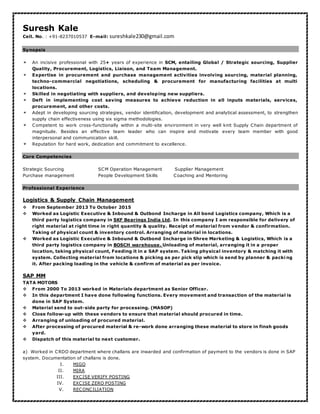

Cv suresh kale updated

- 1. Suresh Kale Cell. No. : +91-8237010537 E-mail: sureshkale230@gmail.com Synopsis An incisive professional with 25+ years of experience in SCM, entailing Global / Strategic sourcing, Supplier Quality, Procurement, Logistics, Liaison, and Team Management. Expertise in procurement and purchase management activities involving sourcing, material planning, techno-commercial negotiations, scheduling & procurement for manufacturing facilities at multi locations. Skilled in negotiating with suppliers, and developing new suppliers. Deft in implementing cost saving measures to achieve reduction in all inputs materials, services, procurement, and other costs. Adept in developing sourcing strategies, vendor identification, development and analytical assessment, to strengthen supply chain effectiveness using six sigma methodologies. Competent to work cross-functionally within a multi-site environment in very well knit Supply Chain department of magnitude. Besides an effective team leader who can inspire and motivate every team member with good interpersonal and communication skill. Reputation for hard work, dedication and commitment to excellence. Core Competencies Strategic Sourcing SCM Operation Management Supplier Management Purchase management People Development Skills Coaching and Mentoring Professional Experience Logistics & Supply Chain Management From September 2013 To October 2015 Worked as Logistic Executive & Inbound & Outbond Incharge in All bond Logistics company, Which is a third party logistics company in SKF Bearings India Ltd. In this company I am responsible for delivery of right material at right time in right quantity & quality. Receipt of material from vendor & confirmation. Taking of physical count & inventory control. Arranging of material in locations. Worked as Logistic Executive & Inbound & Outbond Incharge in Shree Marketing & Logistics, Which is a third party logistics company in BOSCH warehouse. Unloading of material, arranging it in a proper location, taking physical count, Feeding it in a SAP system. Taking physical inventory & matching it with system. Collecting material from locations & picking as per pick slip which is send by planner & packi ng it. After packing loading in the vehicle & confirm of material as per invoice. SAP MM TATA MOTORS From 2000 To 2013 worked in Materials department as Senior Officer. In this department I have done following functions. Every movement and transaction of the material is done in SAP System. Material send to out-side party for processing. (MASOP) Close follow-up with these vendors to ensure that material should procured in time. Arranging of unloading of procured material. After processing of procured material & re-work done arranging these material to store in finsh goods yard. Dispatch of this material to next customer. a) Worked in CRDO department where challans are inwarded and confirmation of payment to the vendors is done in SAP system. Documentation of challans is done. I. MIGO II. MIRA III. EXCISE VERIFY POSTING IV. EXCISE ZERO POSTING V. RECONCILIATION

- 2. b) Dispatch of material to outside party for processing i.e. MASOP I.541 MOVEMENT c) Follow-up of material to the party which is sent for processing and taking assurance from them for timely delivery of processed material. d) Receipt of material in stores & confirmation of the same. I.MB02 II.501 Movement in case material is rejected e)Dispatch of material to another division i.e. Interdivision transfer of material. I.301 Movement f) Dispatch of material to another plant. I.601 Movement g) Dispatch of material to external customer. I.631 Movement h) Raising of purchase requisition indent for the procurement of spare parts for maintenance purpose. From 1998 To 2000 Worked in Productivity Services and Low Cost Automation department as an Officer. Taken part in time study and line balancing of Safari Chassis line. In low-cost automation worked on projects of --- i. Bush pressing machine ii. Bearing pressing machine iii. Waste paper bailing machine I have done procurement, assembly, delivery and commissioning of these projects. From 1996 To 1998 as a Diploma Trainee. One Year basic training & class room input. In this period I have completed a project of JIG-SAW MACHINE. This machine is used for cutting acrylic, thermocoal, plastic, Cores in foundry & wood. One year rotational training in various department i.e. production engineering planning, maintenance, auto projects, productivity services. From 1990 To 1996 as Job Inspector in vehicle assembly (Chassis Line) Chassis inspection while assembling at various stages i.e. at Frame drop stage, Engine drop stage, Final inspection stage, Dynamometer testing stage, under pit inspection stage, brake performance testing stage, smoke value checking. Checking of steering geometry of vehicle having independent suspension. Testing of vehicle on track. Final certification of vehicle for dispatch. Procurement Planning & Management - Listing down the resource needs for procurement, after considering the budgetary parameters set. - Establishing time span for procurement for project execution as per work specifics. - Monitoring procurement status during the course of periodic project review meetings. - Evaluating offers; co-ordinating with Consultants & Sub Contractors for changes in the same. - Co-ordinating with allied departments like Works, Quality Control, Equipment, Quantity Survey, Design & Contracts. Quality Assurance & Control - Performing audits to ensure adherence to budget, quality and delivery norms across the entire course of project execution. - Conducting inspections to ensure designed products are in compliance with pre -set technical specifications. - Taking adequate measures like forming quality circles, maintaining necessary records and conducting audits to comply with statutory quality & environmental standards.

- 3. Purchase / Materials Management: - Spearheading development and implementation of key purchase/ procurement/ sourcing strategies and contingency plans as well as ensuring that plans are aligned with project requirements. - Formulating budgets for timely procurement of various critical components and ensuring uninterrupted supply of components to end users. - Finalising the specifications of materials, establishing quality & quantity limits for effective inventory control and reducing wastages. Supply Chain Management/ Logistics - Handling sourcing through identification of cost effective suppliers for procurement with an aim of improving quality & reliability. - Developing sufficient number of reliable and reputed sources of supply for different items required. . - Sustaining / building up of the logistics network to ensure timely distribution of the merchandise, monitoring availability of stock and making appropriate arrangements to ensure on time deliveries. - Ensuring the transportation costs at optimum level which will be most suitable to both parties. Vendor Development: - Checking the performance of the vendors based on various criterions such as percentage for rejections, quality improvement rate, timely delivery, credit terms, etc. - Monitoring incoming materials supplied by vendors & ensuring they are as per quality & quantity specifications. - Overseeing follow-up with vendors for engineering deliverables, timely deliveries & payments. Inventory Management: - Assessing physical layout of inventories for storage of raw materials and packing materials & consumables. - Overseeing store management activities like receipts, storage and supply chain management. - Preparing standard bill of materials template, streamlining dispatches &customising the inventory management system of the service provider as per requirements. Educational and Professional Qualification Completed P.G.D.B.M from Pune University with First Class in 2014. Completed Diploma in Mechanical Engineering from MSBTE with First class in 1991. Completed NCTVT from New Delhi with Distinction in Oct-1986. Technical Competencies SAP – MM Module Implementation including: Troubleshooting any problems arising in the marketing process. Well versed with MS – Office, Database Dbase II + Operating System Windows and Applications Personal Date of Birth : 20th Aug 1965 Languages Known :-Marathi, Hindi, English Address : Near Dnyanganga Public School, Opposite to Chitrao Ganpati Temple, Behind Moraya Raj Park, Keshav Nagar, Chinchwad, Pune-411033.