Guide line industrial attachment for textile students

•

5 gefällt mir•1,722 views

guide line for industrial attachment

Melden

Teilen

Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

Empfohlen

Weitere ähnliche Inhalte

Was ist angesagt?

Was ist angesagt? (20)

Fabric defects in woven and knitted fabric - hitesh choudhary

Fabric defects in woven and knitted fabric - hitesh choudhary

Study on Button hole Machine & Button attaching machine

Study on Button hole Machine & Button attaching machine

Andere mochten auch

Effect of stitch length on Lycra And Without Lycra plain Single jersey fabric...

Effect of stitch length on Lycra And Without Lycra plain Single jersey fabric...Md. Mazadul Hasan Shishir

inspection of grey & finished knit fabric in wet processingAn investigation on the inspection of grey & finished knit fabric in wet proc...

An investigation on the inspection of grey & finished knit fabric in wet proc...Md. Mazadul Hasan Shishir

Andere mochten auch (20)

Effect of stitch length on Lycra And Without Lycra plain Single jersey fabric...

Effect of stitch length on Lycra And Without Lycra plain Single jersey fabric...

An investigation on the inspection of grey & finished knit fabric in wet proc...

An investigation on the inspection of grey & finished knit fabric in wet proc...

Ähnlich wie Guide line industrial attachment for textile students

ROLE OF FACTORY MANAGER

ROLE OF HUMAN RESOURCE MANAGER

ROLE OF MERCHANDISER

ROLE OF AN INDUSTRIAL ENGINEER

ROLE OF PRODUCTION MANAGER

STRUCTURE AND FUNCTIONING OF MERCHANDISING

EXECUTION OF A GARMENT UNITManufacturing process of a shirt, roles of the managers, structure of merchan...

Manufacturing process of a shirt, roles of the managers, structure of merchan...Dhanushree Sivaprakasam

Ähnlich wie Guide line industrial attachment for textile students (20)

Manufacturing process of a shirt, roles of the managers, structure of merchan...

Manufacturing process of a shirt, roles of the managers, structure of merchan...

ID (201-230-801) Industrial Internship Presentation-4.pptx

ID (201-230-801) Industrial Internship Presentation-4.pptx

Mehr von Md. Mazadul Hasan Shishir

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of 65/35 In Using Two Bath Systemproject on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...Md. Mazadul Hasan Shishir

Mehr von Md. Mazadul Hasan Shishir (20)

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...

project on Application of Disperse & Reactive Dyes In a P/C Blended Fabric of...

PROJECT : REACTION MECHANISM OF REACTIVE DYES IN ON CELLULOSE FIBER.

PROJECT : REACTION MECHANISM OF REACTIVE DYES IN ON CELLULOSE FIBER.

Industrial attachment of Olio apparels ltd (envoy group)

Industrial attachment of Olio apparels ltd (envoy group)

Industrial attachment of divine group of industries limited (dgi).

Industrial attachment of divine group of industries limited (dgi).

Kürzlich hochgeladen

Call Girl Aurangabad Indira Call Now: 8617697112 Aurangabad Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Aurangabad Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Aurangabad understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

Welcome to the April edition of WIPAC Monthly, the magazine brought to you by Water Industry Process Automation & Control.

In this month's edition, along with the latest news from the industry we have articles on:

The use of artificial intelligence and self-service platforms to improve water sustainability

A feature article on measuring wastewater spills

An article on the National Underground Asset Register

Have a good month,

OliverWater Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024Water Industry Process Automation & Control

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Kürzlich hochgeladen (20)

Call for Papers - International Journal of Intelligent Systems and Applicatio...

Call for Papers - International Journal of Intelligent Systems and Applicatio...

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

Roadmap to Membership of RICS - Pathways and Routes

Roadmap to Membership of RICS - Pathways and Routes

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

Water Industry Process Automation & Control Monthly - April 2024

Water Industry Process Automation & Control Monthly - April 2024

chapter 5.pptx: drainage and irrigation engineering

chapter 5.pptx: drainage and irrigation engineering

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Guide line industrial attachment for textile students

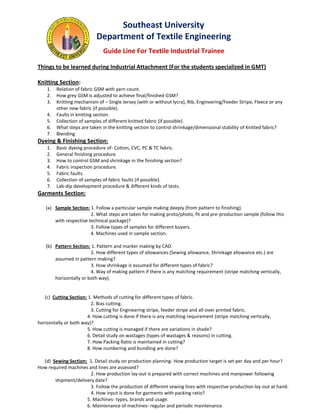

- 1. Southeast University Department of Textile Engineering Guide Line For Textile Industrial Trainee Things to be learned during Industrial Attachment (For the students specialized in GMT) Knitting Section: 1. Relation of fabric GSM with yarn count. 2. How grey GSM is adjusted to achieve final/finished GSM? 3. Knitting mechanism of – Single Jersey (with or without lycra), Rib, Engineering/Feeder Stripe, Fleece or any other new fabric (if possible). 4. Faults in knitting section. 5. Collection of samples of different knitted fabric (if possible). 6. What steps are taken in the knitting section to control shrinkage/dimensional stability of Knitted fabric? 7. Blending Dyeing & Finishing Section: 1. Basic dyeing procedure of- Cotton, CVC, PC & TC fabric. 2. General finishing procedure. 3. How to control GSM and shrinkage in the finishing section? 4. Fabric inspection procedure. 5. Fabric faults. 6. Collection of samples of fabric faults (if possible). 7. Lab-dip development procedure & different kinds of tests. Garments Section: (a) Sample Section: 1. Follow a particular sample making deeply (from pattern to finishing). 2. What steps are taken for making proto/photo, fit and pre-production sample (follow this with respective technical package)? 3. Follow types of samples for different buyers. 4. Machines used in sample section. (b) Pattern Section: 1. Pattern and marker making by CAD. 2. How different types of allowances (Sewing allowance, Shrinkage allowance etc.) are assumed in pattern making? 3. How shrinkage is assumed for different types of fabric? 4. Way of making pattern if there is any matching requirement (stripe matching vertically, horizontally or both way). (c) Cutting Section: 1. Methods of cutting for different types of fabric. 2. Bias cutting. 3. Cutting for Engineering stripe, feeder stripe and all-over printed fabric. 4. How cutting is done if there is any matching requirement (stripe matching vertically, horizontally or both way)? 5. How cutting is managed if there are variations in shade? 6. Detail study on wastages (types of wastages & reasons) in cutting. 7. How Packing Ratio is maintained in cutting? 8. How numbering and bundling are done? (d) Sewing Section: 1. Detail study on production planning- How production target is set per day and per hour? How required machines and lines are assessed? 2. How production lay-out is prepared with correct machines and manpower following shipment/delivery date? 3. Follow the production of different sewing lines with respective production lay-out at hand. 4. How input is done for garments with packing ratio? 5. Machines- types, brands and usage. 6. Maintenance of machines- regular and periodic maintenance.

- 2. 7. Causes of machines and equipments breakdown. 8. Folders and guides used in sewing machines. 9. Study a production report and compare it with target. Find reasons for not fulfilling the target. 10. Quality- detail study on sewing faults (reasons and remedies), in-line inspection, on-line inspection, how operators sewing quality is ensured? 11. Compare performance between lines and between floors. (e) Finishing Section: 1. How finishing target is set per day? Reasons for not fulfilling the target. 2. Follow- ironing, spot removing, attaching labels, tags or any other value adding items, folding, packing into poly and carton. 3. How packing is done for ratio packing as per size and color. 4. Follow type of assortment (Solid size solid color, solid size assorted color, assorted size solid color, assorted size assorted color) and how it is maintained? 5. Detail study on finishing faults (types, reasons & remedies). 6. Follow the items required to pass through metal/needle detecting machine. (f) Printing Section: 1. Types of prints are in practice normally and chemicals used for different types of printing. 2. How design is developed and screen is prepared for printing? 3. Study on printing faults (types, causes and remedies) 4. Assessment of price for different types of prints. 5. Collection of samples of different types of prints (if possible). (g) Embroidery Section: 1.Design development for embroidery. 2. Cost assessment of embroidery with number of stitches, number of colors and machine running time. 3. Threads used in embroidery-types, count and brand. 4. How to prepare appliqué in the embroidery? (h) Washing Section: 1. Types of washes-procedure and their effects. 2. How to follow wash standard? 4. How washing approval is taken from buyer? 3. Study on washing faults. 4. Assessment of cost for different types washes. (i) Merchandising Section: 1.Observe a technical package along with respective sample and swatch board deeply. 2. Analyze a costing sheet. 4. Follow different approvals taken from buyer by a merchandiser. 3. How a merchandiser keeps follow-up with production? 4. How fabric and different accessories booking are done by a merchandiser? 5. Observe different garments, accessories and fabric testing reports. 6. Follow how merchandisers keep communication with buyer and factory people, what problems they face and how they solve these. 7. Collect different fabric and accessories suppliers information from merchandising section. 8. Read different buyer’s manual (if possible). (j) Commercial Section: 1. See basic documents required for export and import such as L/C, commercial invoice, packing list, country of origin, GSP form, bill of entry, bill of exchange, exp form etc. (as much as possible) 2. How an imported good is released from port? What documents are necessary? 3. What documents are needed to be ready while exporting? 4. How C&F agent works? (k) Store : 1. How the store keeps record of fabric and accessories? 2. How quality and quantity of fabric and accessories are checked by store people? Miscellaneous: (a)Quality: 1.Follow pre-final and final inspection conducted by buyer’s QC (if possible). 2. What AQL is maintained during final inspection? (b)Work Study: What is work study? How it works? (c) Find out if any other new technologies and software are used by the factory to improve productivity and efficiency of work.