Pel process application

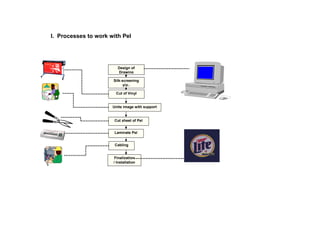

- 1. I. Processes to work with Pel Design of Drawing Silk-screening y/o.. Cut of Vinyl Unite image with support Cut sheet of Pel Laminate Pel Cabling Finalization / Installation

- 2. II. General Diagram Red 220V Power generator Pel

- 3. III. Production of Pel A1. Printing for silk-screening 1) Print along the film (printing for coat) 2) Order the colors of the printing according to the design 3) Use the translucent printing where you want to have colored light 4) Use opaque or metallic ink except for where the Pel is going to be (This is to block light penetration) 5) It has to be printed mirror-inverted (to avoid scratching of the printing) * Advantages of the silk-screen printing: - Low price in high quantity. - Excellent appearance and ending - High quality * Disadvantages: Expensive in low quantities Transparent B2. Using vinyl cut Light Block 1) Design the graphic in “coat” mode using appropriate programs (Illustrator, CorelDraw, etc) * Note: Select the appropriate program to plotter the cut 2It might be necessary to place 2 vinyl cuts on top of each other to block unnecessary light. 3) Cut computerized, montage the vinyl over the Pel.

- 4. 3. Attach the design to the support (film, met acryl) 1) You can moisten the support before you place the vinyl 2) Stick on all the vinyl cuts in the correct order (translucent and opaque) 3) Dry and avoid any left over humidity that enters in the contact with the Pel with being laminated 4. Cut the Pel sheet 1) Cut the Pel according to the design, always leaving some edges with the metalized contacts 2) Attach around the copper to the poles conductive of Pel 3) If the Pel is laminated, allow to expose areas of the conductive poles, using an utter carefully •Note: You have to be careful not to cut the poles of the copper. The covers of the Pel sheet are very fragile 5) Attach the Pel to the meta acryl, film, etc that carry the design mask 6) Join the cables together with the tins over the coppered poles (Excessive time with the soldering burns the Pel) y cable the connections Connection poles in the back of the Pel, using 5. Cabling copper tape 1) To switch on permanently all areas of the Pel, and connect parallel (diagram A) 2) Sequence: With a cable plan of 5 conductors, use a common pole to connect the resistants to every unit per canal. Diagram B 3) The Pel does not have polarity. Humidity ruins the Pel. The over current cuts the utility life (100VAC 400Hz) Diagram A Diagram B