Alfra Consulting First International cross-functional Webinar

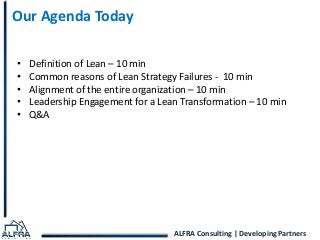

- 1. ALFRA Consulting | Developing Partners Our Agenda Today • Definition of Lean – 10 min • Common reasons of Lean Strategy Failures - 10 min • Alignment of the entire organization – 10 min • Leadership Engagement for a Lean Transformation – 10 min • Q&A

- 2. ALFRA Consulting | Developing Partners What is your definition of Lean?

- 3. ALFRA Consulting | Developing Partners Lean Thinking Lean Enterprise PRODUCT BUILT & SHIPPED CUSTOMER ORDER Short Lead Time Waste out of the System Traditional Business PRODUCT BUILT & SHIPPED CUSTOMER ORDER Very long Lead Time Waste within the system (high inventory, defects, waiting & more… )

- 4. ALFRA Consulting | Developing Partners Lean = Cheaper Mediocrity? • Are You Striving For Excellence? – 20% Headcount Reduction – 75% Reduction In Changeover Time – 50% Improvement In OEE – 30% Reduction In Lead Time – 25% Reduction In Inventory • Do Any Of These ‘Goals’ Make You Excellent? 4© 2008 – 2014 Toyota Way Academy, LLC

- 5. ALFRA Consulting | Developing Partners Lean = Cheaper Mediocrity? 5© 2008 – 2014 Toyota Way Academy, LLC Excellence Is A Pursuit, Not An Absolute Value • Are You Striving For Excellence?

- 6. ALFRA Consulting | Developing Partners ‘Lean’ Process vs. Lean Systems We have high inventory and low output We Need to ‘Lean Out’ our Processes 6 We’ll Introduce Cells and Pull Systems Now We Have a ‘Lean’ Process, Let’s Replicate!

- 7. ALFRA Consulting | Developing Partners Tools Cells, Flow lines Kanban Leveled Schedules Andon, Line Stopping System Standardized Work 5S, Visual Factory Apparent Purpose: One-piece flow is the ultimate in waste elimination Reduce inventory which is the main purpose of lean Unevenness prevents smooth flow and increases inventory Do not let defective products leak out Standardization is the best known way and most efficient Visual control allows everyone to understand the state of the operation by simply looking ‘Lean’ Process vs. Lean Systems

- 8. ALFRA Consulting | Developing Partners ‘Lean’ Process vs. Lean Systems Lean Systems Have One Function Surface Problems 8© 2008 – 2014 Toyota Way Academy, LLC

- 9. ALFRA Consulting | Developing Partners LEAN SYSTEMS Processes that Surface Problems so People can Continually Improve and Learn through PDCA System Surfaces Problems Collect All Problems Align & Prioritize By Business NeedsBusiness Strategy Solve 1 by 1 Using PDCA I Improve Processes Process A Process B Process C

- 10. ALFRA Consulting | Developing Partners A principle-based approach to management that is timeless and universal. There are always different solutions to different problems in manufacturing & service companies. It is a continual journey of learning that never ends! Philosophy (Long-term Thinking) People and Partners (Respect, Challenge and Grow Them) Process (Eliminate Waste) Problem Solving (Continuous Improvement and Learning)

- 11. ALFRA Consulting | Developing Partners The Iceberg Model SMED Andon5S Kanban. Supermarkets Slogans PHILOSOPHY VISIBLE TOOLS & DEVICES

- 12. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure

- 13. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure Why companies don’t get to embed Lean in the Culture Lean is a “Program” with a start & end date. Lets Get in LEAN MODE !!!! Many companies understand Lean as a project/program, which has a timeframe for implementation, activities are assigned, performed and when completed, everybody do business as normal.

- 14. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure Why companies don’t get to embed Lean in the Culture Focused only on financial short-term results. • When a company sees Lean only like a cost cutting methodology, every Lean effort must have a return in measurable ($$) benefits , many companies let aside key systems or efforts, because they don’t bring immediate or direct hard savings/benefits. Some important soft systems are: • People Coaching & development (skill & career) • Award & recognition (keeps the momentum and motivation of associates • Respect (assuring people’s work, internal promotion) • Empowerment Layers • Among others.

- 15. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure Why companies don’t get to embed Lean in the Culture • Fail to develop people at all levels (another short term bet) • Many companies don’t invest in their people, and very few of them invest in development systems at all levels. • They end depending only of few experts in the company.

- 16. ALFRA Consulting | Developing Partners Which are the barriers to establish a Lean Culture in your company? REFLECTION TIME

- 17. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure Why companies don’t get to embed Lean in the Culture • Widespread across the company, but very shallow • Some companies try to spread Lean across the company in a very fast pace, but there is not enough time to get in deep to embed the mindset of the people.

- 18. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure Why companies don’t get to embed Lean in the Culture • Inconsistent & weak leadership direction, Leadership manages from the office (never seen on Gemba)

- 19. ALFRA Consulting | Developing Partners Leadership Role

- 20. ALFRA Consulting | Developing Partners Western Leadership Vs. Toyota Leadership Traditional Western Leader Toyota Leader Work to a financial Plan Reach for True North Vision Quick Results Patient Proud Humble Climb Ladder Rapidly Learn Deeply and gradually Earn Way up Ladder Results at all Costs Need the Right Process to consistently get the Right Results Achieve Objectives through People Develop People through process improvement

- 21. ALFRA Consulting | Developing Partners Servant Leadership Leadership develops the capacity that allows team members to improve what needs to be done Suppliers – Team Members - Customers Team Leaders Group Leaders Asst. Manager/Manager Asst/General Manager Vice President President

- 22. ALFRA Consulting | Developing Partners Servant Leadership Needs Strong Foundations 22 Consistency of Direction through Hoshin Kanri Highly Developed Work Groups Continuous Checking and Adjusting Middle Managers as Coaches Executives as Visionaries & Guides Rock Solid Culture of Continuous Improvement: Skills & Commitment © 2008 – 2014 Toyota Way Academy, LLC

- 23. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure Why companies don’t get to embed Lean in the Culture • Improvement (Lean) is owned by a department, not for all the company. • Everybody requires help from the expert, nobody feel capable to improve by their own, even small steps.

- 24. ALFRA Consulting | Developing Partners Common Reasons of a Lean Transformation Failure Why companies don’t get to embed Lean in the Culture • View lean only as a technical “toolkit”, no strategy at all, isolated application of tools around the company and processes!!

- 25. ALFRA Consulting | Developing Partners It Starts With A Vision • Successful business know what the purpose of their business is; why they exist – People are more strongly motivated by a positive vision – The vision helps define ‘True North’ – A company’s purpose is not the same as a company’s measurable objectives 25© 2008 – 2014 Toyota Way Academy, LLC

- 26. ALFRA Consulting | Developing Partners True North (Hoshin) The process of reflective learning lead by management keeps the organization on track to its True North despite the short-term influences Variables • Economic fluctuations • Materials disruptions • New employees • New customers • New markets • Etc. 26

- 27. ALFRA Consulting | Developing Partners True North • Wherever we are in an organization, we can use our True North to guide our efforts • Represents perfection – we strive toward it knowing it can never be reached • Helps reassure teams that they are achieving the mission the ‘right’ way 27© 2008 – 2014 Toyota Way Academy, LLC

- 28. ALFRA Consulting | Developing Partners 28 Destination (Vision) Starting Point (Current Condition) The Strategic Plan is the “Road” to a Desired Future State of the Organization Use Hoshin to remove the Big Boulders, one at a Time HOSHIN - ROADMAP Use Continuous Improvement to remove small obstacles on an ongoing basis Later Later

- 29. ALFRA Consulting | Developing Partners Comparison between MBO & Hoshin Kanri Management by Objectives Hoshin Kanri Results Oriented Evaluation of Effort Concerned with both Results and Process of getting those Results Top down Communication Top down Direction Setting and Bottom-up Planning & Executing Directive Participative Authority Oriented Responsibility Oriented

- 30. ALFRA Consulting | Developing Partners Results as Lean Strategy EvolvesBusinessResultsfromLeanTransformation Starting Maturity Maturity in Integrating Lean and Business Strategy I. Apply some Tools II. Management Led Lean III. Aligned Continuous Improvement Without Philosophy No strategy at all!! 98% of companies fail here!! With Philosophy Systems that enable the culture development

- 31. ALFRA Consulting | Developing Partners Can we “Sustain the Gains” of Lean like maintaining a machine? “Why are we Slipping?” Process Results Time “Do Lean” (Apply Tools) “Getting Lean” (Lean out Process) “Entropy” Means Decay Results as Lean Strategy Evolves

- 32. ALFRA Consulting | Developing Partners Working Out to Arrest Entropy

- 33. ALFRA Consulting | Developing Partners Counter Entropy With Positive Energy Process Results Time “Early Projects” (Experiment) “Spread Lean” (Learn) ‘Daily Management’ (Leadership) Results as Lean Strategy Evolves

- 34. ALFRA Consulting | Developing Partners Mechanistic Thinking • The organization behaves like a machine • We believe we can ‘optimize’ a value stream – Optimization implies a ‘solution’ – The ‘solution’ will be fixed and standardized for all time – It is a convenient way to think about processes • The introduction of people into the equation makes all ‘constants’ into ‘variables’ 34© 2008 – 2014 Toyota Way Academy, LLC

- 35. ALFRA Consulting | Developing Partners Mechanistic Thinking • Frederick Taylor’s ‘One Best Way’ • Workers Do – Supervisors Plan • After Taylor we have been on a quest to use mathematics to find the ‘optimum.’ • People are machines • Occasional adjustments and updates are needed in their programs • The best programs will yield the best results • We need to find the best program 35© 2008 – 2014 Toyota Way Academy, LLC

- 36. ALFRA Consulting | Developing Partners Systems Thinking • Idea is over 100 years old • If the environment did not change (a closed system) we could develop controls • Organizations are open systems – constantly changing and adapting to stimulii • The goal is to facilitate teams of people to innovate and solve problems 36© 2008 – 2014 Toyota Way Academy, LLC

- 37. ALFRA Consulting | Developing Partners Machine vs. Organic Thinking 37 Mechanistic (Machine) Thinking Organic (Systems) Thinking World view Simple linear chain of cause & effect Interdependent, interacting systems View of environment Control it, buffer organization from change Embrace it, respond flexibly to environmental change Role of people Extensions of machines Thinking and Improving View of people Interchangeable parts Appreciating assets Controls External supervisors, specialists, standard operating procedures Internal self-regulating subsystems Management style Autocratic, command and control Participative, collaborative Purpose Organization’s goals only Members and society’s goals also Risk Taking Discouraged, “If it ain’t broke, don’t fix it” Encouraged, “Experimentation is the best teacher.” Change management Primary responsibility of management and staff specialists Primary responsibility of work groups © 2008 – 2014 Toyota Way Academy, LLC

- 38. ALFRA Consulting | Developing Partners Bureaucracy & Lean Deployment 38 Mechanistic Deployment Organic Deployment Formalization of Lean Support Structure High Low Autonomy to Customize Process Low High Source of lean Expertise Mostly Lean Group Mostly Line Organization Strategy for Deployment of Lessons Learned Audited Compliance Knowledge Sharing Process to Address Organizational Entropy Rules & Regulations Continuous Improvement Based on Kucner, A Socio-technical study of lean manufacturing deployment in the remanufacturing context, unpublished doctoral dissertation, Ann Arbor, University of Michigan, 2008. © 2008 – 2014 Toyota Way Academy, LLC

- 39. ALFRA Consulting | Developing Partners Bureaucratic Lean Deployment Features • A recipe for deployment (some use life cycle models to display tool implementation at different stages) • A set of training modules • Certification for internal experts (like black belt programs) • Lean metrics to measure deployment and outcomes and audit the programs • Executive support to hold business units accountable (e.g., bonuses tied to achieving lean metrics) 39© 2008 – 2014 Toyota Way Academy, LLC

- 40. ALFRA Consulting | Developing Partners Critical Questions to Answer • In your organization, can you confidently ask anyone the following questions? 1. What are your biggest problems? 2. What, specifically, are you trying to achieve in solving those problems and by when? 3. How are you doing it? • These answers should directly link to their Hoshin objectives 40© 2008 – 2014 Toyota Way Academy, LLC

- 41. ALFRA Consulting | Developing Partners What Is Your Situation? • What you work on depends on your company’s current situation 41 Business Purpose People Development Purpose Approach to Change Company Survival Identify and Develop Leaders/ lean coaches for future of company by observing who can lead kaikaku Identify business needs to survive with key performance indicators and use Radical kaikaku of Processes to achieve Critical Customer Issue (quality, cost, delivery) Targeted leadership development/lean coaches on how to achieve target condition through PDCA Targeted kaizen of Processes critical to customer-facing issue based on target conditions Business Need for Specific Results (e.g., productivity improvement) Coach leaders on how to achieve target condition through PDCA Set appropriate target conditions and work to achieve in manageable steps with feedback Begin Journey to operational excellence in stable/growth environment Convince leaders of value of improvement and develop lean coaches Build “Showcase” process or demonstration projects by driving toward target conditions and target outcomes © 2008 – 2014 Toyota Way Academy, LLC

- 42. ALFRA Consulting | Developing Partners Crisis Healthy Primary Purpose Drive Rapid Results Build Foundation for Lean Enterprise Secondary Purpose Develop Future Leaders Develop People and Culture Leadership Top Down Turnaround Top Down Coaching Focus Results through Process Improvement Process to Drive Results and Learning Time Frame Short-term to get to stability Long-term The Extremes 42 Range of Business Conditions © 2008 – 2014 Toyota Way Academy, LLC

- 43. ALFRA Consulting | Developing Partners Conclusion • There is no secret recipe, improvement is everybody’s role. • Leadership by example • Use the approach depeding on your current situation • Establish Lean Systems to develop people and improve processes. 43© 2008 – 2014 Toyota Way Academy, LLC

- 44. ALFRA Consulting | Developing Partners Continuous Learning & Improvement “Every day, little up” “Until you take the first step, it will not be possible to see the next step”

- 45. ALFRA Consulting | Developing Partners Material References Several quotes and information was taken from material & work from the next sources: •The Toyota Way – Jeffrey Liker •The Machine That Changed the World - James P. Womack, Daniel T. Jones, Daniel Roos. •Lean Thinking - James P. Womack, Daniel T. Jones. •The Complete Lean Enterprise – Beau Keyte & Drew Locher •Lean Lexicon - Lean Enterprise Institute •Lean Leadership – Jeffery Liker & Gary Convis