Rechargeable Sodium-ion Battery - The Future of Battery Development

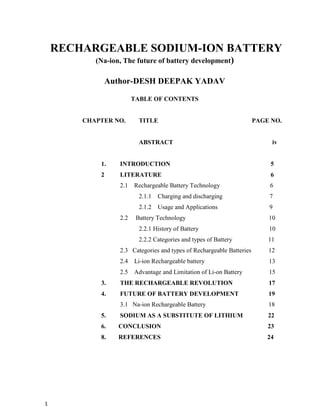

- 1. 1 RECHARGEABLE SODIUM-ION BATTERY (Na-ion, The future of battery development) Author-DESH DEEPAK YADAV TABLE OF CONTENTS CHAPTER NO. TITLE PAGE NO. ABSTRACT iv 1. INTRODUCTION 5 2 LITERATURE 6 2.1 Rechargeable Battery Technology 6 2.1.1 Charging and discharging 7 2.1.2 Usage and Applications 9 2.2 Battery Technology 10 2.2.1 History of Battery 10 2.2.2 Categories and types of Battery 11 2.3 Categories and types of Rechargeable Batteries 12 2.4 Li-ion Rechargeable battery 13 2.5 Advantage and Limitation of Li-on Battery 15 3. THE RECHARGEABLE REVOLUTION 17 4. FUTURE OF BATTERY DEVELOPMENT 19 3.1 Na-ion Rechargeable Battery 18 5. SODIUM AS A SUBSTITUTE OF LITHIUM 22 6. CONCLUSION 23 8. REFERENCES 24

- 2. 2 ABSTRACT Lithium-ion batteries are everywhere, powering phones, cars, and laptops, among other things. However, lithium is a relatively rare element, found in some locations in South America. That not only keeps the price of lithium-ion batteries high, but also makes the supply chain vulnerable to political instabilities. Sodium has a very similar chemistry to lithium, and as soon as lithium-ion batteries came to market, researchers started looking to sodium as a substitute for lithium in rechargeable batteries. Unlike lithium, the reserves of sodium are practically unlimited. The highest hurdle for sodium to clear on its way to battery dominance is the development of suitable electrodes. If batteries can get better, cheaper and store more power safely, then electric cars and solar- or wind- powered homes become more viable - even on cloudy days or when the wind isn't blowing. These types of technological solutions will be one of the more hopeful aspects to beat global warming

- 3. 3 CHAPTER 1. INTRODUCTION Sodium-ion batteries offer an attractive alternative to Li-ion batteries not because they outperform Li-ion batteries, but mainly because of lower costs due to the the nearly unlimited supply of sodium. They are also an attractive alternative in part because unlike their sodium- sulfur battery cousins they can be made in similar sizes to Li-ion batteries. However, the commercial development of sodium-ion batteries has been hampered by the materials used in the negative electrodes. These swell to as much as 400 to 500 percent their original size, leading to mechanical damage and loss of electrical contact. Now researchers at Kansas State University United States have developed a composite, paper- like material made from two 2-dimensional materials—molybdenum disulfide and graphene Nano sheets—that has been shown to overcome this shortcoming. In research published in the journal ACS Nano (“MoS2/Graphene Composite Paper for Sodium- Ion Battery Electrodes”), the 2-D composite material developed proved resistant to the “alloying” reaction that electrode materials typically suffer when in contact with sodium. The research also marks the first time that the flexible paper electrode was used in an anode for sodium-ion battery that operates at room temperature.

- 4. 4 2. LITERATURE 2.1 Rechargeable Battery Technology A rechargeable battery, storage battery, secondary cell, or accumulator is a type of electrical which can be charged, discharged into a load, and recharged many times, while a non- rechargeable or primary battery is supplied fully charged, and discarded once discharged. It is composed of one or more electrochemical cells. The term "accumulator" is used as it accumulates and stores energy through a reversible electrochemical reaction. Rechargeable batteries are produced in many different shapes and sizes, ranging from button cells to megawatt systems connected to stabilize an electrical distribution network. Several different combinations of electrode materials and electrolytes are used, including lead–acid, nickel cadmium (NiCd), nickel metal hydride (NiMH), lithium ion (Li-ion), and lithium ion polymer (Li-ion polymer). Rechargeable batteries initially cost more than disposable batteries, but have a much lower total cost of ownership and environmental impact, as they can be recharged inexpensively many times before they need replacing. Some rechargeable battery types are available in the same sizes and voltages as disposable types, and can be used interchangeably with them. The mobile world depends on lithium-ion batteries — today's ultimate rechargeable energy store. Last year, consumers bought five billion Li-ion cells to supply power-hungry laptops, cameras, mobile phones and electric cars. “It is the best battery technology anyone has ever seen,” says George Crabtree, director of the US Joint Center for Energy Storage Research (JCESR), which is based at the Argonne National Laboratory near Chicago, Illinois. But Crabtree wants to do much, much better. Modern Li-ion batteries hold more than twice as much energy by weight as the first commercial versions sold by Sony in 1991 — and are ten times cheaper. But they are nearing their limit. Most researchers think that improvements to Li-ion cells can squeeze in at most 30% more energy by weight. That means that Li-ion cells will never give electric cars the 800-kilometre range of a petrol tank, or supply power-hungry smartphones with many days of juice.

- 5. 5 2.1.1 Charging and Discharging During charging, the positive active material is oxidized, producing electrons, and the negative material is reduced, consuming electrons. These electrons constitute the current flow in the external circuit. The electrolyte may serve as a simple buffer for internal ion flow between the electrodes, as in lithium-ion and nickel-cadmium cells, or it may be an active participant in the electrochemical reaction, as in lead–acid cells. The energy used to charge rechargeable batteries usually comes from a charger using AC mains electricity, although some are equipped to use a vehicle's 12-volt DC power outlet. Regardless, to store energy in a secondary cell, it has to be connected to a DC voltage source. The negative terminal of the cell has to be connected to the negative terminal of the voltage source and the positive terminal of the voltage source with the positive terminal of the battery. Further, the voltage output of the source must be higher than that of the battery, but not much higher: the greater the difference between the power source and the battery's voltage capacity, the faster the charging process, but also the greater the risk of overcharging and damaging the battery. Chargers take from a few minutes to several hours to charge a battery. Slow "dumb" chargers without voltage or temperature-sensing capabilities will charge at a low rate, typically taking 14 hours or more to reach a full charge. Rapid chargers can typically charge cells in two to five hours, depending on the model, with the fastest taking as little as fifteen minutes. Fast chargers must have multiple ways of detecting when a cell reaches full charge (change in terminal voltage, temperature, etc.) to stop charging before harmful overcharging or overheating occurs. The fastest chargers often incorporate cooling fans to keep the cells from overheating. Battery charging and discharging rates are often discussed by referencing a "C" rate of current. The C rate is that which would theoretically fully charge or discharge the battery in one hour. For example, trickle charging might be performed at C/20 (or a "20 hour" rate), while typical charging and discharging may occur at C/2 (two hours for full capacity). The available capacity of electrochemical cells varies depending on the discharge rate. Some energy is lost in the internal resistance of cell components (plates, electrolyte, interconnections), and the rate of discharge is limited by the speed at which chemicals in the cell can move about. For lead-acid cells, the relationship between time and discharge rate is described by Peukert's law; a lead-acid cell that can no longer sustain a usable terminal voltage at a high current may still have usable capacity, if discharged at a much lower rate. Data sheets for rechargeable cells often list the

- 6. 6 Discharge capacity on 8-hour or 20-hour or other stated time; cells for uninterruptible systems may be rated at 15 minute discharge. Battery manufacturers' technical notes often refer to voltage per cell (VPC) for the individual cells that make up the battery. For example, to charge a 12 V lead-acid battery (containing 6 cells of 2 V each) at 2.3 VPC requires a voltage of 13.8 V across the battery's terminals. Non-rechargeable alkaline and zinc–carbon cells output 1.5V when new, but this voltage drops with use. Most NiMH AA and AAA cells are rated at 1.2 V, but have a flatter discharge curve than alkaline and can usually be used in equipment designed to use alkaline batteries Source:https://www.google.co.in/imghp?hl=en&tab=wi&ei=8UZwVsjBM4OxuQTJj4zIBQ&ved=0EKouCBIo

- 7. 7 2.1.2 Usage and Applications Rechargeable batteries are used for automobile starters, portable consumer devices, light vehicles (such as motorized wheelchairs, golf carts, electric bicycles, and electric forklifts), tools, and uninterruptible power supplies. Emerging applications in hybrid internal combustion- battery and electric vehicles are driving the technology to reduce cost, weight, and size, and increase lifetime. Older rechargeable batteries self-discharge relatively rapidly, and have to be charged before first use; some newer low self-discharge NiMH batteries hold their charge for many months, and are typically sold factory-charged to about 70% of their rated capacity. Grid energy storage applications use rechargeable batteries for load-leveling, storing electric energy at times of low demand for use during peak periods, and for renewable energy uses, such as storing power generated from photovoltaic arrays during the day to be used at night. Load- leveling reduces the maximum power which a plant must be able to generate, reducing capital cost and the need for peaking power plants. The US National Electrical Manufacturers Association estimated in 2006 that US demand for rechargeable batteries was growing twice as fast as demand for disposables. Small rechargeable batteries are used to power portable electronic devices, power tools, appliances, and so on. Heavy-duty batteries are used to power electric vehicles, ranging from scooters to locomotives and ships. They are used in distributed electricity generation and stand-alone power systems. Source:https://www.google.co.in/imghp?hl=en&tab=wi&ei=8UZwVsjBM4OxuQTJj4zIBQ&ved=0EKouCBIoAQ

- 8. 8 2.2 Battery Technologies An electric battery is a device consisting of two or more electrochemical cells that convert stored chemical energy into electrical energy. Each cell has a positive terminal, or cathode, and a negative terminal, or anode. The terminal marked positive is at a higher electrical potential energy than is the terminal marked negative. The terminal marked positive is the source of electrons that when connected to an external circuit will flow and deliver energy to an external device. When a battery is connected to an external circuit, electrolytes are able to move as ions within, allowing the chemical reactions to be completed at the separate terminals and so deliver energy to the external circuit. It is the movement of those ions within the battery which allows current to flow out of the battery to perform work. Although the term battery technically means a device with multiple cells, single cells are also popularly called batteries. 2.2.1 History of Battery In 1749 Benjamin Franklin, the U.S. polymath and founding father, first used the term "battery" to describe a set of linked capacitors he used for his experiments with electricity. These capacitors were panels of glass coated with metal on each surface.[1] These capacitors were charged with a static generator and discharged by touching metal to their electrode. Linking them together in a "battery" gave a stronger discharge. Originally having the generic meaning of "a group of two or more similar objects functioning together", as in an artillery battery, the term came to be used for piles and similar devices in which many electrochemical cells were connected together in the manner of Franklin's capacitors. Today even a single electrochemical cell, e.g. a dry cell, is commonly called a battery. Batteries provided the main source of electricity before the development of electric generators and electrical grids around the end of the 19th century. Successive improvements in battery technology facilitated major electrical advances, from early scientific studies to the rise of telegraphs and telephones, and eventually leading to portable, mobile phones, electric cars, and many other electrical devices. Scientists and engineers developed several commercially important types of battery. "Wet cells" were open containers that held liquid electrolyte and metallic electrodes. When the electrodes were completely consumed, the wet cell was renewed by replacing the electrodes and electrolyte. Open containers are unsuitable for mobile or portable use. Early electric cars used semi-sealed wet cells.

- 9. 9 2.2.1 Categories and Types of Batteries Batteries are classified into primary and secondary forms. Primary batteries irreversibly transform chemical energy to electrical energy. When the supply of reactants is exhausted, energy cannot be readily restored to the battery. Secondary batteries can be recharged; that is, they can have their chemical reactions reversed by supplying electrical energy to the cell, approximately restoring their original composition. Primary batteries, or primary cells, can produce current immediately on assembly. These are most commonly used in portable devices that have low current drain, are used only intermittently, or are used well away from an alternative power source, such as in alarm and communication circuits where other electric power is only intermittently available. Disposable primary cells cannot be reliably recharged, since the chemical reactions are not easily reversible and active materials may not return to their original forms. Battery manufacturers recommend against attempting to recharge primary cells. In general, these have higher energy densities than rechargeable batteries,[23] but disposable batteries do not fare well under high-drain applications with loads under 75 ohms (75 Ω). Common types of disposable batteries include zinc–carbon batteries and alkaline batteries. Secondary batteries, also known as secondary cells, or rechargeable batteries, must be charged before first use; they are usually assembled with active materials in the discharged state. Rechargeable batteries are (re)charged by applying electric current, which reverses the chemical reactions that occur during discharge/use. Devices to supply the appropriate current are called chargers. The oldest form of rechargeable battery is the lead–acid battery. This technology contains liquid electrolyte in an unsealed container, requiring that the battery be kept upright and the area be well ventilated to ensure safe dispersal of the hydrogen gas it produces during overcharging. The lead–acid battery is relatively heavy for the amount of electrical energy it can supply. Its low manufacturing cost and its high surge current levels make it common where its capacity (over approximately 10 Ah) is more important than weight and handling issues. A common application is the modern car battery, which can, in general, deliver a peak current of 450 amperes.

- 10. 10 2.3 COMPARISION OF RECHARGABLE BATTERIES Source: https://en.wikipedia.org/wiki/Rechargeable_battery#Types Source: https://en.wikipedia.org/wiki/Rechargeable_battery#Types

- 11. 11 2.4 Li-ion Rechargeable Battery Pioneer work with the lithium battery began in 1912 under G.N. Lewis but it was not until the early 1970s that the first non-rechargeable lithium batteries became commercially available. Lithium is the lightest of all metals, has the greatest electrochemical potential and provides the largest energy density per weight. Attempts to develop rechargeable lithium batteries followed in the 1980s, but failed due to safety problems. Because of the inherent instability of lithium metal, especially during charging, research shifted to a non-metallic lithium battery using lithium ions. Although slightly lower in energy density than lithium metal, the Li-ion is safe, provided certain precautions are met when charging and discharging. In 1991, the Sony Corporation commercialized the first Li-ion battery. Other manufacturers followed suit. Today, the Li-ion is the fastest growing and most promising battery chemistry. The energy density of the Li-ion is typically twice that of the standard NiCd. Improvements in electrode active materials have the potential of increasing the energy density close to three times that of the NiCd. In addition to high capacity, the load characteristics are reasonably good and behave similarly to the NiCd in terms of discharge characteristics (similar shape of discharge profile, but different voltage). The flat discharge curve offers effective utilization of the stored power in a desirable voltage spectrum. The high cell voltage allows battery packs with only one cell. Most of today’s mobile phones run on a single cell, an advantage that simplifies battery design. To maintain the same power, higher currents are drawn. Low cell resistance is important to allow unrestricted current flow during load pulses. The Li-ion is a low maintenance battery, an advantage that most other chemistries cannot claim. There is no memory and no scheduled cycling is required to prolong the battery’s life. In addition, the self-discharge is less than half compared to NiCd, making the Li-ion well suited for modern fuel gauge applications. Li-ion cells cause little harm when disposed. Despite its overall advantages, Li-ion also has its drawbacks. It is fragile and requires a protection circuit to maintain safe operation. Built into each pack, the protection circuit limits the peak voltage of each cell during charge and prevents the cell voltage from dropping too low on discharge. In addition, the cell temperature is monitored to prevent temperature extremes. The maximum charge and discharge current is limited to between 1C and 2C. With these precautions in place, the possibility of metallic lithium plating occurring due to overcharge is virtually eliminated.

- 12. 12 Aging is a concern with most Li-ion batteries and many manufacturers remain silent about this issue. Some capacity deterioration is noticeable after one year, whether the battery is in use or not. Over two or perhaps three years, the battery frequently fails. It should be noted that other chemistries also have age-related degenerative effects. This is especially true for the NiMH if exposed to high ambient temperatures. Storing the battery in a cool place slows down the aging process of the Li-ion (and other chemistries). Manufacturers recommend storage temperatures of 15°C (59°F). In addition, the battery should be partially charged during storage. Manufacturers are constantly improving the chemistry of the Li-ion battery. New and enhanced chemical combinations are introduced every six months or so. With such rapid progress, it is difficult to assess how well the revised battery will age. The most economical Li-ion battery in terms of cost-to-energy ratio is the cylindrical 18650 cell. This cell is used for mobile computing and other applications that do not demand ultra-thin geometry. If a slimmer pack is required (thinner than 18 mm), the prismatic Li-ion cell is the best choice. There are no gains in energy density over the 18650, however, the cost of obtaining the same energy may double. For ultra-slim geometry (less than 4 mm), the only choice is Li-ion polymer. This is the most expensive system in terms of cost-to-energy ratio. There are no gains in energy density and the durability is inferior to the rugged 18560 cell. The Li-polymer differentiates itself from other battery systems in the type of electrolyte used. The original design, dating back to the 1970s, uses a dry solid polymer electrolyte. This electrolyte resembles a plastic-like film that does not conduct electricity but allows an exchange of ions (electrically charged atoms or groups of atoms). The polymer electrolyte replaces the traditional porous separator, which is soaked with electrolyte. The dry polymer design offers simplifications with respect to fabrication, ruggedness, safety and thin-profile geometry. There is no danger of flammability because no liquid or gelled electrolyte is used. With a cell thickness measuring as little as one millimeter (0.039 inches), equipment designers are left to their own imagination in terms of form, shape and size. Technical difficulties and delays in volume manufacturing have deferred the introduction of the Li-ion polymer battery. In addition, the promised superiority of the Li-ion polymer has not yet been realized. No improvements in capacity gains are achieved — in fact, the capacity is slightly less than that of the standard Li-ion battery.

- 13. 13 2.4 Advantages and Limitations of Li-ion Batteries Lithium ion battery Advantages High energy density: The much greater energy density is one of the chief advantages of a lithium ion battery or cell. With electronic equipment such as mobile phones needing to operate longer between charges while still consuming more power, there is always a need to batteries with a much higher energy density. In addition to this, there are many power applications from power tools to electric vehicles. The much higher power density offered by lithium ion batteries is a distinct advantage. Self-discharge: One issue with batteries and ells is that they lose their charge over time. This self-discharge can be a major issue. One advantage of lithium ion cells is that their rate of self-discharge is much lower than that of other rechargeable cells such as Ni-Cad and NiMH forms. No requirement for priming: Some rechargeable cells need to be primed when they receive their first charge. There is no requirement for this with lithium ion cells and batteries. Low maintenance: One major lithium ion battery advantage is that they do not require and maintenance to ensure their performance. Ni-Cad cells required a periodic discharge to ensure that they did not exhibit the memory effect. As this does not affect lithium ion cells, this process or other similar maintenance procedures are not required. Variety of types available: There are several types of lithium ion cell available. This advantage of lithium ion batteries can mean that the right technology can be used for the particular application needed. Some forms of lithium ion battery provide a high current density and are ideal for consumer mobile electronic equipment. Others are able to provide much higher current levels and are ideal for power tools and electric vehicles.

- 14. 14 Lithium ion battery Limitations Protection required: lithium ion cells and batteries are not as robust as some other rechargeable technologies. They require protection from being over charged and discharged too far. In addition to this, they need to have the current maintained within safe limits. Accordingly one lithium ion battery disadvantage is that they require protection circuitry incorporated to ensure they are kept within their safe operating limits. Fortunately with modern integrated circuit technology, this can be relatively easily incorporated into the battery, or within the equipment if the battery is not interchangeable. Ageing : One of the major lithium ion battery disadvantages for consumer electronics is that lithium ion batteries suffer from ageing. Not only is this time or calendar dependent, but it is also dependent upon the number of charge discharge cycles that the battery has undergone. When a typical consumer lithium cobalt oxide, LCO battery or cell needs to be stored it should be partially charged - around 40% to 50% and kept in a cool storage area. Storage under these conditions will help increase the life. Transportation: Another disadvantage of lithium ion batteries is that there can be certain restrictions placed on their transportation, especially by air. Although the batteries that could be taken in aircraft carry-on luggage are unlikely to be affected, care should be taken not to carry any more lithium ion batteries than are needed. Any carried separately must be protected against short circuits by protective covers, etc. Cost: A major lithium ion battery disadvantage is their cost. Typically they are around 40% more costly to manufacture than Nickel cadmium cells. This is a major factor when considering their use in mass produced consumer items where any additional costs are a major issue. Immature technology: Lithium ion battery technology is a developing area. This can be a disadvantage in terms of the fact that the technology does not remain constant. However as new lithium ion technologies are being developed all the time, it can also be an advantage as better solutions are coming available.

- 15. 15 3. THE RECHARGEABLE REVOLUTION The mobile world depends on lithium-ion batteries — today's ultimate rechargeable energy store. Last year, consumers bought five billion Li-ion cells to supply power-hungry laptops, cameras, mobile phones and electric cars. “It is the best battery technology anyone has ever seen,” says George Crabtree, director of the US Joint Center for Energy Storage Research (JCESR), which is based at the Argonne National Laboratory near Chicago, Illinois. But Crabtree wants to do much, much better. Modern Li-ion batteries hold more than twice as much energy by weight as the first commercial versions sold by Sony in 1991 — and are ten times cheaper. But they are nearing their limit. Most researchers think that improvements to Li-ion cells can squeeze in at most 30% more energy by weight. That means that Li-ion cells will never give electric cars the 800-kilometre range of a petrol tank, or supply power-hungry smartphones with many days of juice. In 2012, the JCESR hub won US$120 million from the US Department of Energy to take a leap beyond Li-ion technology. Its stated goal was to make cells that, when scaled up to the sort of commercial battery packs used in electric cars, would be five times more energy dense than the standard of the day, and five times cheaper, in just five years. That means hitting a target of 400 watt-hours per kilogram (Wh kg−1 ) by 2017. Crabtree calls the goal “very aggressive”; veteran battery researcher Jeff Dahn at Dalhousie University in Halifax, Canada, calls it “impossible”. The energy density of rechargeable batteries has risen only six fold since the early lead–nickel rechargeable of the 1900s. But, says Dahn, the JCESR's target focuses attention on technologies that will be crucial in helping the world to switch to renewable energy sources — storing up solar energy for night-time or a rainy day, for example. And the US hub is far from alone. Many research teams and companies in Asia, the Americas and Europe are looking beyond Li-ion, and are pursuing strategies that may topple it from its throne. Five years ago, Wilcke, who heads IBM's Nano science and technology division in San Jose, California, launched a project to develop a car battery with an 800-kilometre range. At the start, he focused on the theoretical ultimate in energy-dense electrochemical storage: the oxidation of lithium with oxygen drawn from the air. Such 'breathing' batteries have a huge weight advantage over other types, because they do not have to carry around one of their main ingredients. A lithium–oxygen (Li–O) battery can, in theory, store energy as densely as a petrol engine — more than ten times better than today's car battery packs.

- 16. 16 Source: http://www.nature.com/news/the-rechargeable-revolution-a-better-battery-1.14815 Persson and Gerbrand Ceder, a materials scientist at the Massachusetts Institute of Technology in Cambridge, founded a company to develop these higher-charge-carrying batteries. Pellion Technologies, based in Cambridge, is tight-lipped about its results; it has published only one paper about electrolytes2 . A spate of patents published in late 2013 hint that the company is developing more-open electrode structures to help the magnesium ions to flow. Major electronics firms such as Toyota, LG, Samsung and Hitachi are also working on such cells, releasing little information beyond occasional teasers. As companies jostle in secret, Persson continues to run through what she calls the “electrolyte genome”. The sifting-by-supercomputer approach could also help the search for batteries made with other multiple-charge-carrying (or 'multivalent') metals, such as aluminum and calcium. Ceder urges patience, pointing out that research into Li-ion battery chemistry has enjoyed a 40- year head start. “We have so little information about multivalent ions,” he says.

- 17. 17 3. FUTURE OF BATTERIES DEVELEVOPMENT 3.1 Na-ion Rechargeable Battery At the end of November a team of French researchers from the CNRS, the French National Centre for Scientific Research and the CEA, France's Alternative Energies and Atomic Energy Commission, announced in a press release and a CNRS News article that they had produced, in collaboration with the Research Network on Electrochemical Energy Storage, RS2E, a prototype sodium-ion battery that can store an acceptable amount of electricity in the same standard industry format as lithium ion batteries. It is slightly larger than an AA battery—18 mm x 65 mm. Sodium has a very similar chemistry to lithium, and as soon as lithium-ion batteries came to market, researchers started looking to sodium as a substitute for lithium in rechargeable batteries. Unlike lithium, the reserves of sodium are practically unlimited. The highest hurdle for sodium to clear on its way to battery dominance is the development of suitable electrodes. Although the news article calls the composition of the negative electrode "a trade secret," the team applied for a patent in October of this year, describing a negative electrode with a layered structure based on the titanium oxide compound Na2Ti3O7, and a method to produce it. Such electrode structures can store lithium ions, and recently researchers have begun investigating their suitability for storing sodium ions. "The chemistry is very close to that of the lithium battery, and from that point of view there are no major difficulties; the mechanisms are the same ones and all the industrial processes for their

- 18. 18 production are the same," says Laurence Croguennec, a material scientist at the CNRS Institut de Chimie de la Matière Condensée de Bordeaux. One remaining problem is that sodium is less efficient as a charge carrier. "A sodium battery loses 0.3 volts as to compared to a lithium battery. You have to develop materials that can function at higher voltages and that provide ample capacity," says Croguennec. Whether sodium-ion batteries will reach parity with lithium-ion batteries is still an open question. "The development of the electrode has taken six months, so this gives us hope for improvement. The performance that has been announced is quite good for a starting point, and materials can be further optimized," says Croguennec. For the moment the sodium batteries have a storage capacity of 90Wh/kg, which is comparable to the early lithium batteries. Lithium-ion batteries are everywhere, powering phones, cars, and avionics, among other things. However, lithium is a relatively rare element, found in some locations in South America. That not only keeps the price of lithium-ion batteries high, but also makes the supply chain vulnerable to political instabilities. Graphene Composite Offers Critical Fix for Sodium-ion Batteries (source: http://spectrum.ieee.org/nanoclast/semiconductors/nanotechnology/graphene-composite-offers-critical-fix-for- sodiumion-batteries) Sodium has a very similar chemistry to lithium, and as soon as lithium-ion batteries came to market, researchers started looking to sodium as a substitute for lithium in rechargeable batteries. Unlike lithium, the reserves of sodium are practically unlimited. The highest hurdle for sodium to clear on its way to battery dominance is the development of suitable electrodes. At the end of November a team of French researchers from the CNRS, the French National Centre for Scientific Research and the CEA, France's Alternative Energies and Atomic Energy Commission, announced in a press release and a CNRS News article that they had produced, in collaboration with the Research Network on Electrochemical Energy Storage, RS2E, a prototype sodium-ion battery that can store an acceptable amount of electricity in the same standard

- 19. 19 industry format as lithium ion batteries. It is slightly larger than an AA battery—18 mm x 65 mm. Although the news article calls the composition of the negative electrode "a trade secret," the team applied for a patent in October of this year, describing a negative electrode with a layered structure based on the titanium oxide compound Na2Ti3O7, and a method to produce it. Such electrode structures can store lithium ions, and recently researchers have begun investigating their suitability for storing sodium ions. "The chemistry is very close to that of the lithium battery, and from that point of view there are no major difficulties; the mechanisms are the same ones and all the industrial processes for their production are the same," says Laurence Croguennec, a material scientist at the CNRS Institut de Chimie de la Matière Condensée de Bordeaux. One remaining problem is that sodium is less efficient as a charge carrier. "A sodium battery loses 0.3 volts as to compared to a lithium battery. You have to develop materials that can function at higher voltages and that provide ample capacity," says Croguennec. Whether sodium-ion batteries will reach parity with lithium-ion batteries is still an open question. "The development of the electrode has taken six months, so this gives us hope for improvement. The performance that has been announced is quite good for a starting point, and materials can be further optimized," says Croguennec. For the moment the sodium batteries have a storage capacity of 90Wh/kg, which is comparable to the early lithium batteries. "We are not yet close to the energy levels that you can find, for example, in Tesla cars," says Croguennec. At this point, the most reasonable application for sodium batteries is renewable energy storage, as they could be cheaper per stored unit of energy and are scalable in size like lithium batteries, explains Croguennec. The prototypes are not yet ready for the market, but CEA believes they will be of interest to industry. “We are now in discussion with possible industrial partners, says Croguennec.

- 20. 20 5. SODIUM AS A SUBSTITUE OF LITHIUM Sodium-ion batteries offer an attractive alternative to Li-ion batteries not because they outperform Li-ion batteries, but mainly because of lower costs due to the the nearly unlimited supply of sodium. They are also an attractive alternative in part because unlike their sodium- sulfur battery cousins they can be made in similar sizes to Li-ion batteries. However, the commercial development of sodium-ion batteries has been hampered by the materials used in the negative electrodes. These swell to as much as 400 to 500 percent their original size, leading to mechanical damage and loss of electrical contact Now researchers at Kansas State University have developed a composite, paper-like material made from two 2-dimensional materials—molybdenum disulfide and graphene Nano sheets— that has been shown to overcome this shortcoming. In research published in the journal ACS Nano (“MoS2/Graphene Composite Paper for Sodium- Ion Battery Electrodes”), the 2-D composite material developed proved resistant to the “alloying” reaction that electrode materials typically suffer when in contact with sodium. The research also marks the first time that the flexible paper electrode was used in an anode for sodium-ion battery that operates at room temperature. The Kansas State researchers began their work by looking for better ways to synthesize 2-D materials for rechargeable battery applications. This led them to create the large-area composite paper that they used for negative electrodes. The paper is a composite of acid-treated layered molybdenum disulfide and chemically modified graphene in an interleaved structured. “The interleaved and porous structure of the paper electrode offers smooth channels for sodium to diffuse in and out as the cell is charged and discharged quickly,” said Gurpreet Singh, an assistant professor at Kansas State and one of the authors of the paper, in a press release. “This design also eliminates the polymeric binders and copper current collector foil used in a traditional battery electrode.” While the researchers are looking for opportunities to commercialize their technology for rechargeable battery applications, they also feel that they have contributed to the fundamental understanding of how to synthesize 2-D materials. This method should allow synthesis of gram quantities of few-layer-thick molybdenum disulfide sheets, which is very crucial for applications such as flexible batteries, super capacitors, and polymer composites,”

- 21. 21 6. CONCLUSION The first prototype of a sodium-ion battery has been revealed on 3rd December 2015 by the RS2E, a French network bringing together researchers and industrial actors. This technology, inspired by the lithium-ion batteries already used in portable computers and electric vehicles, could lead to the mass storage of intermittent renewable energy sources. The announcement should cause a stir in the highly competitive world of batteries. French researchers from the RS2E network1 on 3rd December 2015 revealed the first prototype of the sodium-ion "18650" battery, a standard format used notably in portable computers. The information may not sound exciting to non-specialists. Yet scientists across the globe, including the US, Japan, the UK, and Israel, are working on this technology which today is considered the most serious alternative to the lithium-ion batteries that equip practically all portable electronic devices (portable computers, tablets, smartphones...) and are beginning to take a serious look at electric vehicles. The battery used for Tesla cars, for example, is nothing more than the combination of several thousand "18650" lithium-ion batteries. It's an ongoing revolution, "It's a critical piece in the whole puzzle in how we stop burning fossil fuels completely."

- 22. 22 9. REFERENCES 1. http://spectrum.ieee.org/energywise/energy/renewables/a-first-prototype-of-a-sodiumion- rechargeable-battery 2. http://feeds.feedburner.com/IeeeSpectrumEnergywiseBlog 3. http://spectrum.ieee.org/nanoclast/semiconductors/nanotechnology/graphene-composite- offers-critical-fix-for-sodiumion-batteries 4. http://spectrum.ieee.org/tag/Li-ion+batteries/?media=all&offset=0&sortby=desc 5. http://www.energie-rs2e.com/en/news/na-ion-batteries-promising-prototype 6. http://www.nature.com/news/the-rechargeable-revolution-a-better-battery-1.14815 7. https://en.wikipedia.org/wiki/Rechargeable_battery 8. https://en.wikipedia.org/wiki/Battery_(electricity) 9. http://www.radio-electronics.com/info/power-management/battery-technology/lithium-ion- battery-advantages-disadvantages.php 10. http://spectrum.ieee.org/tag/graphene/?media=all&offset=0&sortby=desc