Assembling a 632 Mountain Motor

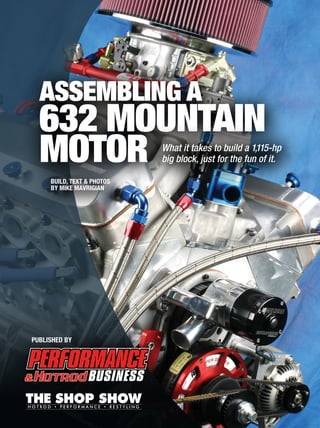

- 1. Assembling a 632 Mountain Motor Build, text & photos by Mike Mavrigian What it takes to build a 1,115-hp big block, just for the fun of it. Published by

- 2. Some folks love to claim that bigger is not always better. While that may be true in some cases, let’s face it—when the conversation turns to displacement, well, bigger is just plain better. The basis of our build began with a stout, no-nonsense Dart Big M iron block that features a 10.2-inch deck height. We hogged the bores to 4.600 inches, and mated this to a whopping 4.75-inch Lunati stroker crank. Compression ratio is 16:1, with no aided boost or nitrous. We call it a 632 Mountain Motor. She pulled 1,115 hp on 114-octane race gas on the dyno, fed through a single 1,150-cfm Holley Pro Dominator mount-ed on a profiler tunnel ram intake. While any custom engine build requires close attention to detail, a build of this na-ture certainly doesn’t represent a “bolt-to-gether- and-go” approach. Due to the intri-cacies involved in clearancing the block due to the long stroke, clearancing the block lifter bores and cylinder heads for fat and offset pushrod clearances, setting the ad-justable- height distributor for proper gear mesh, setting and adjusting the intricate shaft-mounted rocker system and valve lash and port matching the intake manifold (to name but a few of the required tasks), this level of build requires a great deal of serious attention to detail. In this case, the considerable investment of time proved worthwhile. CRANK FIT I first verified our main bearing bores, which mic’d out at 2.9375 inches. We mock-installed the steel Lunati 4.750-inch stroker crank using Clevite Tri-Armor main bearings, tightening the main cap bolts to a value of 100 foot-pounds (with moly on threads and bolt underheads). Installed main bearing diameters mea-sured 2.7535 inches. Our crank main jour-nals mic’d at 2.7495 inches, providing us with main bearing clearance at 0.004 inches. Crank endplay measured 0.007 inches. One obvious concern, given the 4.750- inch stroke of the crank, was counter-weight- to-block clearance. Happily, we had gobs of clearance, with the tightest spots at about a healthy 1/4-inch. With the coated Clevite upper main bearings installed to the block saddles and the lower bearings to the caps, all exposed bearing surfaces were coated with Royal Purple Max-Tuff assembly lube. The cen-ter 1/2-inch main cap bolts were snugged first, followed by tightening the outboard bolts (caps No. 2, 3 and 4 feature splayed locations). I addressed the center cap (No. 3) first, followed by No. 2, No. 4, No. 1, and then No. 5. All bolts were initially snugged to 20 foot-pounds, followed by 40, then 70 and finally 100. Crank rotation was ob-served following each tightening step, with the crank rotating with an applied force of about 1.5 foot-pounds once all caps were fully clamped (not bad, considering the new two-piece rear main seal). Crankshaft endplay was measured at 0.007 inches (spec is 0.006 to 0.008 inch-es). ROD FIT Using our Clevite Tri-Armor rod bearings, I test-assembled all of the Lunati Pro Mod steel rods (with pistons in place), tightening the ARP 200 7/16-inch rod bolts to a stretch value of 0.005 to 0.0055 inches. With our installed rod bear-ing diameter at 2.20325 inches and our rod journals at 2.200 inches, oil clearance was noted at 0.00325 inches. On average, I found only about 0.032 inches of clearance at the tightest point between the rod big end and the block pan rail inboard edge. After marking each location on the rail, I emptied the block and ground pocket reliefs to achieve ap-proximately 0.080 to 0.100 inches clearance (0.060 inches would be adequate, but I went a fudge deeper as long as I was at it). Basically, I cut reliefs at the pan rail in-board edges at a width of 1.05 inches (rod big end thickness is 0.990 inches), a depth of about 0.055 to 0.065 inches and a height from the pan rail surface of about 0.300 inches. I used a die grinder with a spiral-tooth radius-nose cutting bit to create the pockets, followed by a smooth-out and blend with the mini belt grinder, using 120- grit belts followed with 320-grit. When I mocked-up a piston/rod assem-bly onto the crank and rotated, I noticed a portion of the rod big end encroaching into the cam tunnel. The radius hump on the upper portion of the big end needed to be reduced slightly (maybe 0.020 inches or so) to ensure camshaft clearance. Considering the 4.750-inch stroke, this didn’t come as a big surprise. I relieved this small hump (the hump op-posite from the bearing tang side) and re-balanced the rods. While the rod big end clearancing allows the rods to clear the cam, I noticed that these same rod big end shoulders rotate very close (“ouch-close”) to the inboard edges of the cylinder bore bottoms (to the tune of about 0.015-0.020 inches clearance). In order to gain insurance clearance here, I ground an additional 0.080 inches, creating wide pock-ets to clear the rods. (See website article for complete dimensions.) Engine build: 632 Mountain motor

- 3. Engine build: 632 Mountain motor CYLINDER HONING, BALANCING The block was final-machined at Gressman Powersports in Fremont, Ohio. After CNC verifying all block dimensions (relative to the main bore centerline) and after measuring the Dart block’s bores, we noted a raw diameter of 4.590 inches. (Dart leaves enough material to allow the builder to obtain desired diameter). Since our Diamond pistons measured 4.59375 inches, we needed to remove a total of 0.01075 inches in order to achieve the de-sired 0.007-inch clearance. After confirming that our main caps were snugged to 100 foot-pounds, we mounted a pair of BHJ deck plates (tightening these to 70 foot-pounds). Bore honing began with 500-grit dia-mond stones with a high load setting to hog out the bores to an initial 4.599 inches, followed by a final honing pass to remove the remaining 0.00175 inches. All cylin-ders were then treated to four passes with silicon car-bide brushes at 30-percent load for a plateau finish. After weighing all individual components (rod bearings, rings, ring support rails, pistons, pins, pin locks, rod small ends, rod big ends), our bobweights were assembled and installed to the crank. Individual weights included 619.5 grams for rod big ends, 275.0g for rod small ends, 542.0g for each piston, 160.0g for piston pins, ring packs at 46.5g, ring support rails at 9.5g, rod bearing per-rod sets at 49.5g, spiral locks at 4.5g, and after allowing 8.0g for oil, our bobweights were set at 2,383.5g. Our Lunati crank spun up beautifully, with no need for correction in the front. She did want a bit of added weight in the rear counterweight. Of course, the desired position was shrouded by the rear flange, so we secured the crank (upright) on a Bridgeport and drilled through the flange and into the counter- Below Left: Our Dart block was delivered with a raw cylinder bore diameter of 4.590 inches, requiring hone removal of only 0.01075 inches to obtain our de-sired piston clearance. Below Right: The Dart Big Chief II heads are cast from virgin 355-T61 aerospace alloy and CNC ma-chined. Features include 11-de-gree rolled valve angles, raised ports and a spread port design for maximum efficiency. These heads have proven very successful in NHRA Pro Stock drag racing. Far Left: The Dart Big M iron block provides an outstand-ing foundation for this level of build. Among the many per-formance- oriented enhance-ments is a high nickel con-tent for increased strength and stability, 10.2-inch deck height, steel billet main caps and a vastly improved priority main oiling design as com-pared to a stock GM block. Left: Our Lunati forged steel crank features a seri-ously long 4.750-inch stroke, chamfer-relieved counter-weights and 2.7495-inch main journals. Test-fitted with installed Clevite main bear-ings at 2.7535 inches, our main bearing clearance is 0.004 inches. Installed crank endplay was measured at 0.007 inches.

- 4. Engine build: 632 Mountain motor weight, and followed by adding a 1-inch-di-ameter tungsten slug into each hole (flange and counterweight). After re-spinning the crank, we fine-tuned by shaving a bit of weight (about 10g) from the shoulder of the rear counter-weight using a die grinder. Our final bal-ance was within 0.08g, which is tighter than needed, so after a quick journal polish, we were good to go. CAMSHAFT, PISTONS Crane was kind enough to machine a cus-tom grind steel billet solid-roller stick for us. (See website for grind number and special firing order details). Effective lift (with our raunchy 1.85:1 rocker ratio) is almost a full inch—woof! I enlisted Diamond to make our cus-tom pistons. At a measured 4.5937 inches, they’re huge. (And beautiful, too!) When I thought about how these puppies were go-ing to squeeze against the Dart Big Chief II chambers, I couldn’t help getting all giddy with anticipation. The pistons began as high-density forg-ings (DRP76X), and were CNC-machined to the finished state. The custom dome fea-tures a dish, along with valve reliefs for both intake and exhaust valves. The intake valve depth is 0.270 inches, while the exhaust valve depth is 0.064 inches. In combination with a compression height of 1.120 inches, 0.005-inch deck clearance, our Victor MLS gaskets and the 56cc combustion chambers, this should give us a tidy 16:1 compression ratio. The pins are full-floaters, and are designed to be secured via Spirolox retaining rings (0.990-by-0.043 inches). Diamond noted that the installed wall clearance for these pis-tons should be 0.0070 inches. They specify that piston diameter must be measured 90 degrees to the pin bore, at a distance of 0.700 inches down from the oil land. BELT DRIVE, HEADS, SHAFT ROCKER SYSTEM Instead of using a conventional oiled timing chain setup, we opted for Jesel’s way-cool Left: Our Lunati I-beam forged rods fea-ture a center-to-center length of 6.700 inches. Test-fitting revealed a healthy as-sembled 0.020-inch side clearance. Below: During-test fitting with an ex-tended stroke, always check rod big end clearance to the camshaft. Above: Again, due to the extended stroke, the block pan rails required minor notching for each rod’s big end clearance. Note the area to be notched adjacent to the number 8 rod. Left: Cylinders were final-honed to 4.60075 inches, requiring removal of only 0.01075 inches in order to obtain the needed 0.007-inch piston-to- wall clearance. Honing began with 500-grit diamond stones, finishing with plateau brushes.

- 5. belt drive system. This offers adjustability, precise cam timing and the belt soaks up any operational harmonics. (The complete step-by-step assembly is detailed on the website in Part 3 of the 632 build series.) Our massive aluminum heads are Dart’s famed 11-degree Big Chief II units, CNC machined, fea-turing 56cc chambers, 497cc intake port volume, with 2.470-inch titanium intake and 1.800-inch ex-haust valves. Intake valve angles are 11 degrees and exhaust valve angles are 7 degrees. These are heavy-breathing heads, with intake ports darned near big enough to accept our fists. Our rocker system is Jesel’s shaft roller setup fea-turing a very healthy 1.85:1 rocker arm ratio. The first order of business is to install the rocker stands. Each head requires one long stand, positioned across the upper (inboard) area of the rocker gal-ley, in addition to four individual stands across the lower (outboard) area. In order to handle the demands of this engine, I ordered a set of extra-beefy custom pushrods from Manton. Considering the open valve spring pres-sure (928 pounds) and the length of pushrods need-ed, I ordered 1/2-inch-diameter exhaust pushrods at a total length of 11.124 inches and 7/16-inch-diameter single-tapered intake pushrods in two dif-ferent lengths, including 10.953 and 10.805 inches. INTAKE MANIFOLD, CRANK TRIGER During test-fitting, I realized that our Profiler Per-formance tunnel ram intake manifold sat a tad high at the Dart block’s rails (a common situation simply due to the tall-deck nature of our block), so I ob-tained a pair of Dart’s billet machined aluminum end-rail spacers. These spacers are 0.375-inches thick, with ends angle-cut to match the decks. Each spacer features three 0.183-inch holes. In order to prevent the spac-ers from walking out fore or aft (a possibility if I re-lied on RTV alone), I drilled two holes in the block rails (just using the two end holes at the spacers) using a 1/8-inch (measured 0.123-inch) drill and installed 1/8-inch roll pins in the block rails. I drilled to a depth of 0.375 inches and cut the pins to a length of approximately 0.690 inches, leav-ing about 0.330 inches protruding above the block rails. This allows the spacers to be coated with RTV and securely located onto the rails. Since the holes in the billet spacers are larger in OUR PARTS LIST BLOCK Dart Big M with 10.2” deck height CYLINDER HEADS . Dart Big Chief II 11-degree with 56cc chambers CRANKSHAFT Forged 4.75” stroker from Lunati, P/N BS-421 MN (counterweight radius @ 3.700”) CONNECTING RODS Forged I-beam Pro Mod 6.700” Lunati, P/N LB01 CAMSHAFT . Custom billet steel mechanical roller from Crane, P/N13-R001027; grind no. R-288/5201-2S-14 SFO LIFTERS Crane offset solid roller Ultra Pro R/T rollers P/N 13571-16 RETAINERS/KEEPERS Crane titanium set P/N 99681-16 VALVE SPRINGS . Crane triple spring set P/N 96848-16 MAIN BEARINGS Clevite Tri-Armor P/N MS-829 HXK ROD BEARINGS . Clevite Tri-Armor P/N CB-743 HXK OIL PUMP . Moroso billet gerotor P/N 22167 OIL PAN Moroso 2-pc welded billet aluminum, P/N 20376 CARBURETOR . Holley Ultra Dominator 1150 cfm, P/N 0-80673 INTAKE MANIFOLD Profiler P/N 187-10 RAIL SPACERS Dart P/N 62220006 INTAKE MAN. GASKETS . Dart P/N 65002155 TIMING/COVER Jesel belt drive kit KBD-32000 VALVE COVERS Moroso welded aluminum P/N 68334 ROCKER ASSEMBLIES . Jesel shaft roller rocker system P/N KPS 24347 (1.85:1 int & exh) PUSHRODS . Manton 7/16” X 10.805 & 10.953” int; ½” X 11.124” exh. PISTONS . Diamond custom DISTRIBUTOR MSD billet, P/N 85501 CRANK TRIGGER . MSD flying magnet kit P/N 8620 DIST. CLAMP . MSD P/N 8110 SPARK PLUG WIRES MSD 8.5mm Super Conductor P/N 31239 WATER PUMP Mezier WP300 DAMPER . ATI 8” Super Damper P/N 917062 CYL. HEAD GASKETS . Victor MLS P/N 54271 VALVE COVER GASKETS Victor VS50191HTC THERM. HOUSING GASKET Victor (alum. W/silicone seal) P/N C21331 REAR MAIN SEAL Victor 2-pc P/N JV705 EXH. GASKETS Victor Nitroseal Pro-Stock P/N 95178SG FASTENERS ARP Head studs # 235-4312 Header studs # 400-1403 Oil pan studs # 435-1901 Balancer bolt # 235-2501 Carb stud kit #400-2414 Intake manifold bolt kit # 435-2101 Timing cover bolt kit #400-1501 Thermostat housing bolt kit # 430-7401 Flexplate bolt kit # 200-2902 Valve cover stud kit # 400-7615 Distributor stud kit # 430-1701 Water pump bolt kit # 430-3201 ARP moly assembly lube # 100-9906 Engine build: 632 Mountain motor

- 6. diameter than the roll pins, this allows the spacers to self-center left-to-right when the heads are installed. Our MSD flying magnet crank trigger kit included ev-erything needed for an easy installation. Even with mess-ing around with a few minor mods, total installation time was a mere 30 minutes. With the No. 1 cylinder under compression at TDC, the trigger wheel mounts to the face of the 8-inch ATI Super Damper with one of the wheel’s magnets aligned with the center of the non-magnetic pickup. The wheel features a handy arrow to indicate rotational direction, to prevent someone from installing the wheel backwards. Once everything is set, the three mounting bolts are tightened to a value of 25-30 foot-pounds. In order to achieve a nice alignment of the magnet to the wheel (fore/aft), I installed the main mounting bracket to the block using 0.400-inch-thick spacer shims between the bracket and block at both of the 7/16-inch bolt locations. These shims are provided with the kit. Due to a clearance issue between the threaded plate that secures the pickup bracket to the main bracket and our Moroso oil pan, I milled about 0.060 inches from the rear of the plate and from the tip of the pickup bracket’s dowel pin. My distributor of choice is one of MSD’s Pro Billet units, featuring a lockout (no me-chanical advance and a small enough diameter to clear the intake manifold upper ple-num). A lengthy process of fitting the distributor to accommodate this build required test fitting, measuring and machining modifications to achieve proper gear depth engagement. (See the website for details.) Engine build: 632 Mountain motor Right: Scott Gressman installs our bobweights to the Lunati crankshaft. Weight correction to the crank was minimal. Spin balancing achieved a toler-ance of a mere 0.08 grams. Below: The toothed belt drive (as opposed to chain drive) is designed to absorb valvetrain harmonics.

- 7. Engine build: 632 Mountain motor VACUUM PUMP, OIL PUMP & PAN Jones Racing supplied a vacuum pump system featuring its light-weight billet aluminum vacuum pump. This is a two-stage gear-style vacuum pump that runs at 50-percent of engine speed and pulls a constant 15psi, providing enhanced piston ring seal. The negative pressure created by the pump results is less resis-tance on the pistons during the compression downstroke, result-ing in faster piston acceleration. This constant vacuum also helps to draw parasitic oil from the ro-tating assembly (theoretically in-creasing power), and allows the oil pump to function with less resistance, which also aids oil flow. In order to avoid pump pickup cracking (due to anticipated harmonic stress), I opted for a very beefy bil-let gerotor-type oil pump from Moroso. This billet pump features a built-in pickup incor-porated into the bottom of the pump body, so there’s no external pickup to vibrate loose. The matching oil pan to accommodate the Dart block and this pump is Moroso’s billet 2-piece aluminum pan, which also features extra-wide rail spacing both to match the Dart block and to provide added rod clearance. THE DYNO RUN I transported the engine to Gressman Powersports in Fremont, Ohio, that employs a state-of-the-art SuperFlow engine dyna-mometer. After readying the engine on the dyno and priming with seven quarts of 30W oil, initial timing was set at 25 degrees. All timing adjustments were made at the MSD crank trigger sensor (by moving the sensor in relation to the trigger wheel). Scott Gressman allowed her to run for a few minutes at around 1,400-1,500 rpm while monitoring the vitals. We immediately had about 65 pounds of oil pressure (which bumped to 80psi during pulls), and no leaks occurred anywhere on the motor. After allowing the engine to warm up, Scott shut her down and re-checked hot valve lash, setting all valves at 0.028 inches. The first hard pull, with timing set at 27 degrees, netted 1,098 hp at 7,150 rpm. A second pull, with timing at 30 degrees, yanked 1,105 hp at 7,150 rpm. The final pull, at 32 degrees timing and with the camshaft retarded 3 degrees, produced 1,115.5 hp at 7,100 rpm. We felt comfortable that with more timing tweaks, and perhaps switching to dual 1050 carbs, we would likely hit somewhere between 1,150 to 1,200 hp, and I was surprised at how incredibly responsive the engine was. (And the horrific shriek she made at high revs was both scary and wonderful. She’s definitely a nasty lil’ rat!) We hope you’ve enjoyed the project and above all, we hope that the information we’ve provided is of some benefit. Again, this article is a very brief overview. The entire build is fully detailed in a six-part series that can be viewed at www.precisionenginetech.com. Mike Mavrigian has written thousands of technical articles over the past 30 years for a variety of automotive publications, in addition to writing nine automotive technical books for four different publish-ers. Mike also owns and operates Birchwood Automotive in Creston, Ohio, where he builds custom engines, street rods and performs vehicle restorations. Mike can be reached at 330-435-6347 or birchwdag@frontier. com. Birchwood’s website is www.birchwoodautomotive.com. PE Jesel roller rockers are in-dividually shaft-mounted. Notice the offset angles required for the Big Chief II heads. Above: On Gressman Powers-ports’ SuperFlow dyno, the 632- ci engine pulled a respectable 1,115.5 hp at 7,100 rpm and 864.2 foot-pounds at 5,800 rpm. Left: Front view—from left: Jones vacuum pump, MSD crank trigger and Jones race alternator.

- 8. Stock your shelves with these quality motor components. Additional Engine Building Products Analog Valve Spring Tester Goodson Tools & Supplies for Engine Builders, Winona, Minn., introduces a new Analog Valve Spring Tester. The tester features a 600-pound capacity in 10-pound increments, 5-inch-diameter Ashcroft-quality analog pressure gauge and a spring platform that handles springs up to 2-inches diameter by 4.5-inches overall height. The press assembly height is adjustable in 1/2-inch increments, the pressing anvil is adjustable in 1-inch increments and height is measur-able in 1/16-inch increments. An adjustable vertical scale rotates 180 degrees for left or right reading. www.goodson.com Turbochargers MAHLE Clevite, Ann Arbor, Mich., offers a complete line of MAHLE Original turbochargers specifically for the after-market, available in a range of sizes and types. Designed to enhance performance, reduce fuel consumption and lower exhaust emissions, the turbochargers are available for high-performance and high fuel-economy diesel and gasoline engines. They feature high-speed compressor wheels to provide greater balancing precision, optimized speed stability and reduced running noise. Double piston rings on the rotor shaft reduce oil consumption. www.mahle-aftermarket.com Powder-Coating for Piston Skirts Line2Line Coatings, Clarkston, Mich., offers new Abradable Powder-Coatings for piston skirts. APC starts each piston “too tight.” At temperature and under load, the coating wears to the ideal fit that conforms most closely to each individual bore. As the ideal oil film forms, the wear stops. APC reduces friction and secondary motions (piston rock/slap and ring wear) and is formulated to free-up power and improve durability. www.line2linecoatings.com Scion/Subaru Sleeve Kit Darton Sleeves, Carlsbad, Calif., introduces a patented M.I.D. Sleeve Kit for Scion FRS/Subaru BRZ/Toyota T86 ap-plications. The kit allows the conversion of the block to a closed deck utilizing the M.I.D. wet sleeve, allowing builders to take it out to a much larger bore size and still easily handle 50-plus pounds of boost at any compression. The wet sleeve design allows changes of individual sleeves or all four without needing to re-machine the block. www.darton-international.com Race Crimp Hose Ends XRP, South Gate, Calif., presents its new Race Crimp Hose Ends that add hundreds of new fittings to the company’s line. Features include bent tube fixed, double O-ring sealed swivels and ORB ends, plus reducers and expanders in both 37 degrees JIC and clamshell quick-disconnects. They are offered in a choice of full hex or lightweight turned-down swivel nuts. They come in black, blue or Super Nickel. One hose end design and two styles of crimp collars allow the ends to be used on the all-new XRP ProPLUS Race Hose, stainless braided CPE Race Hose and more. www.xrp.com

- 9. LS Valve Cover Adapter Kit Racing Head Service (RHS), Memphis, Tenn., a member of the COMP Performance Group, offers its RHS Small-Block Chevy Valve Cover Adapter Kit for LS engines. The kit allows traditional Gen 1 small-block Chevy valve covers to be used on Gen III/IV LS engines. Created from billet alu-minum, the adapter kit works with center-bolt LS heads and traditional, perimeter-bolt SBC covers. www.racingheadservice.com Precision-Molded Carb Gaskets SCE Gaskets, Valencia, Calif., presents its new Precision-Molded Non-Stick Thermoplastic Gaskets designed to help with changing jets or rebuilding Holley 4150/4160 and 4500 series 4-barrel carburetors. The metering block and bowl gaskets are available in separate pairs, in a one-carb package or in SCE’s exclusive Dyno-Paks of 10 designed for professional engine builders. The fuel and air passages are precision-molded to provide maximum flow, and the pliable, molded gaskets won’t tear, stick or shrink, and can be used time and again. www.scegaskets.com High-Output Alternators Flaming River Industries, Berea, Ohio, presents its Billet HD Amp High-Output Alternators, designed to offer improved output at extremely low engine rpm, more horsepower to the wheels and less energy wasted in the form of heat. Precision-balanced, low-mass rotors allow the alternators to operate safely at shaft speeds of 20,000-plus rpm, and the alternators use Twin Rectifier Plates with twice as many diodes as an OEM alternator, which results in 300-percent more surface area to dissipate heat. www.flamingriver.com SHAFT-MOUNTED ROCKERS Jon Kaase Racing Engines, Winder, Ga., presents its P-38 Small-Block Ford Windsor Cylinder Heads featuring shaft-mounted rockers—a move inspired by oval track, road race and track-day demands seeking high-speed valve train stamina and stability. The new kits include aluminum rockers, each with a nose roller, a hardened pivot shaft operating with a 0.750-inch-wide needle bearing and an H13 tool steel adjuster. Each adjuster is furnished with an ARP-hardened washer and a 12-point Grade 8 nut. A slightly longer rocker pivot length improves valve train geometry. www.jonkaaseracingengines.com See-Through Oil Filter Assembly Billet Connection, Spokane, Wash., and its Clear View Filtration brand, presents a patent-pending Billet Filter As-sembly. The system allows users to see the condition of the oil and perform a visual inspection of the filter element and particles that were filtered out of the engine in seconds without draining, leaking, or the loss of oil, and without unbolting or loosening any fasteners or fittings. It helps determine if the particles are normal or from engine components exces-sively wearing. www.clearviewfiltration.com Additional ENGINE building products

- 10. Electric Water Pump PROFORM Parts, Roseville, Mich., offers its Bowtie Electric Water Pump, now available in Chevy orange. An of-ficial Chevrolet Performance Licensed Part, the pump is designed to circulate up to 35 gpm of coolant. Eliminating the mechanical fan reduces weight and impeller drag. The Chevy Orange finish is durable epoxy powder-coat. Applications include traditional Chevy small- and big-blocks, and the pump includes weather-tight electrical con-nectors and threaded inlet fittings to accommodate 1.75-inch hoses. www.proformparts.com GTR Damper Titan Motorsports, Orlando, Fla., and ATI Performance present a patented Super Damper for the Nissan R35 GTR. The Titan/ATI SuperDamper is a crank damper designed exclusively for high-performance engines to eliminate torsional crankshaft vibrations. The pulley is SFI 18.1 rated and exceeds NHRA requirements for cars going quicker than 11.5 seconds at the drag strip. A direct replacement for the OEM crank pulley, its black zinc chromate finish prevents rust and allows the 360-degree laser-engraved timing marks to be easily read. www.titanmotorsports.com NHRA-Approved Carburetor Edelbrock, Torrance, Calif., presents its Performer Series Carburetors that have been approved for use in NHRA competition. The Edelbrock Performer Series 750-cfm has been granted NHRA approval for use in competition on 1964 Chrysler 426 Max Wedge engines producing 415 hp. The NHRA has approved the Performer as an alternative to the Carter AFB carburetor or Carter AFB Competition Series carburetor. The Performer is designed to offer dependable street performance and smooth throttle response throughout the power band with factory-set float levels. www.edelbrock.com Sprint Car Cam Drives CV Products, Thomasville, N.C., introduces its XTS90306 and XTS90300 cam drives, specifically designed for 410- and 360-ci Sprint Car applications offering a standard and raised cam version. The systems are equipped with the low-backlash patented 40mm Goodyear Engineered Products drive belt that dampens vibrations and harmful frequencies from the valvetrain and withstands temperatures upwards of 300 degrees. They feature a CV patented roller thrust bearing for friction reduction, which also eliminates cam thrust setup. www.cvproducts.com Additional ENGINE building products

- 11. Ford Connecting ROds Oliver Racing Parts, Grand Rapids, Mich., introduces two new Ford-specific connecting rods. The F5400FDLT8 Standard Light rod is designed for use in the 302 Windsor V-8, Ford’s engine of choice in vehicles manufactured through the late 1990s. The F5933MDUL Ultra Light rod is designed for Ford’s Modular 4.6- and 5.0-liter V-8 engines that eventually replaced the 302 Windsor. Designed and manufactured in Grand Rapids from American mill-certified aircraft quality steel, the rods feature a Parabolic Beam design for a high strength-to-weight ratio. www.oliverracingparts.com CNC Vertical Honing Machines Rottler Mfg., Kent, Wash., introduces its H70A Series CNC Vertical Honing Machines that include the latest Windows Touch Screen Control Technology and optional features and equipment that allow complete engine blocks (inline and V-blocks) to be honed automatically and unattended. Features such as load control and lower crash detection allow easy, fast and accurate honing from small to very large cylinders. The H75A is designed for small- to mid-size engines, and the H76A is designed for small- to large-size engines. www.rottlermfg.com Black Diamond 600-cfm Carb Quick Fuel Technology (QFT), Bowling Green, Ky., presents its BD-1957 600-cfm Performance Carb that addresses direct replacement requirements including a single fuel inlet and side-hung fuel bowls. Exclusive features include QuickSet vacuum secondaries, Black Diamond high-temperature coating and a fully adjustable electric choke. Designed as a street performance carb that is also suitable for stock engines, it flows 600 cfm through 1-9/16-inch throttle bores and 1.312-inch venturis. It has a secondary metering plate with changeable jets. www.quickfueltechnology.com Sport Compact Connecting Rods Manley Performance, Lakewood, N.J., offers 20 new Connecting Rods to its lineup of engine components for sport compact applications. The new rods include H-Beam, H-Plus, H-Tuff and Pro Series Turbo-Tuff and Tri-Beam I-Beam rods custom-manufactured for Acura, Audi, Dodge, Honda, Mazda, Mitsubishi, Nissan, Toyota and Volkswagen applications. Additionally, Manley offers complete rotating assemblies that combine rods for Mitsubishi and Subaru applications with standard stroke or “stroker” crankshafts, plus pistons, rings and bearings. www.manleyperformance.com Additional ENGINE building products PE

- 12. Additional Resources for YourBusiness Success! Stay up-to-date on the newest products and hottest trends with these resources from Performance & Hotrod Business Performance & Hotrod Business magazine THE shop resource for professional builders, retailers and racers. Covering street to strip—hot rods, muscle cars, racing products and performance engines—you’ll find everything to equip your shop, fuel your company’s performance and keep your competitive edge. Each issue is loaded with: • Performance industry news and technology trends- know what’s happening in the industry and the potential impact on your business! • Aftermarket products- see what’s new and emerg-ing, find resources for your projects • Shop success stories- learn from your peers, avoid critical mistakes • Builder profiles- get new ideas for your own vehicles • …and more! Performance & Hotrod Business is the ultimate shop tool—a MUST for professional builders, retailers, and racers. Choose your subscription level and subscribe today! LIMITED: with your free limited subscription, you’ll receive ran-dom issues throughout the year as selected by the publisher. PerformanceBiz.com/Limited COMPLETE: get every issue each month plus all bonus reports, including future Precision Engine supplements. Only $45/year. PerformanceBiz.com/Complete Created to meet the needs of shop professionals, THE SHOP SHOW showcases the latest trends in performance products, hot rod restoration and automotive/4x4 aftermarket acces-sories. THE SHOP SHOW is your chance to: • Preview innovative products, new tools, parts, and tech-nologies • Take skill-building classes and see product demonstra-tions up-close • Get new ideas from a dynamic exhibit hall, with custom-built March 13-14, 2015 Indiana Convention Center hot rods, performance and 4x4 vehicles on display • Engage in meaningful conversation with suppliers and manufacturers • Network with your peers You’ll find it all at THE SHOP SHOW. Exclusively for shop pro-fessionals: Your Shop. Your Show. March 13-14, 2015 at the Indiana Convention Center, Indianapolis. Register yourself and your entire staff – It’s Free! Registration opens Fall, 2014. THE-SHOP-SHOW.COM