Francis resume

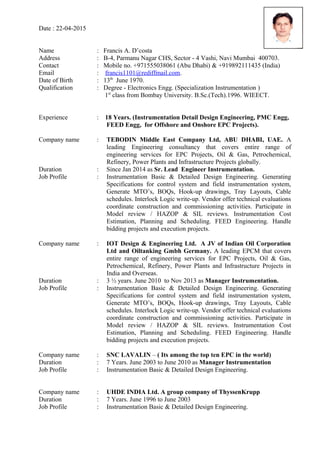

- 1. Date : 22-04-2015 Name : Francis A. D’costa Address : B-4, Parmanu Nagar CHS, Sector - 4 Vashi, Navi Mumbai 400703. Contact : Mobile no. +971555038061 (Abu Dhabi) & +919892111435 (India) Email : francis1101@rediffmail.com. Date of Birth : 13th June 1970. Qualification : Degree - Electronics Engg. (Specialization Instrumentation ) 1st class from Bombay University. B.Sc.(Tech).1996. WIEECT. Experience : 18 Years. (Instrumentation Detail Design Engineering, PMC Engg, FEED Engg, for Offshore and Onshore EPC Projects). Company name : TEBODIN Middle East Company Ltd, ABU DHABI, UAE. A leading Engineering consultancy that covers entire range of engineering services for EPC Projects, Oil & Gas, Petrochemical, Refinery, Power Plants and Infrastructure Projects globally. Duration : Since Jan 2014 as Sr. Lead Engineer Instrumentation. Job Profile : Instrumentation Basic & Detailed Design Engineering. Generating Specifications for control system and field instrumentation system, Generate MTO’s, BOQs, Hook-up drawings, Tray Layouts, Cable schedules. Interlock Logic write-up. Vendor offer technical evaluations coordinate construction and commissioning activities. Participate in Model review / HAZOP & SIL reviews. Instrumentation Cost Estimation, Planning and Scheduling. FEED Engineering. Handle bidding projects and execution projects. Company name : IOT Design & Engineering Ltd. A JV of Indian Oil Corporation Ltd and Oiltanking Gmbh Germany. A leading EPCM that covers entire range of engineering services for EPC Projects, Oil & Gas, Petrochemical, Refinery, Power Plants and Infrastructure Projects in India and Overseas. Duration : 3 ½ years. June 2010 to Nov 2013 as Manager Instrumentation. Job Profile : Instrumentation Basic & Detailed Design Engineering. Generating Specifications for control system and field instrumentation system, Generate MTO’s, BOQs, Hook-up drawings, Tray Layouts, Cable schedules. Interlock Logic write-up. Vendor offer technical evaluations coordinate construction and commissioning activities. Participate in Model review / HAZOP & SIL reviews. Instrumentation Cost Estimation, Planning and Scheduling. FEED Engineering. Handle bidding projects and execution projects. Company name : SNC LAVALIN – ( Its among the top ten EPC in the world) Duration : 7 Years. June 2003 to June 2010 as Manager Instrumentation Job Profile : Instrumentation Basic & Detailed Design Engineering. Company name : UHDE INDIA Ltd. A group company of ThyssenKrupp Duration : 7 Years. June 1996 to June 2003 Job Profile : Instrumentation Basic & Detailed Design Engineering.

- 2. My Job Profile:- 1. Lead Instrumentation Engineer for Detail Engineering, FEED and PMC projects. 2. Prepare, Review, Approve Instrumentation deliverables such as Instrumentation design basis, Instrument Index, IO list, Specifications, Datasheets, Material Requisition for following :- DCS system. Relief Valves ESD system Pressure instruments. F&G system Flow instruments WELL HEAD CONTROL PANELS Level instruments. Christmas Tree valves Temperature instruments Automated Choke valves. Fire and Gas detectors ESD valves. Gas Analyzer Systems MOV Valves Tank gauging systems (TGS) Down Hole Monitoring Systems (DHMS) Clean Agent Systems- NOVEC System. Multi-Phase Flow Meters (MPFM) Custody transfer Metering system (CTMS) Wireless Transmitters. CCTV, Paging System, Access Control Systems. Hydraulic Operated Valve’s Package items Control Valves Cables and Erection Bill of Material 3. Prepare, Review and Approve deliverables such as Control philosophy, Cable Block diagram, System Architecture Drawings, Interconnection wiring drawings. Junction box schedule, Cable Schedules, Hookup Drawings, Loop Wiring Diagrams, Instrument layouts, F&G layouts, CCTV layouts, control room GA, Bulk Material Take-Off MTO. 4. Review Instrumentation calculation and sizing documents such as control valve sizing, orifice calculations, UPS power consumption and Instrument Air consumption calculations. 5. Participate in Model review / HAZOP & SIL reviews. 6. Technical Evaluation of offers. 7. Attend Inspection, FAT and SAT and meetings with vendors. 8. Perform Instrumentation Cost Estimation, Manhour estimation, Planning and Scheduling. 9. Responsible for instrumentation progress, Targets, Man-Hours, and Budget Control. 10. Implementation of change control in Instrumentation. 11. Coordinate Instrumentation Erection, Installation, pre-commissioning and commissioning activities. 12. Participate in meetings with Client, vendors and inter-discipline meetings.

- 3. Projects done at TEBODIN Middle East Company Ltd, ABU DHABI, UAE 1. Client :- ZADCO - WELL HEAD PLATFORMS 01, 02 &11 – OFFSHORE PROJECT PROJECT :- Installation of Electrical Submersible Pumps, Choke Valves, ESD Valves, MPFM, ESD, F&G system at Umm Al Dalkh 03 nos Well head Platforms 01, 02 & 11. Engineering, Design, Procurement and Construction for the Installation of Electrical Submersible Pumps, choke valves, ESD valves, MPFM, ESD & F&G system for offshore Well head Platforms (WHP’s) and control system modifications at the Central Processing Platform (CPC) for Zakum Development Company (ZADCO) Abu Dhabi. This project consists of Well head platforms and CPC modifications along with the Subsea piping and Subsea cabling, Project consists of Electrical Submersible Pumps (ESP’s) and its top side valves, production manifold, testing manifold, demulsifier package, closed drain system, open drain system and its control instrumentation. Detail engineering was done for new SIL rated Well head Control Panels ESD systems, DCS systems, F&G systems, Down Hole Monitoring Systems (DHMS), Multi Phase Flow Meters (MPFM), ESD valves, Choke valves, Wireless Transmitters, MOV’s, Hydraulic Valve’s (ROV), Control Valves, Relief Valves and F&G devices. 2. Client :- ZADCO - WELL HEAD PLATFORMS 07 & 15. – OFFSHORE PROJECT PROJECT :- Installation of Electrical Submersible Pumps, Choke Valves, ESD Valves, MPFM, ESD & F&G system at Umm Al Dalkh Well head Platforms WHP-7 & WHP-15 Engineering, Design, Procurement and Construction for the Installation of Electrical Submersible Pumps, choke valves, ESD valves, MPFM, ESD & F&G system for offshore Well head Platforms (WHP’s) and control system modifications at the Central Processing Platform (CPC) for Zakum Development Company (ZADCO) Abu Dhabi. This project consists of Well head platforms and CPC modifications along with the Subsea piping and Subsea cabling, Project consists of Electrical Submersible Pumps (ESP’s) and its top side valves, production manifold, testing manifold, demulsifier package, closed drain system, open drain system and its control instrumentation. Detail engineering was done for new SIL rated Well head Control Panels ESD systems, DCS systems, F&G systems, Down Hole Monitoring Systems (DHMS), Multi Phase Flow Meters (MPFM), ESD valves, Choke valves, Wireless Transmitters, MOV’s, Hydraulic Valve’s (ROV), Control Valves, Relief Valves and F&G devices. 3. Client :- ZADCO - WELL HEAD PLATFORMS 04, 07, 15 & 16. – OFFSHORE PROJECT PROJECT :- Replacement of CS lines, valves, mpfms and instruments to INCONEL for WELL HEAD PLATFORMS whp 04, 07, 15 & 16. install new valves and esd system at WELL HEAD PLATFORMS whp 04 & 16. Engineering, Design, Procurement and Construction for the Installation of Electrical Submersible Pumps, choke valves, ESD valves, MPFM, ESD & F&G system for offshore Well head Platforms (WHP’s) and control system modifications at the Central Processing Platform (CPC) for Zakum Development Company (ZADCO) Abu Dhabi. This project consists of Well head platforms and CPC modifications. Project consists of replacement of CS lines, valves, MPFM and instruments to INCONEL, install new valves and ESD system.

- 4. 4. Client :- ADCO PROJECT :- Engineering for Construction of MPSM'S and MPFM'S at BUHASA Remote Degassing Stations 1, 2, 3, & Engineering for an entire New Remote Degassing Station RMS-7. Engineering for new MPSM’s, MPFM'S, related field instruments and F&G devices, F&G system, ESD system at BUHASA Remote Degassing Stations 1, 2, 3, and a complete new Remote Degassing Station RMS-7 and its interface with Central Degassing Station CDS at Buhasa. Engineering, Design, Procurement and Construction for the Installation of MPSM – Multiport Selector Manifold and MPFM’s for Remote Degassing Stations 1, 2, 3, & and for an entire New Remote Degassing Station RMS-7 with independent Flare package. Detail engineering was done for all the 4 degassing stations for new MPSM’s, MPFM’s, MOV’s, ESD Valves, SIL rated ESD and F&G system, telecom network for communication the New RMS-7 to RDS-3 at a distance of 15 KM and all related field instruments and F&G devices. 5. Client :- GASCO PROJECT :- Engineering for New 16” condensate Pipeline from Habshan to Ruwais station (110 Km) in Abu Dhabi. It includes 4 Block valve stations and its instrumentation. Instrumentation at Tie-in points at both ends. Instrumentation System consists of Leak detection System (LDS), High Integrity Pressure protection system (HIPPS), SCADA system and F&G system. 6. Client :- ADMA OFFSHORE PROJECT PROJECT :- Engineering for new Tank Gauging System (TGS), ESD System and tank Overfill Protection System for 16 tanks of DAS island crude oil storage terminal of ADMA. ADMA-OPCO intends to replace the existing obsolete Crude Oil Storage Tank Gauging System and Overfill Protection System on Das Island with state of the art Tank Gauging System, a New ESD-PLC system. Modify MOV’s for providing Tank Overfill Protection System. New Tank Gauging System to be in compliant with Custody metering standards. SIL verification for the tank overfill protection system. ASSESS and SELECT stage study for wireless based tank gauging system. ASSESS & SELECT stage study for Tank Gauging System. ASSESS & SELECT stage study for SIL 2 category, Tank Overfill Protection System. Interface the new ESD system and TGS system with existing ABB DCS. The design to be suitable for online installation and construction, without any Hot work 7. Client :- DOLPHIN ENERGY Project :- EPC Emergency Gas Supply to EMAL. Engineering for emergency gas supply pipe line from Dolphin Energy to Emirates Aluminium (EMAL) in Abu Dhabi. It consists of 48” Gas Supply pipe line. Instrumentation for this facility consists of instrumentation for filtration skid, metering skid, pressure reducing station, SCADA system and F&G system. 8. Client :- ADNOC (Onshore Project) PROJECT :- Construction works in Western Region of Abu Dhabi. Engineering for modification in Control Systems, F&G systems, CCTV system etc at various location such as Oil Depots, LPG plants, Oil Distrubution centers of ADNOC.

- 5. Projects done at IOT Design & Engineering 1. EPC of Terminal for IOCL Paradip Refinery. Instrumentation Design and Detailed engineering. Selection, Technical Evaluation, Procurement, Erection & Commissioning. Conduct Plant Performance trail and handover of entire Instrumentation system with proper documentation and training to client. 2. EPC of Terminal at Abu Dhabi, Fujairah for IL&FS, Terminal project on BOOT basis. Instrumentation Design and Detailed engineering. Selection, Technical Evaluation, Procurement, Erection & Commissioning. Conduct Plant Performance trail and handover of entire Instrumentation system with proper documentation and training to client. 3. EPC of Terminal for Indian Oil at Raipur. Terminal project on BOOT basis. Instrumentation Design and Detailed engineering. Selection, Technical Evaluation, Procurement, Erection & Commissioning. Conduct Plant Performance trail and handover of entire Instrumentation system with proper documentation and training to client. 4. Bangalore International Airport Fuel Hydrant System and Fuel tankfarm for Jet A1 fuel storage and refueling services. Facility comprises of Aviation Turbine Fuel (ATF) storage tank farm with Tank truck unloading & SCADA system for tank farm management. Fully automatic fuel hydrant system & Single man refueling 5. Generate EPC Projects Bidding documents for several International and Local projects in field of Oil & Gas, Power and Infrastructure. Projects done at SNC LAVALIN & UHDE INDIA Ltd. 1. Engineering and Construction of 48" underground gas pipeline from SAJAA to Hamriyah for Dubal – Dubai Aluminium. The project included block valve stations, leak detections system and high-integrity pressure protection system (HIPPS) and ESD valves. 2. Uran Trombay Pipeline for ONGC (Mumbai) : The project included installation of a 36 inch pipeline to transport crude from crude storage terminals to refinery and then transfer the same processed oil to oil storage terminal. The pipeline was having both onshore as well as offshore sections to be constructed, with a branch tee-off connection of 30 inches to an Oil loading Jetty. 3. Control system replacement and up gradation for Reformer section at BPCL Mumbai: The project included demolition of existing pneumatic 30 years old control system from Taylor with latest DCS, F&G and ESD system. The project included replacement of control system and field instruments. 4. Offshore Platforms for Iranian Offshore Engineering Co. (IOEC) : Detail Engineering for Gas Processing Wellhead Platforms “SPD-7, SPD-8 and SPD-9. The project included: ESD, DCS, F&G System, Wellhead Control Panel, and MOV, Choke valves, Control valves, Chemical Injection packages, MPFM, Pressure transmitters, DP transmitters, CCTV system and Telecom system. 5. SHELL ETHYLENE CRACKER, Singapore : Plant Designed to meet Ethylene production to down stream units. Plant Consists of Cracker, Benzene Extraction, Hydrogenation, Compression and utility units by Lummas and Axen Technology. The project had ESD, DCS, F&G System, Control valves and related field instruments.

- 6. 6. Fatty Alcohol Plant expansion – for VVF LTD – Design, Erection & Commissioning of large Scale Continuous Plant having almost all categories of modern process equipments.. 7. Hydrogen Gas Generation Plant for VVF LTD of capacity 1750 Nm3/hr – with Hydro- Chem (USA) a division of Linde (BOC). Plant. Design, Erection and Commissioning of High purity hydrogen producing plant using dual feed as Naphtha or Natural gas. 8. Hydrogen Gas Generation Plant for VVF LTD of capacity 2800 Nm3/hr – Implemented modifications needed for conversion of feed and fuel from Naphtha to CNG gas along with UHDE India Ltd. 9. Hydrogen Gas compressor for VVF LTD : Erection and Commissioning of Hydrogen Gas compressor of capacity 2800 Nm3/hr and pressure 280 bar. 10. Fatty Acid plant for VVF LTD.: Additional of distillation columns. Design, Erection and Commissioning. Instrumentation Basic and Detailed engineering, Procurement, technical evaluations and techno-commercial negotiation. Instrumentation Erection, Installation and Commissioning. 11. 300 MW X 3 NOS COAL BASED THERMAL POWER PLANT. Design, Erection & Commissioning of large Scale Power Plant having almost all categories of modern process equipment. Project Planning and Scheduling, Costing estimation, Man-hour Estimation, expense tracking. Instrumentation Basic and Detailed engineering. Instrumentation Procurement, technical evaluations and techno-commercial negotiation. Instrumentation Erection, Installation and Commissioning. 12. Seciality Chemicals Plant for IOC :- Design, Erection & Commissioning of CIBA Speciality Chemicals Plant with State-Of-Art Automation incorporating Emerson's Delta-V DCS having 2000 I/O and standard S88.01 compliant batch control software. System is integrated with Smart and Field bus instruments. In DCS Web Server has been installed for remote monitoring of process operations through Internet. Coordinated with CIBA Switzerland Project team for technology transfer, system validation, Hazop and process optimization. 13. Batch Process Plants for IOC :- Design, Erection & Commissioning of 4 Nos. Batch Process Plants having 800 Equipments. Instrumentation scheme involving 1000 I/O Allen-Bradley CONTROL LOGIX Hybrid DCS-PLC system with Smart transmitters and Field instruments.

- 7. 6. Fatty Alcohol Plant expansion – for VVF LTD – Design, Erection & Commissioning of large Scale Continuous Plant having almost all categories of modern process equipments.. 7. Hydrogen Gas Generation Plant for VVF LTD of capacity 1750 Nm3/hr – with Hydro- Chem (USA) a division of Linde (BOC). Plant. Design, Erection and Commissioning of High purity hydrogen producing plant using dual feed as Naphtha or Natural gas. 8. Hydrogen Gas Generation Plant for VVF LTD of capacity 2800 Nm3/hr – Implemented modifications needed for conversion of feed and fuel from Naphtha to CNG gas along with UHDE India Ltd. 9. Hydrogen Gas compressor for VVF LTD : Erection and Commissioning of Hydrogen Gas compressor of capacity 2800 Nm3/hr and pressure 280 bar. 10. Fatty Acid plant for VVF LTD.: Additional of distillation columns. Design, Erection and Commissioning. Instrumentation Basic and Detailed engineering, Procurement, technical evaluations and techno-commercial negotiation. Instrumentation Erection, Installation and Commissioning. 11. 300 MW X 3 NOS COAL BASED THERMAL POWER PLANT. Design, Erection & Commissioning of large Scale Power Plant having almost all categories of modern process equipment. Project Planning and Scheduling, Costing estimation, Man-hour Estimation, expense tracking. Instrumentation Basic and Detailed engineering. Instrumentation Procurement, technical evaluations and techno-commercial negotiation. Instrumentation Erection, Installation and Commissioning. 12. Seciality Chemicals Plant for IOC :- Design, Erection & Commissioning of CIBA Speciality Chemicals Plant with State-Of-Art Automation incorporating Emerson's Delta-V DCS having 2000 I/O and standard S88.01 compliant batch control software. System is integrated with Smart and Field bus instruments. In DCS Web Server has been installed for remote monitoring of process operations through Internet. Coordinated with CIBA Switzerland Project team for technology transfer, system validation, Hazop and process optimization. 13. Batch Process Plants for IOC :- Design, Erection & Commissioning of 4 Nos. Batch Process Plants having 800 Equipments. Instrumentation scheme involving 1000 I/O Allen-Bradley CONTROL LOGIX Hybrid DCS-PLC system with Smart transmitters and Field instruments.