POROSITY IN DEPOSITED MATERIAL - ADDITIVE MANUFACTURING

•

1 gefällt mir•40 views

An interest document of LPW TECHNOLOGY about a case study of porosity in deposited material of a product made with additive manufacturing.

Melden

Teilen

Melden

Teilen

Downloaden Sie, um offline zu lesen

Empfohlen

Empfohlen

http://www.acksol.com

The purpose with this test was to find out how Controll®INNERSEAL and Controll®INNERSEAL PLUS affect adhesion for two common Epoxy and Acrylic floor paints on impregnated concrete. This test was performed by SP Technical Research Institute of Sweden, Chemistry division (SWEDAC accredited laboratory) according to ISO-4694 standard

Adhesion - Epoxy + Acrylic floor paint on #Controllinnerseal impregnated #con...

Adhesion - Epoxy + Acrylic floor paint on #Controllinnerseal impregnated #con...Acksol Ingeniería Aplicación Nanocristalización #84minerales

Image analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland cement and Bismuth Oxide-A comparative study by MMA Rafique* in Crimson Publishers: Peer Reviewed Material Science JournalsImage analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland ...

Image analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland ...CrimsonPublishersRDMS

Weitere ähnliche Inhalte

Was ist angesagt?

http://www.acksol.com

The purpose with this test was to find out how Controll®INNERSEAL and Controll®INNERSEAL PLUS affect adhesion for two common Epoxy and Acrylic floor paints on impregnated concrete. This test was performed by SP Technical Research Institute of Sweden, Chemistry division (SWEDAC accredited laboratory) according to ISO-4694 standard

Adhesion - Epoxy + Acrylic floor paint on #Controllinnerseal impregnated #con...

Adhesion - Epoxy + Acrylic floor paint on #Controllinnerseal impregnated #con...Acksol Ingeniería Aplicación Nanocristalización #84minerales

Was ist angesagt? (18)

Comparative Study of the Physical Properties of Some Selected Cement Brands i...

Comparative Study of the Physical Properties of Some Selected Cement Brands i...

SURAGUS: Quality Assurance for Wafer-Based Layer Systems

SURAGUS: Quality Assurance for Wafer-Based Layer Systems

Adhesion - Epoxy + Acrylic floor paint on #Controllinnerseal impregnated #con...

Adhesion - Epoxy + Acrylic floor paint on #Controllinnerseal impregnated #con...

IRJET- Evaluation of Strength Characteristics of Triple Blended Concrete usin...

IRJET- Evaluation of Strength Characteristics of Triple Blended Concrete usin...

Minimization of the Casting Defects Using Taguchi’s Method

Minimization of the Casting Defects Using Taguchi’s Method

Conformal Coating Noxious Gas Corrosion Comparison Test

Conformal Coating Noxious Gas Corrosion Comparison Test

Ähnlich wie POROSITY IN DEPOSITED MATERIAL - ADDITIVE MANUFACTURING

Image analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland cement and Bismuth Oxide-A comparative study by MMA Rafique* in Crimson Publishers: Peer Reviewed Material Science JournalsImage analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland ...

Image analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland ...CrimsonPublishersRDMS

Ähnlich wie POROSITY IN DEPOSITED MATERIAL - ADDITIVE MANUFACTURING (20)

IRJET- Optimum Design Parameters for Effective Moldability of Gas Sensor

IRJET- Optimum Design Parameters for Effective Moldability of Gas Sensor

Image analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland ...

Image analysis and Laser Particle Diffraction study of ProRoot-MTA, Portland ...

Coherent, Whitepaper: LAM - Laser Additive Manufacturing with new laser power...

Coherent, Whitepaper: LAM - Laser Additive Manufacturing with new laser power...

Process parameter optimization for fly ash brick by Taguchi method

Process parameter optimization for fly ash brick by Taguchi method

A comparative study between traditional method and mix design with industrial...

A comparative study between traditional method and mix design with industrial...

International Journal of Engineering Research and Development (IJERD)

International Journal of Engineering Research and Development (IJERD)

Design with polymers tools and process - White Paper

Design with polymers tools and process - White Paper

Analyzing Adhesion of Epoxy/Steel Interlayer in Scratch Test

Analyzing Adhesion of Epoxy/Steel Interlayer in Scratch Test

Compatibility Study of Superplasticizers with Cement Partially Replaced with ...

Compatibility Study of Superplasticizers with Cement Partially Replaced with ...

Effect of Mixed Fibers (Steel and Polypropylene) On Strength Properties of Fi...

Effect of Mixed Fibers (Steel and Polypropylene) On Strength Properties of Fi...

Kürzlich hochgeladen

Call Girl Bhosari Indira Call Now: 8617697112 Bhosari Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Bhosari Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Bhosari understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Indian Girls Waiting For You To Fuck

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...Call Girls in Nagpur High Profile

Model Call Girl Services in Delhi reach out to us at 🔝 9953056974 🔝✔️✔️

Our agency presents a selection of young, charming call girls available for bookings at Oyo Hotels. Experience high-class escort services at pocket-friendly rates, with our female escorts exuding both beauty and a delightful personality, ready to meet your desires. Whether it's Housewives, College girls, Russian girls, Muslim girls, or any other preference, we offer a diverse range of options to cater to your tastes.

We provide both in-call and out-call services for your convenience. Our in-call location in Delhi ensures cleanliness, hygiene, and 100% safety, while our out-call services offer doorstep delivery for added ease.

We value your time and money, hence we kindly request pic collectors, time-passers, and bargain hunters to refrain from contacting us.

Our services feature various packages at competitive rates:

One shot: ₹2000/in-call, ₹5000/out-call

Two shots with one girl: ₹3500/in-call, ₹6000/out-call

Body to body massage with sex: ₹3000/in-call

Full night for one person: ₹7000/in-call, ₹10000/out-call

Full night for more than 1 person: Contact us at 🔝 9953056974 🔝. for details

Operating 24/7, we serve various locations in Delhi, including Green Park, Lajpat Nagar, Saket, and Hauz Khas near metro stations.

For premium call girl services in Delhi 🔝 9953056974 🔝. Thank you for considering us!Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...9953056974 Low Rate Call Girls In Saket, Delhi NCR

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Kürzlich hochgeladen (20)

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

FULL ENJOY Call Girls In Mahipalpur Delhi Contact Us 8377877756

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

Call Now ≽ 9953056974 ≼🔝 Call Girls In New Ashok Nagar ≼🔝 Delhi door step de...

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

Roadmap to Membership of RICS - Pathways and Routes

Roadmap to Membership of RICS - Pathways and Routes

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Bhosari ( Call Girls ) Pune 6297143586 Hot Model With Sexy Bhabi Ready For ...

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

The Most Attractive Pune Call Girls Manchar 8250192130 Will You Miss This Cha...

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Walvekar Nagar Call Me 7737669865 Budget Friendly No Advance Booking

POROSITY IN DEPOSITED MATERIAL - ADDITIVE MANUFACTURING

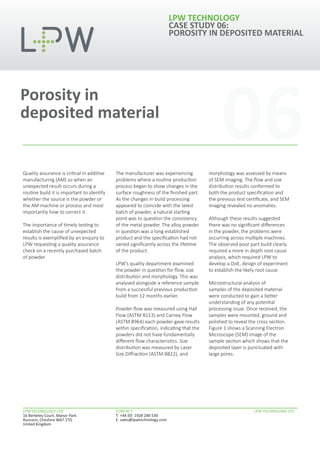

- 1. 06Quality assurance is critical in additive manufacturing (AM) so when an unexpected result occurs during a routine build it is important to identify whether the source is the powder or the AM machine or process and most importantly how to correct it. The importance of timely testing to establish the cause of unexpected results is exemplified by an enquiry to LPW requesting a quality assurance check on a recently purchased batch of powder. The manufacturer was experiencing problems where a routine production process began to show changes in the surface roughness of the finished part. As the changes in build processing appeared to coincide with the latest batch of powder, a natural starting point was to question the consistency of the metal powder. The alloy powder in question was a long established product and the specification had not varied significantly across the lifetime of the product. LPW’s quality department examined the powder in question for flow, size distribution and morphology. This was analysed alongside a reference sample from a successful previous production build from 12 months earlier. Powder flow was measured using Hall Flow (ASTM B213) and Carney Flow (ASTM B964) each powder gave results within specification, indicating that the powders did not have fundamentally different flow characteristics. Size distribution was measured by Laser Size Diffraction (ASTM B822), and morphology was assessed by means of SEM imaging. The flow and size distribution results conformed to both the product specification and the previous test certificate, and SEM imaging revealed no anomalies. Although these results suggested there was no significant differences in the powder, the problems were occurring across multiple machines. The observed poor part build clearly required a more in depth root cause analysis, which required LPW to develop a DoE, design of experiment to establish the likely root cause. Microstructural analysis of samples of the deposited material were conducted to gain a better understanding of any potential processing issue. Once received, the samples were mounted, ground and polished to reveal the cross section. Figure 1 shows a Scanning Electron Microscope (SEM) image of the sample section which shows that the deposited layer is punctuated with large pores. LPW TECHNOLOGY CASE STUDY 06: POROSITY IN DEPOSITED MATERIAL Porosity in deposited material LPW TECHNOLOGY LTD 16 Berkeley Court, Manor Park Runcorn, Cheshire WA7 1TQ United Kingdom LPW TECHNOLOGY LTDCONTACT T: +44 (0) 1928 240 530 E: sales@lpwtechnology.com

- 2. One understandable explanation is that the powder being included in the deposited layer is porous. The powder particles are between 20-53 microns in diameter and measurements of the pores reveal them to be 30-50 microns across, so are highly unlikely to be contained stably within a powder particle. Since powder porosity would also not explain poor surface finish, the machine processing conditions were carefully investigated. A large retained sample of a previous batch of powder which was known to process satisfactorily was used in order to ensure a like for like comparison. After replacing a key component of the deposition system across all machines, that build quality was restored to output products that passed the stringent quality controls. It was confirmed that component deterioration across the machines was the root cause. Outcome Initial flow measurements had indicated that the root cause of poor build was unlikely to be the powder, but it was only by applying in-house industry expertise in AM processing and thorough analysis capabilities of both powder and part, that LPW was able to deliver confidence and a holistic processing solution. LPW TECHNOLOGY CASE STUDY 06: POROSITY IN DEPOSITED MATERIAL LPW TECHNOLOGY LTD 16 Berkeley Court, Manor Park Runcorn, Cheshire WA7 1TQ United Kingdom LPW TECHNOLOGY LTDCONTACT T: +44 (0) 1928 240 530 E: sales@lpwtechnology.com Figure 1 – SEM micrograph of deposited layer-substrate interface