Senior executive achieves sales growth

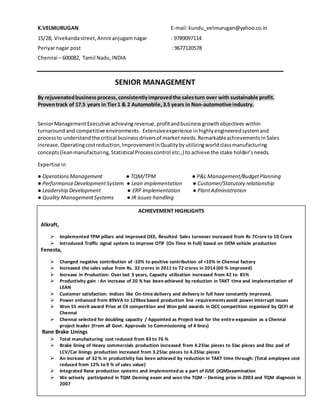

- 1. 1 K.VELMURUGAN E-mail:kundu_velmurugan@yahoo.co.in 15/28, Vivekandastreet,Annni anjugamnagar : 9789097114 Periyarnagar post : 9677120578 Chennai – 600082, Tamil Nadu, INDIA SENIOR MANAGEMENT By rejuvenatedbusinessprocess,consistentlyimprovedthe salesturn over with sustainable profit. Proventrack of 17.5 years in Tier1 & 2 Automobile,3.5 years in Non-automotive industry. SeniorManagement Executive achievingrevenue,profitandbusinessgrowthobjectives within turnaround and competitive environments. Extensiveexperience inhighlyengineeredsystemand processto understand the critical businessdriversof marketneeds.Remarkableachievementsin Sales increase, Operatingcostreduction,ImprovementinQualitybyutilizingworldclassmanufacturing concepts(leanmanufacturing,Statistical Processcontrol etc.,) to achieve the stake holder’s needs. Expertise in ● OperationsManagement ● TQM/TPM ● P&L Management/BudgetPlanning ● PerformanceDevelopmentSystem ● Lean implementation ● Customer/Statutory relationship ● Leadership Development ● ERP implementation ● PlantAdministration ● Quality ManagementSystems ● IR issues handling ACHIEVEMENT HIGHLIGHTS Alkraft, Implemented TPM pillars and improved OEE, Resulted Sales turnover increased from Rs 7Crore to 10 Crore Introduced Traffic signal system to improve OTIF (On Time In Full) based on OEM vehicle production Fenesta, Changed negative contribution of -10% to positive contribution of +10% in Chennai factory Increased the sales value from Rs. 32 crores in 2011 to 72 crores in 2014 (60 % improved) Increase in Production: Over last 3 years, Capacity utilization increased from 42 to 85% Productivity gain : An increase of 20 % has been achieved by reduction in TAKT time and implementation of LEAN Customer satisfaction: Indices like On-time delivery and delivery in full have constantly improved. Power enhanced from 89kVA to 129kva based production line requirementsavoid power interrupt issues Won 5S merit award Prize at CII competition and Won gold awards in QCC competition organized by QCFI at Chennai Chennai selected for doubling capacity / Appointed as Project lead for the entire expansion as a Chennai project leader (From all Govt. Approvals to Commissioning of 4 lines) Rane Brake Linings Total manufacturing cost reduced from 83 to 76 % Brake lining of Heavy commercials production increased from 4.25lac pieces to 5lac pieces and Disc pad of LCV/Car linings production increased from 3.25lac pieces to 4.35lac pieces An increase of 32 % in productivity has been achieved by reduction in TAKT time through: (Total employee cost reduced from 12% to 9 % of sales value) Integrated Rane production systems and implemented as a part of JUSE (JQM)examination We actively participated in TQM Deming exam and won the TQM – Deming prize in 2003 and TQM diagnosis in 2007

- 2. 2 ALKRAFTThermaltechnologies PVTLTD,DGM–Operation, FromNov’14to Present Alkraft is a leading manufacture for Radiators, Intercooler and oil cooler in India and Exports with annual turnover of 135 Crore. Leading Team of 450+ operatives, 15 engineers( including 6 managers) Exposure inInjectionmoulding,Sheetmetal parts, SPMmachines,Welding(MIG/TIG) and Handling of Foundry and produced 2MT/Month(Gravity Die casting) Fenesta Building system (DCM Shiram pvt Ltd) AGM – Regional head operation From June’2011 to Nov’2014 Dedicated 3.5 years of progressive achievements, market leader in the UPVC window industry, Manufacture involves is complex with large use of CNC machines. Major processes include machining, welding, glazing & assembly. Operations Head has to integrate factory & field operations such that it runs as a single JIT supply chain and both outside & inside are lean. Multiple teams reporting to Operations Head include production (2 shifts), purchase, planning, logistics, commercial, surveyors,fitters & contractors. Overall business structure is a matrix with Function Heads & Business Head based at Gurgaon. PositionreportstoZonal Head – SouthINDIA & islargelyautonomous.FY13-14 Saleswas Rs. 160 Cr Span of Control: 300 Operatives, 20 Engineers(includes5managers..,) 2011-12 – seniormanager,Regional headoperation 2012-13 – Assistantgeneral manager,Regional headoperation. 2013-14 – Bestfactory headwithoutstandingaward Accomplishments Financials Quality improvement: In Process Rejection reduced from 2.1% to 0.6% and Re make window cost reduced from Rs 2 lac to 10k Inventory cost reduced from 32 days to 16 days Yield improved in Raw material usage optimization, resulting in annual saving of Rs. 30 Lac Reductioninannual logisticscostbyRs.12 Lac by groupingof consignmentswithmedium sizetrucks Adherence to the statutory norms like Excise, Customs formalities. To cater south region supplies within in one year (After closing of Bombay factory) New factory building /Inspector of factories approvals within time periods to coordination with respective consultant Operations Implemented Quality management system both inside the factory/Outside the factory(Installation and service) PlanningsystemimplementedbasedonthroughRRSconceptandhighleadtime procurementitems Improved customerservice levelfrom65% to95% byimplementingVisualRetail ordertrackingboard Improved Operator’s skills through structured training system implementation Motivate and encourage to solve the shop problems through QC circles by operator itself Recognition and award system introduced by monthly

- 3. 3 Rane Brake Linings Ltd., Manger – Manufacturing.(April 1995 to May 2011) 16.5 years of operations experiencein Rane BrakeLinings (Automotivegroup turn over$ 300 million in year2011) RaneBrake Linings – Leadersin Friction MaterialProductslike Brake linings,Brake pads, clutch linings etc.,businessrevenueof Rs. 100 crores in the Ambatturplant Span of Control: 380 + Operatives, 30Engineers(includes7module Leaders..,) 1995-1997 – Diplomatrainee 1997-1998 – Executive -Shiftsupervisor 2000-2003 –- SeniorExecutive,Moduleleader–Clutchfacing/Tool Room 2003 -2006- AssistantManager,Module leader–NonBarkingmodule (4 modules) 2006-2008 – DeputyManager, Head TQM/LPS,Head - NonBarkingmodule 2008- 2011- Manager, HeadTQM/LPS, Head - Head -Manufacturing(7Modules) Accomplishments (year 1995 to 2011) Operational Excellence Revamped operations through new integrated production system RBPS (Rane Brakes Production System - a combination of TPM and TPS under the shelter of TQM concepts) was projected and appreciated by JUSE during the Japan Quality Medal Examinations Improvement in productivity in brake lining production by implementing TPS and SMED. Brought down Non suggestors from 67 % to 5 % and QCC culture improved from 45% to 75%. By Continuous interaction, motivation to operators. Attained improvement in Schedule Adherence Index by proper utilization of SAP Proficiently achieved improvement in O.E.E from 40% to 60% in TPMModel machines. Reduction in rejection trends by introducing the SPC techniques and DOE level improvements. Operational Cost Annual save of Rs. 5.6 lac in Packing material by VE /Alternative development of suppliers Saving achievedRs 9.83 Lac/ annum by piece rate systems packing and In house drilling facility improvements Introduced energy saving system / Developed new design cutter / Production based consumption system, resulted in Rs 13 lacs/Annum ACADEMIA Completed PG Diploma finance in LIBA, chennai. 2008 MBA in Operations Management, IGNOU. 2006 Engineering graduate in BITS, Pilani 1994 Diploma in Mechanical Engineering in automobile Date of Birth: 19th May 1975 COUNTRIES VISITED: JAPAN Lean ManufacturingSystemtrainingthroughAOTS,SponsoredbyRane PROFESSIONAL & CIVIC AFFILIATIONS Life term member in QCFI, Chennai. Regards K.VELMURUGAN