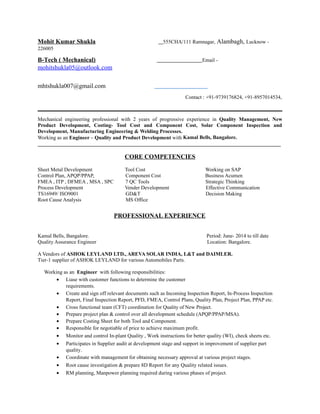

Resume - Copy 1

- 1. Mohit Kumar Shukla 555CHA/111 Ramnagar, Alambagh, Lucknow - 226005 B-Tech ( Mechanical) Email - mohitshukla05@outlook.com mhtshukla007@gmail.com Contact : +91-9739176824, +91-8957014534, Mechanical engineering professional with 2 years of progressive experience in Quality Management, New Product Development, Costing- Tool Cost and Component Cost, Solar Component Inspection and Development, Manufacturing Engineering & Welding Processes. Working as an Engineer – Quality and Product Development with Kamal Bells, Bangalore. _____________________________________________________________________________________________ CORE COMPETENCIES Sheet Metal Development Tool Cost Working on SAP Control Plan, APQP/PPAP, Component Cost Business Acumen FMEA , ITP , DFMEA , MSA , SPC 7 QC Tools Strategic Thinking Process Development Vender Development Effective Communication TS16949/ ISO9001 GD&T Decision Making Root Cause Analysis MS Office PROFESSIONAL EXPERIENCE Kamal Bells, Bangalore. Period: June- 2014 to till date Quality Assurance Engineer Location: Bangalore. A Vendors of ASHOK LEYLAND LTD., AREVA SOLAR INDIA, L&T and DAIMLER. Tier-1 supplier of ASHOK LEYLAND for various Automobiles Parts. Working as an Engineer with following responsibilities: • Liase with customer functions to determine the customer requirements. • Create and sign off relevant documents such as Incoming Inspection Report, In-Process Inspection Report, Final Inspection Report, PFD, FMEA, Control Plans, Quality Plan, Project Plan, PPAP etc. • Cross functional team (CFT) coordination for Quality of New Project. • Prepare project plan & control over all development schedule (APQP/PPAP/MSA). • Prepare Costing Sheet for both Tool and Component. • Responsible for negotiable of price to achieve maximum profit. • Monitor and control In-plant Quality , Work instructions for better quality (WI), check sheets etc. • Participates in Supplier audit at development stage and support in improvement of supplier part quality. • Coordinate with management for obtaining necessary approval at various project stages. • Root cause investigation & prepare 8D Report for any Quality related issues. • RM planning, Manpower planning required during various phases of project.

- 2. • Ensure that the Product Engineering Department fulfils its responsibilities towards TS16949 requirements. • Reports for Various Gauges, Inspection Instruments, Machine that are present in the company. • Project budget preparation, budget controlling & maintains project documentation. • Implementation of Engineering Development Model (EDM) based on design changes (Both Product & Process). • Production of parts as per customer requirement and ensure 100% qualification of Assembly on Inspection Gauge. • Involved in Improvement activities according to fitment point of view. PROJECT DELIVERED CURRENT PROJECTS Development of Brkt. Assy for Pedal Support - • To carry out various development activities associated with development according to APQP Phases and ensure project strictly sticks to its Time Plan. • Improvement in Various Quality issues related to M8 Bolts. • Participated in Various Meetings related to the Development of this Components. • To make various project related documents like APQP, Control Plan, Fixture Report, Inspection Report, Powder Coating Report etc. • Time to time follow up from Supplier and ensure they stick to their Time Plan. • To ensure that all customer requirements are fulfilled according to the need. Development and Ensuring Quality of Various other parts like Battery Carrier, Air Tank Bracket, Cab Mounting bracket, Nozzle Holder, Toggle Clamp etc. PROJECTS COMPLETED Development of Rolar Reflector and Sliding Glass Latch ( Areva Solar India ) - • To ensure all Customer requirements are fulfilled. • To carry out various development activities according to APQP Phases and ensure project strictly sticks to customer Time Plan. • Time to time follow up from Supplier and ensure they stick to their Time Plan. • To Plan Tryout & ensure incoming and in process part quality. • Time to time meeting with customer and stakeholders for project updates. Ensuring Quality related issues of Battery Cover for Defense Vehicles (JABALPUR UNIT)- • Development of Outer Cover for Battery of Defense Vehicles from its development till production. • To check the component is OK or NOT OK as per Dimensions as well as Customer Requirements. • To ensure all Customer requirements are fulfilled. • Time to time follow up from Supplier and ensure they stick to their Time Plan. • Time to time meeting with customer and stakeholders for project updates. EDUCATION & CERTIFICATION • B.Tech Mechanical Engineering from Babu Banarasi Das Engineering College, 2010 ~ 2014 with 67% marks. • Class 12th from UP Board in Year 2008 ~2010 with 78.2 % marks. • Matriculation from UP Board in Year 2008 with 72% marks. • Certification of Auto Cad from PLC Institute, Lucknow.

- 3. TRAININGS UNDERTAKEN • Training on Advance Testing and Calibration from Tespa Institute of Quality Management, Bangalore. • 1 Week training on Working process and Operations performed on CNC Machines of Victor and BFW. • 1 Week training on Wire Cutting EDM of ROBOFIL 300 CHARMILLES TECHNOLOGIES, SPM eZ-Cut and Sodick Machines. • 4 weeks Vocational Training in Wheel Shop at Locomotives, Charbagh in 2012. • 4 weeks Vocational Training in Diesel Shop at Locomotives, Charbagh in 2013. • 4 weeks Vocational Training from Public Welfare Department (PWD) in 2013. ASSET & ACHIVEMENT • Achieved four consecutive promotions within a time span of 1.11 Year. • Co-Ordinator for all the Quality Related issues on the Shop Floor, Welding Section and Powder Coating as well. • Coordinator for Kamal Bells Quality stabilization system for New Project Development. • Result oriented person with open attitude to acquiring and sharing knowledge. • Active participation in various competitions at Company. • Various Customer Appreciation mails. • Good Customer & Vendor Coordination. PERSONAL DETAIL Date of Birth : 16th Sept. 1992 Languages : English & Hindi Gender: Male Nationality : Indian Marital status : Single Domicile : Lucknow-U.P DECLARATION I hereby declare that all the above facts are True and Correct to the best of my knowledge. Date – (MOHIT KUMAR SHUKLA)