5 days TPM Workshop/Implementation Strategies at F&N

•Als PPT, PDF herunterladen•

6 gefällt mir•3,060 views

Implementing Total Productive Maintenance (TPM) towards being World Class in Equipment Maintenance. Our Goal is towards a Zero Downtime,Zero Defects, maximizing Production time to delight our Customers by our commitment to deliver Productivity & 1st Class Quality with on time Delivery towards 21st Century Business of Delighting our Customers.

Melden

Teilen

Melden

Teilen

Empfohlen

Empfohlen

Weitere ähnliche Inhalte

Was ist angesagt?

Was ist angesagt? (20)

TPM the effective maintenance with Autonomous Maintenance

TPM the effective maintenance with Autonomous Maintenance

Autonomous Maintenance (Jishu Hozen) by Ketan Kumar (Raavinnovate)

Autonomous Maintenance (Jishu Hozen) by Ketan Kumar (Raavinnovate)

Total Productive Maintenance (TPM) for EVERTS 20Aug2018

Total Productive Maintenance (TPM) for EVERTS 20Aug2018

Andere mochten auch

Andere mochten auch (15)

Ähnlich wie 5 days TPM Workshop/Implementation Strategies at F&N

Ähnlich wie 5 days TPM Workshop/Implementation Strategies at F&N (20)

Total Productive Maintenance (Tpm) EVERTS 21Aug2018

Total Productive Maintenance (Tpm) EVERTS 21Aug2018

TPM Total Productive Maintenance for Quarry Plant(2)

TPM Total Productive Maintenance for Quarry Plant(2)

Maintenance Total Productive TPMMMMMMMMMMMMMMMMMMM

Maintenance Total Productive TPMMMMMMMMMMMMMMMMMMM

20 hand out on cp assessment methodology -samantha

20 hand out on cp assessment methodology -samantha

Introduction to Productivity SA presentation with GAD

Introduction to Productivity SA presentation with GAD

Preventive Maintenance Best Practices workshop Brochure

Preventive Maintenance Best Practices workshop Brochure

Total quality management (TQM) for IM students of JNTUH

Total quality management (TQM) for IM students of JNTUH

Total Productive Maintenance: A Comprehensive Guide | Enterprise Wired

Total Productive Maintenance: A Comprehensive Guide | Enterprise Wired

Mehr von Timothy Wooi

Mehr von Timothy Wooi (20)

Story of The Soldier Son Portrait who died to save others

Story of The Soldier Son Portrait who died to save others

SEAIETI Online Educational Administration Practices with TQM

SEAIETI Online Educational Administration Practices with TQM

Innovative Leadership in Education for the New Normal

Innovative Leadership in Education for the New Normal

Leadership and the teaching and learning culture in the new normal

Leadership and the teaching and learning culture in the new normal

Communication & Interpersonal Skills at Multi Cultural Workplace

Communication & Interpersonal Skills at Multi Cultural Workplace

The Seven Habits of Highly Effective People by Steven Covey

The Seven Habits of Highly Effective People by Steven Covey

Touraride Penang Downing Street to London Downing Street

Touraride Penang Downing Street to London Downing Street

Disruptive Pandemic School Leadership Management Shift

Disruptive Pandemic School Leadership Management Shift

Kürzlich hochgeladen

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974🔝✔️✔️ Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes. We provide both in- call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease. We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us. Our services feature various packages at competitive rates: One shot: ₹2000/in-call, ₹5000/out-call Two shots with one girl: ₹3500 /in-call, ₱6000/out-call Body to body massage with sex: ₱3000/in-call Full night for one person: ₱7000/in-call, ₱10000/out-call Full night for more than 1 person : Contact us at 🔝 9953056974🔝. for details Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations. For premium call girl services in Delhi 🔝 9953056974🔝. Thank you for considering us Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X7![Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X7](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X7](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X79953056974 Low Rate Call Girls In Saket, Delhi NCR

Kürzlich hochgeladen (20)

Learn the concepts of Thermodynamics on Magic Marks

Learn the concepts of Thermodynamics on Magic Marks

Tamil Call Girls Bhayandar WhatsApp +91-9930687706, Best Service

Tamil Call Girls Bhayandar WhatsApp +91-9930687706, Best Service

Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X7![Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X7](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X7](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

Call Girls in South Ex (delhi) call me [🔝9953056974🔝] escort service 24X7

+97470301568>> buy weed in qatar,buy thc oil qatar,buy weed and vape oil in d...

+97470301568>> buy weed in qatar,buy thc oil qatar,buy weed and vape oil in d...

S1S2 B.Arch MGU - HOA1&2 Module 3 -Temple Architecture of Kerala.pptx

S1S2 B.Arch MGU - HOA1&2 Module 3 -Temple Architecture of Kerala.pptx

HOA1&2 - Module 3 - PREHISTORCI ARCHITECTURE OF KERALA.pptx

HOA1&2 - Module 3 - PREHISTORCI ARCHITECTURE OF KERALA.pptx

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

Hazard Identification (HAZID) vs. Hazard and Operability (HAZOP): A Comparati...

Hazard Identification (HAZID) vs. Hazard and Operability (HAZOP): A Comparati...

Design For Accessibility: Getting it right from the start

Design For Accessibility: Getting it right from the start

scipt v1.pptxcxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx...

scipt v1.pptxcxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx...

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Kuwait City MTP kit ((+919101817206)) Buy Abortion Pills Kuwait

Kuwait City MTP kit ((+919101817206)) Buy Abortion Pills Kuwait

HAND TOOLS USED AT ELECTRONICS WORK PRESENTED BY KOUSTAV SARKAR

HAND TOOLS USED AT ELECTRONICS WORK PRESENTED BY KOUSTAV SARKAR

5 days TPM Workshop/Implementation Strategies at F&N

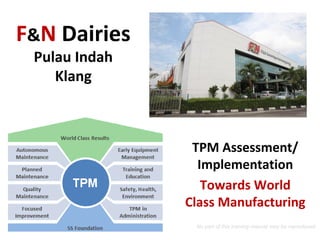

- 1. F&N Dairies Pulau Indah Klang TPM Assessment/ Implementation Towards World Class Manufacturing timothywooi2@gmail.com No part of this training manual may be reproduced.

- 2. • Principal Consultant for Lean Management. Certified TPM & Kaizen Specialist with 30 over years working experience. • Provides Technical Consulting Services on TPM, Kaizen and Cellular System set up. • A Mechanical background Green Innovator recycling and reusing Idle resources to eliminate waste to add Value to promote Green. • Founder of Tim’s Waterfuel, an alternative Hydroxy Fuel supplement using Water that adds power and reduce Co2 emission on automobiles. • An NGO Community worker for Prison, Drug Rehabilitation and CREST North (Crisis Relieve & Training) Malaysia, an organization that respond to Crisis & Flood. Timothy Wooi Add: 20C, Taman Bahagia, 06000, Jitra, Kedah Email: timothywooi2@gmail.com H/p: 019 4514007 (Malaysia)

- 3. Introduction • Yourself • Your name ? • Department / Section Why are you here? Parable of the Pencil.

- 4. TPM Implementation Planning and Preparation: 1. Top management commits to TPM implementation 2. Introductory Education and Training 3. Establish TPM promotion organization 4. Value stream map and select pilot model 5. Collect OEE data / Select a Baseline 6. Set basic policies and targets 7. Create master plan for TPM implementation 8. TPM kickoff

- 5. Full TPM Implementation Implementation 9. Establish system to improve production efficiency – Autonomous Maintenance (Workshop) – Kaizen – Planned Maintenance – Skill enhancement – Small Group Activities 10. Early equipment management 11. Establish a quality maintenance system 12. Improve operation efficiency in the office environment 13. Establish safety, hygiene and working environmental protection system 14. Total application of TPM and raising the level

- 6. TPM Strategy Day 1 – Team Charter/ formation and TPM kick-off – Establish TPM policies, TPM schedule steps – Gather Info/data for AM checklist, – Clean n Inspect, Clean, Oil, Dirt Day 2 – Re access maintenance activities, gather data and validate info for A.M. Check - pictures before. – Identify Improvement Activities Day 3 – Focused Improvements(Kaizen) – Improvement Action Plan-Clean, Dust, Oil – Preparation for Improvement Projects Action List Proposal/AM Training Day 4 – AM Training/Action Implementation – Document Report using standard formats Day 5 – Report Out & Presentation

- 7. Day 1 Morning TPM policies,6 Steps to TPM Installation • Establish basic TPM policies and SMART goals. Analyze the existing conditions and set goals that are SMART. (Gather Info for AM checklist, Clean n Inspect) • 6 Steps to TPM Installation (until Clean & Inspect) • TPM kick-off. Implementation will begin at this stage.

- 8. Noon Cleaning and Inspection • Log Out Tag Out on Machine. • Actual Cleaning and Inspection of Machine to externalize to Autonomous Maintenance. Operators routine cleaning and inspection will help stabilize conditions and stop accelerated deterioration. (reference Clean & Inspection Checklist for Production Machine)

- 9. Day 2 Morning Autonomous maintenance for Operators • Develop an autonomous maintenance program for Operators. • Create a DAILY Autonomous Maintenance Checklist, (Use Visual Roadmap/log out tag out procedures/TPM Board) Operators routine cleaning and inspection will help stabilize conditions and stop accelerated deterioration. (Reference: AM Cleaning and Inspecting followed by AM Checklist for Printing Machine)

- 10. Noon Assessment/Improvements • Identify problems found during Clean & Inspect. • Identify Improvements projects for Moonshine activities – improve 5S – Address dust – Oil n Lubrication (Reference: AM Cleaning and Inspecting followed by AM Checklist for Production Machine)

- 11. Day 3 Focused Improvements (KAIZEN) • Improvement Action Plan-Clean, Dust, Oil Identify causes of Dust and Contamination and Brainstorm actions to address n prevent occurance • Preparation for Moonshine Projects Action List Proposal/AM Training (Use 1H n 4 WHs approach to identify root cause.)

- 12. Day 4 AM Training and Action Implementation • AM Training/Action Implementation • Document Report * (Use Target & Scope, Before n After Cartoon &Kaizen Newspaper to record activities with Pictures with Road Map & Visual identifications for AM. on TPM Board).

- 13. Day 5 Report Out and Presentation • Report out presentation. – Objective/Target and Scope – Improvement Cartoon – Kaizen Newspaper – Review

- 14. Where are we today? Is most of your time spent fire fighting? Are equipment failures and quality issues a problem? Is very little time spent on preventing the failures and quality defects from occurring? Do you have institutionalized rework in your facilities?

- 16. Why TPM? • TPM combines the traditionally American practice of Preventive Maintenance with Total Quality Control and Total Employee Involvement, to create a culture in which the user partners with the Maintenance in maintaining the Equipment towards a “ready to use condition” using energy efficiently. • It is a company-wide team-based effort to build quality into equipment and to improve overall equipment effectiveness

- 17. Why Implement TPM? Cost Reduction for Survival Strict Quality Demands World ClassDiversification of Needs, Shorter Delivery Time Change Work Environment Reduce cost dramatically by pursuing the extreme in equipment (production) effectiveness Establish conditions that will not allow defects and manage conditions that will prevent defects Create unmanned operations and people friendly working equipment Minimize machine setup time and get the product to the customer on time World Class Qualifiers

- 18. Set-Up and Adjustment Idling and Minor Stoppage Reduced Speed Quality: Defects in Process & Rework Reduced Yield Equipment Failures Easy to measure Low impact on profit High impact on profits Labor Materials/spares Outside services Maintenance overhead Equipment Production Losses (Six Big Losses)

- 19. Autonomous Maintenance I run it, you fix it I fix it, you run it

Hinweis der Redaktion

- The first 8 steps are part of our preparation, and you can plan on spending 3 to six months on this stage depending on the size of your company. Step 1 Top management Commits to Implement TPM: The success or failure of TPM greatly depends on the determination and enthusiasm of top management. The top person should personally declare the determination to implement TPM at a staff meeting and that declaration should be printed in a company bulletin or newsletter Step 2 Introductory education and training: Top executives and management should be educated first so they know what their roles are in TPM. The training should then be cascaded down to the rest of the employees. Step 3 Establish TPM promotional organization: TPM is promoted through overlapping small group activities. A TPM promotion office should be established and staffed with full time person’s to promote TPM. Step 4 Value stream map and select pilot model: A value stream map of the area that you intend on first introducing TPM too should be conducted and machine’s prioritized. You should then select your pilot model it is recommended that you do not select the most critical bottleneck as your pilot model machine. You want to make sure you pick a winnable pilot. Step 5 Collect OEE data and Baseline: If OEE data is not available for your pilot model then 2-3 months of OEE data should be collected. This holds true for reliability data as well. This is also the time that you should get the finance department involved to help track costs and benefits of TPM. Step 6 Set basic Policies and targets: Implementing TPM is not a goal in itself. TPM is executed as a means of attaining corporate needs, principles and targets. This should always be kept in mind when setting basic principles and target of TPM. Step 7 Create Master Plan for TPM implementation: The master plan specifies the details of the principle TPM activities and gives start and completion dates for implementation of each of the pillar activities Step 8 TPM Kickoff: TPM kickoff can be as simple as letter from the top executive kicking off the TPM program or as elaborate as a large scale event where all employees are invited to a formal TPM kickoff ceremony.

- Steps 9- 14 are the actual implementation of TPM, and begin immediately following the kickoff. It generally takes 2 1/2 to 3 years to reach world class levels. However Larger businesses with many employees may require 3 to 5 years

- Ask for examples of each of these losses. Which loss is usually the biggest? (Setup is typically the biggest loss.) Many AIW activities are strictly focused on setup reduction with the goal being less than 10 minutes. An example is of a machine setup improvement within Boeing where the setup was reduced from over 4 hours to 3 seconds. Key Points: What gets measured gets done. Let’s make what’s important more measurable, Instead of what’s measurable more important!!!

- The way things usually are today. This can apply to almost any department, take engineering and Maintenance for instance. Instead of I run it you fix it. It would be I design it, you fix and vise versa.