Weitere ähnliche Inhalte

Mehr von Utah Nursery and Landscape Association (20)

Kürzlich hochgeladen (20)

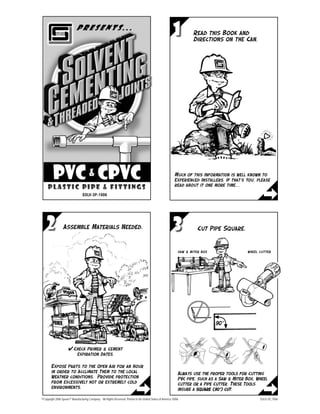

Bill Godwin #4 Irrigation Pipe & Fittings Solvents Wed Jan 27

- 1. R ead This B ook and

D irections on the C an.

M uch of this i nformation is well known to

e xperienced i nstallers. I f that’s y ou, Please

read about it one more time...

SOLV-3P-1006

A ssemble M aterials N eeded. C ut P ipe S quare.

Saw & miter box wheel CUTTER

90°

✔C heck p rimer & C ement

Expiration d ates.

e xpose p arts to the o pen a ir for an h our

in order to a cclimate t hem to the local A lways use the proper tools for cutting

w eather conditions. P rovide Protection PVC Pipe, such as a S aw & Miter B ox, Wheel

from excessively HOT or Extremely COLD c utter or a Pipe C utter. T hese tools

Environments. insure a square (90°) cut.

©Copyright 2006 Spears® Manufacturing Company All Rights Reserved. Printed in the United States of America 10/06 SOLV-3P_1006

- 2. R emove B urrs

and B evel o utside r im. C lean P ipe and F ittings.

c arefully B evel

p ipe with f ile. OR: Use Deburring and

Beveling tools.

Wipe off all j oining s urfaces

10° - 15° with a c lean, dry rag.

D ust, Dirt, Grease (even fingerprints)

D E-Burr with a k nife or D e-Burring t ool and Moisture can interfere with the

and bevel edges to 10°- 15° so the p ipe will penetration and bonding properties of

f it s nugly into s ocket. primer and solvent cement.

C heck Full Interference Fit

U se the C orrect A pplicator

D ry F it . ½ Socket

Depth S ize for the j ob.

Socket

Depth

Net Fit

Socket

Depth

Rough End-Cut

Use an applicator at least

1/2 the size of pipe.

Loose Fit

A good fit is insured

when using ASTM

Standards and Code

approvals.

©Copyright 2006 Spears® Manufacturing Company All Rights Reserved. Printed in the United States of America 10/06 SOLV-3P_1006

- 3. A pply P rimer * A pply S OLVENT C EMENT

F itting p ipe f itting ( p ipe f itting P IPE)

While the primer is still wet and...

W ork into

Surface to

s often.

solvent cement

Wet

Primer

✔C heck P enetration.

Without Softening, Most solvent

Cements will not bond properly. ...work cement onto pipe using a circular

use 2 to 3 thick coats. motion. F ollow with a thin coat in the

fitting, Repeat. K eep applicator in can

*primer.Cements are “one-step” and requireSome

Some

This type of cement is used with

no when not in use.

CPVC, abs and styrene plastics.

...W ork q uickly ! A ssemble i mmediately —

s olvents q uickly e vaporate.

Wet

Primer

45

Don’t let c ement p uddle i nside

f ittings or r un d own

i nside the p ipe.

u se of the proper applicator will

speed up your work and help lay down

a generous and even coat of solvent A dditional h olding or R estraint of p ipe

primer and cement. may be required on l arger s izes.

©Copyright 2006 Spears® Manufacturing Company All Rights Reserved. Printed in the United States of America 10/06 SOLV-3P_1006

- 4. ...W hile c ement is s till w et, r emove e xcess c ement.

P ush and T wist (1/4 Turn) ( U se D isposable M aterial )

s ocket on to p ipe U ntil it

b ottoms o ut.

hold parts together for

about 30 seconds to

avoid push-out.

45

I f left on e xposed p ipe, the

s oftening e ffect of excess

Don’t let go! Keep pressure on pipe solvent could p ermanently

and fitting until cement sets. See page 26 distort or weaken p ipe.

recommended set schedules.

F lush E ntrapped

S olvent C ement v apors. w ait for j oints to s et

S olvents evaporate through the s ystem and before d isturbing.

walls, s oftening both p ipe and f ittings. S ome

s oftening will r emain until s olvents have

fully e vaporated.

F ill w ith w ater

and t horoughly

f lush Before

capping off

or closing.

Avoid pressurization of system until See page 26 for

adequately cured. If there is a strong recommended cure times.

smell of solvents in the piping, vapors

are being generated.

©Copyright 2006 Spears® Manufacturing Company All Rights Reserved. Printed in the United States of America 10/06 SOLV-3P_1006

- 5. A fter c ement has s et, S nake p ipe to

carefully lay a ssembly in allow for T hermal

f inal p osition... e xpansion/ c ontraction.

...and don’t drop it! L ay the pipe in a slight s-curve.

Do Not lay it perfectly straight .

S hade p ipe with b ackfill. w ait for f ull c ure...

Remember...

j oint s ize, e xtreme t emperature

( h ot or C old) and h umidity all have an

effect on s olvent c ement c ure t imes.

Leave all Joints exposed.

See page 26 for

recommended cure times .

©Copyright 2006 Spears® Manufacturing Company All Rights Reserved. Printed in the United States of America 10/06 SOLV-3P_1006

- 6. B ring s ystem u p to i ts P ressure t est s ystem...

o perating T emperature Do Not Use C ompressed

b efore t esting. a ir or g as.

WARNING: Do not use compressed air or gas to test any PVC or CPVC

thermoplastic piping product or system, and do not use devices propelled

by compressed air or gas to clear the systems. These practices may result

in explosive fragmentation of system piping and components causing bodily

injury or death.

This can be done by...

All air must be bled from the system during the initial fluid fill. Pressure

1) Shading with back fill testing of the system must not be made until all solvent cement joints have

properly cured. Initial pressure testing must be made at approximately 10% of

2) Fill system with water of correct tempurature the system hydrostatic pressure rating to identify potential problems prior to

testing at higher pressures.

3) Letting the system “settle in” overnight

For T hreaded C onnections... I f You M ust Use T ape,

Use It Correctly...

Apply to Male

Threads only

wrap in direction

of threads.

Use Only 2

or 3 wraps.

Spears® Hold end and pull tape

Recommends the tight into threads.

use of BLUE 75™

Thread Sealant.

S tress Always cover end of

C racks fitting at the start

to prevent thread

seizing prior to

proper joint makeup .

u se of i ncompatible p aste s ealants NEVER c ombine T ape and p aste!

may result in s tress c racking in

p lastic p ipe and f ittings.

©Copyright 2006 Spears® Manufacturing Company All Rights Reserved. Printed in the United States of America 10/06 SOLV-3P_1006

- 7. T hread f itting o nto

p ipe f inger t ight.

+

i to 2

turns

... O n a j ob w ell d one.

S pears ® M anufacturing C ompany considers

your safety, the quality of its products

and the clarity of its assembly instructions

to be critically important. Consequently,

U se a c ommercial s trap w rench Spears ® offers data sheets, videos and

training for those who wish to expand their

to add no more than two turns knowledge and skills with solvent cement

to the fitting joining methods.

S et and c ure t ime s chedules.

SPEARS® MANUFACTURING COMPANY

Average Initial Set Schedule For PVC/CPVC Solvent Cements**

Temperature Pipe Sizes Pipe Sizes Pipe Sizes Pipe Sizes Pipe Sizes

CORPORATE OFFICE

Range ½” to 1-¼ 1-½” to 2” 2-½” to 8” 10” to 15” 15”+ 15853 Olden St., Sylmar, CA 91342

60°- 100°F 2 Minutes 5 Minutes 30 Minutes 2 Hours 4 Hours

PO Box 9203, Sylmar, CA 91392

40 °- 60 °F 5 Minutes 10 Minutes 2 Hours 8 Hours 16 Hours

0°- 40°F 10 Minutes 15 Minutes 12 Hours 24 Hours 48 Hours (818) 364-1611 • www.spearsmfg.com

NOTE: Initial set schedule is the necessary time to allowbefore thr joint can be carefully handled. In damp or humid

weather allow 50% more set time.

(** These figures are estimates based on our laboratory tests using water; extended set times are required for

PACIFIC SOUTHWEST UTAH

chemical applications. Due to the many variables in the field, these figures should be used as a general guide only. 15860 Olden St. 5395 West 1520 South

Sylmar (Los Angeles), CA 91342 Salt Lake City, UT 84104

Average Joint Cure Schedule for PVC/CPVC Solvent Cements†† (818) 364-1611 • (800) 862-1499 (303) 371-9430 • (800) 777-4154

Relative Cure Time Cure Time Cure Time Cure Time Cure Time Fax (818) 367-3014 Fax (303) 375-9546

Humidity 60% Pipe Sizes Pipe Sizes Pipe Sizes Pipe Sizes Pipe Sizes

or Less ½” to 1-¼” 1-½” to 2” 2-½” to 8” 10” to 15 ” 15” +

Tempature range above above above

ROCKY MOUNTAIN SOUTH CENTRAL

up to up to up to up to up to 4880 Florence St. 4250 Patriot Dr. Suite 300

during assembly 160 to 160 to 160 to

160 psi 160 psi 160 psi 100 psi 100 psi

and cure periods 370 psi 315 psi 315 psi Denver, CO 80238 Grapevine (Dallas), TX 76051-2317

60°- 100°F 15 min 6 hrs 30 min 12hrs 1½ hrs 24 hrs 48 hrs 72 hrs (303) 371-9430 • (800) 777-4154 (972) 691-4003 • (800) 441-1437

40 °- 60 °F 20 min 12 hrs 45 min 24 hrs 4 hrs 48 hrs 96 hrs 6 days Fax (303) 375-9546 Fax (972) 691-4404

0°- 40°F 30 min 48 hrs 1 hour 96 hrs 72 hrs 8 days 8 days 14 days

NOTE: Joint cure schedule is the necessary time to allow before pressurizing system. In damp or humid weather NORTHEAST FLORIDA

allow 50% more cure time. 590 Industrial Dr. Suite 100 9563 Parksouth Court

(††These figures are estimates based on our laboratory tests. Due to the many variables in the field, these figures Lewisberry (Harrisburg), PA

should be used as a general guide only.)

Orlando, FL 32837

17339-9532 (407) 843-1960 • (800) 327-6390

Average Number of Joints per Quart of Cement* (717) 938-8844 • (800) 233-0275 Fax (407) 425-3563

Pipe Diameter ½” ¾” 1” 1½” 2” 3” 4” 6” 8” 10” 12” 15” 18”

Fax (717) 938-6547

Number of 300 200 125 90 60 40 30 10 5 2-3 1-2 ¾” ½”

Joints MIDWEST SOUTHEAST

(*These figures are estimates based on our laboratory tests. Due to the many variables in the field, these figures

should be used as a general guide only.)

1 Gateway Ct . Suite A 4205 Newpoint Pl. Suite 100

Bolingbrook (Chicago), IL 60440 Lawrenceville (Atlanta), GA 30043

NOT FOR USE WITH COMPRESSED AIR OR GAS (630) 759-7529 • (800) 662-6330 (678) 985-1263 • (800) 662-6326

Fax (630) 759-7515 Fax (678) 985-5642

WARNING: Do not use compressed air or gas to test any PVC or CPVC thermoplastic piping product

or system, and do not use devices propelled by compressed air or gas to clear the systems. These

practices may result in explosive fragmentation of system piping and components causing bodily NORTHWEST INTERNATIONAL SALES

injury or death. 4103 C St. NE Suite 200 15853 Olden St.

Auburn (Seattle), WA 98002 Sylmar (Los Angeles), CA 91342

All air must be bled from the system during the initial fluid fill. Pressure testing of the system must (253) 939-4433 • (800) 347-7327 (818) 364-1611 • Fax (818) 898-3774

not be made until all solvent cement joints have properly cured. Initial pressure testing must be

made at approximately 10% of the system hydrostatic pressure rating to identify potential problems Fax (253) 939-7557

prior to testing at higher pressures.

©Copyright 2006 Spears® Manufacturing Company All Rights Reserved. Printed in the United States of America 10/06 SOLV-3P_1006