Phase transformation

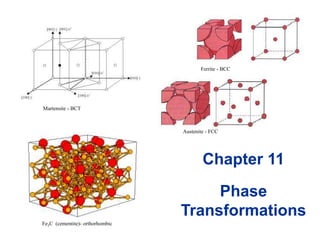

- 1. Chapter 11 Phase Transformations Fe3C (cementite)- orthorhombic Martensite - BCT Austenite - FCC Ferrite - BCC

- 2. Phase Transformations • Transformation rate • Kinetics of Phase Transformation –Nucleation: homogeneous, heterogeneous –Free Energy, Growth • Isothermal Transformations (TTT diagrams) • Pearlite, Martensite, Spheroidite, Bainite • Continuous Cooling • Mechanical Behavior • Precipitation Hardening

- 3. In the study of phase transformations we will be dealing with the changes that can occur within a given system e.g.an alloy that can exist as a mixture of one or more phases A phase can be defined as a portion of the system whose properties and composition are homogeneous and which is physically distinct from other parts of the system The components of a system are the different elements or chemical compound which make up the system Phase Transformations

- 4. Equilibrium Any transformation that results in a decrease in Gibbs free energy is possible

- 5. Phase Transformations Phase transformations – change in the number or character of phases. Simple diffusion-dependent No change in # of phases No change in composition Example: solidification of a pure metal, allotropic transformation, recrystallization, grain growth More complicated diffusion-dependent Change in # of phases Change in composition Example: eutectoid reaction Diffusionless Example: metastable phase - martensite

- 6. Phase Transformations Most phase transformations begin with the formation of numerous small particles of the new phase that increase in size until the transformation is complete. • Nucleation is the process whereby nuclei (seeds) act as templates for crystal growth. • Homogeneous nucleation - nuclei form uniformly throughout the parent phase; requires considerable supercooling (typically 80-300°C). • Heterogeneous nucleation - form at structural inhomogeneities (container surfaces, impurities, grain boundaries, dislocations) in liquid phase much easier since stable “nucleating surface” is already present; requires slight supercooling (0.1-10ºC).

- 7. Supercooling During the cooling of a liquid, solidification (nucleation) will begin only after the temperature has been lowered below the equilibrium solidification (or melting) temperature Tm. This phenomenon is termed supercooling (or undercooling. The driving force to nucleate increases as T increases Small supercooling slow nucleation rate - few nuclei - large crystals Large supercooling rapid nucleation rate - many nuclei - small crystals

- 8. Nucleation of a spherical solid particle in a liquid Liquid The change in free energy G (a function of the internal energy and enthalpy of the system) must be negative for a transformation to occur. Assume that nuclei of the solid phase form in the interior of the liquid as atoms cluster together- similar to the packing in the solid phase. Also, each nucleus is spherical and has a radius r. Free energy changes as a result of: 1) the difference between the solid and liquid phases (volume free energy, GV); and 2) the solid-liquid phase boundary (surface free energy, GS). Transforming one phase into another takes time. G = GS + GV Fe g (Austenite) Eutectoid transformation C FCC Fe3C (cementite) a (ferrite) + (BCC)

- 9. r* = critical nucleus: for r < r* nuclei shrink; for r >r* nuclei grow (to reduce energy) Homogeneous Nucleation & Energy Effects GT = Total Free Energy = GS + GV Surface Free Energy- destabilizes the nuclei (it takes energy to make an interface) g 2 4 rGS g = surface tension Volume (Bulk) Free Energy – stabilizes the nuclei (releases energy) GrGV 3 3 4 volumeunit energyfreevolume G

- 11. Solidification TH T r f m g 2 * Note: Hf and g are weakly dependent on T r* decreases as T increases For typical T r* ~ 10 nm Hf = latent heat of solidification (fusion) Tm = melting temperature g = surface free energy T = Tm - T = supercooling r* = critical radius

- 13. Growth • It begins once an embryo has exceeded the critical size r* • nucleation will continue to occur simultaneously with growth • The growth process will cease in any region where particles of the new phase meet • Growth occurs by long-range atomic diffusion – diffusion through the parent phase, across a phase boundary, and then into the nucleus.

- 14. growth rate

- 16. Computation of Critical Nucleus Radius and Activation Free Energy (a) For the solidification of pure gold, calculate the critical radius r*and the activation free energy ΔG* if nucleation is homogeneous. Values for the latent heat of fusion and surface free energy are -1.16 x109 J/m3 and 0.132 J/m2 , respectively. Use the super-cooling value found in Table 10.1. (b) Now calculate the number of atoms found in a nucleus of critical size. Assume a lattice parameter of 0.413 nm for solid gold at its melting temperature.

- 17. Transformations & Undercooling • For transformation to occur, must cool to below 727°C • Eutectoid transformation (Fe-Fe3C system): g a + Fe3C 0.76 wt% C 0.022 wt% C 6.7 wt% C Fe3C(cementite) 1600 1400 1200 1000 800 600 400 0 1 2 3 4 5 6 6.7 L g (austenite) g+L g +Fe3C a +Fe3C L+Fe3C d (Fe) C, wt% C 1148°C T(°C) a ferrite 727°C Eutectoid: Equil. Cooling: Ttransf. = 727ºC T Undercooling by Ttransf. < 727C 0.76 0.022

- 18. 18 Rate of Phase Transformation Avrami equation => y = 1- exp (-ktn) transformation complete log t Fractiontransformed,y Fixed T fraction transformed time 0.5 By convention rate = 1 / t0.5 Fraction transformed depends on time maximum rate reached – now amount unconverted decreases so rate slows t0.5 rate increases as surface area increases & nuclei grow Avrami relationship - the rate is defined as the inverse of the time to complete half of the transformation. This describes most solid-state transformations that involve diffusion.

- 19. • In general, rate increases as T r = 1/t0.5 = A e -Q/RT – R = gas constant – T = temperature (K) – A = ‘preexponential’ rate factor – Q = activation energy • r is often small so equilibrium is not possible. Arrhenius expression Adapted from Fig. 10.11, Callister 7e. (Fig. 10.11 adapted from B.F. Decker and D. Harker, "Recrystallization in Rolled Copper", Trans AIME, 188, 1950, p. 888.) 135C 119C 113C 102C 88C 43C 1 10 102 104 Temperature Dependence of Transformation Rate

- 20. Generation of Isothermal Transformation Diagrams • The Fe-Fe3C system, for Co = 0.76 wt% C • A transformation temperature of 675°C. 100 50 0 1 102 104 T = 675°C %transformed time (s) 400 500 600 700 1 10 102 103 104 105 Austenite (stable) TE (727C)Austenite (unstable) Pearlite T(°C) time (s) isothermal transformation at 675°C Consider:

- 21. Coarse pearlite formed at higher temperatures – relatively soft Fine pearlite formed at lower temperatures – relatively hard • Transformation of austenite to pearlite: ga a a a a a pearlite growth direction Austenite (g) grain boundary cementite (Fe3C) Ferrite (a) g • For this transformation, rate increases with ( T) [Teutectoid – T ]. 675°C (T smaller) 0 50 %pearlite 600°C (T larger) 650°C 100 Diffusion of C during transformation a a g g a Carbon diffusion Eutectoid Transformation Rate ~ T

- 22. Isothermal Transformation Diagrams 2 solid curves are plotted: one represents the time required at each temperature for the start of the transformation; the other is for transformation completion. The dashed curve corresponds to 50% completion. The austenite to pearlite transformation will occur only if the alloy is supercooled to below the eutectoid temperature (727˚C). Time for process to complete depends on the temperature.

- 23. • Eutectoid iron-carbon alloy; composition, Co = 0.76 wt% C • Begin at T > 727˚C • Rapidly cool to 625˚C and hold isothermally. Isothermal Transformation Diagram Austenite-to-Pearlite

- 24. Transformations Involving Noneutectoid Compositions Hypereutectoid composition – proeutectoid cementite Consider C0 = 1.13 wt% C Fe3C(cementite) 1600 1400 1200 1000 800 600 400 0 1 2 3 4 5 6 6.7 L g (austenite) g+L g +Fe3C a+Fe3C L+Fe3C d (Fe) C, wt%C T(°C) 727°C T 0.76 0.022 1.13

- 25. 25 Transformations Involving Noneutectoid Compositions Hypereutectoid composition – proeutectoid cementite Consider C0 = 1.13 wt% C a TE (727°C) T(°C) time (s) A A A + C P 1 10 102 103 104 500 700 900 600 800 A + P Adapted from Fig. 11.16, Callister & Rethwisch 3e. Adapted from Fig. 10.28, Callister & Rethwisch 3e. Fe3C(cementite) 1600 1400 1200 1000 800 600 400 0 1 2 3 4 5 6 6.7 L g (austenite) g+L g +Fe3C a+Fe3C L+Fe3C d (Fe) C, wt%C T(°C) 727°C T 0.76 0.022 1.13

- 27. Strength Ductility Martensite T Martensite bainite fine pearlite coarse pearlite spheroidite General Trends Possible Transformations

- 28. Coarse pearlite (high diffusion rate) and (b) fine pearlite - Smaller T: colonies are larger - Larger T: colonies are smaller

- 29. 10 103 105 time (s) 10-1 400 600 800 T(°C) Austenite (stable) 200 P B TEA A Bainite: Non-Equil Transformation Products elongated Fe3C particles in a-ferrite matrix diffusion controlled a lathes (strips) with long rods of Fe3C 100% bainite 100% pearlite Martensite Cementite Ferrite

- 30. Bainite Microstructure • Bainite consists of acicular (needle-like) ferrite with very small cementite particles dispersed throughout. • The carbon content is typically greater than 0.1%. • Bainite transforms to iron and cementite with sufficient time and temperature (considered semi-stable below 150°C).

- 31. 10 Fe3C particles within an a-ferrite matrix diffusion dependent heat bainite or pearlite at temperature just below eutectoid for long times driving force – reduction of a-ferrite/Fe3C interfacial area Spheroidite: Nonequilibrium Transformation

- 32. Pearlitic Steel partially transformed to Spheroidite

- 33. single phase body centered tetragonal (BCT) crystal structure BCT if C0 > 0.15 wt% C Diffusionless transformation BCT few slip planes hard, brittle % transformation depends only on T of rapid cooling Martensite Formation • Isothermal Transformation Diagram 10 103 105 time (s)10-1 400 600 800 T(°C) Austenite (stable) 200 P B TEA A M + A M + A M + A 0% 50% 90% Martensite needles Austenite

- 34. An micrograph of austenite that was polished flat and then allowed to transform into martensite. The different colors indicate the displacements caused when martensite forms.

- 35. Martensite The martensitic transformation occurs without composition change The transformation occurs by shear without need for diffusion The atomic movements required are only a fraction of the interatomic spacing The amount of martensite formed is a function of the temperature to which the sample is quenched and not of time Hardness of martensite is a function of the carbon content → but high hardness steel is very brittle as martensite is brittle Steel is reheated to increase its ductility → this process is called TEMPERING

- 36. Isothermal Transformation Diagram Iron-carbon alloy with eutectoid composition. A: Austenite P: Pearlite B: Bainite M: Martensite

- 37. Example 11.2: Iron-carbon alloy with eutectoid composition. Specify the nature of the final microstructure (% bainite, martensite, pearlite etc) for the alloy that is subjected to the following time–temperature treatments: Alloy begins at 760˚C and has been held long enough to achieve a complete and homogeneous austenitic structure. Treatment (a) Rapidly cool to 350 ˚C Hold for 104 seconds Quench to room temperature Bainite, 100%

- 38. Martensite, 100% Example 11.2: Iron-carbon alloy with eutectoid composition. Specify the nature of the final microstructure (% bainite, martensite, pearlite etc) for the alloy that is subjected to the following time–temperature treatments: Alloy begins at 760˚C and has been held long enough to achieve a complete and homogeneous austenitic structure. Treatment (b) Rapidly cool to 250 ˚C Hold for 100 seconds Quench to room temperature Austenite, 100%

- 39. Bainite, 50% Example 11.2: Iron-carbon alloy with eutectoid composition. Specify the nature of the final microstructure (% bainite, martensite, pearlite etc) for the alloy that is subjected to the following time–temperature treatments: Alloy begins at 760˚C and has been held long enough to achieve a complete and homogeneous austenitic structure. Treatment (c) Rapidly cool to 650˚C Hold for 20 seconds Rapidly cool to 400˚C Hold for 103 seconds Quench to room temperature Austenite, 100% Almost 50% Pearlite, 50% Austenite Final: 50% Bainite, 50% Pearlite

- 40. class quiz (bonus) 1. Describe the microstructure present in a 1045 steel after each step in the following heat treatments: a) heat at 820°C, quench to 650°C and hold for 90s, and quench to 25°C; b) heat at 820°C, quench to 450°C and hold for 90s, and quench to 25°C; c) heat at 820°C, and quench to 25°C; d) heat at 820°C, quench to 680°C and hold for 100s, and quench to 25°C; e) heat at 820°C, quench to 720°C and hold for 100s, quench to 400°C and hold for 500 s, and quench to 25°C; f) heat at 820°C, quench to 720°C and hold for 100s, quench to 400°C and hold for 10 s, and quench to 25°C; and g) heat at 820°C, quench to 25°C, heat to 500°C and hold

- 42. ALLOY STEELS Various elements like Cr, Mn, Ni, W, Mo etc are added to plain carbon steels to create alloy steels The alloys elements move the nose of the TTT diagram to the right → this implies that a slower cooling rate can be employed to obtain martensite → increased HARDENABILITY The ‘C’curves for pearlite and bainite transformations overlap in the case of plain carbon steels → in alloy steels pearlite and bainite transformations can be represented by separate ‘C’curves

- 43. ROLE OF ALLOYING ELEMENTS • + Simplicity of heat treatment and lower cost • Low hardenability • Loss of hardness on tempering • Low corrosion and oxidation resistance • Low strength at high temperatures Plain Carbon Steel Element Added Solid solution • ↑ hardenability • Provide a fine distribution of alloy carbides during tempering • ↑ resistance to softening on tempering • ↑ corrosion and oxidation resistance • ↑ strength at high temperatures • Strengthen steels that cannot be quenched • Make easier to obtain the properties throughout a larger section • ↑ Elastic limit (no increase in toughness) Alloying elements • Alter temperature at which the transformation occurs • Alter solubility of C in a or g Iron • Alter the rate of various reactions Interstitial Substitutional

- 44. Austenite Pearlite Bainite Martensite 100 200 300 400 600 500 800 Ms Mf t → T→ TTT diagram for Ni-Cr-Mo low alloy steel ~1 min

- 45. Other elements (Cr, Ni, Mo, Si and W) may cause significant changes in the positions and shapes of the TTT curves: Change transition temperature; Shift the nose of the austenite-to- pearlite transformation to longer times; Shift the pearlite and bainite noses to longer times (decrease critical cooling rate); Form a separate bainite nose; Effect of Adding Other Elements 4340 Steel plain carbon steel nose Plain carbon steel: primary alloying element is carbon.

- 46. Continuous Cooling Transformation Diagrams Isothermal heat treatments are not the most practical due to rapidly cooling and constant maintenance at an elevated temperature. Most heat treatments for steels involve the continuous cooling of a specimen to room temperature. TTT diagram (dashed curve) is modified for a CCT diagram (solid curve). For continuous cooling, the time required for a reaction to begin and end is delayed. The isothermal curves are shifted to longer times and lower temperatures.

- 47. Moderately rapid and slow cooling curves are superimposed on a continuous cooling transformation diagram of a eutectoid iron-carbon alloy. The transformation starts after a time period corresponding to the intersection of the cooling curve with the beginning reaction curve and ends upon crossing the completion transformation curve. Normally bainite does not form when an alloy is continuously cooled to room temperature; austenite transforms to pearlite before bainite has become possible.

- 48. For continuous cooling of a steel alloy there exists a critical quenching rate that represents the minimum rate of quenching that will produce a totally martensitic structure. This curve will just miss the nose where pearlite transformation begins

- 49. Continuous cooling diagram for a 4340 steel alloy and several cooling curves superimposed. This demonstrates the dependence of the final microstructure on the transformations that occur during cooling. Alloying elements used to modify the critical cooling rate for martensite are chromium, nickel, molybdenum, manganese, silicon and tungsten.

- 50. Tempering Heat below Eutectoid temperature → wait→ slow cooling The microstructural changes which take place during tempering are very complex Time temperature cycle chosen to optimize strength and toughness Cementite ORF Ferrite BCC Martensite BCT Temper )(Ce)()(' 3 aa

- 51. Austenite Pearlite Pearlite + Bainite Bainite Martensite100 200 300 400 600 500 800 723 0.1 1 10 102 103 104 105 Eutectoid temperature Ms Mf t (s) → T→ a + Fe3C MARTEMPERING AUSTEMPERING To avoid residual stresses generated during quenching Austenized steel is quenched above Ms for homogenization of temperature across the sample The steel is then quenched and the entire sample transforms simultaneously Tempering follows To avoid residual stresses generated during quenching Austenized steel is quenched above Ms Held long enough for transformation to Bainite Martempering Austempering

- 52. % Carbon → Hardness(Rc)→ 20 40 60 0.2 0.4 0.6 Harness of Martensite as a function of Carbon content Properties of 0.8% C steel Constituent Hardness (Rc) Tensile strength (MN / m2) Coarse pearlite 16 710 Fine pearlite 30 990 Bainite 45 1470 Martensite 65 - Martensite tempered at 250 oC 55 1990

- 53. Examples • Unusual combinations of properties can be obtained by producing a steel with a microstructure containing 50% ferrite and 50% martensite. The martensite provides strength, and the ferrite provides ductility and toughness. Design a heat treatment to produce a dual phase steel in which the composition of the martensite is 0.60% C.

- 54. Mechanical Properties • Hardness • Brinell, Rockwell • Yield Strength • Tensile Strength • Ductility • % Elongation • Effect of Carbon Content

- 55. Mechanical Properties: Influence of Carbon Content C0 > 0.76 wt% C Hypereutectoid Pearlite (med) Cementite (hard) C0 < 0.76 wt% C Hypoeutectoid Pearlite (med) ferrite (soft)

- 56. Mechanical Properties: Fe-C System

- 57. Tempered martensite is less brittle than martensite; tempered at 594 °C. Tempering reduces internal stresses caused by quenching. The small particles are cementite; the matrix is a-ferrite. US Steel Corp. Tempered Martensite 4340 steel

- 58. Hardness as a function of carbon concentration for steels

- 59. Hardness versus tempering time for a water-quenched eutectoid plain carbon steel (1080) that has been rapidly quenched to form martensite. Rockwell C and Brinell Hardness

- 61. Precipitation Hardening • The strength and hardness of some metal alloys may be improved by the formation of extremely small, uniformly dispersed particles (precipitates) of a second phase within the original phase matrix. • Alloys that can be precipitation hardened or age hardened: Copper-beryllium (Cu-Be) Copper-tin (Cu-Sn) Magnesium-aluminum (Mg-Al) Aluminum-copper (Al-Cu) High-strength aluminum alloys

- 62. Criteria: Maximum solubility of 1 component in the other (M); Solubility limit that rapidly decreases with decrease in temperature (M→N). Process: Solution Heat Treatment – first heat treatment where all solute atoms are dissolved to form a single-phase solid solution. Heat to T0 and dissolve B phase. Rapidly quench to T1 Nonequilibrium state (a phase solid solution supersaturated with B atoms; alloy is soft, weak-no ppts). Phase Diagram for Precipitation Hardened Alloy

- 63. The supersaturated a solid solution is usually heated to an intermediate temperature T2 within the ab region (diffusion rates increase). The b precipitates (PPT) begin to form as finely dispersed particles. This process is referred to as aging. After aging at T2, the alloy is cooled to room temperature. Strength and hardness of the alloy depend on the ppt temperature (T2) and the aging time at this temperature. Precipitation Heat Treatment

- 64. Solution Heat Treatment • Heat treatable aluminum alloys gain strength from subjecting the material to a sequence of processing steps called solution heat treatment, quenching, and aging. • The primary goal is to create sub-micron sized particles in the aluminum matrix, called precipitates that in turn influence the material properties. • While simple in concept, the process variations required (depending on alloy, product form, desired final property combinations, etc.) make it sufficiently complex that heat treating has become a professional specialty. • The first step in the heat treatment process is solution heat treatment. The objective of this process step is to place the elements into solution that will eventually be called upon for precipitation hardening. • Developing solution heat treatment times and temperatures has typically involved extensive trial and error, partially due to the lack of accurate process models.

- 65. Aging-microstructure • The supersaturated solid solution is unstable and if, left alone, the excess q will precipitate out of the a phase. This process is called aging. • Types of aging: –Natural aging process occurs at room temperature –Artificial aging If solution heat treated, requires heating to speed up the precipitation

- 66. Overaging • After solution heat treatment the material is ductile, since no precipitation has occurred. Therefore, it may be worked easily. • After a time the solute material precipitates and hardening develops. • As the composition reaches its saturated normal state, the material reaches its maximum hardness. • The precipitates, however, continue to grow. The fine precipitates disappear. They have grown larger, and as a result the tensile strength of the material decreases. This is called overaging.

- 67. Precipitation Heat Treatment PPT behavior is represented in the diagram: With increasing time, the hardness increases, reaching a maximum (peak), then decreasing in strength. The reduction in strength and hardness after long periods is overaging (continued particle growth). Small solute-enriched regions in a solid solution where the lattice is identical or somewhat perturbed from that of the solid solution are called Guinier-Preston zones. Guinier-Preston (GP) zones - Tiny clusters of atoms that precipitate from the matrix in the early stages of the age-hardening process.

- 68. Hardness vs. Time The hardness and tensile strength vary during aging and overaging.

- 69. • 2014 Al Alloy: • TS peak with precipitation time. • Increasing T accelerates process. Influence of Precipitation Heat Treatment on Tensile Strength (TS), %EL precipitation heat treat time tensilestrength(MPa) 200 300 400 100 1min 1h 1day 1mo 1yr 204°C 149°C • %EL reaches minimum with precipitation time. %EL(2insample) 10 20 30 0 1min 1h 1day 1mo 1yr 204°C 149°C precipitation heat treat time

- 70. Effects of Temperature Characteristics of a 2014 aluminum alloy (0.9 wt% Si, 4.4 wt% Cu, 0.8 wt% Mn, 0.5 wt% Mg) at 4 different aging temperatures.

- 71. Aluminum rivets Alloys that experience significant precipitation hardening at room temp, after short periods must be quenched to and stored under refrigerated conditions. Several aluminum alloys that are used for rivets exhibit this behavior. They are driven while still soft, then allowed to age harden at the normal room temperature.

- 72. Several stages in the formation of the equilibrium PPT (q) phase. (a) supersaturated a solid solution; (b) transition (q”) PPT phase; (c) equilibrium q phase within the a matrix phase.

- 73. 0 10 20 30 40 50 wt% Cu L a+La aq q q+L 300 400 500 600 700 (Al) T(°C) composition range available for precipitation hardening CuAl2 A Precipitation Hardening • Particles impede dislocation motion. • Ex: Al-Cu system • Procedure: -- Pt B: quench to room temp. (retain a solid solution) -- Pt C: reheat to nucleate small q particles within a phase. Temp. Time -- Pt A: solution heat treat (get a solid solution) Pt A (solution heat treat) B Pt B C Pt C (precipitate q) At room temperature the stable state of an aluminum-copper alloy is an aluminum-rich solid solution (α) and an intermetallic phase with a tetragonal crystal structure having nominal composition CuAl2 (θ).

- 74. 24 • Hard precipitates are difficult to shear. Ex: Ceramics in metals (SiC in Iron or Aluminum). • Result: y ~ 1 S PRECIPITATION STRENGTHENING

- 75. Aging • Aging either at room or moderately elevated temperature after the quenching process is used to produce the desired final product property combinations. • The underlying metallurgical phenomenon in the aging process is precipitation hardening. Due to the small size of the precipitate particles, early understanding was hampered by the lack of sufficiently powerful microscopes to actually see them. • With the availability of the transmission electron microscope (TEM) with nanometer-scale resolution, researchers were able to actually image many precipitate phases and build on this knowledge to develop improved aluminum alloy products.

- 76. Aluminum • Aluminum is light weight, but engineers want to improve the strength for high performance applications in automobiles and aerospace. • To improve strength, they use precipitation hardening. Age-hardening heat treatment phase diagram

- 77. Quenching • Quenching is the second step in the process. • Its purpose is to retain the dissolved alloying elements in solution for subsequent precipitation hardening. • Generally the more rapid the quench the better, from a properties standpoint, but this must be balanced against the concerns of part distortion and residual stress if the quench is non-uniform. Changes in Microstructure due to quenching