Live wire testing lock out tag out safe work procedure

•

1 gefällt mir•439 views

Safe work Procedure for live wire lock out tag out , electrical high voltage hazards, arc flash prevention

Melden

Teilen

Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

Empfohlen

Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational Safety and Health Act 1994 (Act 514)Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational S...

Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational S...Ts. Dr. Mohammad Lui Juhari

Weitere ähnliche Inhalte

Was ist angesagt?

Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational Safety and Health Act 1994 (Act 514)Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational S...

Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational S...Ts. Dr. Mohammad Lui Juhari

Was ist angesagt? (20)

Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational S...

Occupational Safety & Health (Noise Exposure) Regulations 2019 Occupational S...

Emergency Preparedness and Response Training by BCMSA

Emergency Preparedness and Response Training by BCMSA

Ähnlich wie Live wire testing lock out tag out safe work procedure

Ähnlich wie Live wire testing lock out tag out safe work procedure (20)

MACHINE SAFEGUARDING TRAINING & PSHR requirements by JULIAN KALAC

MACHINE SAFEGUARDING TRAINING & PSHR requirements by JULIAN KALAC

Mehr von Julian Kalac P.Eng

Mehr von Julian Kalac P.Eng (20)

VOLVO EATS RACK LEAN TRANSFORMATION by Julian Kalac, P.Eng

VOLVO EATS RACK LEAN TRANSFORMATION by Julian Kalac, P.Eng

PRE-START HEALTH SAFETY REVIEW REPORT of 1000 TON MECHANICAL TRANSFER PRESS

PRE-START HEALTH SAFETY REVIEW REPORT of 1000 TON MECHANICAL TRANSFER PRESS

1000 TON TRANSFER PRESS SAFE WORK PROCEDURE ;DIE SETUP/CHANGEOVER

1000 TON TRANSFER PRESS SAFE WORK PROCEDURE ;DIE SETUP/CHANGEOVER

Custom Lean Eyelet machine SOP with 5 min changeover

Custom Lean Eyelet machine SOP with 5 min changeover

DFMEA DUE DILIGENCE TRAINING FOR LITENS AUTOMOTIVE

DFMEA DUE DILIGENCE TRAINING FOR LITENS AUTOMOTIVE

JULIAN KALAC -EXAMPLES OF LEAN SIX SIGMA BLACK BELT PROJECTS

JULIAN KALAC -EXAMPLES OF LEAN SIX SIGMA BLACK BELT PROJECTS

LEAN Setup Reduction (SMED) training for welding by JULIAN KALAC

LEAN Setup Reduction (SMED) training for welding by JULIAN KALAC

Kürzlich hochgeladen

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Sex Service At Affordable Rate

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...Call Girls in Nagpur High Profile

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Indian Girls Waiting For You To Fuck

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...Call Girls in Nagpur High Profile

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

Kürzlich hochgeladen (20)

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

Structural Analysis and Design of Foundations: A Comprehensive Handbook for S...

Structural Analysis and Design of Foundations: A Comprehensive Handbook for S...

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

Call for Papers - Educational Administration: Theory and Practice, E-ISSN: 21...

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

Live wire testing lock out tag out safe work procedure

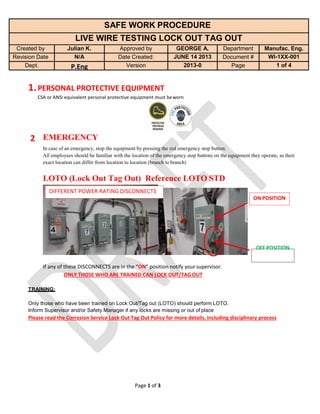

- 1. Page 1 of 3 SAFE WORK PROCEDURE LIVE WIRE TESTING LOCK OUT TAG OUT Created by Julian K. Approved by GEORGE A. Department Manufac. Eng. Revision Date N/A Date Created: JUNE 14 2013 Document # WI-1XX-001 Dept. P.Eng Version 2013-0 Page 1 of 4 1.PERSONAL PROTECTIVE EQUIPMENT CSA or ANSI equivalent personal protective equipment must beworn 2 EMERGENCY In case of an emergency, stop the equipment by pressing the red emergency stop button. All employees should be familiar with the location of the emergency stop buttons on the equipment they operate, as their exact location can differ from location to location (branch to branch) LOTO (Lock Out Tag Out) Reference LOTO STD DIFFERENT POWER RATING DISCONNECTS ON POSITION OFF POSITION If any of these DISCONNECTS are in the “ON” position notify your supervisor. ONLY THOSE WHO ARE TRAINED CAN LOCK OUT/TAGOUT TRAINING: Only those who have been trained on Lock Out/Tag out (LOTO) should perform LOTO. Inform Supervisor and/or Safety Manager if any locks are missing or out of place Please read the Corrosion Service Lock Out Tag Out Policy for more details, including disciplinary process

- 2. Page 2 of 3 SAFE WORK PROCEDURE LIVE WIRE TESTING LOCK OUT TAG OUT Created by Julian K. Approved by GEORGE A. Department Manufac. Eng. Revision Date N/A Date Created: JUNE 14 2013 Document # WI-1XX-001 Dept. P.Eng Version 2013-0 Page 1 of 4 Lock Out Tag Out Procedure 1. Prepare For Shutdown Everyone in the area must be informed that Lockout/Tagout will be performed and on whichmachines. 2. Identify Sources of Hazardous Energy on the machine/equipment Assess equipment and identify the hazardous energy sources (figure 1.0), either potential or kineticand determine the most effective method to achieve a “ZERO ENERGY STATE”. ContactManufacturing Engineer (Julian Kalac) to help identify system shutdownprocedures. 3. Shutdown Follow proprietary equipment and system shutdown procedures normally used to stopping the equipment and return equipment to a “ZERO ENERGY STATE” by methods described under“General Lockout Guidelines” in Figure 1.0. This will likely mean turning or pressing the “stop”button 4. Apply Lock and Tag Information. Locks — Each worker will shall obtain his/her own individually keyed lock. This is the workers ownsafety equipment is not to be loaned. (No duplicate or master keys). — When more than one person use a multi-hinged hasp lockout device. Tags Lockout tags should include the followinginformation: — Date, Time. Workers Name(s), Department(s). — Reason why equipment has been disconnected 5. Verify Effectiveness of Lockout Ensure that all equipment energy sources are re-tested and a “ZERO ENERGY STATE” has ben achieved. Use equipment specified testing devices for system shutdown confirmation such as Volt Meters, pressure gauges, blocks, bleeding devices or cycling systemsprocedures. 6. Release From Lockout/Tagout Before locks/tags are removed and energy is restored to the machine/equipment, inspect the work area to ensure components are operationally intact. Each lock and tag should be removed from eachenergy- isolating device by the worker who applied the lock andtag. FULL ARC FLASH PPE

- 3. Page 3 of 3 SAFE WORK PROCEDURE LIVE WIRE TESTING LOCK OUT TAG OUT Created by Julian K. Approved by GEORGE A. Department Manufac. Eng. Revision Date N/A Date Created: JUNE 14 2013 Document # WI-1XX-001 Dept. P.Eng Version 2013-0 Page 1 of 4 Second Person – 'Safety Monitor' Where a worker is either working on live equipment; or where a worker is near exposed live electrical equipment a second worker who is not engaged in the work must be appointed by the supervisor as a 'safety monitor'. The function of the 'safety monitor' is to: 1) warn other people in the area of the hazard; and 2) ensure that all safety precautions and procedures are complied with. A 'safety monitor' must be: 1) informed of the duties of a 'safety monitor' and of the hazards involved in the work; 2) trained and instructed in the procedures to follow in the event of an emergency; 3) authorized to immediately stop any part of the work that the monitor considers dangerous; and 4) not have any other duties or interruptions that might interfere with the duties as 'safety monitor'. Flash Protection Boundary Voltage distance meters feet 50 to 750 0.9 3 750 to 2 000 1.2 4 2000 to 15,000 4.8 16 15,000 to 36,000 5.7 19 Over 36,000 calculate calculate

- 4. Page 4 of 3 SAFE WORK PROCEDURE LIVE WIRE TESTING LOCK OUT TAG OUT Created by Julian K. Approved by GEORGE A. Department Manufac. Eng. Revision Date N/A Date Created: JUNE 14 2013 Document # WI-1XX-001 Dept. P.Eng Version 2013-0 Page 1 of 4

- 5. Page 5 of 3 SAFE WORK PROCEDURE LIVE WIRE TESTING LOCK OUT TAG OUT Created by Julian K. Approved by GEORGE A. Department Manufac. Eng. Revision Date N/A Date Created: JUNE 14 2013 Document # WI-1XX-001 Dept. P.Eng Version 2013-0 Page 1 of 4 ENERGY FORM ENERGY SOURCE GENERAL LOCKOUT GUIDELINE Electricity power transmission lines; machine power cords; motors; solenoids; capacitors (stored electrical energy) Turn off power at machine first (i.e., at point of operation switch), and then at the main disconnect switch for the machine; lock and tag main disconnect switch (or remove fuses from box, and then lock and tag box). Fully discharge all capacitive systems (e.g., cycle machine to drain power from capacitors) according to manufacturer’s instructions. Fluid pressure hydraulic systems (e.g., hydraulic presses, rams, cylinders, hammers) Shut off, lock (with chains, built-in lockout devices, or lockout attachments) and tag valves; bleed off and blank lines as necessary. Air pressure pneumaticsystems(e.g., lines, pressure reservoirs, accumulators, air surge tanks, rams, cylinders) Shut off, lock (with chains, built-in lockout devices, or lockout attachments) and tag valves; bleed off excess air; if pressure cannot be relieved, block any possible movement of machinery. Kinetic energy blades; flywheels; materials in supply lines of bins or silos Stop and block machine parts (e.g., stop flywheels and ensure that they do not recycle); review entire cycle of mechanical motion, ensure that all motions are stopped. Block material from moving into area of work; Potential energy springs (e.g., in air brake cylinders); actuators; counter weights; raised loads; top or movable part of a press or lifting device If possible, lower all suspended parts and loads to the lowers (rest) position, block parts that might be moved by gravity; release or block spring energy. Pressurized liquids and gases supply lines; storage tanks and vessels Shut off, lock (with chains, built-in lockout devices, or lockout attachments) and tag valves; bleed off excess liquids or gases; blank lines as necessary.

- 6. Page 6 of 3 SAFE WORK PROCEDURE LIVE WIRE TESTING LOCK OUT TAG OUT Created by Julian K. Approved by GEORGE A. Department Manufac. Eng. Revision Date N/A Date Created: JUNE 14 2013 Document # WI-1XX-001 Dept. P.Eng Version 2013-0 Page 1 of 4 CAUSE OF ARC FLASH SAFETY ISSUE---ELECTRICAL PANELS & TRANSFORMERS High Voltage Transformer exposed live wires are a Serious Safety hazard DANGEROUS 600V LIVE TERMINAL DO NOT TOUCH