Lathe Machines

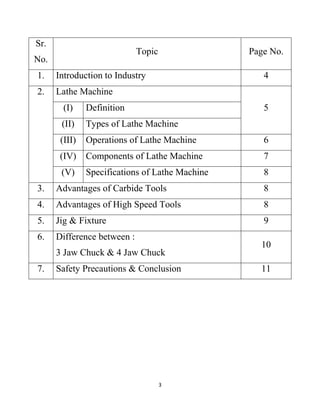

- 1. 3 Sr. No. Topic Page No. 1. Introduction to Industry 4 2. Lathe Machine 5(I) Definition (II) Types of Lathe Machine (III) Operations of Lathe Machine 6 (IV) Components of Lathe Machine 7 (V) Specifications of Lathe Machine 8 3. Advantages of Carbide Tools 8 4. Advantages of High Speed Tools 8 5. Jig & Fixture 9 6. Difference between : 3 Jaw Chuck & 4 Jaw Chuck 10 7. Safety Precautions & Conclusion 11

- 2. 5 LATHE MACHINE Lathe Machine:- A lathe machine is a machine tool which is used to remove metals from a workpiece to give a desired shape and size. In other words it is a machine that is used to hold the workpiece to perform various metal removing operations such as turning, grooving, chamfering, knurling, facing, drilling, etc. with the help of tools. It is also called as mother of machine. Types of Lathe Machines:- The various types of lathe machines are as follows:- Engine lathe Turret lathe Tracer lathe Bench lathe Computerized numerically controlled lathe

- 3. 6 Operations of Lathe:- The various operations performed on lathe machines are as follows:- Facing:- In this, the workpiece is held in the chuck and the facing tool is feed from the centre of workpiece towards the outer surface or from outer surface to the centre with the help of cross slide. Plane Turning:- It is the process in which excess amount of material is removed from the surface and its diameter of workpiece is reduced. The feed is longitudinal to the tool. Grooving/Cutoff:- Grooving is the act of making grooves of reduced diameter in the workpiece. Chamfering:- It is the operation performed by a cutting tool on the edges of faces of external diameters for restricted length. Chamfering removes sharp edges. The cutting edge of tool is directly apply to workpiece at an angle of a chamfer. Knurling:- It is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Drilling:- It is the operation of making a hole in the workpiece with the help of drill in its centre. The ill dris held in tail stock and feed manually into the rotating workpiece. Reaming:- It is an operation of finishing the previously drilled hole. In this operation reamer is held in the tail stock and reamer is fed into hole in similar way as per way of drilling.

- 4. 7 Components of Lathe Machine:- The main components of Lathe Machine are as follows:- Bed:- The bed of the lathe provides the foundation for the whole machine and holds the headstock, tailstock and carriage in alignment. The surfaces of the bed that are finely machined - and upon which the carriage and tailstock slide - are known as "ways". Head Stock:- Head stock is generally installed on the left side of the lathe machine. It is a housing for the drive pulleys and gears. The chuck is attached in this part of lathe. With the help of chuck the rotary motion is transferred to the workpiece. Tailstock:- Tailstock is used for centering the job when a long job is tied on the chuck. It provides a good support to damp the vibration. It is generally mounted on the inner ways. Carriage:- Carriage holds the tools and provides movement of the tool in both cross and longitudinal directions. For taper turning and facing cross feed is used for conventional turning carriage provides longitudinal feed. Carriage contains some other parts. It runs through the outer ways. Cross Slide:- Cross Slide Provides the cutting motion of the tool. Cross Slide can be operated by hand or by the cross feed equipment. The alignment of the cross slide is perpendicular to the center of the lathe. Tool Post:- It is mounted above the compound rest. It serves to rigidly clamp the cutting tool and or tool holder in a desired position.

- 5. 8 Specifications of Lathe Machine:- Width of the bed Type of drive Speed of lathe Lead screw diameter & pitch Distance between Headstock & Tailstock Carbide Tip Tool :- Advantages :- 1. Carbide tipped tools should always be used when machining highly abrasive materials. 2. Carbide tipped tools improve surface finish and hold size far longer for better quality. 3. Carbide tipped tools retain their cutting edge hardness at high machining temperature generated by high speed & feeds that reduce machining cycle time. High speed cutting tool Advantages 1. High working hardness 2. High wear hardness 3. Excellent toughness 4. High retention of hardness and red hardness

- 6. 9 Jigs and Fixtures:- The device which guides the tool is called jig and the device which holds the job in position is called fixture. Uses of Jigs and Fixtures:- To achieve higher accuracy. To reduce production cost. To increase the production. To provide for interchangeability. To control quality control expenses. To assure the high accuracy of parts. There use partially automates the machine tool It is used to reduce the cost of production as there use elimination being out work and setting up of tools. Improve the safety at work, thereby lowering the rate of accidents. Difference between 3 Jaw & 4 Jaw Chuck:- 3 Jaw Chuck 4 Jaw Chuck Setting up of work is easy. Setting up of work is difficult. Has less gripping power. More gripping power. Depth of cut is comparatively less. More depth of cut can be given. Heavier jobs cannot be turned. Heavier jobs can be turned. Workpiece cannot be set for eccentric turning. Workpiece can be set for eccentric turning.

- 7. 10 Safety Precautions taken on Lathe Machine:- Never lean on the lathe. Always wear protective eyewear. Remove chuck keys and wrenches before operating. Does not stop the lathe before making adjustments. Never attempt to measure work while it is turning. Handle sharp cutters, centres, and drills with care. Use pliers or a brush to remove chips. Conclusion:- Lathes are normally robust in construction and they will, with good care, last for many years. It is not unusual for instance to see good lathe still in uses that are 50 years old. To ensure good, accurate, trouble free use it is necessary that the correct maintenance routines are regularly carried out and that important surfaces such as slide-ways are kept well protected so as to reduce wear and thus maintain good accuracy, and the lubricants used, are all factors that require your attention.