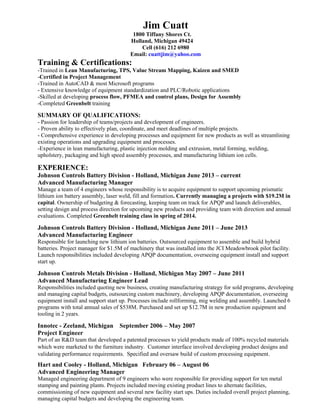

Resume112414

- 1. Jim Cuatt 1800 Tiffany Shores Ct. Holland, Michigan 49424 Cell (616) 212 6980 Email: cuattjim@yahoo.com Training & Certifications: -Trained in Lean Manufacturing, TPS, Value Stream Mapping, Kaizen and SMED -Certified in Project Management -Trained in AutoCAD & most Microsoft programs - Extensive knowledge of equipment standardization and PLC/Robotic applications -Skilled at developing process flow, PFMEA and control plans, Design for Assembly -Completed Greenbelt training SUMMARY OF QUALIFICATIONS: - Passion for leadership of teams/projects and development of engineers. - Proven ability to effectively plan, coordinate, and meet deadlines of multiple projects. - Comprehensive experience in developing processes and equipment for new products as well as streamlining existing operations and upgrading equipment and processes. -Experience in lean manufacturing, plastic injection molding and extrusion, metal forming, welding, upholstery, packaging and high speed assembly processes, and manufacturing lithium ion cells. EXPERIENCE: Johnson Controls Battery Division - Holland, Michigan June 2013 – current Advanced Manufacturing Manager Manage a team of 4 engineers whose responsibility is to acquire equipment to support upcoming prismatic lithium ion battery assembly, laser weld, fill and formation. Currently managing a projects with $19.2M in capital. Ownership of budgeting & forecasting, keeping team on track for APQP and launch deliverables, setting design and process direction for upcoming new products and providing team with direction and annual evaluations. Completed Greenbelt training class in spring of 2014. Johnson Controls Battery Division - Holland, Michigan June 2011 – June 2013 Advanced Manufacturing Engineer Responsible for launching new lithium ion batteries. Outsourced equipment to assemble and build hybrid batteries. Project manager for $1.5M of machinery that was installed into the JCI Meadowbrook pilot facility. Launch responsibilities included developing APQP documentation, overseeing equipment install and support start up. Johnson Controls Metals Division - Holland, Michigan May 2007 – June 2011 Advanced Manufacturing Engineer Lead Responsibilities included quoting new business, creating manufacturing strategy for sold programs, developing and managing capital budgets, outsourcing custom machinery, developing APQP documentation, overseeing equipment install and support start up. Processes include rollforming, mig welding and assembly. Launched 6 programs with total annual sales of $538M. Purchased and set up $12.7M in new production equipment and tooling in 2 years. Innotec - Zeeland, Michigan September 2006 – May 2007 Project Engineer Part of an R&D team that developed a patented processes to yield products made of 100% recycled materials which were marketed to the furniture industry. Customer interface involved developing product designs and validating performance requirements. Specified and oversaw build of custom processing equipment. Hart and Cooley - Holland, Michigan February 06 – August 06 Advanced Engineering Manager Managed engineering department of 9 engineers who were responsible for providing support for ten metal stamping and painting plants. Projects included moving existing product lines to alternate facilities, commissioning of new equipment and several new facility start ups. Duties included overall project planning, managing capital budgets and developing the engineering team.

- 2. Johnson Controls - Holland, Michigan March 2003 – February 06 Advanced Manufacturing Engineering Manager Managed a department of 14 advanced manufacturing engineers who were responsible for the launch of 49 different automotive interior products ($825M annual sales). Worked with sales and finance departments to develop and present proposals for potential new business. Part of a team that researched and documented best practices for manufacturing methods within the US plants. Also part of a team that developed corporate specifications for custom built manufacturing equipment. Johnson Controls - Sindelfingen, Germany March 2001 – February 2003 Manufacturing Engineering Manager Objective of a two-year assignment was to become part of the core product launch team in Germany who was responsible for the design and prototype phases of four total interiors for Mercedes 2005 vehicles. Responsibilities were to define all processes, create the capital and tooling budgets ($65M budget), forecast spending and worked with German engineering team to design products for US assembly. Johnson Controls - Saltillo, Mexico July 1999 – January 2001 Technical Manager – New facility start up. Objective of the two-year assignment was to start up a new JIT facility in Mexico. Responsibilities included implementation of lean manufacturing on all new assembly cells, mentoring Mexican staff on APQP documentation, working closely with GM to resolve quality issues, production manager over several departments and coordinating the communication between the Mexican and US engineering departments. Johnson Controls - Holland, Michigan February 1994 - July 1999 Advanced Manufacturing Engineer Defined assembly processes and oversaw the build of all custom manufacturing equipment for 15 new product launches. Responsible for all capital and tooling expenditures, lean manufacturing implementation, ergonomic analysis, defining plant size, utilities and layouts. Gained a solid knowledge of PLC applications, interface between ILVS broadcast systems and assembly cells and working with facilities department to design and build a new manufacturing facility. Johnson Controls - Holland, Michigan July 1992 – January 1994 Manager of Maintenance and Manufacturing Engineering Supervised a focused factory of 5 manufacturing engineers and 9 maintenance workers. Taught corporate lean manufacturing classes (5S, Kan Ban, Kitting of Components and Workload Balancing). Lead Kaizen events on 21 existing product lines resulting in a 25% reduction in floor space through reduction in inventory and overall organization. Enabled the plant to add new products and increase revenue by 18%. Johnson Controls - Holland, Michigan July 1990 – June 1992 Manufacturing Engineer Supported production on multiple product lines by troubleshooting assembly equipment to determine root cause of quality issues and inefficiencies. Worked closely with urethane foam, fabric cutting and injection molding departments. Developed fixtures and equipment that would improve ergonomics, safety and efficiency. Trained operators on Lean Manufacturing and led Kaizen groups. United Technologies Corp. - Plainwell, Michigan Machine Design Engineer 1989 – 1990 Designed and developed equipment that would perform secondary operations to plastic extrusions. Primary project was to develop a machine that performed a cut to length operation on seat welting. Machine utilized a vision system integrated with a servo drive. That division of United Technologies was sold in 1990. EDUCATION: Bachelor of Science - Mechanical Engineering, June 1989 Western Michigan University, Kalamazoo, MI