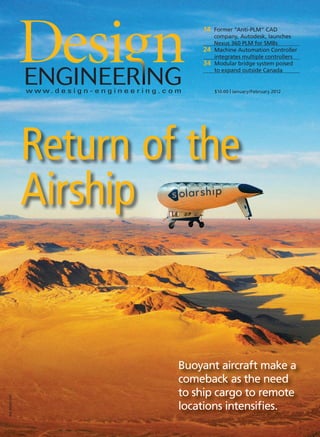

January/February 2012 | $10.00 | Return of the Airship

- 1. $10.00 | January/February 2012 PM40069240 Return of the Airship 14 Former “Anti-PLM” CAD company, Autodesk, launches Nexus 360 PLM for SMBs 24 Machine Automation Controller integrates multiple controllers 34 Modular bridge system poised to expand outside Canada Buoyant aircraft make a comeback as the need to ship cargo to remote locations intensifies. 1-DES.indd 1 12-02-13 7:49 AM

- 2. Solid Edge. Design better. The best product designers have an edge. Solid Edge 3D CAD Software Product designers have never been more important to the success of their companies. Creative, efficient designers are the key to delivering better products faster. Too often, however, CAD tools get in the way of their tal- ent—and the company’s success. Solid Edge with synchronous technology is different. It helps you create designs more intuitively. It helps you instantly revise any design, even complex designs from other CAD systems. And it’s built on our bulletproof Parasolid kernel – the industry-standard for reliable performance. Our new “Get the Edge” program shows how Solid Edge will help you reach your design potential—and help your company realize greater success. Learn more today at www.siemens.com/plm/gettheedge or call 800-807-2200. 2011siemens_SE_DE_OCT2011.indd 1 10/3/11 8:38:46 AM Hi Tr Lo M fo à DesignE 2-3-DES.indd 2 12-02-07 10:59 AM

- 3. :38:46 AM ® 976 Bergar Laval, Québec Canada H7L 5A1 © COPYRIGHT 2012 OMEGA ENGINEERING,INC.ALL RIGHTS RESERVED ® MD MD omega.ca Visit/Visitez omega.ca/px5500-i High Performance Pressure Instruments Instruments de pression haute performance Micro-Machined Silicon with High Temp. Performance For Industry, Automotive, Test, And Aerospace Applications Silicone micro-usiné Performance haute temp. pour l’industrie, l’automobile, les tests et l’aéronautique • High Accuracy ±0.08% BSL Includes Linearity, Hysteresis, and Repeatability • Broad Temperature Compensated Range -29 to 85°C (-20 to 185°F) PX409 Series Starts at $ 475• Grande précision ±0,08 % MLD incluant linéarité, hystérésis et répétitivité • Plage étendue de température compensée -29 à 85°C (-20 à 185°F) Visit/Visitez omega.ca/px409_series © Rainer Plendl/ Dreamstime.com High-Performance Pressure Transducer Ultra-High Long-Term Stability Manotransducteur haute pe formance Ultra haute stabilité à long terme PX5500 Series/Série Starts at Á partir de $695 All Stainless Steel Pressure Transducers High Performance Silicon Technology Manotransducteurs tout en inox avec technologie de silicium haute performance PX309 Series/Série Starts at Á partir de $175 Visit/Visitez omega.ca/px309 Miniature Industrial Compression Load Cell with Through-Body Mounting Holes Cellule de charge miniature industrielle à compression avec orifices de fixation directe LCGB Series/Série Starts at Á partir de $ 460 Visit/Visitez omega.ca/lcgb DesignEng_0112_Layout 1 1/25/12 9:21 AM Page 1 2-3-DES.indd 3 12-02-07 10:59 AM

- 4. SCHAEFFLER GROUP INDUSTRIAL The Straight Line on Linear Solutions Operational reliability begins with design. INA linear products from Schaeffler are designed with maximum load capacities across the range, as well as high rigidity and misalignment compensation within series designs. Patented lubrication and sealing technology ensures maintenance free operation, while continuous product innovation embraces linear solutions with increasingly longer and quieter service lives. Behind design is versatility and service. INA offers an extensive range of products backed by a comprehensive service center to quickly create and deliver highly customized linear assembly solutions. INA linear solutions from Schaeffler… the straight line to operational reliability. www.schaeffler-group.com Straight Line 10/24/07 12:06 PM Page 1 5-DES.indd 4 12-02-07 10:50 AM

- 5. IN THE NEWS ?? Tex to go here Tex to go here Tex to go here Tex to go here ?? Tex to go here Tex to go here Tex to go here Tex to go here ?? Tex to go here Tex to go here Tex to go here Tex to go here ?? Tex to go here Tex to go here Tex to go here Tex to go here ?? Tex to go here Tex to go here Tex to go here Tex to go here ?? Tex to go here Tex to go here Tex to go here Tex to go here ?? Tex to go here Tex to go here Tex to go here Tex to go here 5IN THE NEWS 8 Amphibious “tank” design validated by Autodesk 8 University of Waterloo names new dean of engineering 8 JMP Engineering opens new office 8 Digi-Key, Dynastream sign distribution agreement 10 Manufacture of 2012 Honda CR-V begins in Alliston, ON 10 Tricorder XPrize competition launched 10 DALSA sensors to guide Mars rover 12 Waterloo spin-off wins recognition for smarter alloy technology 12 Study suggests Canada less trade dependent than previously thought Annual Subscription Rate In Canada: $52.95 (1 year) $71.95 (2 year) Outside Canada: $99.95 (1 year) Single Copy In Canada: $10.00 Outside Canada: $22.00 Directory Rates In Canada: $27.00 Outside Canada: $45.00 Reader Service Contact Information ecallaghan@bizinfogroup.ca T: Toronto 416 442 5600 X 3538 Elsewhere -866-543-7888 Mail: Business Information Group Design Engineering Circulation Dept 80 Valleybrook Drive North York, ON M3B 2S9 Printed in Canada READER SERVICES Contents | Volume 58, No. 1 14 CAD Report Formerly the “Anti-PLM” CAD company, Autodesk launches Nexus 360 PLM for SMBs 20 HardWire Researchers leverage 3D mice and six degrees of freedom control for robot design and flight manipulation 26 Power Transmission Compact design envelope of Lunar project prototype relies on mini-slides 30 Idea Generator The latest in industrial products including motors, sensors, fluid power and motion 34 Canadian Innovator Modular bridge system, Make-A-Bridge, poised to expand outside Canada Columns 18 Will Additive Manufacturing Change Manufacturing? AM could very well become the most diverse, flexible and accessible manufacturing technology ever 22 Return of the Airship Long ignored buoyant aircraft are making a comeback as the need to ship cargo to remote locations intensifies 24 All-in-One Automation Omron’s Machine Automation Controller integrates multiple controllers while maintaining high performance Features 26 34 18 24 22 20 www.design-engineering.com January/February | 2012 5-DES.indd 5 12-02-07 10:50 AM

- 6. 6 EditorialViewpoint I enjoy hearing from you so please contact me at MMcLeod@design-engineering.com and your letter could be published in an upcoming issue. @ To say that the Canadian aerospace market is poised to “take off” in 2012 is not only a terrible cliche but a bit of an understatement. While most of the manufacturing sector continues suffer from the effects of the worldwide reces- sion, aerospace OEMs and their suppliers have pulled out of the dive of the last three years and are now hitting the afterburners. According to research from market analyst firm RNCOS, aerospace in Canada will experience a compound annual growth rate (CAGR) of 6.7 percent in 2012-2013, as the U.S economy strengthens. For those in the MRO space, the outlook is even better, as aerospace maintenance hubs such as Manitoba and Quebec are expected to see CAGR of 10 percent or better in coming years. Other forecasters are similarly optimistic. After declines in 2010 and little to no growth last year, Export Development Canada (EDC) Economics estimates exports of aircraft and parts will surge by 22 percent this year. Currently, the U.S. represents the biggest aerospace market, with estimated sales of US$ 215.2 Billion in 2009, and is Canada’s largest export destination. However, emerging markets like Brazil, Mexico, India and especially China may one day soon overtake it. Analysts anticipate China alone will buy more than 3,700 airplanes by 2028, worth an estimated US$390 Billion. In the here and now, though, Canada’s big aerospace players have already begun to benefit from the improving economic environment. For example, Quebec-based landing gear manufacturer, Heroux-Devtek, recently reported that its net profits, in the third quarter of its 2012 fiscal year, were 33.8 per cent higher than the $5.2 million it earned a year earlier. Similarly, flight simulator firm, CAE has landed several contracts in the last few months including more than $100 million worth from Canada’s Department of National Defence, Malaysia, the German Air Force and the Royal Air Force. In addition, it has signed $65-million worth of contracts to supply customers in Asia with five flight simulators. Not to be out done, Montreal-based Bombardier boasted at the end of 2011 that it will add between $10 and $16 billion in revenue to its current $18 billion. The company reports that production of its CSeries planes are fully booked in 2014 and 2015 and is two-thirds to capacity for 2016. This ramp up in activity translates to growing employment opportunities, particularly in Quebec, says Comité sectoriel de main‐d’œuvre en aérospatiale (CAMAQ), a Quebec-based non-profit industry organization. Its annual Employ- ment Census and Forecast survey conducted last fall found that 95 percent of the 215 survey respondents expect the coming year to be as good or better than 2011. More importantly, the survey found that 3,040 jobs were added in 2011 and another 3,642 positions will need to be filled in 2012, including engineers, machinists, assemblers and maintenance technicians. CouplingCAMAQ’ssurveyresultswiththeengineerdeficitprojectedbyEngineers Canada’s recent employment study, it looks like the industry’s high density centres like Montreal will be a safe place for engineers to land in 2012 and beyond. Mike McLeod Take-Off, Non? www.design-engineering.com Publisher Alan Macpherson (416) 510-6756 AMacPherson@design-engineering.com Group Editorial Director Lisa Wichmann (416) 510-5101 LWichmann@canadianmanufacturing.com Accounts Manager Laura Gergley (416) 510-5230 lgergley@design-engineering.com Editor Michael McLeod (416) 442-5600 ext. 3231 mmcleod@design-engineering.com Technical Field Editor Pat Jones, P. Eng. Art Director Kathy Smith (416) 442-5600 ext. 3215 KSmith@plant.ca Market Production Manager Jessica Jubb (416) 510-5194 jjubb@bizinfogroup.ca Circulation Manager Cindi Holder (416) 442-5600 ext. 3544 CHolder@bizinfogroup.ca BIG Magazines LP Executive Publisher Tim Dimopoulos Vice-President of Canadian Publishing, Alex Papanou President of Business Information Group, Bruce Creighton Publications Mail Agreement #40069240 ISSN number: 0011-9342 Privacy Notice: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Phone: 1-800-668-2374 Fax: 416-442-2191 E-mail: privacyofficer@businessinformationgroup.ca. Mail to: Privacy Officer, 80 Valleybrook Drive, North York, ON M3B 2S9 Subscriber Services: To subscribe, renew your subscription or to change your address or information contact us at 1-800-387-0273. Subscription Price: Canada: $52.95 for 1 year; $71.95 for 2 years; $10 for single copy. Outside Canada: $99.95 for 1 year; $22 for single copy. Directory/buyer’s guide: Canada $27; Outside Canada $45. Design Engineering, established in 1955, is published 6 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues. Published by BIG Magazines LP, a division of Glacier BIG Holdings Company Ltd. Tel: 416-442-5600, Fax: 416-510-5140 80 Valleybrook Dr., Toronto, ON M3B 2S9. Contents of this publication are protected by copyright and must not be reprinted in whole or in part without permission of the publisher. DE receives unsolicited features and materials (including letters to the editor) from time to time. DE, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such submissions in whole or in part in any form or medium whatsoever, without compensation of any sort. DE accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. DE is indexed in the Canadian Business Index by Micromedia Ltd., Toronto, and is available on-line in the Canadian Business Current Affairs Database. We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities. January/February | 2012 www.design-engineering.com 6-DES.indd 6 12-02-09 10:22 AM

- 7. Product Description AutomationDirect Price/Part Number JUST A FEW PRICES ON SAFETY DEVICES AutomationDirect prices are U.S. published prices as of March 2011. Prices subject to change without notice. Safety light curtain with 30mm resolution - 24VDC, sender and receiver pair (sold separately) 0.25 to 12 meter operating distance, 279mm protective height, safety category 4 Safety limit switch, pull-reset action, plunger actuator, 30mm plastic body, 1/2 NPT Safety relay module, single channel, for E-stop circuits, 24 VDC, 2 N.O. contacts $250.00 YBB-30S4-0250-G012 (sender) $12.75 AP2R11X11 $88.00 LG5924-02-61-24 $275.00YBB-30R4-0250-G012 (receiver) www.automationdirect.com/safety www.automationdirect.com 1-800-633-0405 Go online or call to get complete information, request your free catalog, or place an order. It could cost you a lot more in the long run. But you don’t need to overpay to get reliable, high-performance safety devices that conform to all the latest standards. Our prices on safety relays, switches and light curtains mean you can do even more to protect what’s important. Safety relays protect people and machines. • Single and dual channel safety relays for E-stop and safety gate applications • Two-hand Control units for positive protection • Light curtain controller modules are used in conjunction with light curtains for monitoring/control Safety light curtains in finger (14mm) or hand (30mm) protection resolutions • Protective height: 14mm resolution - 142 to 1045mm 30mm resolution - 279 to 1827mm • Operating distance: 14mm resolution - up to 3.5 mches 30mm resolution - up to 12 mches • Double PNP outputs • M12 quick-disconnect models (order cable separately) • IP65 rated; Type4and Category4PLe Don’t let price stand in the way of making a machine or process as safe as possible Safety switches with key or hinge interlocks, limit switches and cable pull switches give precise, quick action. • Visible operation • Immunity to electromagnetic disturbances • Electrically separated contacts with positive opening operation on N.C. contacts • Actuation speeds of 0.5 m/s (max) to 0.01 m/s (minimum) • IEC 947-5-1, EN 60947-5-1, UL 508, CSA C22.2 No 14 approvals 6-DES.indd 7 12-02-07 11:45 AM

- 8. 8 University of Waterloo names new dean of engineering The University of Waterloo has named professor, Pearl Sullivan P.Eng, C.Eng, as its new dean of engineering—the eighth in the university’s history and the first woman to hold that post. Currently the chair of the Department of Mechanical and Mechatronics Engineering at Waterloo, Sullivan will begin her five-year term on July 1, 2012. She takes over from Adel Sedra, an authority in microelectronic circuits, who has served two terms as dean and is retiring. Originally from Malaysia, but in Canada for nearly 30 years, Sullivan earned her PhD from the Department of Metals and Materials Engi- neering at the University of British Columbia. She is the founding director of Waterloo’s joint graduate program in nanotechnology within the faculties of engineering and science. www.uwaterloo.ca JMP Engineering opens new office Engineering, systems integrator and solutions provider JMP Engineering, Inc. has opened a new office in Dallas–Fort Worth, TX as part of its continued expansion plans across North America. Marc Goulet, a JMP manager and solution provider, will oversee the new office, along with Dan Foster, a professional with a background in automation and packaging. www.jmpeng.com Digi-Key, Dynastream sign distribu- tion agreement Electronic components distributor Digi-Key Cor- poration announced the addition of products from Dynastream Innovations. The company is an industry leader in wireless monitoring products, including the Dynastream ANT series, a wireless sensor network protocol and silicon solution for ultra-low power networking applications. With an installed base of over a million nodes, ANT is engineered for ultra-low power, low system cost, ease-of-use, scalability and flex- ibility that enables sensors to operate for up to three years on a coin cell battery. The ANT protocol handles peer-to-peer, star, tree and practical mesh topologies. www.digikey.ca Up Front Canadian amphibious “tank” design validated by Autodesk Simulation ARKTOS Developments Ltd. (ADL) —designer and manufacturer of an amphibious vehicle known as the ARKTOS Craft—is using simu- lation software from Autodesk to design its products to operate in the world’s most environmentally demanding locations. Originally designed as an amphibious evacuation craft for Arctic offshore oil facilities, the ARKTOS Craft can move from frigid -50°C (-122°F) temperatures, through burning flames, and back again, as in thecaseofevacuatingaburningoilrig.Additionally,theARKTOSCraft can navigate ice-rubble fields, ice ridges and open water—and can even climb up or down vertical steps. The company’s Craft is currently oper- ating in Alaska, China and the Caspian Sea in Kazakhstan. Delta, B.C.’s Valmont West Coast Engineering, which provides finite element analysis (FEA) services to ADL, was responsible for predicting vehicleperformanceinsevereenvironments.“WeusedAutodeskSimu- lation technology to predict critical stresses for the ARKTOS at extreme temperaturesandloadingconditions,”saidIoanGiosan,Ph.D.,P.Engat Valmont. “After finding an optimal design using FEA, we relied on physical testing and field use to validate the accuracy of our results.” ThekeytotheARKTOSCraft’smobilityisanarticulatedarmbetween the vessel’s two main compartments. As the Craft climbs up onto an ice shelf from the water, the hydraulics in that arm help push the Craft up out of the water so that the special track spikes can grab the ice. Using the multiphysics capabilities of Autodesk Simulation, Valmont was able to show ADL engineers how thermal stress caused by tem- perature extremes would combine with mechanical stress within the articulated arm between the units. Additionally, since the arm would see repeated compressive and tensile loading, Valmont also analyzed fatigue life using the Autodesk Simulation multiphysics tools. “We continue to modify the original ARKTOS design for each of our new customer’s unique needs,” said Bruce Seligman, president at ADL. “Autodesk software makes it easy for us to design new attachments for the craft, and then simulate how they will affect performance.” www.arktoscraft.com DesignNews January/February | 2012 www.design-engineering.com Pearl Sullivan B.C.-based ARKTOS Development’s amphibious craft. 8-13 DES.indd 8 12-02-07 10:33 AM

- 9. 513-521-4261 www.clippard.com Cincinnati, OH 888-WAINBEE Mississauga, Ontario 513 521 4261 miniature pneumatic and electronic control devices stainless steel cylinders • shuttle valves • push-quick fittings pushbutton actuators • acrylic subplates • manifolds • solenoid valves slip-on fittings • frls • brass cylinders • toggle valves • quick-connect fittings stem valves • hose • modular valves • 10 and 15 mm valves • pneumatic circuits tubing • brass valves • pressure sensors • flow controls • pressure gauges 8-13 DES.indd 9 12-02-07 10:33 AM

- 10. 10 DesignNews January/February | 2012 www.design-engineering.com (Left to Right) Nobuyuki Sanui, President, Honda of Canada Mfg. and Takashi Sekiguchi, President and CEO, Honda Canada Inc. Manufacture of 2012 Honda CR-V begins in Alliston, ON In January, production of the 2012 Honda CR-V officially began at Honda of Canada Mfg. in Alliston, ON. The addi- tion of the CR-V to HCM’s production lineup makes it the first Honda plant in North America to produce four distinct models (Civic, CR-V, MDX and ZDX) on one line. In November 2011, Honda celebrated 25 years of manu- facturing in Canada at its facilities in Alliston, Ontario. Since 1987, Honda has built close to 6 million vehicles and invested more than $2.6 billion in Canada. The company also purchases more than $1.1 billion in goods from Cana- dian suppliers per year, the company says. http://hondacanada.ca Tricorder XPrize competition launched At the 2012 Consumer Elec- tronics Show, the X PRIZE and Qualcomm Foundations announced the launch of the $10 million Qualcomm Tri- corder X PRIZE, a competi- tion to create a real world Star Trek’s medical Tricorder. According to the contest spon- sors, the goal spurs develop- ment of devices that allow consumers to make medical diagnoses independent of a healthcare provider. To score the $10 million top prize, the winning entry will be the mobile platform that most accurately diagnoses a set of 15 diseases across 30 consumers in three days. Teams must also deliver a compelling consumer experience while captur- ingreal-timehealthmeasurements—bloodpressure,respira- tory rate and temperature, etc.—so user can tell if they need professional help and provide “next step” advice. www.qualcommtricorderxprize.org DALSA sensors to guide Mars rover Teledyne DALSA announced that its NASA-designed, Tele- dyne DALSA-manufactured CCD sensors were used in Navcam and Hazcam cameras of the Curiosity Rover for navigation on the surface of Mars. The Rover will use 4 Navcam cameras and 8 Hazcam cameras. Mounted on a pan/tilt mast 2 meters above the ground, four Navcams black-and-white cameras will use visible light to gather panoramic, three-dimensional imagery. The navigation camera unit is a stereo pair of cameras, each with a 45-degree field of view that will support ground navigation planning. The rover’s eight Hazcams, mounted on the lower por- tion of the front and rear of the rover, will use visible light to capture three-dimensional imagery to safeguards against the rover getting lost or crashing into obstacles. The rover uses pairs of Hazcam images to map out the shape of the terrain as far as 3 meters in front of it and 4 meters wide. Teledyne DALSA’s semiconductor wafer foundry has supported NASA’s missions to Mars since 1997. www.teledynedalsa.com PyroGenesis awarded waste-to-energy contract PyroGenesis Canada Inc.—a Montreal-based company that makes plasma waste-to-energy systems and plasma torch products—announced that the U.S. Air Force 1st Special Operations Civil Engineering Squadron (1 SOCES) has signed an 18-month, $2.73 million contract. Under its terms, PyroGenesis will operate, maintain and collect operations data on its Plasma Resource Recov- ery System (PRRS) at the Air Force’s base in Hurlburt Field, Florida. PyroGenesis designed and manufactured the PRRS, which uses plasma to convert waste to energy and usable products. The system began operational testing at the Florida Air Force base late last year. www.pyrogenesis.com Qualcomm’s Tricorder XPrize promises $10 million to first to invent a real world Star Trek-like diagnostic tricorder. NASA’s Curiosity Rover incorporates CCD sensors manufactured by Teledyne-Dalsa in its four Navcam and eight Hazcam cameras. 8506-8-13 DES.indd 10 12-02-07 12:07 PM

- 11. 8506-24 RunWise 7.875x10.75.indd 1 1/20/12 2:13 PM8-13 DES.indd 11 12-02-07 10:33 AM

- 12. 12 IPT’s Multiple Memory Material technology “remembers” multiple shapes based on varying temperatures. Waterloo spin-off wins recognition for smarter alloy technology Waterloo University spinoff, Innovative Processing Tech- nologies (IPT), has been recognized for its Multiple Memory Material (MMM) technology. The company’s technology allows typical memory alloys, which change shape at a specific temperature, to memorize multiple shapes at different temperatures. IPT and a Waterloo Engineering team, led by professor Norman Zhou, have been awarded $130,000 by the Ontario Centres of Excellence (OCE) to develop prototypes for auto- motive applications. OCE also awarded, IPT’s co-founder and Waterloo mechanical engineering alumnus, Ibraheem Khan, a $50,000 one-year fellowship to help commercialize OCE-funded research. According to IPT, its memory material technology promises to enhance applications of shape memory alloys for micro electromechanical systems (MEMS), medical devices, valves, automotive applications, among others. Located in the Toronto-based MaRS Discovery District, IPT is currently working with a number of clients in the automotive and aerospace sectors. www.engineering.uwaterloo.ca Study suggests Canada less trade dependent than previously thought According to a Conference Board of Canada study, “Adding Value to Trade Measures: An Introduction to Value-Added Trade” Canada is less trade-dependent than previously thought; has a smaller trade relationship with the United States than commonly believed; and relies on the services sector for a much larger share of its trade. According to the study’s authors, conventional trade measures have not been adapted to gauge transactions accu- rately when more than one country is involved in the produc- tion of a single good. Instead, the Conference Board’s value-added analysis utilizes a methodology to estimate value-added in the context of trade. The first major outcome of the value-added trade method is to eliminate double counting, which occurs when inputs cross borders multiple times before becoming a finished product. The second is to allocate the value embedded in a traded product back to its source. For example, an exported car contains a variety of inputs including raw materials, engineering services and even electricity. Accordingtotheanalysis,Canadaislesstrade-dependent; itstrademixisdifferent;anditislessdependentontheUnited States,thanpreviouslythought.Forexample,usingvalue-added trade measures, Canada’s share of global trade falls from 3.1 percentto2.9percent;servicesaccountforabout40percent ofCanada’strade;andtheU.S.shareofCanada’soveralltrade falls from 69 per cent to less than 62 percent. www.conferenceboard.ca DesignNews January/February | 2012 www.design-engineering.com Baumer Inc. · 4046 Mainway Drive · Burlington · Ontario · L7M 4B9 Phone 905-335-8444 · sales.ca@baumer.com · www.baumer.ca Rugged, Accurate, Programmable Unparalleled Flexibility „ IP67 design withstands temperatures -40 to +100C „ Industry leading precision and shock handling „ Field programmable resolution and output voltage HS35 Motor Feedback Encoder 8-13 DES.indd 12 12-02-07 10:33 AM

- 13. Novotechnik U.S., Inc. • 155 Northboro Road • Southborough, MA 01772 • Tel: 508-485-2244 Fax: 508-485-2430 The RSM2800 Magnetic Encoder counts turns, measures angles down to the last degree, and remembers shaft positions without power Don’t try this with other encoders: imagine your machine with the RSM2800 inside both lose power and are still turning without power; when power is restored, the RSM2800 reports the correct position including the counts that occurred with no power! RSM2800 magnetic encoders provide the level of reliability and accuracy sought in demanding applications like: • Material Handling • Agricultural Machines • Forklifts • Cable Extension Transducers • Overhead Doors • Medical Equipment The RSM2800 is based on Novotechnik’s patented non-contact multi-turn for absolute 5,760° (16 turns) measurement. This new wear-free technology combines advanced capabilities with mechanical simplicity in a very compact and sturdy housing to provide for longer life and lower cost than optical encoders. Contact us for samples or for complete specs, visit www.novotechnik.com/rsm RSM2800 Specifications: Absolute multi-turn Up to 16 turns Up to 0.1° resolution Up to 0.1% independent linearity Outputs: 0.1 to 10V or 4 to 20 mA or 0.25 to 4.75V Housing OD=30 mm IP rating options: IP54 or IP67 No gears, no optics, no batteries I I I I I I I I I I I I I I I I 8-13 DES.indd 13 12-02-07 10:33 AM

- 14. January/February | 2012 www.design-engineering.com 14 Formerly the “Anti-PLM” CAD company, Autodesk launches Nexus 360 PLM for SMBs. By Ralph Grabowski When people stand around the office cooler, sharing horror stories of PLM implementations, one thinks of the old joke defining a yacht: A hole in the water into which you pour money. PLM has a similar patina, so software com- panies like Aras and Autodesk have developed systems to keep down the cost of implementing and operating PLM. PLM(productlifecyclemanagement)isacollectionofsoftware that promises to manage products from concept to CAD, to CAM, to distribution, and to disposal—“womb to tomb,” as some put it. PLM systems are sold generally to large corporations by other larger corporations. In the CAD world, this includes Dassault Systems who offers Enovia for PLM; Siemens PLM Systems (Teamcenter); and PTC (Windchill). There are some very large non-CAD software companies who also offer PLM, including Oracle (Agile) and SAP (ECC). For a CAD vendor, PLM can earn more in revenues than CAD, ironically. Indeed, when Siemens AG purchased UGS, it put “PLM” in the name, not ‘CAD,’ and when PTC relaunched Pro/E as Creo, it was in part acknowledging that it had let CAD development lag at the expense of PLM. This leaves Autodesk, the largest CAD vendor of all, with- out PLM. Company CEO Carl Bass had, in the past, boasted that Autodesk was the anti-PLM vendor. “We have less belief in the PLM market, and are happy to leave others to it,” he declared at a media event some years ago. In interviews I have held with Autodesk executives, they would insist that Vault was sufficient. Vault is Autodesk’s product data management (PDM) software, which runs on a server. It manages the data related to product designs, such as drawing and Word files. “PLM is different from data management,” executive VP of Manufac- turing Industry Group, Robert Kross told me five years ago. “We are looking at data management differently than all other CAD companies.” At the time, his group’s focus was on digital prototyping, and his plan was to store product data in Inventor files. Autodesk Embraces PLM CADReport 14-17-DES.indd 14 12-02-07 10:34 AM

- 15. www.design-engineering.com January/February | 2012 NSD TupH. A breakthrough in protection at the molecular level. At last it’s here. A cost-effective alternative to stainless steel for the harshest environments. NORD innovation busts the protection racket. NSD TupH, NORD’s new sealed surface conversion, is corrosion, chip and chemical resistant and highly cleanable. Utilized on NORD’s robust aluminum alloy housings, it establishes the required protection of your most demanding applications at a fraction of the cost you have been forced to pay for stainless steel. Welcome to NSD TupH, the better solution you have been asking for is here. Now, you can start saving big money on protection without compromise. Contact us today and find out how you can profit from NORD innovation. I n n o v a t I o n b e y o n d t h e o r d I n a r y 1.800.668.4378 www.nord.com NORDTupH. Surface protection reinvented! NORDTupH. Surface protection reinvented! harshest environments. NORD innovation busts the protection racket. NSD TupH, NORD’s new sealed surface conversion, is corrosion, chip and chemical resistant and highly cleanable. Utilized on NORD’s robust aluminum protection of your most demanding applications at a fraction of the cost you have been forced to Autodesk Does a 180 with 360 Then, a year ago, the anti-PLM tone changed. In an interview with the British DEVELOP3D webzine, Mr Bass admitted, “As the most outspoken critic of PLM, I have changed my mind in a couple of ways.” We didn’t know it at the time, but when the interview was being held, Autodesk had already been working on its PLM software for a year. After all its poo-pooing of traditional PLM, Autodesk had to make sure its PLM was different. It would be cheaper, run on Vault for managing data, make use of Buzzsaw for sharing data and require no customization. PLM customization means big bucksforconsultants,andsoAutodesk’splanistomakeavailable hundredsofspecializedmodulesthatuserscustomizethemselves. Autodesk spent the last year secretly acquiring a dozen small companies whose technologies are now modules in “Autodesk Nexus360forPLM”—thenameitchoseforitsnewPLMsystem. And it is a “system,” not a single software package. What Might Be In Nexus 360 The problem is that Nexus 360 isn’t available yet, and so I can report only what Autodesk says it will be—and what won’t be—in its marketing literature and through interviews with the media. Autodesk found that companies use PLM mostly for managing CAD, managing engineering change orders (ECO) and generating bills of mate- rials (BOM). But when implement- ing a PLM system, firms had to put up with costs from installing servers, backup units, deployments, software maintenance fees and the custom code required to tie everything together. This PLM implementation typically takes up to a half year to get running. Initially, Nexus 360 will consist of three products. Vault will continue its traditional role as server-based software that handles PDM, but adds hosting Nexus 360 modules. BuzzsawalsocontinuesinitstraditionalroleastheWeb-based portal for project collaboration, but its mandate will expand fromAECtoMCAD.Nexusisnew,andisthehomeformodules that manage business processes. The modules run in SaaS fash- ion (software as a service) on Amazon-hosted cloud servers. Cloud-based PLM is not a new concept. Ever since the Internet exploded in popularity in the late 1990s, companies like Arena Solutions have provided cloud-based PLM. The only thing that’s new is the term “cloud-based”. Previously, you This example of a home page for Nexus 360 assigns tasks. 15 14-17-DES.indd 15 12-02-07 10:34 AM

- 16. January/February | 2012 www.design-engineering.com 16 CADReport might have known the technology as SaaS, browser-based, plugin-free or on-demand. In your firm, Autodesk’s PLM would work like this: 1. You may already have Vault installed through software like Autodesk’s Inventor-based Factory Design and Product Design suites. An updated version hosts Nexus 360 modules. 2. You might already be using a Buzzsaw account to con- trol AEC projects through Web browsers. An update will host MCAD projects. 3.Nexus360will come with a few basic modulesthatrunon Autodesk’sCloud.Youstartwiththeseandthenaccessadditional ones to suit your company’s work flow. Some of the modules men- tioned include data entry forms, compliancemanagement,NPI(new product introduction), CAPA (cor- rective and preventive action) and FMEA (failure modes and effective analysis). 4. You still customize the system to make it work for your firm, doing it in-house with graphical tools. For security, your CAD data stays inside your corporate firewall. External access is done through Buzzsaw. Backups will be provided by Autodesk, says the company. Taking a page from Apple, Autodesk plans to make modules written by customers available through their Exchange online app store. However, the company has no plan for Android or iOS apps; the workaround is to access Nexus 360 through the Web browser running on your phone or tablet. Built on the Salesforce.com business model, Autodesk says it’ll price Nexus 360 in the range of $15 to $125 per-user per- month for all modules, whether your firm uses one or all. Nexus 360 is probably best suited for small firms. Large firms already have PLM imple- mented, and the way PLM reaches octopus-like into all areas of a company, existing systems are hard to extract. I don’t see Autodesk making replacement sales. Its appeal will be to people who want to implement PLM one con- firmed step at a time and will appeal primarily to firms using Autodesk software, rather than those using CAD from competitors. DE www.autodesk.com In Nexus 360, administrators will be able to build customized workflows graphically. 14-17-DES.indd 16 12-02-07 10:34 AM

- 17. Our Protogammi design aid is a cool hexa-kaleidocycle that shows the effect of materials on finishes. Visit www.protolabs.com/parts today and request your free Protogami! Enter code DE12B. GET YOUR PROTOGAMI! Call 877.479.3680 or visit www.protolabs.com ©2012 Proto Labs, Inc. ISO 9001:2008 Certified Realparts. Really fast. Check out our video design tips! Receive FirstQuote® interactive quote. Part ready for shipping. Part ready for shipping. Machining begins. Finalize confirmation, order with credit card. Computerized automated toolpaths sent to CNC Machine. Upload 3D CAD file. 1–15 Days 1–3 Days A product development team needs parts to meet its rapidly approaching deadline. Receive a ProtoQuote® interactive quote. Finalize quote and submit P.O. Mold design and milling. Receive order confirmation with gate and ejector layout. Approve. Part production. 1-10 parts 10-10,000+ parts How Many Parts? It’s easy to work with Proto Labs. Just upload your 3D CAD model and choose the best process for your project: CNC machining in 1–3 days or injection molding in 1–15 days. Real parts in real materials, in days—not weeks. And that’s the real story. 14-17-DES.indd 17 12-02-07 10:34 AM

- 18. January/February | 2012 www.design-engineering.com 18 AM could very well become the most diverse, flexible and accessible manufacturing technology ever. By Terry Wohlers Additive manufacturing (AM) was once viewed as a tech- nology used almost exclusively for making models, prototypes and patterns. Most people didn’t anticipate that it would one day be used for making end-use products or parts. Yet given what I am seeing, I believe AM will eventually have a greater breadth of impact on the production of prod- ucts than any manufacturing technology in recent history. Think this is an exaggeration? Consider the following: Aircraft parts: For years, Boeing has used AM, specifically laser sintering (LS), to produce highly complex environmen- tal control ducting for its military jets. Today, it is also produc- ing them for the 787 commercial aircraft. The plastic ducting has substantially reduced inventory, labor, assembly lines, weight, maintenance and mountains of certification paper- work. “More than 20,000 of them are currently flying without a single failure,” said Chris Glock of On Demand Manufactur- ing, a former Boeing company. Parts for UAVs: The development of parts for unmanned aerial vehicles (UAVs) has become a test bed for additive manufacturing. Companies are using the technology to cre- ate new wing designs with elaborate lattice structures, as well as other types of parts, because they are smaller and the regulatory requirements are not quite as difficult as they are with large-scale military and commercial aircraft. Specialty automobiles: Fifty AM parts were used in the Abruzzi car from Panoz Auto Development Co., initially for a photo shoot. The company found that many of the interior and exterior parts were good enough for the final prod- uct, so they used them in the entire production run of 81 cars. Nine of the AM parts were used in the instrument panel, while others were used in the center console and armrests. Most of the interior parts were covered in leather or another material. 928 Motorsports LLC, an after-market parts company, is using AM to manufacture intake runners for the Porsche 928, which went out of production in 1995. The company is manufactur- ing the part on demand in carbon-filled nylon 12 for the 900- hp engine. The nylon part weighs 1.4 kg (3.1 lbs) versus 3.6 kg (7.9 lb) for the aluminum version. Manufacturing tools: A number of manufacturing com- panies are using AM to make jigs, fixtures, alignment and drill guides, gauges and other manufacturing and assembly tools. Thogus Products, a custom injection molder located outside of Cleveland, OH, uses FDM from Stratasys extensively for these types of parts in its 76,000-sq-ft. manufacturing facility. According to Matt Hlavin, the company’s CEO, Tho- gus saves $150,000 a year in factory automation using FDM to build manufacturing tools. Orthopedic implants: An estimated 30,000 orthopedic implants have been produced by electron beam melting (EBM) worldwide,mostlyinEurope.About half have been implanted into patients.Afewofthetitaniumalloy (Ti-6Al-4V) implants are custom, but most are standard products, such as acetabular cups for hip joints.Orthopedicdevicemanufac- turers in Europe received CE certi- fication in 2007 and have been manufacturing artificial hips by EBM since then. The FDA gave the green light to manufacture certain orthopedic implant products by EBM in the U.S. in February 2011. Will Additive Manufacturing Change Manufacturing? RapidPrototyping Panoz Auto Development Co.’s Abruzzi incorporates numerous AM production parts in its instrument panel, arm rest and center console. BMW AG uses a Stratasys FDM system to create inexpensive and ergonomic assembly tools. (Image courtesy of Cimetrix Solutions.) 18-19-DES1.indd 18 12-02-07 10:36 AM

- 19. www.design-engineering.com January/February | 2012 19 Dental restorations: European dental labs are using pro- cesses, such as direct metal laser sintering (DMLS) from EOS, to produce copings for crowns and bridges. A coping is the main structure of a crown or bridge that is custom-made to fit the patient. Dental technicians typically coat the copings in porcelain to match the color of the patient’s teeth. These technicians can produce about eight to 10 crowns per day using traditional techniques. With a machine, such as an EOSINT M 280 from EOS, a dental lab can produce about 400 copings in 20 hours. Data for the copings must be prepared using special software by a skilled technician and the copings must be removed from the build plate and finished. Fashion products: Additive manufacturing is having an impact on the fashion industry. High-heeled shoes have been designed, manufactured, and worn by models. For example, the eye-catching Melonia Shoe, designed by Naim Josefi and Souzan Youssouf, were featured at the Stockholm Fashion Show in February 2010. Meanwhile, special clothing garments, even jackets and dresses, have been produced by laser sinter- ing and worn in fashion shows, such as a recent event in Paris. The examples discussed thus far are targeted at profes- sionals. A consumer market for products by additive manu- facturing is also developing. Some are high-end products that come with high-end prices, such as thousands of dollars. Other products can be purchased for under $100—even less than $10. Furniture: An example of a high-end consumer product is the beautiful Holy Ghost chair by designer Lionel Dean of Future Factories. The chair is impressive and can be yours for a mere $10,300 for the nylon version and $13,200 for the metal-plated version. Less expensive products are avail- able, such as the lighting designs from i.materialise and .MGX by Materialise. Some of the designs are stunning and are available for a few hundred dollars. Protective covers for phones: A number of covers for smart phones have been designed and produced by AM. An example is the Double Mesh product designed by Janne Kyttanen of Freedom of Creation for Freshfiber. Apple purchased the exclusive rights of this particular design and offers it at its on-line store for about $54. Video game characters: In December 2007, FigurePrints brought World of Warcraft (WoW) characters to life through its additive manufacturing service. At figureprints.com, play- ers can order a statue for $130 or bust for $70 of their WoW character. The product is printed in full color using a 3D printer from Z Corp. and infiltrated with resin to strengthen the delicate features. The product is then mounted, covered in a glass dome, and shipped. The company recently introduced the manufacture of Xbox LIVE avatars for $50. Custom dolls: A company named That’s My Face can put your face on a doll or action figure or frame it for display. Customers upload one or two jpg images of a face and the company does the rest. That’s My Face uses a color 3D printer from Z Corp. to produce the likeness of you or someone else. Prices are from $29 for a small product to $129 for a 12-in. action figure. The market potential for products made by additive manufacturing is immeasurable. The preverbal tip of the iceberg is emerging. What we do not know is the enormity of the iceberg below the surface. Based on what I’m seeing, hear- ing and expecting, it could be very large. In effect, AM could very well become the most diverse, flexible and accessible manufacturing technology ever. DE Terry Wohlers is principal consultant and president of Wohlers Associates, Inc. and has authored nearly 400 books, magazine articles and technical papers on Additive Manufacturing. This column was published in the May/June 2011 issue of Time Compression. RapidPrototyping 154 Hobart Street, Hackensack, NJ 07601 USA +1.201.343.8983 • main@masterbond.com www.masterbond.com Epoxy Impregnant Seals Metals And Non-Metals One Component EP19HT • Chemically resistant • Low viscosity • Resists up to 400°F • Solvent free tight security Laser-sintered forms compose the back and arm rest of Future Factories’ $10,000 “Holy Ghost” chair. 18-19-DES1.indd 19 12-02-07 10:36 AM

- 20. January/February | 2012 www.design-engineering.com 20 Researchers leverage 3D mice and six degrees of freedom control for robot design and flight manipulation. When Danny Ellis was first introduced to CAD in high school with a course in Autodesk Inventor, little did he know he would someday be designing and flying aerial robots. As Ellis advanced into the engineering program at the University of Michigan, he was introduced to CATIA and 3Dconnexion 3D mice. “Between my freshman and sophomore years, I became irritated at how cumbersome it was to rotate a model using a traditionalmouseinCATIA,”saysEllis.“Ithought,IbetIcould getatrackballmouseandprogramitsowhenIrotatethemouse, itrotatesthepart.IdidaGooglesearchtoseeifithadbeendone before, and that’s when I came across 3Dconnexion—it was exactly what I had been looking for. I ordered the SpaceNaviga- tor right away and haven’t stopped using it since.” In 2009 during his senior year, Ellis began researching an aerial robot competition he could undertake at the university. Five days later, he started the Michigan Autonomous Aerial Vehicles (MAAV) team with 15 members ranging from fresh- man to graduate students studying Aerospace, Computer, Electrical and Mechanical Engineering. Within a week, the team kicked off their first quad-rotor design for the International Aerial Robotics Competition (IARC). At the end of the first year, MAAV successfully built two quad-rotor vehicles capable of manual flight. “The IARC challenge is to build a flying robot of any type you want that can fly through an unknown building completely on its own,” explains Ellis. “There can be no communication with the device—the robot follows signs, must avoid detection from security cameras, locate a room, retrieve a flash drive, drop off the decoy and get out in under 10 minutes. No one has completed the mission yet, but we are one of the better teams competing.” When Ellis started the team, he wanted to get a 3Dcon- nexion 3D mouse for everyone. “It makes modeling CAD designs so much faster and easier,” says Ellis. In addition, the team quickly realized trying to fly the quad-rotor with a standard joystick didn’t mimic the movements very well and wasn’t intuitive enough for the user, while a 3D mouse could mimic the exact movement of the robot. “We used the 3Dconnexion SDK to develop a driver to control the quad-rotor with the SpaceExplorer. It quickly allowed us to control pitch and roll, zoom control height, and rotation control yaw,” says Ellis. “In addition, the SpaceEx- plorer’s Intelligent Function Keys control other commands such as on/off and camera control. It’s much more intuitive to fly with the 3D mouse.” Today, Ellis is still the head of the MAAV team, while also completing two masters in Aerospace Engineering and Robot- ics. He continues to use CATIA for all of his designing, both for the team and his class projects. He also works at a student lab training other students involved in competitions in CAD modeling and machining, and 3D mice are integral to his training efforts. “CATIA is a sophisticated and powerful application, but it takes time to learn how to interact with the model,” says Ellis. “This can be a barrier for people, especially if they’ve never used any CAD software before. 3Dconnexion 3D mice make training new students much easier, helping them visualize how to move and rotate the model. Once they get that, it’s pretty much universal navigation across all CAD systems.” Ellis currently uses the SpacePilot PRO and is a big fan of the Intelligent Function Keys, as they allow him to use the most frequently used commands without ever needing to touch the keyboard. And, if Ellis goes into the lab and doesn’t have a 3D mouse with him? “It’s really tedious,” he says. “It takes me twice as long to do anything without a 3D mouse. Really, I couldn’t live without it.” DE www.3dconnexion.com Hardwire Aerial robot takes flight with 3D mouse Gr Th A en in F sp w sc to 20-DES.indd 20 12-02-07 10:36 AM

- 21. ENGINEERS SEE THE WORLD DIFFERENTLY. INCLUDING THEIR RETIREMENT PLANS. STRING TENSION CONTROLLED BACKSPIN MORE COURT TIME DUE TO LOWER MANAGEMENT FEES Engineers Canada is the business name of the Canadian Council of Professional Engineers. Great-West Life and the key design are trademarks of The Great-West Life Assurance Company (Great-West), used under licence by its subsidiaries, London Life Insurance Company (London Life) and The Canada Life Assurance Company (Canada Life). Group retirement, savings and payout annuity products are issued by London Life and Canada Life respectively, and marketed and serviced by Great-West. Sponsored by At Great-West Life, we know your high standards extend well beyond your engineering career. Our group retirement plan offers an impressive array of investment options combined with lower-than-market management fees. Find out more about the only retirement plan officially sponsored by Engineers Canada. Call 1-800-724-3402 or visit www.brainshark.com/grs/mygroupadvantage. You can also scan this code with a QR code reader-enabled mobile phone to easily access more information. 20-DES.indd 21 12-02-07 10:36 AM

- 22. January/February | 2012 www.design-engineering.com 22 Long ignored buoyant aircraft are making a comeback as the need to ship cargo to remote locations intensifies. By Mike McLeod Except for the occasional sighting at a Super Bowl half-time, buoyant aircraft (better known as blimps) have been out of sight and out of vogue in aerospace circles for nearly a cen- tury. Images of the Hindenburg crash of 1937 grounded future airship development and continue to haunt those who strive to commercialize the flying machines. Now, after a decade of steadily rising fuel costs and the hunt forhigh-pricedresourcesmovesinexorablyfartherintoremote, hard-to-reach locations, interest in airships has experienced a renaissance.Whilestillconsideredsomewhatofa“fringe”mode of transport,proponentssaytheeconomictippingpointinfavor of modern heavy-lift airships—capable of ferrying 50 tons or more—is only few years away. “We have more demand for more things moving by air than ever before,” says Dr. Prentice, a professor of supply chain man- agement at the I.H. Asper School of Business, University of Manitoba. “But we also have more places in the world we want to get to that don’t have infrastructure; 70 percent of Canada’s land mass, for example, has no roads.” Where the Roads End An outspoken supporter of airships for more than a decade, Prenticepointstothefactthatapproximately30,000Manitobans inremotecommunitiesdependtheannualconstructionof2,200 kilometersofwintericeroadsforcriticalsupplies.Ifthatconstruc- tion is delayed, due to a short winter, supplies have to flown in, drivingthecostofgoodstotwoorthreetimestheirmarketprice. At the same time, the expense of permanent roads, he says, is enormous and is money better spent elsewhere. “Building all-weather gravel roads in northern Manitoba costs $1 million per kilometer,” Prentice says. “It can be done, but when you have Muskeg, permafrost, rock outcrops and so on, it just isn’t economic. So what’s left?” More than an advocate, Dr. Prentice is also president and CEO of Buoyant Aircraft Systems International (BASI) with partnerandBASIChiefScienceOfficerDaleGeorge.InDecem- ber2011,thepairunveiledtheir24-metrelongGiizhigo-Misameg (which means Sky Whale in Oji-Cree) airship at the University of Manitoba. The relatively small-scale blimp will be used for research to test the vessel’s ballast exchange, electrical propulsion and fuel cells under cold weather conditions. Once proven, the intent is to build much larger airships to service resource operations in Northern Canada as well as remote communities. “Mining will be the first big markets for airships,” says Prentice. “The problem with this type of transport, given the value of the equipment and the number of cycles you have to make during a year to pay for it, is that your market length is in the 250 to 300 mile range. We have many markets like that in Canada. All you have to do is look at a map and see where the roads and rail lines end.” Combat to Cargo As with many advances in aerospace technology, interest in modern airship initially took off with the military. In fact, in lastsixyears,thevariousbranchesoftheU.S.armedforceshave invested more than $1.13 billion in four airship programs. Thelargestdealhasbeenthe$517-millioncontractsignedby the U.S. Army with Northrop Grumman in June 2010 to buy at leastthreeairships.DestinedforsurveillancedutyinAfghanistan, theUSArmy’slong-endurancemulti-intelligencevehicle(LEMV) will be designed and built by Northrop partner, Hybrid Air Vehicles (HAV) of the U.K. Like BASI, the Bedfordshire-based airship company is also eyeing the cargo transport market. In August 2011, HAV signed a preliminary agreement with Yellowknife’s Discovery Air— Canada’s second largest aircraft operator—to design and develop a potential fleet of commercial hybrid airships to transport supplies to Canada’s north. Both companies hope to reach a final design soon and see delivery of the first of several 50-ton capacity HAV 366 hybrid airships begin by 2015. ForStephen“Fig”Newton,B.Eng., direc- tor of business development at Discovery Air, the business case for airships is an obvious one. “You can pretty much do anything with these vehicles,” he says. “You can land on water, snow or ice. You can turn it inside its own body length; you can take off fully loaded within four body lengths; and you can pick up vertically 40 percent of its maximum payload. So it has all the benefits of a helicopter or fixed-wing with very few of the downsides of any of them.” Return of the Airship 22-23-DES.indd 22 12-02-07 2:12 PM

- 23. www.design-engineering.com January/February | 2012 23 Rise of the Hybrid Still, many are sceptical of airships. One of the main reasons is thattheairship’sbiggestadvantage(i.e.“free”verticallift)isalso itsbiggestdesignheadache,especiallyforheavycargoapplications. After all, what happens when a huge airship, filled with enough helium to equalize the weight of 50-tons, loses its cargo? Tradi- tionally, dealing with buoyancy has required ground crews, mooring lines and the delicate balance of ballast management. YetPrenticesays,modernairshipsareaworldawayfromtheir predecessors. BASI’s Sky Whale handles the buoyancy problem bycompressingtheheliumduringlandingandcargounloading. Thedensegasthenactsasballastwhileatmosphericairispumped into ballonets to retain the envelope’s shape. After unloading, the helium is pumped back in for the trip back. Hybrid Air Vehicles tackles the problem from a different approach. It’s HAV 366 vehicle is a hybrid airship and not subject to many of the same challenges of a traditional blimp, say its creators. Heavier than air, hybrids gain lift by a combi- nation of three forces. Helium assists with take-off and flight, but nearly half the vessel’s lift comes from the aerodynamic shape of its envelope. In addition, lift off, landing and sustained hover are further assisted by vectored thrust nacelles at the envelope’s aft and front quarters. As a result, heavier-than-air hybrids require less volume to lift heavy loads than a comparable dirigible. “The other crucial element is HAV’s air cushion landing system that blows air toward the ground,” says Andy Barton, HAV’s chief designer for heavy cargo airships. “The air cush- ion system, paired with the vectored thrust, makes sure you have a gentle landing.” “That airflow is also reversible,” he adds. “So once you have landed,thedirectionoftheairflowissuckingyoutotheground and can cope with significant unevenness. That also allows 30 tonstoberemovedimmediately,whiletheshipisrefueling.Once that’s done, the rest of the cargo can be taken off.” Whilerelativelyslow,BartonsaystheHAV366’s2400-hpPratt Whitney Canada gas turbine engines will produce a typical cruising speed 80 knots fully loaded with bursts up to 110 knots. Inaddition,thevessel’sconsiderablesize(109mx55.7mx32.7m) and shape bolster its stability in rough weather. “We’re okay in winds up to 80 knots, and we can do ground handling in winds up to 50 knots without masting up,” Barton says.“Duetotheairship’scrosssection,theimpactofcrosswinds is less than for the traditional blimp shape. And since we are heavier and we have some aerodynamic trim on the design, we have better handling properties.” Sustainable Flight Many of the design challenges have been overcome, but the real obstacles holding airship development back aren’t technical but economic,saysJayGodsall,founderandCEOofToronto-based Solar Ship. The problem, he says, is that the cost to develop a heavy-lift airship hovers around $1 million per ton of lift, mak- ing it difficult to find investors willing to fund a vessel large enough (20 or more tons of lift) to be economically viable— especially when a technology has yet to be proven. Of course, the only way to prove it is to make the initial investment. “Withairships,thereisnoentrepreneurialfirststepwhereyou raiseabitofmoney,getalittlefirstcustomerandthenincremen- tallygrow.Thisisanimmediatebigplay,”hesays.“Theonlyway around that, is if you figure how to make a smaller airship and make it useful to a customer.” That’swhereSolarShipislookingtopositionitself.Thecom- pany is currently developing a unique hybrid concept designed toferrymedicalsuppliesandothercargotoremotelocationsand areas in need of disaster relief. “If you trying to get to a place like Haiti after the earthquake, when you couldn’t get emergency supplies in for eight and a half days, then you don’t need carry 20 tons,” he says. “A ton of critical cargo into Haiti in eight and half hours would have saved a lot of lives.” Like the HAV hybrid, Solar Ships’ aircraft is heavier- than-air and, as such, gains 60 percent of its lift from its delta-wing design. This allows the airship to take off, land andpilotmorelikeaconventionalplaneandisthereforemore manoeuvrable and resistant to wind conditions. At the same time, helium increases cargo carrying capacity andcutsthespaceneededtotake-offandlanddownto50to100 meters.Moststrikingly,thehybrid’slarge,inflatedwingprovides ample surface area for the solar panels that power its engines. “Not having to burn fossil fuels, in certain parts of the world, isreallyvaluablething,”Godsallsays.“ForCanada,itmakessense for us to run a hybrid fuel system. But in regions of the Congo, the Amazon or Indonesia, they don’t have fuel at any price.” Although the need for cargo transport to remote locations is growing,thefactremainsthatmanyhavetriedtocommercialize airships before without success. Still, proponents say economic pressures and technological advancements have reached a point that the age of the airship is inevitable. “Technology without demand is just a curiosity, but the demandisthere,”saysPrentice.“Soon,wearegoingtoseeairships flying in the U.S. military. Once that happens, people will see opportunities for profit, and the flood gates will open.” DE Hybrid Air Vehicle’s HAV 366 heavy lift hybrid airship, say its creators, will economically transport 50-ton loads to Canada’s remotest locations. Toronto’s SolarShip is in development of a solar-powered hybrid airship—intended to ferry critical cargo to remote locations—that combines the lift capacity of a blimp with the flight properties of a plane. 22-23-DES.indd 23 12-02-07 2:12 PM

- 24. By Mike McLeod In November, Omron Industrial Automation announced what the company billed as a new category in automation control, the Machine Automation Controller (MAC). While similar to established categories (e.g. PLC, PAC and Industrial PC), the company says the MAC incorporates aspects of each but combines and coordinates the various functions to create an architecture unmatched in the industry. To fill this newly created category, Omron unveiled its Sys- mac NJ-Series MAC, a high-end controller that integrates and synchronizes motion, logic and vision in one unit. Like a PLC, the NJ-Series is “hardened” for industrial environments but houses a fanless processor at its core like an Industrial PC. Comparatively, says Omron commercial engineer for PLCs and IO, Johnston Hall, the NJ-Series MAC is most like an enhanced version of the Programmable Automation Control- ler (PAC); the MAC handles the same functions but can coordinate motion, logic and vision synchronously and at an exceptionally high speed. “With a PAC, you add software to a controller for all the different functions, but the different software still has to ‘talk’ to each other and, therefore, aren’t really synchronized,” he says. “With the MAC, the three processes are unified and synchronized; that way there is no time loss.” According to Omron, the NJ-Series updates motion, network and user application updates in the same scan to ensure syn- chronicity. In addition, it handles more axes (16, 32 or 64) than typical controllers but its response time remains very fast—1ms for applications up to 32 axes and 2ms for 64 axes. Part of that speed is due to the NJ-Series’ hardware. The controller runs a 1.66 MHz dual core Intel Atom processor running an embedded real time operating system (RTOS) in non-volatile RAM. Added to that, the MAC leverages the speed and determinism of the Ether- CAT protocol. While the industrial Ethernet protocol transmits standard 802.3 Ether- net frames, it adds a unique data packet that EtherCAT compatible devices (up to 192 nodes) read and inject, on the fly. In addition, a slave clock in each node allows the mas- ter controller to use the timestamp of income and returning packets to determine propagation delay offset and thereby ensure accurate synchronization between devices with less than 1 microsecond jitter. To communicate less time sensitive data, the Omron’s MAC also “speaks” the popular EtherNet/IP protocol, facilitating remote access; interface with HMIs and SCADA software; and tie the controller into the larger peer-to-peer network. EtherNet/IP also serves as the communication conduit to the last piece of Omron’s MAC puzzle: Sysmac Studio, the company’s software that serves as an IDE programming envi- ronment as well as for configuration, simulation and monitor- ing. Compliant with the IEC 61131-3 standard, Sysmac Studio supports ladder logic, structured text and function block pro- gramming languages. The package also includes a CAM editor for programming of motion profiles and a 3D sequence and motion simulation environ- ment to assist debugging. “Customers told us they were having trouble integrating the three technologies as well as maintaining machines because there were too many software packages and too many cables,” Hall says. “Now, with the MAC, a user can program, back up and tune from a single point.” DE www.omron.com January/February | 2012 www.design-engineering.com 24 All-in-One Automation Omron’s Machine Automation Controller integrates multiple controllers while maintaining high performance. AutomationInsight Like its hardware counterpart, Sysmac Studio combines an IDE with configuration, monitoring and simulation. Omron’s NJ-Series Machine Automation Controller (MAC) combines logic, motion, I/O and vision with EtherCAT to create a high-end, all-in-one controller. DMR_E 24-DES.indd 24 12-02-07 10:37 AM

- 25. DMR_EssentialComponents_September-2011-outline_01.indd 1 8/15/2011 12:43:40 PM 24-DES.indd 25 12-02-07 10:37 AM

- 26. January/February | 2012 www.design-engineering.com 26 Manned or not, this lunar project has a prototype. By Larry Hansen When NASA Langley Research Center hired Honeybee Robotics Spacecraft Mechanisms Corporation to develop a totally mechanical tool changer, Honeybee was ready. The tool changer was for the end of what Langley’s Lunar Surface Manipulation System (LSMS) team describes as a robot that could unload landers. Then, after the landers were unloaded, it could, in addition to doing base assembly, mate with tools to take science experiments. This robot could be likened to a crane but with more dexterity. The crane was designed to work remotely so that it could be used on an unmanned mission without human interaction. It’s completely autonomous. That’s one of the driving factors. And the tool changer does have other applications if they decide they want to use it on Mars or even in outer space for a robotic arm and end effectors. Since Honeybee has been developing harsh-environment, mission-critical end-effectors for over 25 years and has worked on the equipment for other space missions, they were specially suited to tackle this challenge. Making It Work Basically, Honeybee was given an envelope—a footprint to stay within—and all the requirements for load ratings and misalignment allowances. Lee Carlson, a Systems Engineer who was part of the Honeybee team, describes the project. “The crane might be sitting on the lander deck or on the lunar surface and would be driven from quite a distance away from the tool to be mated to; this required designing for large misalignment allowances … this was our first design chal- lenge,” he says. “The end of the crane and target tool could be misaligned by as much as a couple inches in any direction with up to 20 degrees angular misalignment when attempting a mate.” But, Carlson adds, there were other considerations too. “The tool changer had to be capable of carrying around 1000 lbs. so [the tool changer] had to be very robust,” he says. “Also, since this was a lunar project, it has to be tolerant to moon dust. These two design criteria required special seals to pro- tect large roller bearings. If this design was for space, it becomes considerably simpler. All of the loads would be reduced and dust is no longer an issue. But the Moon is a very harsh envi- ronment and lunar dust is a major concern when designing for missions there.” When NASA had an ‘afterthought’, Honeybee engineers had a real challenge. The original assignment called for ‘dummy’ tools requiring no power. The crane would do all the work. Tools would range from a fork lift attachment, a shovel or scoop for acquiring surface samples or digging, or even a bucket for lifting human passengers. Then NASA decided it wanted the capability of attaching an electronic or electromechanical tool to the end of the crane. Now the tool changer would have to provide an electrical connection as well. Solving this problem fell to Carlson. “The contract was expanded to add an electrical connec- tor to the existing mechanical connector,” he says. “You’d have a power source on the LSMS, on the crane itself. Your tools could then be powered. So your tools capabilities could expand into the realm of cameras or tools with cameras on them or even a light jackhammer.” However, they had not left space to accommodate an electri- Fly Me To The MoonManned Or Not, This Lunar Project Has A Prototype PowerTransmission Top isometric view of connector within enclosure. The bottom view of Honeybee’s LSMS connector extended. 26-28-DES.indd 26 12-02-07 10:38 AM

- 27. www.design-engineering.com January/February | 2012 27 cal connector because it was not a part of the original contract and the budget did not allow for starting from scratch. The Crucial Ten Square Inches Carlson had to work within the constraints of the current design because NASA did not want a redesign of the whole tool changer. They just wanted to add an electrical connector to it without increasing the current envelope. He only had roughly two and a half by four inches of free space to incor- porate the male side of the new autonomous connector. The connector has to mate itself to a female connector mounted on the tool. “We make small stuff all the time and if there were more space, there are many different ways that I could have designed it,” Carlson says. “This is, probably, the most compact I’ve ever had to make anything.” Honeybee designed both the male and female sides of the connector. The female side had to be inexpensive and easy to create because each tool would have to have its own female connector versus a single male connector attached to the crane. The female connector has no moving parts but is slightly compliant. The male connector has all the moving parts. It is cylindri- cal and populated with eleven 1/16-inch diameter aluminum pins which are plated with gold over nickel configured in a standard MIL/Spec pattern. The connector rides on compact slides—miniature guides called SEBS made by NB Corpora- tion. The top faces of the two glides are facing each other and Honeybee’s components are in between the two glides - sup- porting this connector. This configuration reduces the moment loads on the slides. Precise Movements Lee Carlson describes how it works. “We actually used a total of six slides within the space—three on each side. The slides ride on each other in the manner of drawer slides that are PowerTransmission CAD rendering of extended male connector (without enclosure). Mini-guide appears white. 26-28-DES.indd 27 12-02-07 10:38 AM

- 28. January/February | 2012 www.design-engineering.com 28 stacked to extend the distance they can open a drawer,” he says. “Our configuration achieves an extension of the move- ment equal, approximately, to the length of three slides. So instead of a half-inch stroke, we could get an inch and a half stroke—within a very, very small footprint. Low mass, low load and very low profile were all required for this application.” Carlson says that the reason that they chose these par- ticular guides was that they were some of the smallest slides he could find. His one caveat was that he wanted to work with one of the slide suppliers that Honeybee had worked with before—not take chances on a new supplier. It also had to be a guide that, even though this was a prototype, was completely made of stainless steel without any plastics. Plastics are gen- erally avoided unless they are specially chosen and approved. As for lunar dust tolerance, the whole electrical connector assemblage will be sealed in a bellows to protect it from the harsh lunar regolith. Honeybee was able to choose from the widest selection of miniature linear slide guides on the market. The standard SEBS guides major advantage is that they have a standard radial clearance that is twice as accurate as other standard miniature guides. Most manufactures do not claim that their preload eliminates all clearance. Their standards are plus to minus, which allows gaps, i.e. clearance, to exist. Minus means there is some preload so there’s no gap. NB’s are from zero to minus as a stan- dard, making for greater accuracy because there is no clearance. In other words a negative clearance means the ball is larger than the space adding more pressure and greater rigidity. This increased rigidity is desirable in high precision applications. NB’s standard fabrication requires more control in the assembly and manufacturing process in order to adhere to this higher quality standard. As Honeybee waits to complete assembly and testing with the LSMS, they look forward to the future when, hope- fully, the project will make its way to the Moon—the final test of all. DE www.honeybeerobotics.com Larry Hansen is a director and the general sales manager for NB Corporation of America PowerTransmission The NB Corporation Mini SEBS is one of the smallest guides on the market. |TS11-03USA| A 26-28-DES.indd 28 12-02-07 10:38 AM

- 29. |TS11-03USA| www.beckhoff.ca/TwinSAFE TwinSAFE from Beckhoff: from I/O to drives it's the universal and flexible safety system. TwinSAFE I/O for the EtherCAT Terminal system makes optimum use of the exceptional performance offered by EtherCAT: Compact: Safety PLC in a 12 mm terminal block Powerful: up to 128 safety devices per Safety PLC Versatile: integrated function blocks for emergency stop, protective door, two-hand control Modular: standard and safety I/Os integrated in a single system Flexible: “fieldbus-neutral” communication, eliminates dedicated safety networks Certified: solution up to SIL 3 according to IEC 61508, EN 954 Cat. 4 and DIN EN ISO 13849 PLe (approved for use throughout North America) Safety inputs Safety PLC Safety outputs Safety DrivesStandard PLC Motion Automation I/O IPC TwinSAFE: Machine Safety Simplified. Combine safety PLC Terminals, safety I/O and standard I/O on one EtherCAT network. 26-28-DES.indd 29 12-02-07 10:38 AM

- 30. January/February | 2012 www.design-engineering.com 30 Motion Control Multi-Bus Servo Drive Kollmorgen announced that its AKD servo drive now supports the functional- ity of the base analog drive, indexing drive, CANopen drive and EtherCAT drive. In addition, the drive supports a variety of feedback devices and Ethernet motion buses including Smart Feedback Devices (SFD), Endat, BiSS, Analog Sine/ Cos encoders, incremental encoders, HIPERFACE and resolvers. In addition to EtherCAT and CANopen motion buses, the AKD supports SynqNet, PROFINET, EtherNet/IP and Modbus/TCP. The drive is rated for operation in ambient temperatures ranging from 0°C to 40°C (up to 55°C with de-rating), and boast a MTBF of nearly 660,000 hours. www.kollmorgen.com Wi-Fi Industrial Ethernet Modem Weidmuller has introduced its WI-MOD-E-G wire- less Ethernet appliance, a 2.4Ghz, Wi-Fi industrial Ethernet device designed for process/automation applications connecting to PLCs, DCS/SCADA, data loggers or field instruments with an RS232/485 or Ethernet port/interface. Built around the 802.11b/g standard, the device’s throughput scales up to 108Mbps and features 400mW of transmit power. The unit can oper- ate as a Wi-Fi router/bridge, access point/ client and serial server (RS232/485). By attach- ing an I/O expansion unit, a user can send or receive up to 16 digital or 8 analog signals and Ethernet (Wi-Fi) at the same time. For security, the unit features WEP and WPA2 PSK encryption, MAC address filtering, IP filtering, password login and white/black list authentication. www.weidmuller.com Managed Ethernet Switch AutomationDirect’s line of Stride Eth- ernet products now includes industrial- grade managed Ethernet switches, designed with redundant power inputs with surge and spike protection and auto-crossover. Built with aluminum housings, all models are designed for an operating temperature range of -40 to +75°C. The switches’ Real-Time Ring technology provides fast recovery of all the redundancy options on the switch. Most models feature multiple 10/100BaseT RJ45 Ethernet ports; additional models include ST or SC type fiber optic connections. Gigabit managed switches are also available, with 10/100/1000BaseT RJ45 ports and combination SFP ports that accept noise-immune fiber optic links. www.automationdirect.com Ethernet Switches WAGO Corporation announced that its 852 Series Ethernet Switch family now features two wide temperature models for operation between -40°C to +70 °C. The mid-range, 8-port unmanaged 852-103 Ethernet Switch features a redundant power supply and a 9V-48V supply voltage range. A top-mounted DIP Switch sets an alarm relay to monitor loss of 24 VDC or port status (selectable by port). Beyond eight 100BASE-TX ports, the 852-103 provides two 100BASE-FX SFP ports for fiber optic cables. The 7-port 852-104 managed switch provides Xpress Ring and Jet Ring networking features. Xpress ring enables networks to recover from link failure within 50ms; Jet Ring provides redun- dant data-transmission routes during link failure/damage within 300ms. In addition, the 852-104 provides Web-based management, port configuration and data packet prioritization. www.wago.com Motors Brushless PM Motor NovaTorque, Inc. introduced its Gen2.0 PremiumPlus+, 3-hp and 5-hp brushless permanent magnet motors with motor-only rated point efficiencies of 93 percent and 92 percent, the company says. In addition, the company says its patented flux-focusing stator and rotor hub geometry allows the motor to maintains this performance using an all-ferrite (versus rare earth) magnet design. NovaTorque PremiumPlus+ motors are packaged in standard NEMA frame sizes and mounting dimensions and are com- patible with readily available variable frequency drives (VFDs) from most leading manufacturers. www.novatorque.com Stepper Drive/Controller Tolomatic has added Ethernet con- nectivity to its ACS stepper drive/ controller. The component supports both Ethernet/IP and Modbus TCP, allowing connectivity to Allen Bradley and many other PLCs and HMIs. The ACS with Ethernet is capable of command- ing motion with immediate move command or preconfigured moves for infinite position capability. Each move has configurable motion profile parameters (position, velocity, acceleration/deceleration, force) that are independent for each move. The Ethernet connectivity also provides additional status and diagnostic information to the control system for monitoring and fault recovery. The ACS comes with a starter kit that includes the configuration software and two setup manuals. www.tolomatic.com IdeaGenerator 30-33-DES.indd 30 12-02-07 2:13 PM