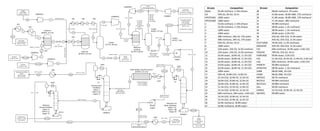

Weitere ähnliche Inhalte Ähnlich wie DME Production Process Flow Diagram (20) 1. 540 C, 33.3 bar

HX2

HX1

Natural Gas

91.63% Methane

@ 35 ᵒC, 34 bar

HP Steam

@ 230 ᵒC, 9 bar

Preformer

@540ᵒC, 33.3 bar

Reformer

@ 940ᵒC, 29.6 bar

940 ᵒC, 29.6 bar

Methanol

Synthesis

@ 250 ᵒC, 48 bar

HX4 HX5

940 ᵒC, 29 bar 400 ᵒC, 28.9 bar

75 ᵒC, 28.3 bar

@141ᵒC, 48 bar

Water

99.99%

@ 75ᵒC, 1 bar

HP Steam

@ 230 ᵒC, 9 bar

51.3% CO2

23.5% H2

11.8% CO

3.5% methanol

104 ᵒC, 29.6 bar

Oxygen

93% oxygen

@ 104 ᵒc, 12 bar COMPRES2

COMPRES3

52% CO2

23% H2

12% CO

5% argon

3% nitrogen

Gas Purge

@ 67ᵒC, 1 bar

(to furnacefor energy)

59.8% methanol

35.1% water

4.6% carbon dioxide

78 % carbon dioxide

11% methanol

4.4% hydrogen

2.2 % carbon monoxide

@ 25ᵒ C, 1 bar

(to furnacefor energy)

PUMP1

62.7% methanol

36.9% water 25ᵒC, 15.7 bar

FLASH1

@ 75ᵒC, 28.9 bar

Methanol and

Water Distillation

Boilup: 5.21

Reflux: 1.88

Stages: 30

DHX1

P1

KREBOIL1

98.7% methanol

@147 ᵒC, 15.2 bar

FLASH2

@ 68ᵒC, 47.5 bar

FLASH3

@ 25ᵒC, 1 bar

DMECatalytic Plug Flow Reactor

@ 300 ᵒC, 15.1 bar

40% dimethyl ether

40% water

18.8% methanol

@14.5 bar, 300 ᵒC

Dimethyl Ether

Distillation

Boilup: 2

Reflux: 8.75

Stages: 35

DHX2

P2

KREBOIL2

@ 21 ᵒC, 5.1 bar

HX9

@ 17 ᵒC, 5 barDimethylether (DME)

98.5%

500 tonne/day

@ 17 ᵒC, 5 bar

DHX3

P3

Methanol

Recycle Distillation

Boilup: 8

Reflux: 2.1

Stages: 25

KREBOIL3

129 ᵒ C, 5.1 bar

69 ᵒC, 1.2 bar

99.99% methanol

@ 67ᵒC, 1.1 bar

PUMP2

99.99% methanol

@ 67ᵒC, 15.2 bar

300 ᵒC

HX11

Methanol

(forsale) 99.99%

@ 30ᵒC, 1 bar

99.99% Water

@ 105 ᵒC, 1.2 bar

(LPS recycle)

HX10 30 ᵒC, 1 bar

COMPRES4

151.7 ᵒC, 48.2 bar

Water

99.99%

@ 199.1 Water

99.99%

@ 199.1 ᵒC, 15.2 bar

(use as HPS)

COMPRES1

@540 ᵒC, 33.3 bar

V1

540ᵒC, 29.6 bar

COMPRES5

141 ᵒC, 48 bar

68 ᵒC, 1 bar

O2 7

11

14

22

NGAS

2

3

HX3

@450ᵒC,29.6bar

8

HX6

18

TURBINE1

F23

CO2PURGE

26

27

METHA2

HX3

28

31

WATER3

SPLIT2

99,9% methanolrecycle

SPLIT1

97.2% syngasrecycle

HPWATER

Reactor Dimensions:

6.15 m in length

1.55 m in diameter

32

SYNREC

LDME

METH

RECYCLE1

SELL

29

RECYCLE

3516

VDME

HPSTEAM2

1

4

105 6 9

HPSTEAM1

15

1312

21

23

17

52% CO2

22.7%

24 25

Stream Composition Stream Composition

NGAS 91.6% methane, 5.72% ethane 28 98.6% methanol, 1% water

O2 93% O2, 2% N2, 1% Ar 29 41.8% water, 40.8% DME, 17% methanol

HPSTEAM1 100% water 30 41.8% water, 40.8% DME, 17% methanol

HPSTEAM2 100% water 31 71.3% water, 28% methanol

1 91.6% methane, 5.72% ethane 32 99.99% methanol

2 91.6% methane, 5.72% ethane 33 98.9% water, 1.1% methanol

3 100% water 34 98.9% water, 1.1% methanol

4 100% water 35 99.8% water, 0.2% CO2

5 48% methane, 24% H2, 17% water 36 45% N2, 35% CO2, 15.3% water

6 48% methane, 24% H2, 17% water 37 45% N2, 35% CO2, 15.3% water

7 93% O2, 2% N2, 1% Ar CO2 PURGE 78.4% CO2, 11.2% methanol

8 100% water EMISSION 45% N2, 35% CO2, 15.3% water

9 52% water, 21% O2, 14.5% methane F23 60% methanol, 34.9% water, 4.6% CO2

10 52% water, 21% O2, 14.5% methane FREEAIR 78% N2, 21% O2, 1% Ar

11 63.6% water, 18.8% H2, 11.1% CO2 H20PURGE 99.8% water, 0.2% CO2

12 63.6% water, 18.8% H2, 11.1% CO2 H21 51.3% CO2, 23.5% H2, 11.9% CO, 3.5% methanol

13 63.6% water, 18.8% H2, 11.1% CO2 H23 60% methanol, 34.9% water, 4.6% CO2

14 63.6% water, 18.8% H2, 11.1% CO2 HPMETH 99.99% methanol

15 63.6% water, 18.8% H2, 11.1% CO2 HPWATER 98.9% water, 1.1% methanol

16 100% water LDME 98.6% DME, 1% CO2

17 50% H2, 29.8% CO2, 13.9% CO VDME 98.6% DME, 1% CO2

18 52.1% CO2, 23.9% H2, 12.1% CO METHA2 98.7% methanol

19 50.6% CO2, 25.8% H2, 12.2% CO RECYCLE 99.99% methanol

20 50.6% CO2, 25.8% H2, 12.2% CO RECYCLE1 99.99% methanol

21 51.3% CO2, 23.5% H2, 11.9% CO SELL 99.9% methanol

22 52.1% CO2, 23.9% H2, 12.1% CO SYNREC 52.1% CO2, 23.9% H2, 12.1% CO

23 60% methanol, 34% water, 4.6% CO2 WATER3 99.99% water

24 52.1% CO2, 23.9% H2, 12.1% CO

25 52.1% CO2, 23.9% H2, 12.1% CO

26 62.8% methanol, 36.8% water

27 62.8% methanol, 36.8% water