Weitere ähnliche Inhalte

Ähnlich wie Web site msa presentation gauge error (20)

Kürzlich hochgeladen (20)

Web site msa presentation gauge error

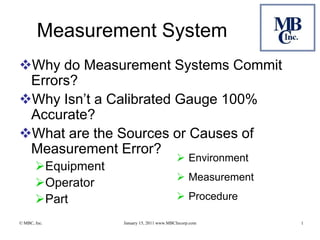

- 1. Measurement System

Why do Measurement Systems Commit

Errors?

Why Isn’t a Calibrated Gauge 100%

Accurate?

What are the Sources or Causes of

Measurement Error?

Environment

Equipment

Measurement

Operator

Part Procedure

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 1

- 2. Measurement System

Equipment

The Equipment i.e. Gauge has design limitations!

The Gauge has display limitations!!

– Digital (Number of Digits Displayed)

The Gauge has Interpretation Limitations!!!

– Dial Read-Out

– Micrometer

– Any Linier Scale

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 2

- 3. Equipment

LSL USL

0.994

0.995 1.000 1.005

|X| XX |X|

0.996 0.998

0.997 0.999

•When the part’s actual size is different than the gauge’s display

capability. The gauge reports the closest available value. For

these two parts the gauge would report both as 0.998.

•When the actual size is directly between two values the gauge will

report either of the two available values. In this case the gauge would

report either 0.999 or 1.000, or alternate between these two values.

•This means a “Window-of-error” exists between each

available display value. The less repeatable the gauge

the larger the “Window-of-error”.

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 3

- 4. Operator

Following Proper Procedure to Obtain the

Measurement

Fixture Gauging

Part Cleaning

Location of Measurement

Manual Recording of the Result

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 4

- 5. Gauge Design & Within Part

Variation

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 5

- 9. Measurement Procedure or

Instruction

Well Defined

No Assumptions

Training

Adequate

Enforced

Enforcement

Apathy

Leadership Response

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 9

- 10. Trials K1 Appraisers K2 K1 = 0.5908

NQS 2

3

0.8862

0.5908

2

3

0.7071

0.5231

K2 = 0.5231

K3 = 0.3146

Part Number: 1233451 Gauge Name: Digital Caliper Date: 2/26/07

Characteristics: Diameter Guage Number: 123 Performed By:

Specification Upper: 1 Units mm Gauge Type: 6" WR Martin

Specification Lower: -1 Units mm

Appraisers = 3 Trials = 3 Parts = 10

From Data Sheet: R-double bar = 0.0034 X-bar diff =0.0016 Range p = 0.0091

% Total Variation (TV)

Measurement Unit Analysis (Preferred)

Repeatability -- Equipment Variation (EV) R&R = 5.15 Standard

EV = 0.001989 %EV = 55.79% Deviations of the

Reproducibility -- Appriaiser Variation (AV) Repeatability/Reproducibility

AV = 0.00073 %AV = 20.61% Error

Repeatability and Reproducibility (R & R)

This is Approximately Equal

R & R = 0.00212 Parts

2

K3

0.7071

%R&R = 59.47%

to – 99% Conf.

Part Variation (PV) 3 0.5231

4 0.4467

PV = 0.002866 5 0.4030 %PV = 80.39%

6 0.3742

7 0.3534

Total Variation (TV) 8 0.3375 Number of Distinct Categories (ndc)

9 0.3249

TV = 0.00357 10 0.3146 ndc = 1

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 10

- 11. Measurement Uncertainty

Window

0.995 1.000 1.005

{

0.996 |X |

0.997

0.998

0.999

A Given Part Measurement Result Is Displayed By The Gauge as 0.997”

Given That a Gauge has some Amount of “Error”. What is the “True

Value” of this Part?

GR&R Value = 1 Standard Deviations of the Measurement System

Error

Measured Value (X) +&- 2 Standard Deviations give approx 95%

Confidence of the Measurement Uncertainty Window

The True Value Falls within this Window – 95% of the time

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 11

- 12. Corrective Action

Study

MSA

Plan

What Do I Do Next?

What Information do I Need to Take the Next Step

Do

Make and Follow a Plan

Check

Verify Test Results

Action

Implement the Corrective Action(s) that are Approved

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 12

- 13. Problem Analysis

Operator Part Average Comparison

3 Operators - 3 Trials - 10 Parts

1.66

1.655

1.65

1.645

1.64

1.635

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

Appraiser A Appraiser B Appriaser C

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 13

- 14. Problem Analysis

Part Average Operator Overlay

3 Operators - 3 Trials - 10 Parts

1.66

1.655

1.65

Appraiser A

Appraiser B

Appraiser C

1.645

1.64

1.635

1 2 3 4 5 6 7 8 9 10

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 14

- 15. Problem Analysis

Range Data Operator Range Comparison

UCL Range 3 Operators - 3 Trials - 10 Parts

0.012

0.01

0.008

0.006

0.004

0.002

0

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

Appraiser A Appraiser B Appriaser C

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 15

- 16. Problem Analysis

Part Operator Range Overlay

3 Operators - 3 Trials - 10 Parts

0.012

0.01

0.008

Appraiser A

0.006 Appraiser B

Appraiser C

0.004

0.002

0

1 2 3 4 5 6 7 8 9 10

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 16

- 17. Problem Analysis

Part Comparison by Operator

3 Operators - 3 Trials - 10 Parts

1.665

1.66

1.655

1.65

Appraiser A

Appraiser B

Appraiser C

1.645

1.64

1.635

1.63

1

2

3

4

5

6

7

8

9

0

t1

rt

rt

rt

rt

rt

rt

rt

rt

rt

Pa

Pa

Pa

Pa

Pa

Pa

Pa

Pa

Pa

r

© MBC, Inc. January 15, 2011 www.MBCIncorp.com Pa 17

- 18. Improvement is

By Choice

Not by Chance?

Reliability

Measurement System

Improvement

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 18

- 19. Thank You

My Sincere Desire is that Everyone Benefits

from this Brief Presentation

Bill Martin – President

Martin Business Consulting, Inc.

www.MBCIncorp.com

Cell – 931-637-1446

E-mail – Bmartin@MBCIncorp.com

© MBC, Inc. January 15, 2011 www.MBCIncorp.com 19