Documentation System - Explained

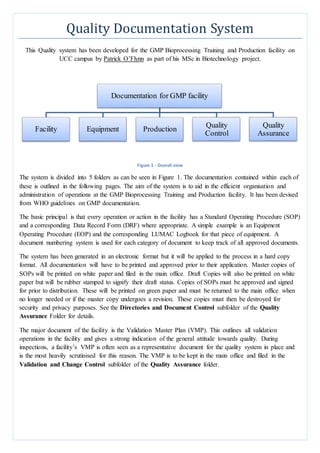

- 1. Quality Documentation System This Quality system has been developed for the GMP Bioprocessing Training and Production facility on UCC campus by Patrick O’Flynn as part of his MSc in Biotechnology project. Figure 1 - Overall view The system is divided into 5 folders as can be seen in Figure 1. The documentation contained within each of these is outlined in the following pages. The aim of the system is to aid in the efficient organisation and administration of operations at the GMP Bioprocessing Training and Production facility. It has been devised from WHO guidelines on GMP documentation. The basic principal is that every operation or action in the facility has a Standard Operating Procedure (SOP) and a corresponding Data Record Form (DRF) where appropriate. A simple example is an Equipment Operating Procedure (EOP) and the corresponding LUMAC Logbook for that piece of equipment. A document numbering system is used for each category of document to keep track of all approved documents. The system has been generated in an electronic format but it will be applied to the process in a hard copy format. All documentation will have to be printed and approved prior to their application. Master copies of SOPs will be printed on white paper and filed in the main office. Draft Copies will also be printed on white paper but will be rubber stamped to signify their draft status. Copies of SOPs must be approved and signed for prior to distribution. These will be printed on green paper and must be returned to the main office when no longer needed or if the master copy undergoes a revision. These copies must then be destroyed for security and privacy purposes. See the Directories and Document Control subfolder of the Quality Assurance Folder for details. The major document of the facility is the Validation Master Plan (VMP). This outlines all validation operations in the facility and gives a strong indication of the general attitude towards quality. During inspections, a facility’s VMP is often seen as a representative document for the quality system in place and is the most heavily scrutinised for this reason. The VMP is to be kept in the main office and filed in the Validation and Change Control subfolder of the Quality Assurance folder. Documentation for GMP facility Facility Equipment Production Quality Control Quality Assurance

- 2. Figure 2 - Focus on Facility The Facility Folder is designed to hold all documentation pertaining to the facility itself (building and utilities). This is visually illustrated in Figure 2. Note the sub-folders. The contamination control plan and all its procedures and data record forms will be documented here. The “Systems” folder holds all SOPs regarding the Operation, Maintenance and Calibration of utilities in the facility. This includes procedures regarding the HVAC system and purified water loop as well as aseptic sampling of process equipment such as a the Bioreactor. The “Cleaning of Facility”, “Disinfection, Fumigation”, “Environment Monitoring” and “Pest Control” folders hold SOPs, DRFs and Logbooks regarding each of their relevant topics. The “Flow Plans” folder contains details for the flow of product, supplies, staff and waste disposal. This includes flow plans and diagrams. See the Validation Master Plan for details regarding these activities too. The “Cleaning and Sterilisation” folder contains SOPs for the cleaning and sterilisation of materials that will come in direct contact with the product. These materials must be more stringently cleaned and maintained as their direct contact with the product has a direct impact on product quality. The “Access Control and Hygiene” folder contains a number of SOPs outlining activities such as Access Control, Hygiene, Gowning, Degowning, Material Transfer and Personnel Conduct. Documentation for GMP facility Facility Systems Operation, Maintenance, Calibration Cleaningof Facility SOPs, DRFs andLogs Disinfectant, Fumigation SOPs, DRFs andLogs Environmental Monitoring SOPs, DRFs andLogs Pest Control SOPs, DRFs andLogs Flow plans Product, Supply, Staff, Waste and Dosposal Cleaningand Sterilisation Garments, Glassware Access Control, Gowning SOPs Entry andExit to Cleanrooms SOPs, Posters Equipment Production Quality Control Quality Assurance

- 3. Figure 3 - Focus on Equipment The Equipment folder has been designed to hold all the documentation pertaining to the equipment in the facility. This is visually outlined in Figure 3. Note the sub-folders and their contents. The Operation, Maintenance and Calibration category is probably the most important as this contains the Equipment Operating Procedures (EOPs). These will be heavily referenced throughout the system in other SOPs requiring the use of the equipment. The LUMAC (Log of use, maintenance and cleaning) logbook system is designed to keep track of all activities involving the operation, maintenance and cleaning of equipment. All operation manuals, product specifications, data sheets, health and safety information for the equipment and cleaning reagents used in their maintenance are also stored in this folder. Documentation for GMP facility Facility Equipment Operation, Maintenance and Calibration Equipment Operating Procedures (EOPs) Equipment Data RecordForms LUMAC, logs and other DRFs. Preparationof Cleaning Solutions SOPs for cleaning solutions Cleaningagents data sheets, product infofor cleaningagents Equipment monitoringand alarms procedures, schedules, parameters. Calibration of NIST equipment Procedures and Records Operation Manuals Maunals, product info etc. Production Quality Control Quality Assurance

- 4. Figure 4 - Focus on Production The production folder has been designed to hold all documentation directly pertaining to production operations. This is visually outlined in Figure 4. Note the sub-folders and their contents. The Master Formulae (MF) folder is probably the most important here. It contains a SOP for the writing, approval, distribution and utilisation of the MF and Batch Processing Records as well as a template for an MF. This has been designed so that a fresh MF plan can be set up with each new client while still using the same template each time. This gives uniformity and flexibility to the process. The other folders contain documents pertaining to specific sections of the production process which can be categorised according to each individual campaign and client. The Biological Starting Materials folder is most important here as this holds the records for all biological materials (bacteria, fungi, cells, viruses etc.) used in production processes in the facility. This record must be well-maintained. Documentation for GMP facility Facility Equipment Production Master Formulae SOP, Template and guide to MF In-Process Tests SOPs, DRFs for tests Preparationof Process Buffers and Solutions SOPs, DRFs for sol. prep. Environmental Sampling SOPs, DRFs, EU guidelines Biological Starting Materials SOP for regulation. data sheets for all bio materials. Raw Materials Specifications, Product Codes Supplier Approval Receipt and Storage Quarantine, Release and Approval. Quality Control Quality Assurance

- 5. Figure 5 - Focus on Quality Control The Quality Control folder has been designed to hold all documentation pertaining to quality control operations. This is visually illustrated in Figure 5. Note the sub-folders and their contents. The different operations have been broken down into categories for ease of reference and filing of results. Each sub-folder contains SOPs and DRFs for the relevant operations therein. The Analytical Assay folder will be heavily referenced throughout the other folders in SOPs requiring the application of such assays for the relevant tests. Documentation for GMP facility Facility Equipment Production QualityControl Product Testingand Release SOPs, DRFs, QC Data sheets Raw Material Testing SOPs, DRFs, QC Datasheets Analytical Assays SOPs, DRFs Samples - Test andRetention SOPs, Coded sample log, Summary Protocol of QC results CollectedQC Datasheets Stability studies SOPs, DRFs Reference Standardand Control Maintenance andTesting Recertification of QC equipment Calibration records QC reagent andmaterial preparation SOPs, DRFs Quality Assurance

- 6. Figure 6 - Focus on Quality Assurance The Quality Assurance Folder has been designed to hold all documentation pertaining to Quality Assurance and administrative operations. This is visually illustrated in Figure 6. Note the sub-folders. The Batch record review folder contains all documents related to reviewing the production process. This includes batch record sheets, batch approval log and SOPs for the review of a batch process. These are essential in ensuring the product has been produced to the pre-determined specifications. Adverse events are documented through incident reports and suitable CAPAs (corrective action, preventive action) are initiated in response to these. The quarantine, release, rejection and storage of product procedures are outlined in SOPs found in the same folder for ease of reference. In the case of storage, temperature monitoring must be maintained to avoid deviations in storage conditions. Product Distribution, Complaints and Recall procedures and records are all documented together for ease of reference too. All employee records are maintained in the main office. This includes both professional (CVs) and health records with appropriate confidentiality maintained. All training received by staff as part of their employment in the facility is documented in the training records. The responsibilities of all staff members are also outlined in a clear and concise manner. The Validation and Change control folder contains the Validation Master Plan, as well as protocol and report templates for an array of qualification and validation activities. All validation in the facility is to be documented in this folder. The Directories and Document Control folder contains the SOP master list as well as other similar directories for the purpose of documentation control (Equipment tracker codes, LUMAC directory, Validation protocol/report lists etc.). The procedure for the preparation, authorisation and distribution of SOPs is also found here. Documentation for GMP facility Facility Equipment Production Quality Control Quality Assurance Batch Record Review Batch record sheets, approval log, SOP etc. Quarantine, Release, Rejection, Storage SOPs for each step. Temperature monitor records Product Distribution, Complaints, Recall Procedures andRecords Adverse Events Reports Incident reports (SOP andDRFs) Employee records professional (CVs) and health records. Trainingand Responsibility Training records, responsiblity descriptions Validation and Change Control Protocols, Reports, Validation Master Plan. Directories, Document control SOP Master list, LUMAC list, tracker codes, SOP prep. etc. Inspection Internal, Contractor and Vendor Audits Audit SOP and records,

- 7. Figure 7 - Current Hierarchy in System The current documentation system references the hierarchy illustrated in Figure 7. Note the different positions and their titles. Responsibilities are delegated to the titles listed here and anyone employed under these titles must take on these responsibilities. Where an SOP refers to the “Area Manager”, it means the relevant manager to the person in question. For example, if a production operation is to be reported to the Area Manager then the Production Manager should be notified. Current SOPs reference these titles when outlining responsibilities, procedures and reporting action to be taken during operation at the facility. This hierarchy can either be altered to suit the number of personnel in the facility or those taking on extra responsibilities can just inherit the extra title(s). Managing Director Quality Assurance Manager QA Supervisor QA Specialist Quality Control Manager QC Supervisor QCAnalyst Maintenance Manager Maintenance Supervisor Maintenance Engineer Production Manager Production Supervisor Production Microbiologist, Operator