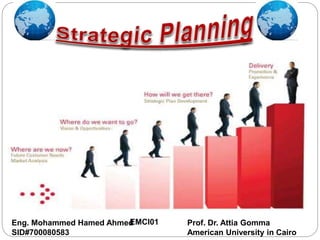

Strategic Planning

- 1. By Eng. Mohammed Hamed Ahmed Soliman

- 2. Vision Mission Values Strategic Objectives Strategy Plans Strategic Planning Main Components

- 3. Strategic Planning Process Gather Facts SWOT Analysis Review Inputs Strategic Matrix Define Strategies Final Review Where are you? Where we want to be? How we will do it? How are we doing? •Overview •Environmental Scan(SWOT) •GAP Analysis •Benchmark & Competitors Analysis •Industry Analysis •Company Performance •Company Strategies External Analysis •Opportunities •Threats Internal Analysis •Strengths •Weakness •All stakeholders •Review Inputs •Review SWOT Analysis •Define strategies to address SWOT combinations • Opportunities VS Strengths •Opportunities VS Weakness •Threats VS Strenghts •Threats VS Weakness •Objectives •Key Strategies •Short & long term goals •Operational plans •All stakeholders •Review strategies •Review goals • Review plans •Adjust as necessary

- 4. About Crystal Asfour Established in 1961, Asfour Crystal has a deep-rooted history and continues to lead the industry in innovation and quality, lighting up rooms and lives with a degree of sophistication. Asfour Crystal was established in the great city of Cairo on an area of 2,200 square meters. The business started with manpower of 200 workers and simple tank kilns (ovens) were used as main production tools at the time. Today, Asfour Crystal is the largest single manufacturer of full-cut lead crystal in the world, as well as one of the biggest chandelier manufacturers in the world, exporting its production to key international markets all over the globe. The company is based on a build-up that exceeds 1.2 million square meters and employs more than 35,000 highly selected employees. Asfour's highly skilled workers use the most sophisticated tools and techniques in the field, most of which have been designed, developed & manufactured within the boundaries of our factory. The production capacity is up to more than 170 tons of crystal per day, this makes Asfour Crystal the leading international manufacturer of the finest quality of transparent and colored full lead crystal (more than 30% PbO.)

- 6. •The world's largest producer of full lead crystal. •The world's biggest built-up facilities for crystal production. •The world's single largest employer of skilled crystal workforce. •The world's most used crystal brand by European & key international chandelier manufacturers.

- 8. Operational Factories Showrooms Asfour 1- Shobra Asfour 3- Bahtem Asfour 5-Al Menia Shobra EL Baroon Center Future Projects Asfour Alex Crystal Asfour

- 9. Company Main Structure Chairman Vice Chairman Production Sector Crystal Manufacturing Technology Sector Engineering Sector Financial Sector Warehouses Sector

- 10. Company’s Vision: brings people closer to the preciousness of the moment and shares with them the joy of observing and the fascination for the beautiful and hidden. The world belongs to those who can see beauty. Experience the moment. Mission: We consider it our duty to constantly improve what is good, to surprise our customers time and time again and to exceed their expectations. Our humanistic values are displayed in openness and respect towards all people and cultures as well as in social responsibility towards employees and society. Values: We consider it our duty to constantly improve what is good, to surprise our customers time and time again and to exceed their expectations. Our humanistic values are displayed in openness and respect towards all people and cultures as well as in social responsibility towards employees and society.

- 12. Engineering Sector Grinding Dept Electric Dept Crystal Rises Service Dept Industrial Services Dept PPM Dept Electric Dept Manager Engineers Engineers Engineers Engineers Engineers Technician Supervisors Technician Supervisors Technician Supervisors Technician Supervisors Technician Supervisors

- 14. To achieve a level of proactive operational excellence that establishes us as the leader within our industry. Our maintenance mission is the provision of timely, high quality, cost-effective service and technical guidance to support short-range and long-range company's vision and its strategic and operations (production) plan. We will ensure, through proactive practices rather than reactive, that assets are maintained to required levels of reliability, availability, output capacity, quality and customer service. The maintenance mission seeks to continuously improve work practices and maintenance effectiveness and will actively seek out and eliminate waste. Our mission is to be fulfilled within a working environment that fosters the highest levels of safety, morale and job fulfillment for all members of the maintenance team while protecting the surrounding environment." To achieve a level of proactive operational excellence that establishes us as the leader within our industry.

- 15. SWOT ANALYSIS

- 16. Strengths -Most of Equipments have redundancy. -There is a reliability in many process system designs. -Top management commitment. -The sector is ready to invest for the developing process. -The sector has the desire to train his engineering's & staff on the modern maintenance concepts and last up to date technologies & techniques. Weakness -There is no control or follow up for what is planned. -Most of the sector staff is so far from the reliability culture. -There are some production losses without care. -Bad contact between the maintenance & production. -Labor training is so week. -There are a lot of hidden wastes in the maintenance procedures. -There is lake of data & information availability -No standardization for all maintenance procedures. -Each dept is working with different order and system ”no unification”. Threats -People is resistant to change. -Chairman support will be needed at some stages. -Intensive training is required for the other dept heads & engineers. Opportunities -There is a good chance for a new reliable system for management and control -CMMS Implementation. -Maintenance wastes and costs can be reduced. -Productivity can be increased. SWOT

- 17. GAP ANALYSIS

- 18. • The sector vision is fair enough but a little optimistic, we need to have a more look at the future in order to be able to take the up coming challenges to compete in the market. • During 2011 there are some bad accidents occurred with some maintenance assets, we need more control, more training to our engineers to control the maintenance activities. • We are still so far from the maintenance reliability concept, we don’t have advanced methods & techniques in our maintenance programs. • All maintenance activities are based in PM & CM, no PdM applied for the critical equipments. • We don’t have a criticality assessment for our assets, and we don’t lok specially at the high risk/safety equipments. • We done better during 2010, our company now is having more competitors in the market, we need to lean our maintenance.

- 19. Benchmark: We don’t have competitors to compare with, we are the unique crystal production company in the middle east, we are comparing the maintenance performance with the other companies working in the field of maintenance and with the industrial best practice because we are seeking for the best!.

- 20. Maintenance Strategic Objectives Maintain all our assets and infrastructure on a planned and scheduled basis. Extend the life of assets Improved Reliability and Availability Enhanced and consistent product quality Quick response and repair times Continuity of production and suppliers

- 21. SMART Goals/Strategic Objectives Calculations: Perspective Key Indicator Measuring Finance Annual Maintenance Cost Maintenance Cost/ Total Operation Cost Downtime losses Productivity losses due to maintenance downtimes Maintainability Reliability of critical equip Available time/planned Availability of critical equip Total working time-total downtime/total working time Training Total training hrs per year Skills Crew Efficiency Actual hours completed/ estimated time Supervision control Unplanned labor hrs/total labor hrs Planning Planned work Total work actually completed to schedule/total work in schedule Planned compliance All labor hrs actually completed to schedule/ total labor hrs PM Performance Backlog ratio

- 22. Strategic Objectives & Benchmark Perspective Key Indicator Current 2011 Internal Benchmark External Benchmark Finance Maintenance cost ratio Downtime losses 0.25% 0.1% 10-20% Maintainability Reliability of critical equip 95% 98% 99.9999% Availability of critical equip 98.5% 99.5% 99.9999% Training Total training hrs per year 20-30hrs 100hrs 200hrs Skills Crew Efficiency 90% 95% 95% Supervision control 40% 20% 10% Planning Planned work 45% 20% 10% Planned compliance 40% 70% 90% PM Performance Backlog ratio 20% 30% 50-60%

- 23. Perspective Key Indicator 2011 2012 2013 2014 2015 Finance Maintenance Cost ratio Downtime losses 0.25% <0.25% <0.12% <0.1% 0.05% Maintainability Reliability of critical equip 95% >95% 98% 99% 99.9999 % Availability of critical equip 98.5% >98.5% 99% 99.5% 99.9999 % Training Total training hrs per year NA >50hrs >100hrs >150hr s 200hrs Skills Crew Efficiency 90% >90% >92% 95% 98% Supervision control 40% 30% 20% <20% 10% Planning Planned work 45% 30% 20% <20% 10% Planned compliance 40% >50% >75% >80% 90% PM performance Backlog ratio 20% 30% 40% 50% 60% Goals & Targets

- 25. Aggressively identify all assets and associated tasks to be included in the preventive maintenance program and enter this information into our Database. Schedule and coordinate preventive maintenance activities to take full advantage of available human and fiscal resources. Establish preventive maintenance as our top priority and measure schedule compliance. Progressively incorporate facilities/asset condition assessment into the preventive maintenance program. Planned and regular maintenance are fully funded on an annual basis. All stuff to be go in a process of change culture/management process to match the new maintenance vision. Optimization the usage of lean principles a long with the maintenance procedures. Assign a complete performance evaluation system to be declared periodically. Maintenance Strategies

- 26. Strategy” Objectives” Perspective Strategy Objective Measurements Targets Initiatives Finance Reduce maintenance costs Maintenance cost/ total operation cost Cost reduction program Reduce maintenance downtimes Productivity losses due to maintenance downtimes 0.05% -/yr TPM & PdM programs Maintainability Increase reliability Available time/planned 2% +/yr Integration of PdM policy Increase availability Total working time-total downtime/total working time 0.5% +/yr RCM Training Increase training time 50hr +/yr Training program Skills Improve crew efficiency Actual hours completed/ estimated time 2% +/yr Training program+7 Wastes Reduce unplanned hours Unplanned labor hrs/total labor hrs 10 % -/yr New maintenance planning program Planning Increase planning performance Total work actually completed to schedule/total work in schedule 10% -/yr PM follow up program Increase planning Time/reduce unplanned All labor hrs actually completed to schedule/ total labor hrs 10% +/yr PM program PM performance Achieve all PM tasks/Increase PM performance Backlog ratio 10% +/yr WO system

- 27. ACTION PLAN

- 28. Work Breakdown Structure Trainin g Data Gatherin g WO Implementatio n Data Scanning & Problems Analysis PM re planning Lean Scope of Work: Advanced Maintenance Management System Location Company : Crystal Asfour International Sector : Engineering Sectors Job Type : Internal

- 29. Calendar: Sat Sun Mon Tues Wed Fri 7 7 7 7 7 7 Responsibilities & Team Work: Planning Head Engineer. 4 Mechanical Engineers. 2 Electrical Engineers. 1 Programmer Conditions: Time Frame : 2yrs Start Date : 1st JAN 2012 End Date :

- 30. Code Activities Predecess or Duration (hrs) Resource s Responsibili ty 101 Maint Overview 12 Meeting room + Computer PM Head 102 Work Order 101 12 103 Criticality Analysis 102 9 104 KPIs & Evaluation System 103 6 105 PM Planning 104 9 106 Reliability of Maintenance 105 6 107 CMMS 106 60 108 Lean Maintenance 107 9 Estimated time frame for this job based on the calendar: Training Calendar: Days Sunday Thursday Hours 3 3 Training Activities

- 31. Code Activities Predecesso r Duration Resources Responsibility 201 Equipments Data 1 month Programmer + data entry person All the team + the programmer + PM Head 202 Labor Data 201 1 month 203 Preventive Maintenance Data 202 1 month 204 WO Data 203 1 month 205 Resources Data 204 2 weeks 206 Inventory, Purchase & Others 205 2 weeks 207 Developing current CMMS program In parallel with all above 1 month 208 Assigning KPIs 207 1 month Estimated time frame for this job: 6 months Data Gathering Activities:

- 32. Code Activities Predecessor Duration Resources Responsibility 301 Sheets design 1 week Printer + Papers+ Boards All the team + PM head + maintenance supervisions 302 Flows & planning 301 2 week 303 Methods of Controlling 302 2 weeks 304 Labors & supervisions Training 303 2 weeks 305 Production Coordination 303 2 weeks 306 Follow Up & Control 305 2 weeks 307 Implementation 306 308 Workshops Arrangement 307 2 week Estimated time frame for this job: 3 months WO Implementation Activities

- 33. Code Activities Pred Duration Resources Responsibility 401 Data Scanning & Problems Analysis 307 2 months 402 Priorities Assignment 401 2 weeks 403 Performance Analysis 402 1 week 404 Analysis & Root Causes 403 2 weeks 405 Define strategies 404 1 month Data Scanning & Problems Analysis (Downtimes Analysis)

- 34. Code Activities Predecessor Duration Resources Responsibility 501 PM programs review 405 1 week Papers + Printer + 5S & lean tools Planner Head + Team 502 Define requirements 501 1 week 503 Implementation 502 1 month 504 Routine Maintenance 503 2 weeks 505 Measuring 504 2 months 506 Wastes Allocation 505 1 month 507 Resources Utilization 506 3 months 508 Claims Analysis 507 1 month 509 Labor Training 508 3 months PM re planning & Control

- 35. Code Activities Predecessor Duration Resources Responsibility 601 Visualization Management 509 6 months Visual boards + some lean tools Planning Head + Team 602 Lean Maintenance (TPM, RCM, PdM, 5S, 7 Wastes, FMEA) 601 6 months 603 Training 602 Lean Principles Implementation Eng. Mohammed Hamed Ahmed Soliman Industrial Engineering Consultant & Lecturer Email: mhamed206@yahoo.com m.h.ahmed@ess.aucegypt.edu https://eg.linkedin.com/in/mohammedhamed Tel: +201001309903