CURRICULUM-Vaibhav_Pawar

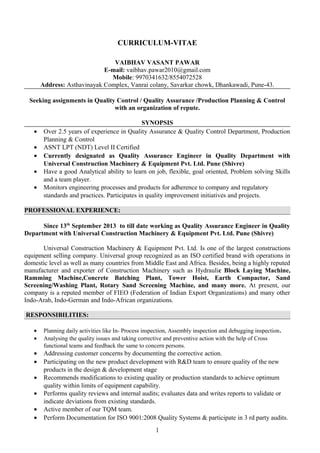

- 1. CURRICULUM-VITAE VAIBHAV VASANT PAWAR E-mail: vaibhav.pawar2010@gmail.com Mobile: 9970341632/8554072528 Address: Asthavinayak Complex, Vanrai colany, Savarkar chowk, Dhankawadi, Pune-43. Seeking assignments in Quality Control / Quality Assurance /Production Planning & Control with an organization of repute. SYNOPSIS · Over 2.5 years of experience in Quality Assurance & Quality Control Department, Production Planning & Control · ASNT LPT (NDT) Level II Certified · Currently designated as Quality Assurance Engineer in Quality Department with Universal Construction Machinery & Equipment Pvt. Ltd. Pune (Shivre) · Have a good Analytical ability to learn on job, flexible, goal oriented, Problem solving Skills and a team player. · Monitors engineering processes and products for adherence to company and regulatory standards and practices. Participates in quality improvement initiatives and projects. PROFESSIONAL EXPERIENCE: Since 13th September 2013 to till date working as Quality Assurance Engineer in Quality Department with Universal Construction Machinery & Equipment Pvt. Ltd. Pune (Shivre) Universal Construction Machinery & Equipment Pvt. Ltd. Is one of the largest constructions equipment selling company. Universal group recognized as an ISO certified brand with operations in domestic level as well as many countries from Middle East and Africa. Besides, being a highly reputed manufacturer and exporter of Construction Machinery such as Hydraulic Block Laying Machine, Ramming Machine,Concrete Batching Plant, Tower Hoist, Earth Compactor, Sand Screening/Washing Plant, Rotary Sand Screening Machine, and many more. At present, our company is a reputed member of FIEO (Federation of Indian Export Organizations) and many other Indo-Arab, Indo-German and Indo-African organizations. RESPONSIBILITIES: · Planning daily activities like In- Process inspection, Assembly inspection and debugging inspection. · Analysing the quality issues and taking corrective and preventive action with the help of Cross functional teams and feedback the same to concern persons. · Addressing customer concerns by documenting the corrective action. · Participating on the new product development with R&D team to ensure quality of the new products in the design & development stage · Recommends modifications to existing quality or production standards to achieve optimum quality within limits of equipment capability. · Performs quality reviews and internal audits; evaluates data and writes reports to validate or indicate deviations from existing standards. · Active member of our TQM team. · Perform Documentation for ISO 9001:2008 Quality Systems & participate in 3 rd party audits. 1

- 2. · Coordinating with Logistics for Domestic & Export Dispatch. · Prepare the documentations like QMS, Quality plan, QA/QC procedures , In process Inspection Reports,PDIR (Pre Dispatch Inspection Reports),Final Inspection Reports, RFD (Ready For Dispatch ), corrective action reports (CAR) & make discrepant material reports. etc · Conducting welding trials and Robot weld joints testing by using DP technique. · Recommends modifications to existing quality or production standards to achieve optimum quality within limits of equipment capability. PROFESSIONAL EXPERIENCE: Since 7th September 2012 to 6th September 2013 working with GKN Sinter Metals Pvt. Ltd.Pune (Previously Mahindra Sinter Products Ltd) GKN Sinter Metals is the worlds leading supplier of metal powder precision components. Their global production and sales network employs approximately 6,500 associates in more than 30 faclities on five continents. With a history dating back to the 1930s, today they have production sites in Germany,Italy,South Africa, India,China,Brazil,Argentina,Canada and the USA. RESPONSIBILITIES: · Production planning, controlling, monitoring. · Distribution of work load to operators in order to achieve daily production target. · Implementing and monitoring preventive actions to reduce line rejection.. · Familiar with various problems solving tools like 7 QC tools Responsible for same implementation. · Active involvement in cycle time reduction without affecting any quality standards. · Coordinating logistics for Export Dispatch. · Inspecting In-process and pre-dispatch material. · To maintain the 5’S in shop · Prepare documents for audits such as ISO 9001:2008 ,TS & OSHAS certifications · Keep eyes on inventory level. · Regular updating daily production in to the system and also checking physical stock of material against the system CORE COMPETENCIES: · Customer Focus. · Ethics & Values. · Organizing. · Peer relationship. · Time Management. SKILLS: · Knowledge of MIS & Works with a variety of audit methods, tools and techniques · Metallurgy Lab knowledge is added advantage · Ability to analyze problems, identify root causes and provide efficient solutions. · Strong interpersonal and leadership skills with good oral and written communication skills. · Strong project and team leadership. · Willingness to walk extra miles to achieve excellence. 2

- 3. ACADEMIC DETAILS: Degree School/Institute Marks (%) Year Of Passing University/ Board B.E. (Mechanical) Sinhgad Academy Of Engineering, Kondhwa, Pune. D-Pune. 73.53% First Class (Distinction) 2011-12 Pune. Diploma (Mechanical) Karmveer Bhaurao Patil College of Engg. & Polytechnic. Satara 82.67% First Class (Distinction) 2009 M.S.B.T.E. Mumbai. H.S.C. Sadguru Gadge Maharaj College, Karad. D-Satara. 69.83% First Class 2007 Maharashtr a State Board. S.S.C. Kai Dynogirao Salunke High School Patan.D-Satara. 77.06% First Class (Distinction) 2005 Maharashtr a State Board. PROJECT DETAILS: · B.E -Design and Develop Roller Burnishing Tool. To Design and Develop Roller Burnishing Tool. This tool is work on the cold working process and by using this Roller Burnishing Tool we get higher surface finish as compared with other surface finishing processes. Sponcered By: Forbes Marshall Pvt Ltd. Pune. · DIPLOMA- Parkinson Gear Testing Machine The Principle of this device is to mount a standard gear on a fixed vertical spindle and gear to be tested on another similar spindle mounted on a sliding carriage, maintaining the sliding carriage as then meshes by spring pressure. Sponsored By: Vinay Engineers & Febricators, Satara. PROFESSIONAL TRAINING ATTENDED: Institute Name: Sinhgad Academy of Engineering, Kondhwa, Pune. D-Pune. Period: 17th -18th September 2010 Subject: Two Day Workshop on “Entrepreneurship Awareness Camp” Organized by Pune University. Company Name: Forbes Marshall Pvt Ltd. Kasarwadi Pune .D-Pune. Period: 1st Dec 2011-31st March 2012. Subject: In plant Training for the Project Design and Develop Roller Burnishing Tool. Institute Name: Weldcon Services Pune. D-Pune. Period: 11th May 2014 Subject: One Day Workshop on “Fundamentals about Welding” TECHNICAL SKILLS: · Conversant with Business Planning Control System, BPCS (An ERP System), Baan. 3

- 4. · Having knowledge of Auto Cad, Pro-E, Master Cam. · Working Knowledge of MS Office, Windows 98/XP & Internet Browsing. EXTRA CURRICULAR ACTIVITIES: · 2011-2012: Paper Present in National Level Paper Presentations Competition, Akola. · 2011-2012: Work as Event Co-Ordinator for the event “LATHE WAR” (INNOFEST- 2012). PERSONAL DETAILS: · Date Of Birth: 20 September1989. · Marital Status: Single · Nationality: Indian · Permanent Address: At Post-Nade (Navarasta) Pin-415205.Tal-Patan , Dist-Satara (MS) · Contact No: 9970341632/8554072528 · Email ID : vaibhav.pawar2010@gmail.com · Hobbies: Reading Books, Playing Cricket, Traveling. · Languages Known: English, Hindi and Marathi I hereby declared that all the above information is true to the best of my knowledge. Vaibhav V. Pawar. 4