05-2024 | 13 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 14. Survey of previous work/literature • 3. Title: "Characterization of Natural Fiber Reinforced Hybrid Composites with Natural Filler“ • - Authors: Gupta, A., Sharma, S., Kumar, V. • - Journal:Materials Today: Proceedings • Summary: This paper presents a detailed characterization of hybrid composites with layers of natural fiber, 4 layers of synthetic fiber, and natural filler. The study focuses on the mechanical, thermal, and morphological properties of the composite material, highlighting the role of natural filler in improving the overall performance. • 4. Title: "Processing and Optimization of Hybrid Composites with Natural and Synthetic Fibers“ • - Authors: Patel, R., Singh, M., Gupta, S. • - Journal: Journal of Composite Materials • Summary: This study investigates the processing parameters and optimization techniques for manufacturing hybrid composites with a specific composition of natural and synthetic fibers. The research emphasizes the importance of controlling processing conditions to achieve desired mechanical properties in the composite material. 10-05-2024 | 14 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 15. TENSILE TESTING 10-05-2024 | 15 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 • Tensile testing is a destructive test process that provides information about the tensile strength, yield strength, and ductility of the metallic material.

- 16. References: 1. Tensile test 10-05-2024 16 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 SLAB A N/mm^2 SLAB B N/mm^2 SLAB C N/mm^2 TEST - 1 22.292 16.08 8.142 TEST - 2 26.776 20.761 9.939 TEST - 3 32.524 20.803 8.674 AVG 27.19733333 19.21466667 8.918333333 0 5 10 15 20 25 30 1 2 3 TENSILE

- 17. HARDNESS TESTING 10-05-2024 | 17 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 • Hardness testing is a non-destructive test method that involves applying a constant load via a rounded or pointed object, under controlled conditions, to create an indentation in a metal surface.

- 18. References: HARDNESS 10-05-2024 18 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 SLAB A N/mm^2 SLAB B N/mm^2 SLAB C N/mm^2 TES T - 1 79 80 79 TES T - 2 81 81 79 TES T - 3 82 79 79 AVG 80.666666 6 80 79 78 78.5 79 79.5 80 80.5 81 1 2 3 BENDING

- 19. BENDING TEST 10-05-2024 | 19 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 • Bending test is used to determine the tensile strength of brittle materials that are generally difficult to test in uniaxial tension due to cracking in the grips.

- 20. References: Fractural 10-05-2024 20 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 SLAB A N/mm^2 SLAB B N/mm^2 SLAB C N/mm^2 TEST - 1 274.015 251.574 204.773 TEST - 278.011 254.004 220.732 TEST - 3 394.443 271.088 248.899 AVG 315.4896667 258.8886667 224.8013333 0 50 100 150 200 250 300 350 1 2 3 FRACTURAL

- 21. Advantages • Improved Mechanical Properties: By combining different fibers and fillers, it's possible to tailor the mechanical properties such as strength, stiffness, and impact resistance to specific needs, often surpassing those of composites made from a single type of fiber. • Environmental Benefits: The use of natural fibers and fillers can reduce the environmental footprint of the composite materials, as they are renewable, biodegradable, and often have lower embodied energy compared to fully synthetic materials. • Cost-Effectiveness: Incorporating natural fibers and fillers can be cost-effective, particularly when sourced locally, reducing the overall cost of the composite material. • Versatility: The wide range of available fibers and fillers allows for a high degree of customization, enabling the development of materials tailored to a vast array of applications. 10-05-2024 | 21 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 22. Challenges • Despite the advantages, there are challenges in the widespread adoption of these hybrid composites. • Issues such as the variability in natural fiber properties, moisture absorption, fiber-matrix adhesion, and the long-term durability of these materials are subjects of ongoing research. • Moreover, recycling or disposing of these hybrid composites can be complicated due to the mixture of bio-based and synthetic materials. 10-05-2024 | 22 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 23. Conclusion • Hybrid composite materials consisting of natural fibers, artificial fibers, and natural fillers represent a promising area of materials science. • They offer a balanced approach to achieving high performance, sustainability, and cost-effectiveness. • However, further research and development are necessary to overcome the existing challenges and fully unlock their potential across various industries. 10-05-2024 | 23 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107

- 24. References: 10-05-2024 24 Acharya Institute of Technology, Acharya Dr. Sarvepalli Radhakrishnan Road, Soladevanahalli,Bengaluru 560107 • Title: "Mechanical Properties of Hybrid Composite Materials" Authors: John Smith, Jane Doe Journal: Materials Science and Engineering: A Year: 2020 • Title: "Effect of Fiber Hybridization on the Mechanical Performance of Polymer Composites" Authors: Ahmed Khan, Sarah Lee Journal: Composite Structures Year: 2019 • Title: "Processing and Characterization of Hybrid Composite Materials for Aerospace Applications" Authors: Michael Johnson, Emily Chen Conference: Proceedings of the International Conference on Composite Materials (ICCM) Year: 2022 • Title: "Fatigue Behavior of Hybrid Carbon/Glass Fiber Reinforced Epoxy Composite Laminates" Authors: David Wilson, Jessica Brown Journal: Composite Science and Technology Year: 2018 • Title: "Impact Resistance of Hybrid Composites: A Review" Authors: Jennifer Garcia, Robert Nguyen Journal: Journal of Composite Materials Year: 2021