Hexachrommium VI.pptx

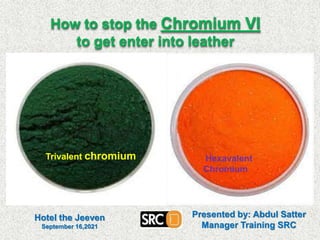

- 1. How to stop the Chromium VI to get enter into leather Hexavalent Chromium Trivalent chromium Presented by: Abdul Satter Manager Training SRC Hotel the Jeeven September 16,2021

- 2. 1. Need to understand Some basic terms. 2. Formation and Health Hazards of chromium VI 3. Recommendation for Chromium (VI) Avoidance. 4. Product available in market to inhibit the chrome VI in leather 5. Screening system for post-production / during shipment. 6. Testing procedures and protocols. AGENDA…………………….

- 3. FREE RADICAL Free radicals are short-lived, highly-reactive intermediate products which can develop through a reaction with oxygen. Free radicals can for example be fat residues in leather which has not been degreased carefully and which therefore triggers a chain of reaction which leads to an increasing number of free radicals. Free radical can promote the development of Chromium (VI). Free radicals can be caught through antioxidants and thus made harmless. Antioxidants are therefore known as radical catchers. BASIC TERMS……….

- 4. IODINE COUNT The iodine count is the measurement used to measure how unsaturated a compound is. Fats with high iodine counts contain a lot of double bonds. Fat liquors with iodine counts within a range of 5-20 are ideal. Fish oils have iodine counts of between 100 and 200. IODINE-STARCH PAPER TEST Test of the oxidative potential by using potassium iodine starch paper (oxidation agent test). The oxidative potential is indicated through blue discoloration of the test strip. BASIC TERMS……….

- 5. UV RADIATION The main source is the sun (Normal day light,) but also UV lamp and fluorescent tubes also emit UV rays. UV radiation is not visible and is high in energy. In leather UV rays can lead to formation of extremely reactive substances and free radicals, through which Chromium (VI) formation is promoted BASIC TERMS……….

- 6. Oxidation Gain of oxygen. Or loss of hydrogen /electrons during chemical reaction Reduction Loss of oxygen or gain of hydrogen / electrons. Latin word meaning "to lead back.“ Oxidizing Agent Takes electrons from that other substance or Gives oxygen to another substance i.e. An oxidizing agent oxidizes something else. Examples of oxidation/Reduction Reaction- fire, the rusting, the browning of fruit, and respiration and photosynthesis etc. BASIC TERMS……….

- 7. Antioxidant (Reducing agent) Removes oxygen from another substance i.e. An Reducing agent reduce something else Oxidation- a chemical reaction that can produce free radicals and chain reactions and Antioxidants are compounds that inhibit oxidation (Antioxidants are considered free radical scavengers/ catchers) Examples Vegetable tannins- commonly used in the leather industry (Mimosa, Quebracho, Sumac, Tara, valonea and chestnut) and Sugar,etc The results show that gallotannins within the hydrolysable tannins have taken the first places in ranking with superior antioxidant activities Based on sulfer and phosphonium – Sodium bisulfite and tetrakis- hydroxymethylphosphonium sulfate. BASIC TERMS……….

- 8. Basic chromium sulfate Preparation- Reduction of chromate salts with sulfur dioxide, sugar etc: Na2Cr2O7 + 3 SO2 + H2O → Cr2(SO4)3 + 2 NaOH. [Cr2(H2O)6(OH)4]SO4 (CAS#39380-78-4) BASIC TERMS……….

- 9. POSSIBLE SOURCES OF HEXAVALANT CHROMIUM Direct sources: Unreduced chromium present in the leather auxiliaries are the direct source of Cr (VI).e.g; Basic Chromium Sulfate (BCS) used as a main tanning agent Chrome syntan and chrome Alam syntan Certain class of metal complex dyes Inorganic pigments (Particularly in the case of pigments based on lead chromate) Indirect Sources: Apart from the direct sources many tools, substances, auxiliaries, chemicals and process parameters could contribute significantly to the conversion of trivalent chromium into hexavalent chromium. e.g; Exposure to direct sunlight or quick drying in heat chambers. Application of Ammonia or Ammonium bicarbonate prior to the dyeing process.

- 10. POSSIBLE SOURCES OF HEXAVALANT CHROMIUM Chromium III tanned leather can generate traces of Chromium VI when exposed to certain environmental conditions (heat, UV radiation, changes in pH) or in the presence of unsaturated organic compounds and oxidizing agents Heat and adhesives in shoe production promotes the formation of chromium VI. Leathers with a higher proportion of tannin chromium (III) are more prone to the formation of chromium (VI) than a leather with a lower chromium (III) content. There is evidence that the amount of free chromium is one important Parameter for the formation of Cr(VI) in leather Too low humidity during storage greatly accelerates the chromium VI formation. If stored for a long duration, the leather should be tested for chromium VI.

- 11. CHROMIUM VI FORMATION MECHANISM: Chromium-VI has sometime been detected in chrome tanned leathers and it is unexpected because chromium-VI is not stable in the presence of high proportion of organic matter at low pH. It is widely investigated & believed that auto oxidation of Cr -III to Cr-VI in leather is catalyzed by temperature and ultraviolet radiation during drying or intermediate drying process. In the presence of heat & UV radiations the atmospheric oxygen attacks the double bonds in various leather auxiliaries already used in crusting & dying process which results in formation of unstable and highly reactive peroxide molecules. These radicals further react with other double bonds and start a free radical chain reaction and this chain reaction provides a favorable environment in which chromium-III can easily be changed in to chromium -VI.

- 12. HEALTH HAZARDS OF CHROMIUM VI Chromium (VI) is known to cause various health effects. When it is a compound in leather products, it can cause allergic reactions, such as skin allergies, dermatitis and ulcerations. The most common way of human body penetration by the chromium compounds is through inhalation into the lungs. Hexavalent chromium causes lung cancer in humans.` Hexavalent chromium can irritate the nose, throat, and lungs. Repeated or prolonged exposure can damage the mucous membranes of the nasal passages and cause ulcers to form. Hexavalent chromium is very irritating to the skin. Prolonged contact can cause ulcers to form. Some workers develop an allergic sensitization to chromium. Hexavalent chromium is an eye irritant. Direct eye contact with chromic acid or chromate dusts can cause permanent eye damage. Weakened immune systems, Kidney and liver damage, Alteration of genetic material. Death

- 13. Specification/Label Application Limit EN 420:1998 Standard Leather Protective Gloves 2mg/Kg European Eco-label Footwear 10 mg/Kg Toxproof (TUV-Rheinlan) label Textiles, Leather Undetectable Oko-tex 100 Label (Detection level:0.5 mg/kg) Textiles, Leather Undetectable SG Label Textiles, Leather, Paper, Wood Undetectable LGR Label Leather Undetectable EUROPEAN ECO-LABEL FOR FOOTWEAR. VARIOUS LIMIT LEVELS PRESCRIBED BY DIFFERENT INSTITUTIONS ARE PRESENTED HERE UNDER.

- 14. Check the pH values during the individual process steps Liming & De-liming Reduce the excessive use of ammonia and ammonium salts. Wash the limed hides carefully after liming and de-liming. Avoid products with oxidative potential, e.g. peroxide, permanganate or perborate. If using these products, check the oxidative potential with iodine-starch paper and if necessary, reduce the oxidation agent using a reducing agent prior to the addition of chromium Degreasing Degreasing is of utmost importance for the oxidation behavior of leather. Remove natural grease, which otherwise oxidize generating reactive peroxide lipids and eventually Cr(VI). Carefully degrease the raw skins/raw hides Use aqueous degreasing agents (Based on Fatty Alcohol)and ensure sufficient removal of the naturally occurring residual fat, which possesses an oxidative potential The fattier sheep leather are more susceptible than cowhide. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE:

- 15. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Tanning Chromium (VI)-free agents—Use Cr(VI) free tanning Agents and chemicals, tested for Cr(VI) and procured from a reputable supplier. Bleaching agents - Avoid or reduce the bleaching agents used prior to the tanning process and never use bleaching agents after tanning. Basification-Ensure as complete a fixation of the Chrome tanning agent as possible pH Values- Carefully check the pH values during the individual process steps Check the pH value of the Chrome tanning liquor if it is to be re-used; this should lie below pH 4. Recycled Chrome tanning agents - Do not use self-recycled Chrome tanning agents without prior inspection for Chromium (VI) (e.g. EN ISO 19071) Only use recycled Chrome tanning agents from preparation companies who are able to guarantee that their products are free of Chromium (VI

- 16. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Re-chromming Avoiding Cr-retannage reduces the risk of Cr(VI) formation. Since this is in many cases not possible. Wash the wet-blue carefully after re-chroming to remove excess of free Cr(VI). Neutralization Neutralizing agents—Use neutralizing auxiliaries (Neutralizing /Dispersing syntans )with reduction capability in neutralization and wetting back of crusts. Use Neutralizing Syntans to avoid over-neutralization and give at the same time a good homogeneity of the pH in the cross-section of the leather. Avoid chemicals containing ammonia during neutralizing. pH Values- Higher the pH in neutralization, the higher will be the risk of Cr(VI) formation in the finished leather. Neutralize leather materials to the lowest possible pH value and avoid pH peaks (Maintain pH below 6.5) during neutralization Washing - Avoid the accumulation of free chromium on leather surface by washing after the neutralizing.

- 17. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Colorants –Dyes & Pigments Do not use pigments or dyes that contain chromium if possible as chromium- based colorants and/or chromium-based after-treatments may cause these materials to exceed established Cr (VI) limits. Chromium-based colorants available in the market should be carefully checked to ensure compliance. Use dispersing Syntans during purging and dying Instead of Ammonia or ammonia containing chemicals. Re-Tanning Vegetable tanning agents specially Tara and Sodium thiosulfate (HYPO)works like sun block and protect the leather to react with heat and UV radiation during exposure to sun. Add antioxidant chemicals in the re-tanning process (e.g., Use 1-4% vegetable tannins) to provide additional protection against oxidation.

- 18. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Fat liquoring The influence of free fatty acids in fat liquors cannot be ignored so never use fat liquors with a high proportion of unsaturated fatty acids, such as fish , animal or vegetable oils -sulfonated and sulfited fish oils and others like natural and blended oils having free fatty acids more than 10% Use fat liquors with oxidation protection, synthetic fat liquors and/or softening polymers from certified manufacturers. Use fat liquors that are oxidation-stable. Fixing Finish the wet process (Crusting) and ensure Final fixing thoroughly by Formic acid at pH 3.5~4.0 by running more. Reducing agents—Use reducing agents such as sodium bisulfite, Sodium thiosulphate, Sodium meta-bisulfite may be used in the final washing of leather. Oxidizing agents—Use Do not use aggressive bleaches; Peroxides and Potassium permanganate (KMnO4) as bleaching agents after tanning. The pH value of the crust should lie below pH 5, ideally at pH 3.5-4 Such treatments may alter the shade and color intensity of the leather and hence accordingly the process of dyeing needs to be re-standardized

- 19. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Supplemental washing Where feasible, carry out an Batch washing with emulsifier during /after process to wash out any free Chrome & natural fats in leather. Ageing Ageing (piling) plays an important role in process as more time is required to complete the reaction while water is being removed from leather. Perform mechanical operation on leather only after conditioning with water (Moisture level 14-17%). Mold formation Avoid the formation of mold over the entire process. Preserve wet blues and dyed leather with sufficient amounts of biocidal agents that have been certified for the purpose

- 20. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Final Finishing /Finish Use suitable chemicals from certified manufacturers from safe sources Do not use finishing agents with alkaline adhesive coatings Do not use dyes and pigments that contain Chromium Use suitable finishing products (e.g. colors and coatings) which ideally feature anti-oxidation properties. Avoid excessively high temperatures during final finishing Preservation during Storage & transportations in finished goods Avoid storage and transport of leathers in air polluted heavily with oxidizing gases like ozone, nitrogen oxides and sulfur oxides. During transport, manufacture and use of leather items, avoid prolonged exposure to low humidity, high temperatures and direct sunlight. Avoid heating chrome-tanned leather to apply prints or set adhesives. Check the leather for Chromium (VI) contamination after prolonged storage Post-production checks—after prolonged periods of storage, check leather for post-production formation of chromium (VI).

- 21. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Screening Risks of chromium VI in the whole life cycle of a leather product must be closely monitored. Water-repellent leather, leather in darker shades and vegetable re-tanned leather are less likely to result in formation of chromium VI, compared to split leather or bright leather. Perform risk-based checks of your suppliers’ materials via testing from third-party lab to ensure the Cr(VI) limits are not exceeded. Every fail report with values falling into 3-5 mg/kg range, should be re- confirmed by a different third party Lab. Note: There is also an EU regulation that places an upper limit of 1 mg/kg for Cr(VI) in textile articles. Consider applying the ageing test to leather samples. This step will artificially age the leather in conditions that will drive Cr(VI) generation This will give some indication of how your leather goods will fare under oxidative conditions.

- 22. RECOMMENDATION FOR CHROMIUM (VI) AVOIDANCE: Sourcing Require suppliers to submit a confirmation of material compliance or a test report from a third-party laboratory that is experienced in analyzing the specific matrix.

- 23. Evolite S-87 Composition: Fatty Alcohol Ethoxylate Appearance: Colorless To Slightly Yellowish Transparent Liquid Concentration: Active =75% ±1 pH: 7 ± 1 Properties: Environment Friendly, Highly Effective Degreasing, Excellent Dispersing of Natural Fats with Low Fogging value, Compatible with acid, alkali, electrolytes and polyvalent cations Washing ability for Fur Skins. Recommendations: highly effective emulsifying & Degreasing system with an all-purpose field of application.

- 24. Resolan UF Composition: Fatty Alcohol Ethoxylated Appearance: Opaque Thick Paste Concentration: pH: 8 ± 1 Properties: High degreasing power High concentration, Provides clean and smooth grain, Prevents chrome soap formation in the wet blue and Compatible with electrolytes Recommendations: high efficiency degreasing agent for hides and pelts.

- 25. Resolite 1907 Composition: Synergistic mixture of surfactants & Organic nitrogen derivatives Appearance: Yellowish Transparent Thick Liquid Concentration: Solids: 45±1 pH: 9±1 Properties: soaking, liming, de-liming and degreasing agent It has a buffering effect against sudden swelling and good soaking results. Helps in good water absorption even without over milling during soaking, liming making the hair removing action more efficient and flattening the wrinkles giving a more relaxed and nice looking pelts Recommendations: soaking, liming, de-liming and degreasing agent

- 26. Resolite W Composition: Ethoxylated product Appearance: Pour able paste Concentration: Solids: 45±1 pH: 5.0 - 8.0 Properties: Very effective wetting & degreasing, Provide clean wool and grain, Biodegradable and Compatible with electrolytes. In bating and de-liming helps to disperse and dissolve the heavy soluble liming chemicals. Having good natural fat dispersing property. Gives fine, smooth grain and tight flanks. Recommendations: Effective wetting and degreasing agent.

- 27. RESOCROME A (with antioxidant property) Key Attributes RESOCROM A Basic chromium sulphate reduced with SO2 having Cr2O3 26 +0.5% with 33% basicity. RESOCROM A powders are readily soluble even in cold suitable to be used in powder form Thanks to excellent penetration and even distribution of RESOCROM powders gives full & bright wet blue, suitable for dark as well as pastel colors and white crust.

- 28. FORMECO AO (With antioxidant property) Key Advantages Tanning Process High in strength, 25% less consumption than Formic acid Regulates the pH during tanning without altering the strength Gives more smoothness to grain as these products maintain the polymer structure of leather during tanning. Thanks to their post process properties the wet blue shows excellent leveling during re-tanning and dying with more elastic, fine, round, smooth and tight grain with improved tensile and tear strength. FORMECO AO has excellent antioxidant properties minimize the risk of Chromium VI formation in leather during storage. Dying process Products gives more depth and uniformity to dyes due to their excellent Fixing property, Less acid retention after washing Health and Environmental Benefits Safe to handle and does not burn the skin Eco-Friendly product for leather processing Reduce the effluent treatment cost

- 29. ECOTAN CROM VI Antioxidant Composition : Derivative of Monosaccharides Appearance : Slightly Reddish Transparent Liquid Concentration: Active 12 ± 0.5% pH: 2-3 Compatible with acid and Alkali bath Free of organic solvents and phenolic derivatives, Suitable for wet end & Finishing application as it forms no film owning to its chemical nature 1. Recommended for Wet Blue, Crusting & Dyeing up to 0.5-1.5%. 2. Dilute the product with water and spray on flesh of leather. Quantity can be adjusted as per requirement. 3. Dry the leather, after drying; keep at room temperature for overnight to complete the reaction.

- 30. Quick test chromium VI content Study of rapid tests in 2016 Provide too many false results due to the complexity of the test materials and the objects to be scanned. Estimated future chemistry is partially highly corrosive; the durability of the DPC reagent is of very short duration; the study is carried out only on the surface of the leather which result in falsified results; dyes in leather can interfere with the visibility of the pink color (chromium VI) and the chemistry used can potentially destroy the material. This concludes that a quick test is not on a par with professional laboratory tests. RECOMMENDED TESTING PROCEDURES AND PROTOCOLS.

- 31. Limitation in test methods EN 17075 is the official test method for Cr-VI in leather. This method specifies “No Detection” of Cr-VI at the detection limit of 3 ppm. Some eco labels demand maximum 1 or 2 ppm Cr-VI using the same test method - but technically lower detection limits are not justified with this test method. Remedies for such sensitive limits and harmonization among various test houses A method developed by CLRI using Ion-Chromatography after membrane separation of colorants is gaining recognition with reproducibility and reliability at more than 95%. This method overcomes the shortcomings associated with the official test protocol with reference to both false positive and false negative results.

- 32. CHROMIUM (VI) CONTENT----- – Inspection for maintenance of the legal limit value: Chromium (VI) in leather is determined on a cut sample according to EN ISU 17075 standards after extraction. The direct determination of the Chromium (VI) content in the leather matrix is not currently possible. The quantity of the Chromium (VI) found in the extract is calculated back to the content in the leather. The verification limit of the procedure is 3mg/kg Chromium (VI) per kg leather. The conditions stipulated in the standard for the extraction must be adhered to strictly, otherwise there is a risk of a false-positive result. An extraction of composite samples for the determination of Chromium (VI) is not recommended, as it can lead to false results if one leather sample is contaminated with Chromium (VI), but the other features a reductive potential

- 33. CHROMIUM (VI) AGING…… – Inspection for the formation of Chromium (VI) during the leather aging process: Under laboratory conditions, thermal aging is simulated on the leather. To do this, the cut sample is stored according to the CADS methods at 80°C and with relative air humidity of up to 5% for 24h in a drying cabinet without ventilation, air circulation or any openings to the outside. Subsequently, the Chromium (VI) determination according to the EN ISO 17075 standards takes place as described above

- 34. CHROMIUM SOLUBLE – Inspection as to whether a leather sample releases larger quantities of soluble Chromium under wearing conditions: Chromium soluble is mainly tested on leather samples which may come into contact with the skin during the intended application of the respective leather product. In this test approach, wearing conditions are simulated which provide information on the possible Chromium release under realistic conditions. The determination takes place according to EN ISO 17072-1 after extraction of the leather with an acidic perspiration solution at 37°C.

- 35. TOTAL CHROMIUM CONTENT – Inspection of whether leather has been chromium tanned or has been through a chromium-free tanning process: For the measurement, the leather is completely dissolved according to EN ISO 17072-2 or 5398 Part 1-4 (total disintegration process). The total chromium content of chromium is a piece of leather. Based on this data, conclusions can be drawn concerning the tanning method used. In case of a total Chromium content of below 1000mg/kg, the leather is classified as chromium-free tanned leather according to EN 15987.

- 36. If any query Please contact our office…………… SRC Pvt. Ltd. SIALKOT OFFICE Shop No 12-13 Chaudhary Plaza Haji Pura Road Sialkot OFFICE: (052)3558842 E-Mail: Sialkot @src.com.pk Contact Persons: Mr Hafiz Badar (0300-8471262) Mr Tahir Munir (0301-8406155) Mr Haseeb Zahid (0322-5707322)