SteelDesign_PlateGirder_Fu_New.pdf

•

0 gefällt mir•18 views

Steel plate girder

Melden

Teilen

Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

Empfohlen

Weitere ähnliche Inhalte

Ähnlich wie SteelDesign_PlateGirder_Fu_New.pdf

Ähnlich wie SteelDesign_PlateGirder_Fu_New.pdf (20)

Spot welding basic parameters setting - basic calculations / equations

Spot welding basic parameters setting - basic calculations / equations

Study of Steel Moment Resisting Frame with Reduced Beam Section

Study of Steel Moment Resisting Frame with Reduced Beam Section

Refurbishment of a Three-Phase Induction Motor Reflecting Local Voltage Condi...

Refurbishment of a Three-Phase Induction Motor Reflecting Local Voltage Condi...

Reinforce Concrete Design I - By Dr. Iftekhar Anam

Reinforce Concrete Design I - By Dr. Iftekhar Anam

Mehr von ReigerRoyal

Mehr von ReigerRoyal (13)

Kürzlich hochgeladen

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

From customer value engagements to hands-on production support, our Services span across every stage of our customers digital transformation journey, to help ensure that every customer is successful in their adoption of our solutions.

• Implementation, Upgrade, Migration, and Maintenance Services

• On-Premises and On-Cloud

• COTS Training Services; On-Site and Virtual

• Software Support Services; Legacy and 3DEXPERIENCE

• Value Engagement & Blueprinting

• Specialized Consulting and Support Services

• Customized Training Services

• Automation and Configuration Services

• Technical Resource Augmentation Services

• Project Management

• Know-how Training (mentoring) and Resource AugmentationNavigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...Arindam Chakraborty, Ph.D., P.E. (CA, TX)

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Sex Service At Affordable Rate

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...Call Girls in Nagpur High Profile

Kürzlich hochgeladen (20)

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Block diagram reduction techniques in control systems.ppt

Block diagram reduction techniques in control systems.ppt

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

chapter 5.pptx: drainage and irrigation engineering

chapter 5.pptx: drainage and irrigation engineering

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

VIP Model Call Girls Kothrud ( Pune ) Call ON 8005736733 Starting From 5K to ...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Design For Accessibility: Getting it right from the start

Design For Accessibility: Getting it right from the start

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

Top Rated Call Girls In chittoor 📱 {7001035870} VIP Escorts chittoor

SteelDesign_PlateGirder_Fu_New.pdf

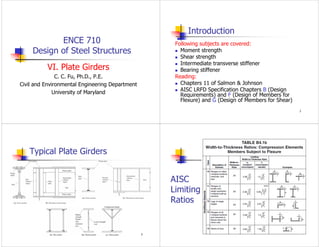

- 1. ENCE 710 Design of Steel Structures VI. Plate Girders C. C. Fu, Ph.D., P.E. Civil and Environmental Engineering Department University of Maryland 2 Introduction Following subjects are covered: Moment strength Shear strength Intermediate transverse stiffener Bearing stiffener Reading: Chapters 11 of Salmon & Johnson AISC LRFD Specification Chapters B (Design Requirements) and F (Design of Members for Flexure) and G (Design of Members for Shear) 3 Typical Plate Girders 4 AISC Limiting Ratios

- 2. 5 AISC Design of Members for Flexure (about Major Axis) 6 Beam vs Plate Girder (for doubly symmetric I-shaped sections) Plate Girder: A deep beam “Slender” web problems: 1.Web buckling 2. Buckling of the compression flange due to inadequate stiffness of the web 3. Buckling due to shear 7 Vertical Buckling (the compression flange) (a) Lateral buckling (b) Torsional buckling (c) Vertical buckling 8 AISC Maximum Web h/tw Stiffened girder (for a/h ≤ 1.5) h/tw = 12.0 √E/Fy (AISC-F13.3) Stiffened girder (for a/h > 1.5) h/tw ≤ 0.40E/Fy (AISC-F13.4) (S & J Table 11.3.1) Unstiffened girder h/tw ≤ 260 (proportioning limits for I-shaped members)

- 3. 9 AISC Nominal Moment Strength If h/tw ≤ 5.70√E/Fy – AISC Table B4.1 treated as rolled beams If h/tw > 5.70√E/Fy Case 1 – Compression flange yielding Mn = RpgFySxc (F5-1) Case 2 – Lateral-Torsional Buckling Mn = RpgFcrSxc (F5-2) (a) Lp < Lb ≤ Lr (F5-3) (b) Lb > Lr (F5-4, 5, 6) (F4-11) (for WLB) aw = ratio of web area to compression flange area ( ≤10) hc = 2 x centroid to inside face of the compression flange y p r p b y y b cr F L L L L F F C F 3 . 0 2 2 t b b cr r L E C F y t r F E r L 7 . 0 1 70 . 5 300 1200 1 y w c w w pg F E t h a a R 6 / 1 ( 12 w fc t a b r 10 AISC Nominal Moment Strength (cont.) Case 3 - Compression flange local buckling Mn = RpgFcrSxc (F5-7) Fcr a. λ ≤ λp: Fcr = Fy b. λ p < λ ≤ λr : (F5-8) c. λ > λr : (F5-9) kc = 4/√(h/tw) and 0.35 ≤ kc ≤ 0.763 Case 4 – Tension-flange yielding (Sxt<Sxc) Mn = FySxt (F5-10) pf rf pf y y cr F F F 3 . 0 2 2 9 . 0 f f c cr t b k F Rpg bending strength reduction factor 11 Limit States in Flexure for plate girder with slender web (AISC-F5) 12 Comparison of LTB (AISC-F5 with AISC-F2)

- 4. 13 Classical Shear Theory (applied to plate girder web panel) 14 Intermediate Stiffener Spacing 15 AISC Nominal Shear Strength If h/tw ≤ 1.10 √(kvE/Fy) - Vn = 0.6 AwFy same as rolled beam (G3-1) If h/tw > 1.10 √(kvE/Fy) (G3-2) (S & J Figs. 11.8.1 & 11.8.2) Except (1) end panel (2) a/h > 3 or a/h > [260/(h/tw)]2 2 1 15 . 1 1 6 . 0 h a C C F A V v v yw w n 16 AISC Nominal Shear Strength (cont.) For 1.10 √(kvE/Fy) ≤ h/tw ≤ 1.37 √(kvE/Fy) Cv = 1.10 √(kvE/Fy) / (h/tw) (G2-4) For h/tw > 1.37 √(kvE/Fy) Cv = 1.51 kvE/[(h/tw)2Fy] (G2-5) kv = 5 + 5/(a/h)2 if a/h ≤ 3 and [260/(h/tw)]2 5 otherwise (S & J Fig. 11.8.3)

- 5. 17 Shear Capacity Available Figure 11.8.1 Shear capacity available, considering post-buckling strength. 18 Tension-Field Action. Figure 11.8.2 Tension-field action. 19 Buckling of Plate Girder Web Figure 11.7.3 Buckling of plate girder web resulting from shear alone—AISC-G2 20 Forces from Tension-Field

- 6. 21 Force in Stiffener (resulting from tension-field action) 22 State of Stress 23 Intermediate Transverse Stiffeners (at nominal shear strength Vn including tension-field action) 24 Shear and Moment Strengths (under combined bending and shear)

- 7. 25 Intermediate Transverse Stiffeners Intermediate Transverse Stiffener (not required if h/tw ≤ 2.45√E/Fy) (1) Stiffness Criterion Ist ≥ jatw 3 (G2-6) where j = 2.5/(a/h)2 – 2 ≥ 0.5 (2) Strength Criterion Ast > Fy/Fyst (0.15 Dshtw (1 – Cv) Vu/ΦvVn – 18 tw 2)≤0 (G3-3) 26 Intermediate Transverse Stiffener connection to flange 27 Bearing Stiffener (effective cross-sections) 28 Bearing Stiffener Bearing Stiffener ΦRn ≥ Ru (1) Bearing Criterion (LRFD – J8.1) Φ = 0.75 Rn= 1.8 FyApb (2) Column Stability Criterion KL/r = 0.75 h/r where r of 12 tw or 25tw ΦcFcr = LRFD Table 3-36 Reqd. Ast = Ru/ΦcFcr → Reqd. t (3) Local Buckling Criterion (AISC 13th Edition Table B4.1 Case 3) Min. t = w/(0.56/√E/Fy)

- 8. 29 Effect of Longitudinal Stiffener on plate girder web stability 30 Example – Girder loading and support for design 31 Example - Factored moment and factored shear envelopes for two-span continuous beam of illustrative example 32 Example - Design Sketch