Cleaning validation-volume-iii

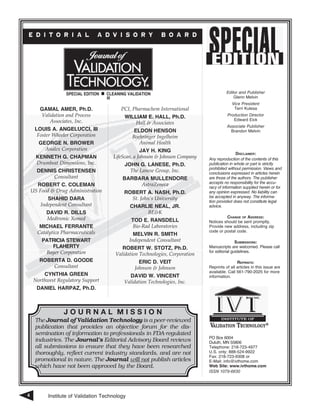

- 1. Institute of Validation Technology4 E D I T O R I A L A D V I S O R Y B O A R D J O U R N A L M I S S I O N The Journal of Validation Technology is a peer-reviewed publication that provides an objective forum for the dis- semination of information to professionals in FDA-regulated industries. The Journal’s Editorial Advisory Board reviews all submissions to ensure that they have been researched thoroughly, reflect current industry standards, and are not promotional in nature. The Journal will not publish articles which have not been approved by the Board. Gamal Amer, Ph.D. Validation and Process Associates, Inc. Louis A. Angelucci, III Foster Wheeler Corporation George N. Brower Analex Corporation Kenneth G. Chapman Drumbeat Dimensions, Inc. Dennis Christensen Consultant Robert C. Coleman US Food & Drug Administration Shahid Dara Independent Consultant David R. Dills Medtronic Xomed Michael Ferrante Catalytica Pharmaceuticals Patricia Stewart Flaherty Bayer Corporation Roberta D. Goode Consultant CYNTHIA GREEN Northwest Regulatory Support Daniel Harpaz, Ph.D. PCI, Pharmachem International William E. Hall, Ph.D. Hall & Associates Eldon Henson Boehringer Ingelheim Animal Health JAY H. KING LifeScan, a Johnson & Johnson Company JOHN G. LANESE, Ph.D. The Lanese Group, Inc. Barbara Mullendore AstraZeneca ROBERT A. NASH, Ph.D. St. John’s University Charlie Neal, Jr. BE&K TOD E. RANSDELL Bio-Rad Laboratories MELVIN R. SMITH Independent Consultant ROBERT W. STOTZ, Ph.D. Validation Technologies, Corporation ERIC D. VEIT Johnson & Johnson David W. Vincent Validation Technologies, Inc. Special Edition n Cleaning Validation III Editor and Publisher Glenn Melvin Vice President Terri Kulesa Production Director Edward Eick Associate Publisher Brandon Melvin Disclaimer: Any reproduction of the contents of this publication in whole or part is strictly prohibited without permission. Views and conclusions expressed in articles herein are those of the authors. The publisher accepts no responsibility for the accu- racy of information supplied herein or for any opinion expressed. No liability can be accepted in anyway. The informa- tion provided does not constitute legal advice. Change of Address: Notices should be sent promptly. Provide new address, including zip code or postal code. Submissions: Manuscripts are welcomed. Please call for editorial guidelines. Reprints: Reprints of all articles in this issue are available. Call 561-790-2025 for more information. PO Box 6004 Duluth, MN 55806 Telephone: 218-723-4977 U.S. only: 888-524-9922 Fax: 218-723-9308 or E-Mail: info@ivthome.com Web Site: www.ivthome.com ISSN 1079-6630

- 2. Equipment Cleaning Validation: Microbial Control Issues . . . . . . . . . . . . . . . . . . . . . . . 6 by Destin A. LeBlanc, M.A. Cleaning Validation: Maximum Allowable Residue: Question and Answer . . . . . . . 13 by William E. Hall, Ph.D. Development of Total Organic Carbon (TOC) Analysis for Detergent Residue Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 by James G. Jin and Cheryl Woodward Total Organic Carbon Analysis for Cleaning Validation in Pharmaceutical Manufacturing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 by Karen A. Clark Detergent Selection – A First Critical Step in Developing a Validated Cleaning Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 by Mark Altier Analysis Cleaning Validation Samples: What Method? . . . . . . . . . . . . . . . . . . . . . . . . . . 35 by Herbert J. Kaiser, Ph.D., Maria Minowitz, M.L.S. Control and Monitoring of Bioburden in Biotech/Pharmaceutical Cleanrooms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 by Raj Jaisinghani, Greg Smith and Gerald Macedo A Cleaning Validation Program for the ELIFA System . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 by LeeAnne Macaulay, Jeff Morier, Patti Hosler and Danuta Kierek-Jaszczuk, Ph.D. A Cleaning Validation Master Plan for Oral Solid Dose Pharmaceutical Manufacturing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 by Julie A. Thomas Proposed Validation standard — VS-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 BONUSBONUS Special Edition: Cleaning Validation III 5 C O N T E N T S T A B L E O F Special Edition n Cleaning Validation III

- 3. T he PDA spring conference was held in Las Vegas, Nevada in March 20, 2001. The conference showcased clean ing validation, residue limits, bio burden, microbial limits, and sani tization. This paper is based on a presentation at that conference. The initial focus of regulatory documents relating to cleaning validation for process equipment in pharmaceutical manufacturing involved measuring residues of the drug active and the cleaning agent. For example, the introduction to the Food and Drug Administration (FDA) guidance document on clean ing validation1 states: “This guide is intended to cover equipment clean ing for chemical residues only.” While admitting that microbial res idues are beyond the scope of the guideline, that guidance document further states, “microbiological aspects of equip ment cleaning should be considered,” particularly with reference to preventive measures so that micro bial proliferation does not occur during storage. The European PIC/S document,2 that was issued several years later, does explicitly mention microbial resi dues. In Section 6.2.1, contaminants to be removed include “the previous products, residues of cleaning agents as well as the control of potential microbial con taminants.” However, Section 6.7 of thisdocumentthatcovers“Microbio logical Aspects” focuses exclusively on the same issue discussed in the FDA guidance document, namely the issue of preventing microbial pro liferation during storage. As a practical matter, microbial residues on equipment surfaces are part of the contaminants that should be reduced to an acceptable level; that acceptable level being what is safe for the manufacture of the sub sequently manufactured product. Unfortunately, very little has been written on what is a safe level for microorganisms following cleaning and/or sanitation.3,4 Part of the reason for this is that microbial residues are significantly different from chemi cal residues. Chemical residues are “inert” in the sense that it is easy to calculate (especially using scenarios of uniform contamination in the subsequently manu factured product) the potential levels and effects of those chemical residues in the subsequently manu factured product should they be transferred to that subsequently manufactured product. With microbial residues left after the cleaning process, the situation is somewhat different. Because microorganisms are living organisms, those left as residues on equipment may change in number after the cleaning process, but Institute of Validation Technology6 Equipment Cleaning Validation: Microbial Control Issues By Destin A. LeBlanc, M.A. Cleaning Validation Technologies v }…it is becoming more common for regulatory authorities to cite manufacturers for deficiencies related to microbial control in cleaning validation programs.~

- 4. Special Edition: Cleaning Validation III Destin A. LeBlanc, M.A. before the manufacture of the subsequently manu factured product. Those microbes transferred to the subsequently manufactured product may also change in number after they are incorporated into the subse quently manufactured product in the manufacturing step. This change may be a significant reduction in bioburden, either due to drying of the equipment or due to a preservative in the finished drug product, for example. This change may also involve rapid proliferation, either due to suitable growth conditions in wet equipment during storage, or due to suitable growth conditions in the finished drug product. Or, they may result in no significant change in microbial level, because the bioburden was due to bacterial spores (that will survive readily in dried equipment), or because the subsequently manufactured product was a dry product (with low water activity). Therefore, knowing the levels of microorganisms left on the equipment following cleaning does not necessarily give one the full story of the potential hazards of those microbialresidues.Additionalinfor mation is required to assess those potential hazards. Why has microbial evaluation during cleaning of process equip ment been a little discussed topic? Part of the reason is that it is not a significant problem in process man ufacturing. Yes, it could conceivably be a problem if cleaning and storage were inadequate. However, for the most part, cleaning and storage of process equip ment, in so far as it applies to microbial residues, probably is done relatively well in most pharmaceu tical manufacturing facilities. On the other hand, it is becoming more common for regulatory authorities to cite manufacturers for deficiencies related to micro bial control in cleaning validation programs. One reason for this seeming anomaly is that while firms are adequately controlling microbial contamination of process equipment, there may be little documentation to support this. This lack of documentation includes any measurement of microbial residues during the cleaning validation and/or during routine monitoring. Some companies will measure the change in micro bial levels on equipment surfaces during storage of the cleaned equipment. However, many times this does not include any assessment as to the effect of that unchanged bioburden level on the subsequently manufactured product. This paper will address issues covering approaches to control of microorganisms in process equipment, setting of acceptance limits, sampling techniques, and approaches to providing acceptable documentation. Microbial Control Measures Control measures to reduce the bioburden on cleaned process equipment include control of bio burden of raw materials, the cleaning process itself, a separate sanitizing step, and drying of the equip ment following cleaning. Bioburden of raw materials includes the active, excipients, water, and any process ing aids. In many cases, the manufacturer may have little control over the bioburden of raw materials other than to accept a specification by the raw material sup plier. The most critical raw materials probably will be natural products, in which there may be considerable variation in the levels and types of microorganisms. A solid monitoring program to control incoming bio burden of raw material is necessary. If there could be significant variation in bioburden, then that should be addressed in the cleaning validation Performance Qualification (PQ) trials. At least one PQ trial should utilize the worst-case incoming bioburden of raw materials to demonstrate adequate cleaning and micro bial control under those conditions. 7 }Some companies will measure the change in microbial levels on equipment surfaces during storage of the cleaned equipment. However, many times this does not include any assessment as to the effect of that unchanged bioburden level on the subsequently manufactured product.~

- 5. Institute of Validation Technology Destin A. LeBlanc, M.A. A second means of microbial control is the cleaning process itself. The conditions of aqueous cleaning are often hostile to microbial survival. These conditions include high temperature (commonly 60-80ºC), pH extremes (>11 and <4), and the presence of oxidizers (such as sodium hypochlorite in biotechnology manu facture). In addition, the presence of surfactants in the cleaning solution can assist in providing good physical removal of microbes (without necessarily killing them). Good cleaning is also beneficial to microbial control in that chemical residues left behind can provide a physi cal “microbial trap” to allow microorganisms to survive even in the presence of chemical sanitizers. Those chemical residues left behind might also serve as a nutrient source that allows microbes to proliferate dur ing improper storage. Based on the author’s experience, in most cases, effective control of microorganisms in pharmaceutical process equipment can be achieved with the use of an effective cleaning process, without the need for a separate chemical sanitizing step. In some cases, a separate sanitizing step may be necessary. This may include sanitation by steam or by chemical sanitizers. Suitable chemical sanitizers for process equipment include sodium hypochlorite (chlo rine bleach), quaternary ammonium compounds, alco hol (ethyl or isopropyl), hydrogen peroxide, and per acetic acid. It should be noted that, with the exception of alcohol and hydrogen peroxide, additional rinses would be necessary to remove any chemical residues of the sanitizer from the equipment. Those chemical residues may also have to be evaluated as residues to be measured in the cleaning validation protocol. For such chemical treatments, it is not an expectation that the equipment be sterile. Unless the final rinse is with sterile water, microorganisms will be reintroduced into the equipment from the use of Water-for-Injection (WFI) or purified water as the final rinse. Some companies will use an alternative to sanitizing immediately after cleaning. This usually involves sani tizing after storage and immediately before use. This may be used in situations where it is difficult to control microbial recontamination or proliferation during stor age. It should be noted that control of storage condi tions, if possible, is preferable. The practice of relying solely on a separate sanitizing step immediately before manufacture should be discouraged. If this is practiced, then the sanitization step should be shown to be effec tive in reducing bioburden under the worst-case storage conditions (“initial” bioburden, time, temperature, and humidity). Needless to say, if the chemical sanitizing step is performed immediately prior to manufacture of the subsequently manufactured product, then removal of the sanitizer chemical residues to an acceptable level should also be demonstrated. A fourth consideration for control of microor ganisms is drying the process equipment surfaces following the final rinse. Drying the surfaces will further reduce the levels of vegetative organisms on the surface. In addition, drying will assist in prevent ing microbial proliferation during storage. Drying can be achieved by heated air, heated nitrogen, or by rinsing with alcohol. In all cases, the process can be assisted by application of a vacuum (to speed the evaporation of the water or, in the case of an alcohol rinse, of the alcohol itself). Limits for Microbes As mentioned earlier, it is possible to reasonably predict levels of chemical residues in subsequently manufactured products based on the levels present on equipment surfaces.5,6 With microorganisms, it is pos sible to measure levels on equipment surfaces; how ever, the effect of those residues will depend on what happens to those microorganisms once they come in contact with the subsequently manufactured product. Areas that may have to be evaluated include the species (including the so-called “objectionable” organisms), type of organism (vegetative bacteria versus bacterial spore, for example), the presence of preservatives in that subsequently manufactured product, the water activity of the subsequently manufactured product, as well as any subsequent sterilization process performed on that product. As a general rule, if the water activity is less than 0.6, then it can be expected that microorganisms will not proliferate (although they may continue to sur vive without reproducing).7 Water activity is a physical- chemical measurement that expresses the water vapor pressure above the test sample as a fraction of the water vapor pressure of pure water at the same temperature as the test sample. For aqueous products with a neutral pH, microbial proliferation can generally be expected unless there is a preservative in the product. If there is a possibility of microbial proliferation because the product is unpreserved and neutral, then that should be addressed in setting limits. 8

- 6. Special Edition: Cleaning Validation III Destin A. LeBlanc, M.A. Three methods to set microbial limits will be addressed. The first (Case I) involve limits where the subsequent product does not allow microbial prolif eration and is not subject to any further sterilization process. The second (Case II) involves subsequently manufactured products that are terminally sterilized. The third (Case III) involves subsequently manufac tured products that are processed aseptically. Case I Limits If the subsequently manufactured product does not allow microbial proliferation, then the determination of acceptable microbial limits in the cleaned equip ment can be calculated using the same principles used for chemical residues with one important exception. This process involves first determining the accep tance limit in the subsequently manufactured product. This limit is typically given in Colony Forming Units (CFU) per gram of product. Once this is determined, then the limit per surface area of equipment (assum ing uniform contamination) can be calculated based on the batch size of the subsequently manufactured product and the equipment surface area. How is the limit in the subsequently manufactured product determined? For chemical residues, it is based on dosing information for actives or toxicity information for cleaning agents. Such concepts cannot be directly applied to microbes. Fortunately, there are two good sources of information relating to levels of microorgan isms in products. One is the manufacturer’s own Quality Control (QC) specifications for the product, that may include a limit for bioburden in the product. A second source is information given in the proposed United States Pharmacopeia (USP) <1111> relating to “Microbial Attributes of Nonsterile Pharmacopeial Articles.”8 Examples of those limits are given below: Solid oral: ≤1000 CFU/g Liquid oral; ≤100 CFU/g Topicals: ≤100 CFU/g Note: Although these limits were discussed and proposed in the Pharmacopeial Forum, these spe cific recommendations were not adopted officially as part of the 24th edition of the USP. Unfortunately, this is where the one exception to the conventional treatment arises. When one looks at the bioburden in a finished drug product, the equip ment surfaces are not the only source of bioburden. One must also consider the raw materials themselves, as well as the primary packaging, as potential sources of microorganisms. The best way to deal with this issue is to develop information on the bioburden of the raw materials and the primary packaging, and factor these into the limits calculation. For example, if one were dealing with an oral liquid, one might calculate the contribution from the raw materials (assuming the upper limit bioburden for each raw material) as a maximum of 27 CFU/g. At the same time the contribu tion from the primary packaging is determined to be 3 CFU/g. Therefore, the amount allowed from equipment surfaces would be 70 CFU/g (100 minus 27 minus 3). An additional safety factor should be used to account for the significant variability in microbiological enu meration. An appropriate factor may be on the order of 5. Therefore, in this case, the limit (in CFU/g) that would be allowed solely due to the cleaned equipment surfaces would be 14 CFU/g (obtained by dividing 70 by 5). Higher safety factors also could be considered. These numbers are given for illustration purposes only. It should be realized that the contribution percentage allowed from cleaned equipment would vary depend ing on the contributions from the raw materials and the primary packaging. Once the limit in the subsequently manufactured product allowed from the cleaned equipment sur faces is determined, the next step is to determine the limit per surface area (CFU/cm2 ). This is calculated exactly as it would be for chemical residues: Limit per surface area = LSP x MBS SA where LSP = Limit in the subsequent product MBS = Minimum batch size SA = Product contact surface area In the example above, if the batch size is 200 kg and the product contact surface area is 260,000 cm2 , then the microbial surface limit of the cleaned equip ment is: Limit per surface area = (70 CFU/g)(200,000g) = 54 CFU/ cm2 (260,000 cm2 ) 9

- 7. Institute of Validation Technology Destin A. LeBlanc, M.A. If sampling were done with a typical contact plate of 25 cm2 , this would correspond to a limit of over 1300 CFU per contact plate. Since it is reasonable to count a maximum of only 250 CFU on a typical contact plate, this would clearly be in the TNTC (too numerous to count) category. Needless to say, this will vary with the limit in the subsequently manufactured product, the portion allowed from cleaned surfaces, the safety factor used, batch size, and the shared surface area. However, under most reasonable scenarios, the calculated limit due to microorganisms on the cleaned equipment surfaces will be significantly above what should be (and can be) achieved by proper cleaning. As a general rule, a good cleaning process should produce surfaces that contain no more than 25 CFU per contact plate (1 CFU/cm2 ). When failures occur, generally they will be gross failures, with counts gen erally above 100 CFU per-plate. Case II Limits This involves setting limits for cleaned equipment when the product subsequently manufactured in that equipment is to be sterilized. In this case, the microbial limit in the subsequently manufactured product can be established based on the assumed bioburden of that product at the time of sterilization. In other words, any validated sterilization process depends on an assumed bioburden of the item being sterilized. That assumed bioburden then becomes the limit in the subsequently manufactured product. Once that limit in the subse quently manufactured product is established, then the calculations are the same as for Case I – a certain por tion of that total limit is allowed from cleaned equip ment surfaces, a safety factor is applied, and then the limit per surface area is calculated using the minimum subsequent product batch size and the product contact surface area. It is significant that this issue is actually addressed in the FDA’s cleaning validation guidance document; that states: “…it is important to note that control of bio burden through adequate cleaning and storage of equipment is important to ensure that subsequent sterilization or sanitization procedures achieve the necessary assurance of sterility.”9 Case III Limits This third case involves setting limits on equip ment surfaces where the subsequently manufactured product is aseptically produced. This case is slightly different from Case II in that it is the equipment itself, and not the product, which is subsequently sterilized. This case is relatively straightforward, because the microbial limits on the surfaces of cleaned equipment are established based on the assumed bioburden of the equipment surfaces for sterilization validation of that equipment. No information on batch sizes or surface areas is necessary. The assumed bioburden for the sterilization validation can be used directly for limit purposes. The only adjustment may be the incorpora tion of a safety factor (to accommodate normal varia tion in microbiological enumeration). Measurement Techniques Conventional tools used for microbial enumeration from surfaces can be used. These include rinse water sampling (usually with membrane filtration), swab bing (with desorption of the swab into a sterile solu tion and then a pour plate count), and use of a contact plate. The choice of recovery medium and incubation conditions is usually dictated by the expected organ isms. As a general rule, the initial focus is on aerobic bacteria. However, if anaerobic bacteria or molds/ yeasts are suspected problems, these should be also evaluated. One issue that does not translate directly from chemical residue measurements is the idea of deter mining percent recovery using the sampling method. In the measurement of chemical residues, the target residue is spiked onto a model surface and the quan titative percent recovery is determined. The amount recovered as a percent of the amount spiked is consid ered the sampling method percent recovery. Percent recoveries in chemical sampling measurement are generally above 50 percent. This percent recovery is then used to convert an analyzed sample value; for example, if a chemical residue measured by a swab bing technique gives 0.6 µg of residue, then with a 50 percent recovery, this actually represents the possibil ity of 1.2 µg being on that surface. This concept can not be applied directly to microbiological sampling. The reason for this is partly the inherent variability in microbiological testing. If one measured 10 CFU in one test and 5 CFU in a duplicate test (a 50 percent difference), one would be hard pressed to say that 10

- 8. Special Edition: Cleaning Validation III Destin A. LeBlanc, M.A. those numbers are significantly different. In addition, how would one actually measure the percent recovery in a microbiological test? If a model surface is spiked with a specific number of a certain bacterium, and then that surface is allowed to dry and is sampled, just the process of drying might cause a low recovery of bacteria (due to the dying of vegetative bacteria by drying). In addition, what species of bacteria would be used for the recovery study? It is recognized that microbiological sampling methods may understate the number of microbes on a surface (indeed the concept of a CFU, that may contain any number of bacteria, also clouds the issue). There are two ways to view such an issue. One is to make it clear that whatever variation exists in measur ing microorganisms on surfaces is probably equally an issue when one sets limits based on product limits or sterilization bioburden limits. Therefore, the variabili ty issue becomes a “wash.” The other perspective is to account for such variation by choosing extremely high safety factors. In the calculation example for Case I, a factor of 5 was used as a safety factor. Even if that safety factor were increased to 10 or 20, the calculated acceptance limits would have still been extremely high, and still beyond what one should achieve with a well-designed cleaning program. Documentation Strategies How these issues will be addressed will depend on the stage of the cleaning process development. For a new process being designed, the best strategy is to pre pare a calculation of microbial limits, and then design the cleaning process to meet those acceptance criteria. Included in that evaluation should be any change in bioburden (in particular, any increase or proliferation) on storage of the equipment. The microbial acceptance limits should be included in the validation protocol, and measured as part of the three PQ trials. One should also include the absence of “objectionable” organisms as part of the acceptance criteria. To deal with processes for which cleaning valida tion has already been completed, but for which no microbial evaluation has been done, there are two strategies available. The objective of each is to devel op documentation that the cleaning process consis tently provides equipment surfaces with acceptable bioburden. One option is to perform a cleaning validation PQ, measuring only bioburden on sur faces for comparison to calculated acceptance limits. The other option is to initiate a routine microbiologi cal monitoring program as part of the monitoring of cleaning. This may involve something as simple as monitoring the bioburden in the final rinse water to demonstrate con sistency. This data, combined with product QC data on bioburden, may satisfy the need for adequate docu mentation. One should also consider one’s motivation for wanting to obtain assurance that the bioburden is acceptably low after cleaning. If the impetus for action is due to lack of data, one should resist the impulse to immediately add a sanitizer into the cleaning program. The focus should be on developing data to demonstrate the sufficiency of the current cleaning process. Adding a separate sanitizing step only complicates matters by adding additional residue concerns. If the impetus for action is due to observed high microbial counts on equipment surfaces or (more likely) in manufactured product, then it is important to determine by careful investigation whether that unacceptable contamination is due to issues with the cleaning process, with stor age, or to both. In such a case, a separate sanitizing step should only be added if the data fully support it. Conclusion Bioburden on cleaned equipment is an impor tant concern in the cleaning process. Fortunately, most aqueous cleaning processes, properly designed, should provide low and acceptable bioburden levels onequipmentsurfacesfollowingthecleaningprocess. 11 }One issue that does not translate directly from chemical residue measurements is the idea of determining percent recovery using the sampling method.~

- 9. Institute of Validation Technology Destin A. LeBlanc, M.A. Proper drying and storage should provide assurance that microbial proliferation does not occur before the manufacture of the subsequently manufactured product in that equipment. Any scientifically justi fied determination of acceptable bioburden levels, particularly for non-sterile products, is generally far higher than what should be achieved in conventional practice. This is becoming more of a regulatory and compliance issue, not because microbial contami nation is a widespread problem, but rather because pharmaceutical manufacturers may lack appropriate documentation to support their practices. This can easily be remedied by a separate validation protocol to address microbial issues, or by routine monitoring to demonstrate consistency. o About the Author Destin A. LeBlanc, M.A., is with Cleaning Validation Technologies, providing consulting in the area of pharmaceutical cleaning validation. He has 25 years experience with cleaning and microbial con- trol technologies. He is a graduate of the University of Michigan and the University of Iowa. He can be reached by phone at 210-481-7865, and by e-mail at destin@cleaningvalidation.com. References 1. FDA. “Guide to Inspections of Validation of Cleaning Pro cesses.” 1993. 2. Pharmaceutical Inspection Cooperation Scheme. Recommen dations on Cleaning Validation. Document PR 1/99-2. Geneva, Switzerland. April 1, 2000. 3. A.M. Cundell. Microbial Monitoring. Presented at the 4th IIR Cleaning Validation Conference, October 20-22, 1997. (http:// microbiol.org/files/PMFList/clean.ppt, accessed May 29, 2001). 4. S.E. Docherty. “Establishing Microbial Cleaning Limits for Non- sterile Manufacturing Equipment.” Pharmaceutical Engineering. Vol. 19 No. 3. May/June 1999. Pp. 36-40. 5. G.L. Fourmen and M.V. Mullen. “Determining Cleaning Validation Acceptance Limits for Pharmaceutical Manufacturing Operations.” Pharmaceutical Technology. Vol. 17 No. 4. 1993. Pp. 54-60. 6. D.A. LeBlanc. “Establishing Scientifically Justified Acceptance Criteria of Finished Drug Products.” Pharmaceutical Technology. Vol. 19 No. 5. October 1998. Pp. 136-148. 7. R.R. Friedel. “The Application of Water Activity Measurements to Microbiological Attributes Testing of Raw Materials Used in the Manufacture of Nonsterile Pharmaceutical Products.” Pharmacopoeial Forum. Vol. 25 No. 5. September-October 1999. pp. 8974-8981. 8. 1111 Microbial Attributes of Nonsterile Pharmacopoeial Articles (proposed). Pharmacopoeial Forum. Vol. 25 No. 2. March-April 1999. Pp. 77857791. 9. FDA. “Guide to Inspections of Validation of Cleaning Pro cesses.” 1993. 12 CFU: Colony Forming Units FDA: Food and Drug Administration PQ: Performance Qualification QC: Quality Control USP: United States Pharmacopeia WFI: Water-For-Injection Article Acronym Listing

- 10. W e are involved in the pro duction of soft gelatin capsules and tablets in our newly built facility. Our prod ucts consist of at least 17 minerals and multivitamins in a single pro duct, while other products consist of the same ingredients having some quantity (in MG) varying with the previous one. In some products, some vitamins are not present. I want to know how to conduct a cleaning validation study of each product. Again, I want to know which ingre dients I have to check after cleaning of the equipment to determine the residues? • Whatwillthelimitbeforthemicro bial contamination for the cleaning validation studies, and what will be the rationale for the same? • If I’m using some cleaning agent, then what rationale is used for keeping the limit the same? A:Thank you for your question. It is a very good one because it represents cleaning from the point of view of a manufacturer of vitamins and min erals, which in some countries, are considered drugs, and in other countries, are considered as “nutraceuti cals,” an important and emerging part of our business. The first specific question you asked related to how to conduct a cleaning validation for each prod uct, and how to select which ingredient to check after cleaning to verify that the cleaning is adequate. The choice of which ingredient in a multi-ingredient product should serve as the focus of the cleaning validation is often a difficult one for vitamin and mineral products. For classical pharmaceutical products, the choice is usually based on choos ing the most potent ingredient, or the least water soluble ingredient, or a combination of these two factors. For vitamins and minerals the choice may be more difficult because of the many ingredients present in the formulation and the relatively small amounts present. Coupled with these difficulties is often the difficulty in assaying the very small amounts of active residues that might be pres ent after cleaning. My suggestion would be to identify an ingredient for which there is a good sensitive assay available. For example, if one of the ingredients happens to show good detectable levels of fluorescence (e.g., riboflavin, folic acid, and certain B vitamins show good fluorescence) in water, then this material could be selected as the “marker” material, and could serve as the ingredient to focus on during the analysis of the rinse samples. In the case of vitamins and min erals, it may be necessary, and even highly desirable, to take this approach because of the extremely low levels of residues present after cleaning. It may also be possible to examine equipment in a dark room with the use of an ultraviolet light to identify areas of equip ment that are not cleaned sufficiently (an enhanced visual examination), again utilizing the known fluo Special Edition: Cleaning Validation III 13 Cleaning Validation: Maximum Allowable Residue Question and Answer }…sometimes the many possible combinations of products and equipment would result in so many studies that the company would never be able to complete them during a reasonable period of time.~

- 11. Institute of Validation Technology William E. Hall, Ph.D. rescent behavior of certain vitamins. A brief study will need to be carried out to determine if this approach is appropriate and adequate for your particular situation. I would suggest that you not try to conduct cleaning validation for every product. The reason I say that is because sometimes the many possible combina tions of products and equipment would result in so many studies that the company would never be able to complete them during a reasonable period of time. If, for example, you have 50 products, and each could be run on ten (10) different pieces of equipment, then you would need 500 studies to cover all the possible combinations and permutations. That is simply too much of a resource and cost issue for the average company to face. It would be much better to divide your products into groups or families, and choose one or two representatives from each group to conduct full cleaning validation. The assumption is that you can pick some “worst-case,” most difficult to clean, potent products from each group. The first step is to divide the products into groups. I don’t know the names and ingredients of the products your company manufactur ers; however, you did mention that some products are vitamin products and others are mineral products. So I think there would be two major groups – vitamins and minerals. Then each of these groups might be further divided, if necessary. For example, in the vitamin cat egory you may have some products that contain water soluble vitamins, and some that contain fat soluble vitamins. So now we have three (3) major groups (water soluble vitamins, fat soluble vitamins, and mineral products). So you begin to see our approach. It might be that if you have vastly different types of mineral products you might want to also further divide that group into smaller groups. In any event, you want to have probably four (4) to ten (10) products in each group, and then pick a worst-case representative from each group. So by choosing this “grouping approach,” you have reduced the work from a very large resource requirement to a doable or achievable project. The choice of the worst-case representative should be based on a combination of aqueous solubility and potency. The potency can be determined for some products by determining the amount present in the product from the label or package insert. Sometimes this may be a little confusing for vitamin products because the amounts are listed in units instead of quantitative amounts, such as milligrams. In these cases, I would suggest that you refer to the Internet, and conduct a search on the toxicity or potency of these materials. You may be surprised to find that a vita min, such as folic acid, is quite potent in terms of its medical effect and dosage. The limits for these products can be calculated by allowing a certain small fraction of vitamins or minerals to carry over to each dose of the following product. Again, you will need basic information, such as the medical dosage of the initial product, the batch size and dosage of the next or subsequently manufac tured product. In terms of the safety factor, i.e., the factor that is used to reduce the allowable dosage, I suggest that you use a factor of 1/100th for vitamin and mineral products. A factor of 1/1000th is often used for pharmaceuticals, but I feel a more generous factor of 1/100th is appropriate for vitamin and min eral products. You could refer to some of the articles published in the Journal of Validation Technology for the details of how to calculate specific limits. Your last question related to what rationale should be used for the cleaning agent itself. The basic requirement is that you be able to provide data that demonstrates that the cleaning agent itself is removed during the cleaning process, usually by the final rinse. You will need to go through the same rationale for the product residue limits, i.e., establish a scientific basis or justification that shows that the most potent ingredient in the cleaning agent is reduced to a medi cally insignificant level. It is beyond the scope of this answer to go into the mathematical details of how to calculate this data, but again the details can be found in the various articles published in the Journal of Validation Technology. You will need to know about the ingredients in your cleaning agent, as they are typically multi-ingredient formulations, just like our pharmaceutical products, and you will need to get that information from your supplier of cleaning agents. The good news is that if you use the same cleaning agent and cleaning procedure for many products, then you only have to do a single cleaning validation study (three runs) for the cleaning agent. o This answer was provided by an Editorial Advisory Board Member, William E. Hall, Ph.D. Dr. Hall be reached by phone at 910-458-5068, or by fax at 910- 458-1087, and by e-mail at cleandoct@aol.com. 14

- 12. T he 1993 FDA Guideline for cleaning validation states that the removal of deter gent residues should be evaluated and there should be no or very low detergent levels left after cleaning.1 Currently,thepharmaceuticalindus try employs varieties of detergents for cleaning and different cleaning validation programs. Many com panies have not included detergent residue evaluation as part of their cleaning validation programs main ly due to unavailability of effective methodologies or lack of awareness of the requirement by management. In the late 1970s, Total Organic Carbon (TOC) analysis had been used for monitoring water quality in pharmaceuticals and environmental controls. More recently, the biotech nology and pharmaceutical industry has become increasingly interested in the use of TOC as an analytical tool in cleaning validation programs. TOC analy sis has been used as an analytical tool for cleaning validation in the biotechnology industry for years.2,3 Westman and Karlson recently conducted a compari son study for different analytical methods – visual detection of foam, pH, conductivity measurements, and TOC for detergent residue evaluation. They concluded that the visual detection of foam was the best method for the detergents they tested.4 The method of visual detection of foam is only effective for foaming detergents, but is invalid for low foaming deter gents. From a user’s point of view, this paper documents that TOC is an effective and quantitative method for detergent residue verification. Total Organic Carbon Methodology TOC is a non-specific method for the compound analyzed. However, TOC analysis is sensitive to very low levels of 0.002-0.8 ppm carbon, depending on whether the sample is a water sample or a swab sample. Currently, two major oxidation tech nologies dominate the TOC market: combustion and Ultra Violet (UV)/ persulfate. There has been debate about which technique is better suited for TOC testing since the late 1980s. The major differences for each technique5 are described in Figure 1, and give the user appropriate information to make an informed deci sion as to which technique better serves their needs. The best TOC oxidation technology is the one that meets the application and analytical needs of the Special Edition: Cleaning Validation III 15 Development of Total Organic Carbon (TOC) Analysis for Detergent Residue Verification By James G. Jin and Cheryl Woodward Boehringer Ingelheim Pharmaceuticals, Inc. v }…the biotechnology and pharmaceuti- cal industry has become increasingly interested in the use of TOC [Total Organic Carbon] as an analytical tool in cleaning validation programs.~

- 13. Institute of Validation Technology James G. Jin user’s situation. The UV/Persulfate method meets precision and accuracy requirements for low-level calibration check standards such as 0.5 ppm carbon in detergent residue evaluation. However, if captur ing the particulate organic matter in the TOC value is important, then combustion would be the better oxidation technology. The instrument we chose is a Tekmar-Dohrmann Phoenix 8000 with the UV/Per sulfate oxidation technique. Chemistry of Oxidation and Total Organic Carbon Analysis of UV/Persulfate Wet chemistry oxidation of carbon compounds utilizes two chemical reactions to complete the analysis. A 21 percent solution of phosphoric acid is utilized in converting inorganic carbon species. Acidification of the sample allows for attack on inor ganic species such as carbonates and bicarbonates to convert them to carbon dioxide. This, along with any dissolved carbon dioxide in the sample is then sparged out, and either exhausted to vent or routed to the Non-Dispersive Infrared detection (NDIR) for quantification when analyzing for Inorganic Carbon (IC) or TOC by difference (TC-IC). H+ + CO3 -2 → H2 O + CO2 Persulfate is used to do the rest of the oxidation chemistry that is required for analysis. Sodium persul fate, at a concentration of 10 percent, and phosphoric acid, five percent are added to the UV chamber for analysis. The persulfate species in the presence of UV light breaks down at a weak oxygen-oxygen bond yielding two radicals per molecule. These radi cals start chain reactions that ultimately lead to the degradation of all carbon species to carbon dioxide, water, and other oxides of heteroelements. The UV light alone induces breakdown of many carbon spe cies with the persulfate providing additional help to attack compounds difficult to oxidize. The radical reactions are aggressive and indiscriminate in their attack. S2 O8 -2 → SO4 -1 + R → H2 O + CO2 The NDIR is constructed in such a way as to be sensitive and selective for carbon dioxide present in the gas flow. An infrared beam from the source is passed through a chopper and down the sample chamber to a dual chamber detector. Each chamber is filled with carbon dioxide and is separated by a thin membrane. Varying intensity of the light hitting the cell causes fluctuation in temperature and thus the pressure of the gas inside the detector. This causes the membrane to deflect, which is ultimately read as a millivolt output signal from the detector. Detergent Evaluation Three detergents (CIP-100, CIP-200, and Sparquat 256) were tested both in-house using the Tekmar Dohrmann Phoenix 8000 TOC Analyzer and at a contract lab, Quantitative Technologies Inc. (QTI), to verify the total amount of organic carbon in each detergent at its original concentration. The method and instrument used at QTI was a Perkin-Elmer CHN Analyzer 2400. This experiment was performed to make a comparison between our instrument and the instrument in a qualified contract laboratory for infor mation purposes only. One detergent (Chlor-Mate) was tested in-house and compared with the available 16 Figure 1 Types of Total Organic Carbon Techniques Oxidation Detection Technique Analytical Range (TOC) Official Methods Combustion Thermal Conductivity Detector (TCD) 0.5 – 100% AOAC 955.07 Combustion Coulometric 1 – 100% ASTM D4129 UV/Persulfate Non-Dispersive Infrared Detector (NDIR) 0.002 – 10,000 mg/L USP 643 Heated Persulfate NDIR 0.002 to 1,000 mg/L USP 643 Combustion NDIR 0.004 – 25,000 mg/L USP 643 UV/Persulfate Membrane/Conductivity 0.0005 – 50 mg/L USP 643 UV Conductivity or NDIR 0.0005 – 0.5 mg/L USP 643

- 14. Special Edition: Cleaning Validation III James G. Jin vendor’s specification. The TOC results for all the detergents are shown in Figure 2. The differences between the in-house and QTI results with respect to the TOC assay for CIP-100 and CIP-200 are 5.0 percent and 9.6 percent, respectively. These differences are relatively low compared to the 20 percent recovery criteria during recovery studies. The difference between the in-house and QTI results with respect to the TOC assay for Sparquat 256 is 28.4 percent. The in-house result was reviewed and no error was noted in the performance of the test ing procedure. The major differences may be due to instrument and testing method variations. The result for Chlor-Mate is within the vendor’s specification. Swab Selection It has been known for years that polyester is a suitable material for TOC swabbing analysis. Over 20 different kinds of polyester swab samples were received from The Texwipe Company LLC. Five of them were chosen for TOC evaluation based on sample design and the convenience for use. The purpose of this experiment was to select a type of swab that has little TOC background interference and with consistent TOC results over time. Ultra purified water with 0.05 to 0.08 ppm carbon was used for swab analysis. The TOC results obtained from our TOC analyzer are shown in Figure 3. Swabs TX761 and TX741A showed increasing TOC results from 0.0813 to 0.9692 ppm carbon and from 0.1724 to 1.1246 ppm carbon over five days, respectively. Swab TX700 showed an unacceptably high TOC result of 46.1991 ppm carbon at the begin ning of the experiment, and was therefore not tested further. None of these swabs are suitable for our TOC analysis. Both polyester wipers AlphaSorb® HC TX2412 and TX2418 show acceptable results with respect to result consistency. The average of the seven TOC results from TX2412 and TX2418 found in Figure 3 is 0.8327 ± 0.1860 ppm carbon. The variation is acceptable compared to the acceptance criterion of three ppm carbon. These two swabs with the same material were selected to be our TOC swabs (cut to 5x5 cm2 ) for detergent residue verification. The TX3340 TOC cleaning validation kit including Eagle EP Picher 03464-40mL clear vials, Texwipe® TX714L-large SnapSwabsTM , and blank vial labels may be chosen since it is specially designed for TOC swabbing purposes. Detergent Recovery Evaluation from Stainless Steel Surface Ten stainless steel templates were spiked with detergent solution and swabbed using the polyester wipers AlphaSorb® HC TX2418 (5x5 cm2 ) for the detergent recovery study. The spiking and swabbing procedures were the same as those used for drug substance recovery studies. Forty mL of ultra puri fied water was added to each test tube as the extrac tion solution, vortexed about one minute, and then sonicated for five minutes for testing. The results are shown in Figure 4. The recoveries for CIP-100, CIP-200, and Chlor- Mate are over 80 percent and no correction factor is necessary. For Sparquat 256, a correction factor of 0.61 will be used. For example, if a result of 0.5 ppm carbon is obtained from the TOC analyzer, the final reported result would be 0.82 (0.5 ÷ 0.61) ppm carbon. Detergent Recovery Evaluation from Non-Stain less Steel Surfaces The aforementioned study was repeated using non-stainless steel templates. Two or three non-stain 17 Figure 2 Total Organic Carbon Results for Detergent Evaluation Detergent Manufacturer/Lot Total Organic Carbon Result TOC Results Identification From BIPI* From QTI/Vendor CIP-100 Vestal Convac lot 211097 4.0208 ± 0.0139% 4.22% CIP-200 Convac lot 213915 2.4986 ± 0.0114% 2.26% Sparquat 256 ISSA (lot: n/a) 14.0232 ± 0.9336% 18.0% Chlor-Mate WestAgro® lot J8G0489AR 1.29% ± 0.0086% 1 – 1.5% *Boehringer Ingelheim Pharmaceuticals, Inc.

- 15. Institute of Validation Technology James G. Jin less steel templates were spiked with each detergent solution and swabbed using the polyester wipers AlphaSorb® HC TX2418 (5x5 cm2 ). The results are shown in Figure 5. For CIP-100 and CIP-200, the recoveries from each non-metal surface are over 80 percent. There fore, no correction factor is needed with respect to the TOC recovery. For Sparquat 256, the recoveries vary with different surfaces. The correction factors are as follows: For Delrin surface: correction factor = 0.74 For Glass surface: correction factor = 0.75 For Nylon surface: correction factor = 0.43 For Lexan surface: correction factor = 1.0 Evaluation of Detergent Residue After Rinsing The purpose of this experiment was to evaluate: ∂ The suitability of the Acceptance Criterion (AC) of three ppm carbon ∑ The effect of detergent concentration on deter gent residue after rinsing ∏ Recovery of detergent from different surfaces with and without rinsing π Rinsing efficiency and rinse time Four detergents (CIP-100, CIP-200, Sparquat 256, and Chlor-Mate) were used in both a concen trated form and at a working concentration of 0.5 oz/gal. Approximately one mL of detergent solution was pipetted and spiked onto the templates with different materials of construction and dried with ventilation under a hood in the research and devel 18 Figure 3 Total Organic Carbon Results (ppm C) for Swab Selection Swab TOC/Two Hours TOC/Four Hours TOC/One Day TOC/Two Days TOC/Five Days Description in H2 O in H2 O in H2 O in H2 O in H2 O Polyester Alpha 0.0813 0.3221 0.3926 0.9410 0.9692 swab TX761 ± 0.0041 ± 0.0853 ± 0.0166 ± 0.0288 ± 0.0299 Polyester Alpha 0.1724 0.2509 0.5330 0.8091 1.1246 swab TX741 A ± 0.0144 ± 0.0068 ± 0.0250 ± 0.0200 ± 0.0394 Polyester wipers 1.1665 0.6091 0.8602 0.7535 0.9723 AlphaSorb® ± 0.0406 ± 0.0490 ± 0.0264 ± 0.0328 ± 0.0668 HC TX2412 Polyester wipers 0.7406 0.7269 N/A(1) N/A(1) N/A(1) AlphaSorb® ± 0.0056 ± 0.0297 HC TX2418 Polyester Alpha 46.1991 N/A N/A N/A N/A swab TX700 ± 8.0761 1. Polyester wipers AlphaSorb® HC TX2412 and polyester wipers AlphaSorb® HC. TX2418 is same material cut to different sizes. Figure 4 Total Organic Carbon Recovery Results from a Stainless Steel Surface Detergent Percent Number Percent Recovery of Relative Samples Standard Deviation CIP-100 111.7 30 5.92 CIP-200 92.4 10 4.10 Sparquat 256 61.0 20 8.47 Chlor-Mate 99.1 10 2.76 Note: Results were automatically corrected for the instrument blank effect. Figure 5 Total Organic Carbon Recovery Results from a Non-Stainless Steel Surface Detergent Lexan Delrin Glass Nylon Surface Percent Percent Percent Percent Recovery Recovery Recovery Recovery CIP-100 106.9 113.8 107.6 127.0 CIP-200 90.3 92.3 97.4 93.2 Sparquat 83.3 74.0 75.1 42.5 256

- 16. Special Edition: Cleaning Validation III James G. Jin opment manufacturing area for a minimum of four hours. The templates were swabbed per standard swabbing procedure either before or after rinsing, using the polyester wipers AlphaSorb® HC TX2412 cut to 5x5 cm2 . The rinse was first conducted using tap water and then purified water United States Pharmacopoeia (USP), both at room temperature and with a slow flow rate of approximately 2.7 L/ min. Two different rinse times (30 seconds and 60 seconds) were evaluated for different detergents on different templates to simulate the final rinse step in our manual cleaning process. The recovery results are reported in Figure 6. The Tekmar Dohrmann Phoenix 8000 TOC ana lyzer was easily able to detect the non-rinse samples with the results of 3.911 ppm carbon, 2.0928 ppm carbon, and 10.0868 ppm carbon for CIP-100, CIP- 200, and Sparquat 256, respectively. The results indicate that the AC of three ppm carbon is still high for detergents CIP-100, CIP-200, and Sparquat 256. The AC of one ppm carbon is acceptable. There were no differences in detectable residue for all four detergents (both concentrated and at 0.5 oz/gal) on stainless steel after a 30-second tap water rinse fol lowed by a 30-second purified water, USP rinse. Delrin was chosen for a typical material of construc 19 Figure 6 Total Organic Carbon Results on Detergent Residue by Rinsing Sample Concentration Templates Rinse Time Area TOC Results Identification Swabbed (ppm C)d CIP-100 0.5 oz/gal SS a No rinse 100 cm2 3.9111 CIP-100 0.5 oz/gal SS a 30”/30” b 100 cm2 Less than blank CIP-100 Concentrated SS a 30”/30” b 100 cm2 Less than blank CIP-100 0.5 oz/gal Delrin 30”/30” b 100 cm2 Less than blank CIP-100 0.5 oz/gal Delrin 60”/60” b 100 cm2 Less than blank CIP-100 0.5 oz/gal Nylon 30”/30” b 100 cm2 0.6682 CIP-100 0.5 oz/gal Glass 30”/30” b 100 cm2 0.0001 CIP-100 0.5 oz/gal Lexan 30”/30” b 100 cm2 Less than blank CIP-200 0.5 oz/gal SS a No rinse 100 cm2 2.0928 CIP-200 0.5 oz/gal SS a 30”/30” b 100 cm2 Less than blank CIP-200 Concentrated SS a 30”/30” b 100 cm2 Less than blank CIP-200 0.5 oz/gal Delrin 30”/30” b 100 cm2 Less than blank CIP-200 0.5 oz/gal Delrin 60”/60” b 100 cm2 Less than blank CIP-200 0.5 oz/gal Nylon 30”/30” b 100 cm2 0.7720 CIP-200 0.5 oz/gal Glass 30”/30” b 100 cm2 0.0133 CIP-200 0.5 oz/gal Lexan 30”/30” b 100 cm2 Less than blank Sparquat 256 0.5 oz/gal SS a No rinse 100 cm2 10.0868 c Sparquat 256 0.5 oz/gal SS a 30”/30” b 100 cm2 0.2693 c Sparquat 256 Concentrated SS a 30”/30” b 100 cm2 Less than blank Sparquat 256 0.5 oz/gal Delrin 30”/30” b 100 cm2 Less than blank Sparquat 256 0.5 oz/gal Delrin 60”/60” b 100 cm2 Less than blank Sparquat 256 0.5 oz/gal Nylon 30”/30” b 100 cm2 0.3866 c Sparquat 256 0.5 oz/gal Glass 30”/30” b 100 cm2 Less than blank Sparquat 256 0.5 oz/gal Lexan 30”/30” b 100 cm2 Less than blank Chlor-Mate 0.5 oz/gal SS a 30”/30” b 100 cm2 Less than blank Chlor-Mate Concentrated SS a 30”/30” b 100 cm2 Less than blank Notes: a. Stainless steel. b. 30”/30” or 60”/60” – rinse time in seconds, tap water/purified water United States Pharmacopoeia (USP). c. Result without correction factor.

- 17. Institute of Validation Technology James G. Jin tion and 30/60 seconds were chosen for evaluation of the rinse time. There was no difference in detectable residue for CIP-100, CIP-200, and Sparquat 256 on the Delrin surface after 30-second and 60-second rinse times. The results also show that it is more dif ficult to remove residues of CIP-100, CIP-200, and Sparquat 256 from a Nylon surface than from other materials. Acceptance Criterion for Detergent Residue There is no universal AC for detergent residue allowed to be left on GMP equipment surfaces. In our detergent residue verification program, the AC for each detergent residue left on equipment surfaces depends on the sensitivity of the instrument used for analysis. This means we must set a low AC that is still quantifiable and applicable. Toxicity of the detergent is not a concern at these trace amounts detergent level. Effects on human health from residue left on equipment surfaces should be insignificant at a low concentration such as 0.5 oz/gal and with a routine rinse procedure. Our objective in this program is to demonstrate that we are able to verify whether or not the detergent residues are removed to an acceptable low-level we can achieve. Therefore, the AC should be established as close to the instrument’s level of detection as possible. We tighten the initial limit of three ppm carbon to AC = 1.0 ppm carbon (net reading automatically corrected with blank by the instrument in a 40 mL solution), which is less than two times the blank baseline. The AC can also be expressed as AC ≤ 10 ppb carbon/ cm2 . This AC is practical and verifiable. The significance of the 1.0 ppm carbon AC for each detergent can be explained in Figure 7. We can see from the above calculations that AC = 1.0 ppm carbon means, for all detergents at 0.5 oz/gal, that we allow the maximum of 1 ÷ 3.92 = 0.26 mL of CIP-100, 1 ÷ 2.44 = 0.41 mL of CIP-200, 1 ÷ 13.68 = 0.07 mL of Sparquat 256, and 1 ÷ 1.26 = 0.79 mL of Chlor-Mate to be left on 100 cm2 of equipment surface after cleaning, respectively. Detergent Residue Verification Program Our detergent verification program is designed to be a one-time verification for each detergent used. This was based on the rinse experiment and the assumption that our routine rinsing procedures performed by well trained operators are sufficient to remove detergent residues to the level of less than the AC. This assumption has been verified from the results shown in Figure 6 that all the residues are eas ily removed by a 30-second tap water rinse followed by a 30-second purified water, USP rinse with very low spray rate. Verification rather than validation is currently required by the 1993 FDA, Guide to Inspec tions of Validation of Cleaning Procedures due to the fact that detergent residue is less significant than drug substance residue left after cleaning. Summary The detergent residue verification program has been successfully established using the Tekmar Dohrmann Phoenix 8000 TOC analyzer. This paper has shown the program development, and presents critical data to support the detergent verification reports for each detergent used. The instrument Installation Qualification (IQ), Operational Qualification (OQ), system calibration, and the TOC analysis method development were performed but not discussed in this paper. The poly ester wipers AlphaSorb® HC TX2412 and TX2418 cut to 5x5 cm2 have been selected as the swabs for sampling detergent residue from equipment surface for TOC analysis. The AC for the detergents CIP- 100, CIP-200, Sparquat 256, and Chlor-Mate with respect to TOC has been established as AC ≤ 10 ppb carbon/cm2 . Two different rinse times, 30 seconds and 60 seconds, were evaluated. The results show 20 Figure 7 Significance of Total Organic Carbon Results for Detergent at 0.5 oz/gal CIP-100 CIP-200 Sparquat 256 Chlor-mate 1 mL at 0.5 oz/gal 3.92 ppm 2.44 ppm 13.68 ppm 1.26 ppm diluted to 40 mL 1.0 ppm C per 100 cm2 0.26 mL 0.41 mL 0.07 mL 0.79 mL corresponding to

- 18. Special Edition: Cleaning Validation III James G. Jin that 30-second/30-second rinse time (30-second rinse with tap water and then 30-second rinse with puri fied water, USP) is sufficient to remove the detergent residues from different material templates including stainless steel, Delrin, Glass, Nylon, and Lexan to a level below the AC. The correction factors were deter mined based on the results of the recovery studies and will be used by analytical sciences to report the final TOC results for the detergent residue verification. o About the Authors James G. Jin is Chairman of the Cleaning Validation Committee for Boehringer Ingelheim Pharmaceuti cals, Inc., which is responsible for cleaning valida- tion program development and implementation. He has more than ten years experience in pharmaceuti- cal science and business arenas. He can be reach ed by phone at 203-798-5309. Cheryl Woodward is Associate Director of Research and Development (RD) Manufacturing, for Boeh ringer Ingelheim Pharmaceuticals, Inc. She is responsible for all aspects of GMP manufacturing for clinical supplies and has over 18 years experi- ence in the pharmaceutical and related industries. She can be reached by phone at 203-798-5367. References 1. FDA. Guide to Inspections of Validation of Cleaning Proce dures. July, 1993. 2. Jenkins K.M., Vanderwielen A.J, Armstrong J.A, Leonard L.M, Murphy G.P, Piros N.A. 1996. “Application of Total Organic Carbon Analysis to Cleaning Validation.” PDA. Journal of Pharmaceutical Science and Technology. 50. Pp 6-15. 3. Guazzaroni M., Yiin B., Yu J., 1998. “Application of Total Organic Carbon Analysis for Cleaning Validation in Pharmaceuti cal Manufacturing.” American Biotechnology Laboratory. Septem ber. Pp. 66-67. 4. Westman L., Karlsson G., 2000. “Methods for Detecting Resi dues of Cleaning Agents During Cleaning Validation.” Research Article, Vol. 54, No. 5. September/October. 5. Furlong J., Booth B., Wallace B. 1999. “Selection of a TOC Analyzer: Analytical Considerations.” Tekmar-Dohrmann Application Note. Vol. 9.20. 21

- 19. I n the pharmaceutical industry, Good Manufacturing Practice (GMP) requires that the clean ing of drug manufacturing equip ment be validated.1 Many different validation techniques can demon strate that the manufacturing equip ment is cleaned and essentially free from residual active drug substanc es and all cleaning agents. Common analytical techniques in the validation process include High Performance Liquid Chrom atography (HPLC), spectrophotom etry Ultraviolet/Visible (UV/Vis) and Total Organic Carbon (TOC). HPLC and UV/Vis are classified as specific methods that identify and measure appropri ate active substances. TOC is classified as a non- specific method and is ideal for detecting all carbon- containing compounds, including active species, excipients, and cleaning agent(s).2,3,4,5 The disadvantage of specific methods, particular ly HPLC, is that a new procedure must be developed for every manufactured active drug substance. This development process can be very time consuming and tedious, plus important sampling issues must also be considered. In addition, HPLC analyses must be performed in a relatively short time period after sampling to avoid any chemical deterioration of the active substance. Finally, the sensitivity of HPLC methods can be limited by the presence of degrada tion products. Of course the disadvantage to non- specific methods like TOC is that they cannot identify exactly what the residue material is. Depending on the chosen cleaning process and established acceptance limits, a non-specific method may be all that is needed to validate the process. TOC analysis can be adapted to any drug compound or clean ing agent that contains carbon and is “adequately” soluble in water. Studies have been conducted to demonstrate that TOC methods can also be applied to carbon containing compounds that have limited water solubility, and recovery results are equal to those achieved by HPLC.6 TOC methods are sensitive to the parts per billion (ppb) range and are less time consuming than HPLC or UV/Vis. United States Pharmacopoeia (USP) TOC methods are standard for Water-for-Injection and Purified Water,7 and simple modifications of these methods can be used for cleaning validation. Methodology TOC analysis involves the oxidation of carbon and the detection of the resulting carbon dioxide. A num ber of different oxidation techniques exist, including photocatalytic oxidation, chemical oxidation, and high-temperature combustion. In this study, an Anatel A-2000 Wide-Range TOC Analyzer, equipped with an autosampler, was used. The Anatel A-2000 Wide- Institute of Validation Technology22 Total Organic Carbon Analysis for Cleaning Validation in Pharmaceutical Manufacturing By Karen A. Clark Anatel Corporation v }TOC analysis can be adapted to any drug compound or cleaning agent that contains carbon and is ‘adequately’ soluble in water.~

- 20. Special Edition: Cleaning Validation III Karen A. Clark Range Analyzer measures TOC in accordance with American Society for Testing and Materials (ASTM) methods D 4779-88 and D 4839-88. It measures TOC directly by adding phosphoric acid to the water sample to reduce the pH from approximately two to three. At this low pH any inorganic carbon that is present is liberated as CO2 into a nitrogen carrier gas and is directly measured by a non-dispersive infrared (NDIR) detector. Any remaining carbon in the sample is assumed to be TOC. A sodium persulfate oxidant is then added to the sample, and in the presence of UV radiation, the remaining carbon is oxidized to CO2 . The amount of CO2 generated is then measured by the NDIR to determine the amount of TOC originally present in the water. For equipment cleaning validation there are two types of TOC sampling techniques. One is the direct surface sampling of the equipment using a swab. The second consists of a final rinse of the equipment with high-purity water (typically 500 ppb TOC) and collecting a sample of the rinse for analysis. In general, direct surface sampling indicates how clean the actual surface is. This study demonstrates how to develop and validate a TOC method to measure a variety of different organic residues on stain less steel surfaces. Performance parameters tested include linearity, method detection limit (MDL), limit of quantitation (LOQ), accuracy, precision, and swab recovery. Linearity TOC analysis should provide a linear relationship between the measured compound concentration and the TOC response of the analyzer. We evaluated four different types of cleaning agents for linearity: ∂ CIP-100® (alkaline) ∑ CIP-200® (acidic) ∏ Alconox® (emulsifier) π Triton-X 100 (wetting agent) Results are shown in Figures 1-4. Correlation coefficients ranged from 0.9787 to 0.9998. Alconox and Triton-X 100 have a tendency to foam, depend ing on the concentrations that are analyzed and this foaming phenomena can have a negative effect on the accuracy of the TOC result (reduced R2 ). Three 23 Figure 1 Linearity of CIP-100 9000 8000 7000 6000 5000 4000 3000 2000 1000 0 MeasuredTOC(ppb) CIP 100 Concentration (ppm) 0 50 100 150 200 250 y=39.254x + 1.462 R2 =0.9997 Figure 2 Linearity of CIP- 200 9000 8000 7000 6000 5000 4000 3000 2000 1000 0 MeasuredTOC(ppb) CIP 200 Concentration (ppm) 0 100 200 300 400 500 y=19.132x + 51.042 R2 =0.9998 Figure 3 Linearity of Alconox 45 40 35 30 25 20 15 10 5 0 MeasuredTOC(ppm) Alconox Concentration (ppm) 0 200 400 600 800 1000 y=0.0355x + 1.1983 R2 =0.9787

- 21. Institute of Validation Technology Karen A. Clark representative examples of active substances were also tested for linearity: an excipient (sucrose), an antibiotic (vancomycin), and endotoxin. Results are shown in Figures 5-7. All three compounds demonstrated excellent linearity with correlation coefficients (R2 ) ranging from 0.9996 to 0.9998. Method Detection Limit and Limit of Quantitation We determined the Method Detection Limit (MDL) by measuring the TOC response of the meth od blank. A method blank consists of the sampling vial, swab, and recovery solution. In this study, the recovery solution was low TOC ( 25 ppb) water. Ten pre-cleaned vials were filled with the low TOC water. One swab was placed in each vial (Texwipe Alpha Swab TX761; tips cut off). Solutions were vortexed and allowed to stand for one hour prior to analysis. Four replicates from each vial were ana lyzed. The four replicates from each of the ten blank vials were averaged. These ten values were averaged again and a standard deviation was calculated. The standard deviation was multiplied by the Student t number for n-1 degrees of freedom (3.25 for n=10), at 99% confidence levels to determine the method detection limit. The MDL was calculated to be 50 ppb. The Limit of Quantitation (LOQ) was calcu lated by multiplying the MDL by three. A value of 150 ppb was obtained (see Figure 8). Precision and Accuracy 24 Figure 4 Linearity of Triton-X 100 12500 10000 7500 5000 2500 0 MeasuredTOC(ppb) Triton-X 100 Concentration (ppm) 0 5 10 15 20 25 y=415.76x + 16.997 R2 =0.9982 Figure 6 Linearity of Vancomycin 8000 6000 4000 2000 0 MeasuredTOC(ppb) Vancomycin Concentration (ppb) 0 2000 4000 6000 8000 y=0.8758x + 62.133 R2 =0.9998 Figure 5 Linearity of Sucrose 12000 10000 8000 6000 4000 2000 0 MeasuredTOC(ppb) Sucrose Concentration (ppb) 0 2000 4000 6000 8000 10000 12000 y=1.003x + 45.185 R2 =0.9996 Figure 7 Linearity of Endotoxin 8000 7000 6000 5000 4000 3000 2000 1000 0 MeasuredTOC(ppb) Endotoxin Concentration (ppb) 0 2000 4000 6000 8000 y=0.9287x + 30.8 R2 =0.9998

- 22. Special Edition: Cleaning Validation III Karen A. Clark To demonstrate the precision and accuracy for this TOC method, a representative solution of CIP-100 as 1000 ppb, or one ppm as carbon, was analyzed sequen tially ten times. This carbon concentration was chosen to evaluate these method parameters because, in gen eral, TOC residual limits are typically around one ppm. Results are listed in Figure 9. At this TOC level, the precision was ± 1% and the accuracy was ± 5%. Swab Recovery Stainless steel plates were used in the swab recov ery test to simulate manufacturing equipment. One side of each plate was spiked with a solution of active substance or cleaning agent. The plates were allowed to completely dry overnight at room temperature. A Texwipe alpha swab TX761 was moistened with low TOC ( 25 ppb) water and the spiked plate surface was swabbed both vertically and horizontally. The swab end was cut off, placed into a vial to which we added 40-mL of low TOC water. The vial was capped tight, vortexed, and allowed to stand for one hour prior to analysis. The same volume of each solution that was spiked onto the plates was separately spiked directly into 40-mL of low TOC water and analyzed. The per cent recoveries of the different substances are listed in Figure 10. Reported values are the average of three individual swab samples for each substance. The swab recoveries varied between 79.3% to 95.9% Conclusion This study demonstrates that TOC analysis is suitable for measuring organic residues on stain less steel surfaces, and that it is a reliable method for cleaning validation as demonstrated by surface residue recoveries of 79%-96%. This methodology 25 Figure 8 Calculated TOC Averages from 10 Blank Vials Vial Number Average TOC (ppb) 1 58 2 72 3 75 4 93 5 79 6 102 7 60 8 83 9 67 10 54 Average 74.3 Standard Deviation 15.5 MDL (Student t, n=10) 50 ppb LOQ 151 ppb Figure 9 Calculated Accuracy and Precision from 10 Replicates of a 1ppm CIP- 100 Solution as Carbon Vial Number Measured TOC (ppb) 1 1041 1 1025 1 1039 1 1057 1 1054 2 1034 2 1042 2 1048 2 1054 2 1055 Average 1045 Standard Deviation 10.5 % CV (precision) 1.0% % Recovery based on 105% 1 ppm C (accuracy) Figure 10 Representative Examples of Swab Recoveries from Cleaning Agents and Active Substances Substance ppm C of Spike ppm C of Spiked % Recovery % RSD Standard Solution Plate CIP-100 1810 1710 94.5 1.8 Sucrose 2663 2112 79.3 4.9 Vancomycin 661 634 95.9 3.0 Endotoxin 902 736 80.0 2.8

- 23. Institute of Validation Technology Karen A. Clark shows that low limits of detection, excellent linear ity, precision, and accuracy can be obtained. All of these TOC results, with the exception of Alconox and Triton-X 100, were generated using the same TOC method, making TOC analysis a low cost and less time consuming alternative for cleaning valida tion. o About the Author Karen A. Clark is a Product Manager at Anatel Corporation. She has over 15 years experience in the pharmaceutical/biotechnology industry focus- ing on drug formulations, analytical methods devel- opment and validation, and GLP/GMP laboratory management. Clark holds a B.S. in Biochemistry from Millersville University and an M.S. in Chemical Engineering from the University of Colorado. She can be reached by e-mail at kclark@anatel.com or at Anatel Corporation, 2200 Central Avenue, Boulder, CO 80301. References 1. FDA. Current Good Manufacturing Practice Regulations, 21 CFR 211.220. 2. Baffi, R. et al. 1991. “A Total Organic Carbon Analysis Method for Validating Cleaning Between Products in Biopharmaceutical Manufacturing.” Journal of Parenteral Science and Technology 45, no. 1: 13-9. 3. Jenkins, K. M. et al. 1996. “Application of Total Organic Carbon Analysis to Cleaning Validation.” PDA Journal of Pharm aceutical Science and Technology 50, no. 1: 6-15. 4. Strege, M. A. et al. 1996. “Total Organic Carbon Analysis of Swab Samples for the Cleaning Validation of Bioprocess Fermentation Equipment.” BioPharm (April). 5. Guazzaroni, M. et al. 1998. “Application of Total Organic Car bon Analysis for Cleaning Validation in Pharmaceutical Man ufacturing.” American Biotechnology Laboratory 16, no. 10 (September). 6. Walsh, A. 1999. “Using TOC Analysis for Cleaning Validation.” Presented at The Validation Council’s Conference on Cleaning Validation, 27 October, Princeton, New Jersey. 7. USP 23, Fifth Supplement, 15 November 1996. 26

- 24. Special Edition: Cleaning Validation III Advertisement 27 The Journal of Validation Technology and the Journal of GXP Compliance are looking for authors to submit case studies on contemporary validation and compliance topics and issues. If you would like to submit an article for consideration or request a copy of editorial guidelines, please fill out this form and fax it to: Institute of Validation Technology – Editorial Department. Phone: (218) 740-7028 • Editorial Department Fax: (218) 740-6308. Name: ____________________________________________________________________ Title:______________________________________________________________________ Company:_________________________________________________________________ Address:__________________________________________________________________ City: _ ____________________________________________________________________ State:_____________________________________________________________________ Zip:���������������������������������������������������������������������� Country:_ ________________________________ Telephone:________________________ Fax:______________________________________________________________________ E-Mail:������������������������������������������������������������������� Topic:�������������������������������������������������������������������� What are you are you working on today? We’d like like to hear about it… PO Box 6004 Duluth, MN 55806 Phone: 218-740-7028 U.S. Only: 888-524-9922 Fax: 218-740-6308 E-Mail: info@ivthome.com Web Site: www.ivthome.com

- 25. T he FDA recognizes the importance of effective cleaning and sanitizing pro tocols as a proactive measure in preventing cross-contamination in the pharmaceutical and cosmetic industries: 21CFR 211.67: “Equipment and utensils shall be cleaned, main tained, and sanitized at appropriate intervals to prevent malfunctions or contamination that would alter the safety, identity, strength, qual ity, or purity of the drug product beyond the official or other estab lished requirements.” In order to comply with this reg ulatory requirement, sound clean ing and sanitizing protocols must be developed and followed. One of the most critical components of any cleaning program is detergent selection. Different processes and potential contaminants may require different detergents that are appro priate for the application. In certain cleaning applications, a neutral foaming detergent might be appropriate, whereas in others, a non-foam ing alkaline detergent is desirable. The choice of detergent for a given application should be based on sound, scientific reasoning. A sound rationale for detergent selection begins at the manufactur ing site, where the process and cleaning program will take place. A full evaluation of the process, clean ing strategies, potential contaminant levels, and available utilities is a good first step. Following this step, laboratory testing is required to determine the exact nature of the potential contaminant. Next, ident ification and testing of various clean ing chemistries against the potential contaminant is performed to deter mine which detergent type is best suited for contaminant removal. The next step is to return to the manufac turing site, test the cleaning chem istry, and optimize the program. This approach provides a sound, scientific rationale for the detergent selection and lays a firm foundation to the formal cleaning protocol, once developed. This article will discuss the key factors that must be addressed when selecting a detergent. Each factor will be discussed in detail and examples are given when appropriate. The roles Institute of Validation Technology28 Detergent Selection – A First Critical Step in Developing a Validated Cleaning Program By Mark Altier Ecolab, Inc. v }This article will discuss the key factors that must be addressed when selecting a detergent. Each factor will be discussed in detail and examples are given when appropriate. The roles of laboratory testing and plant optimization are also addressed.~