Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

Empfohlen

Weitere ähnliche Inhalte

Ähnlich wie Rotor repair

Ähnlich wie Rotor repair (20)

Zero Pollution Solutions for Age Old Problems on Ships

Zero Pollution Solutions for Age Old Problems on Ships

Altra: Manufacturing Market Applications & Innovations

Altra: Manufacturing Market Applications & Innovations

Molykote selector guide for automotive applications

Molykote selector guide for automotive applications

Delo family of products proof of performance - mack concrete trucks - compone...

Delo family of products proof of performance - mack concrete trucks - compone...

Mehr von Sue Jones

Mehr von Sue Jones (7)

Rotor repair

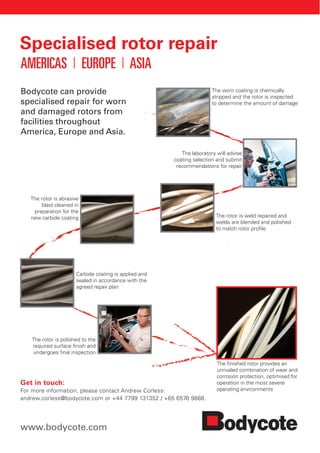

- 1. Specialised rotor repair www.bodycote.com Get in touch: For more information, please contact Andrew Corless: andrew.corless@bodycote.com or +44 7799 131352 / +65 6576 9888. The worn coating is chemically stripped and the rotor is inspected to determine the amount of damage The laboratory will advise coating selection and submit recommendations for repair The rotor is weld repaired and welds are blended and polished to match rotor profile The rotor is abrasive blast cleaned in preparation for the new carbide coating Carbide coating is applied and sealed in accordance with the agreed repair plan The rotor is polished to the required surface finish and undergoes final inspection The finished rotor provides an unrivaled combination of wear and corrosion protection, optimised for operation in the most severe operating environments Bodycote can provide specialised repair for worn and damaged rotors from facilities throughout America, Europe and Asia. AMERICAS | EUROPE | ASIA