Inverted Pendulum Capstone Project

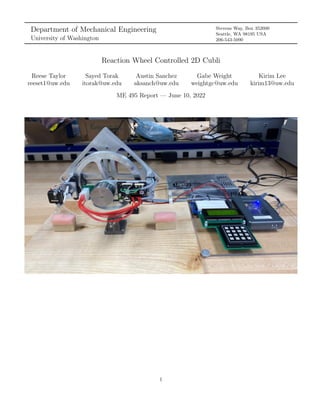

- 1. Department of Mechanical Engineering University of Washington Stevens Way, Box 352600 Seattle, WA 98195 USA 206-543-5090 Reaction Wheel Controlled 2D Cubli Reese Taylor reeset1@uw.edu Sayed Torak itorak@uw.edu Austin Sanchez aksanch@uw.edu Gabe Weight weightgc@uw.edu Kirim Lee kirim13@uw.edu ME 495 Report — June 10, 2022 1

- 2. Contents 1 Executive Summary 5 2 Introduction 5 2.1 Project Definition . . . . . . . . . . . . . . . 5 2.2 Functional Specifications . . . . . . . . . . . 5 2.3 Design approach . . . . . . . . . . . . . . . 6 3 Dynamic Model 6 3.1 Non-Linear Model . . . . . . . . . . . . . . 6 3.2 Linearized Model . . . . . . . . . . . . . . . 7 4 Control Overview 7 4.1 PI Controller . . . . . . . . . . . . . . . . . 8 4.2 Linear Quadratic Integral Controller . . . . 8 5 Simulation Design 8 5.1 Parameter Estimation . . . . . . . . . . . . 9 5.2 Linear vs Non-Linear Model . . . . . . . . . 9 5.3 Jump-up Modeling . . . . . . . . . . . . . . 9 5.4 Current Step Disturbance . . . . . . . . . . 10 5.5 Recovery Angle . . . . . . . . . . . . . . . . 10 6 Prototype Design 11 6.1 Purpose . . . . . . . . . . . . . . . . . . . . 11 6.2 Critical Component Selection . . . . . . . . 11 6.2.1 Motor . . . . . . . . . . . . . . . . . 11 6.2.2 Motor Controller . . . . . . . . . . . 12 6.2.3 Servo . . . . . . . . . . . . . . . . . 12 6.2.4 Collet Prop Adapter . . . . . . . . . 12 6.2.5 IMU . . . . . . . . . . . . . . . . . . 13 6.3 Mechanical Design . . . . . . . . . . . . . . 13 6.3.1 Frame and Motor Cantilever . . . . 13 6.3.2 Flywheel . . . . . . . . . . . . . . . 13 6.3.3 Braking System . . . . . . . . . . . . 14 6.3.4 CAD Model . . . . . . . . . . . . . . 14 6.3.5 Manufacturing . . . . . . . . . . . . 15 6.4 Electrical Design . . . . . . . . . . . . . . . 15 6.4.1 NI myRio-1900 . . . . . . . . . . . . 15 6.4.2 Power Supply . . . . . . . . . . . . . 15 6.4.3 Servo Battery . . . . . . . . . . . . . 15 6.4.4 Encoder . . . . . . . . . . . . . . . . 16 6.5 Computational Design . . . . . . . . . . . . 16 6.5.1 Complementary Filter . . . . . . . . 16 6.5.2 Finite State Machine . . . . . . . . . 17 6.5.3 Off State . . . . . . . . . . . . . . . 18 6.5.4 Speed Up State . . . . . . . . . . . . 18 6.5.5 Brake State . . . . . . . . . . . . . . 18 6.5.6 Brake to Balance State . . . . . . . 18 6.5.7 Balance State . . . . . . . . . . . . . 18 6.6 Final Assembly . . . . . . . . . . . . . . . . 18 7 Testing 18 7.1 IMU vs Encoder . . . . . . . . . . . . . . . 18 7.2 Current Disturbance Response . . . . . . . 19 7.3 Jump Up Response . . . . . . . . . . . . . . 19 7.4 Max Recovery Response . . . . . . . . . . . 20 7.5 Hall Sensor Issue . . . . . . . . . . . . . . . 20 7.6 Comparison to Functional Specifications . . 21 8 Risk and Liability 21 9 Ethical Issues 22 10 Impact on Society 22 11 Impact on the Environment 22 12 Cost and Engineering Economics 22 13 Codes and Standards 23 14 Conclusions 23 14.1 Continued development . . . . . . . . . . . 23 14.2 Final product configuration . . . . . . . . . 23 15 Appendix 25 15.A Simulink Block Diagrams . . . . . . . . . . 25 15.B Manufacturing Drawings . . . . . . . . . . . 29 15.C Wiring Diagram . . . . . . . . . . . . . . . 35 15.D Code . . . . . . . . . . . . . . . . . . . . . . 36 15.D.1 Main Thread Diagram . . . . . . . . 36 15.D.2 IRQ Timer Thread Diagram . . . . 37 15.E Component Specification Sheets . . . . . . . 38 15.E.1 Motor Specifications . . . . . . . . . 38 15.E.2 Motor Controller Specifications . . . 40 2

- 3. List of Figures 1 Cubli Body Free Body Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2 Cubli Wheel Free Body Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3 Nonlinear Cubli Plant Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 4 PI Control Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 5 LQI Control Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6 Comparison of Linear and Nonlinear Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7 Simulated Jump Up Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 8 Simulated current disturbance state variable response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 9 Simulated controller current response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 10 Simulated 2◦ recovery angle response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 11 Maxon EC 45 Flat 70W Brushless DC Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 12 ESCON 36/3 EC Motor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 13 Reefs RC 99 Micro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 14 Collet Prop Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 15 SparkFun LSM9DS1 9DOF IMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 16 Frame CAD Render . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 17 Flywheel CAD Render . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 18 Braking System CAD Render - Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 19 Braking System CAD Render - Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 20 Final Prototype CAD Render . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 21 Final Prototype CAD Render - Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 22 Reaction Wheel Manual CNC Manufacturing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 23 NI myRio-1900 Embedded Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 24 24V Mean Well power supply with 12.5A output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 25 6V 1600mAh RC Servo Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 26 US Digital S2-2000-B Optical Quadrature Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 27 Complementary Filter Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 28 Complementary Filter Bode Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 29 State Transition Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 30 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 31 Encoder vs IMU response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 32 5A current disturbance state variable response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 33 Controller current response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 34 Jump Up to Balancing Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 35 Maximum Recovery Angle Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 36 Hall Sensor Issue - Actual vs Measured Wheel Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 37 Simulated jump up response using recorded wheel data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 38 Full Simulink Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 39 Cubli Plant Simulink Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 40 Simulink Braking System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 41 Simulink PI Speed Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 42 Simulink LQI Balance Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 43 Frame Drawing File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 44 Cantilever Base Drawing File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 45 Cantilever Motor Mount Drawing File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 46 Flywheel Drawing File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 47 Caliper Drawing File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 48 Servo Mount Drawing File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 49 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 50 Main Thread Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 51 Timer IRQ Thread Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 3

- 4. List of Tables 1 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 2 List of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3 List of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4 EC 45 Flat 70W specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 5 ESCON 36/3 EC Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 6 Reefs RC 99 Micro Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 7 Comparison to Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 8 Purchase list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 4

- 5. 1 Executive Summary The three-dimensional Cubli is a reaction wheel con- trolled inverted pendulum system that is capable of balanc- ing itself on an edge or corner as well as jumping itself up to a balance position from flat on a table. This report de- scribes the design process, dynamic modeling, simulation, physical implementation, testing, and results of building a two-dimension prototype of the full Cubli system. It com- pares the results of simulation predictions to that of the physical prototype for several distinct testing procedures, justifies the differences, and discusses areas of improvement for future iterations. A mathematical model of the two-dimensional Cubli dy- namic system was derived from basic equations of motion and physics relationships, and two different linear con- trollers were developed to control the speed of the fly- wheel and to balance the system about a corner based on this model. The controllers were designed to meet the functional specifications outlined at the start of the project. The model and controllers were then simulated using Simulink and a MATLAB script to predict the be- havior of the system during a jump up process, a current disturbance, and an angle initial condition response. Several components of the prototype were manufactured in the ME machine shop out of available aluminum stock material. These components included the frame, flywheel, braking system, and motor cantilever mounts, all of which were designed in Solidworks to maximize strength and min- imize weight, while providing robust connections between critical components. State estimation and feedback was accomplished via a Sparkfun 9Dof Inertial Measurement Unit (IMU) to mea- sure the angle and angular velocity of the cubli body, and Hall sensors built into the flywheel motor to measure the angular velocity of the wheel. The use of an IMU over an encoder for angle measurements allowed the system to stay balanced while the orientation of the supporting base is changed. A complementary filter was implemented to pro- vide a more accurate estimation of the angle of the body by combining data from both the accelerometers and gy- roscopes. The computational control and data collection for the system were accomplished using a program built in C run- ning on a myRIO-1900 embedded computer. This com- puter communicates with the Cubli prototype to estimate the current state via the IMU and Hall sensors, provide current to the motor to speed up the flywheel, and con- trol the orientation of an RC servo to actuate the braking system. The Maxon EC 45 Flat 70W Brushless DC motor was controlled using an ESCON 36/3 EC 4-quadrant mo- tor controller that received analog set values for the desired motor current from the myRIO-1900. The RC servo motor orientation was controlled by adjusting the duty cycle of a Pulse Width Modulated (PWM) signal sent to the servo motor via the myRIO-1900. The C program integrates this state estimation with a fi- nite state machine to control the current sent to the Cubli prototype and the transition between five distinct states including an off state, a speed up state, a brake state, a brake to balance state, and a balancing state. The state machine relies on a separate Timer IRQ thread for timing with a sample rate of 5ms, and the transitions are con- trolled by conditions related to the current state variables, keypad button presses, and timing variables. A final prototype was assembled and several tests were conducted to compare the simulated dynamic behavior to the real world behavior. These tests included jump up to balance tests, a 5A forced current disturbance test, and a maximum recovery angle test, all of which showed close agreement between the simulated and real results. Fur- ther analysis was presented to quantify the difference be- tween the simulation predictions and actual results, and limiting issues were identified and discussed. Final conclu- sions were presented that consider the overall success of the project and recommended directions in which future iterations should proceed. 2 Introduction 2.1 Project Definition The Cubli is a reaction wheel controlled inverted pendu- lum system in the shape of a cube and was first developed by The Institute for Dynamic Systems and Control at ETH Zurich university [1]. The system is capable of transferring momentum stored in the three actively controlled onboard flywheels to the external frame via a mechanical braking system, allowing it to jump up from a face onto an edge or corner and actively balance while rejecting disturbances. The goal of this capstone project is to design and develop a functioning two-dimensional prototype of the full three- dimensional Cubli with only one rotational degree of free- dom. This prototype will be able to jump up from its edge to a corner and actively balance in an unstable position by applying torque to the system’s flywheel. The design will include a mechanical braking system, a PI speed controller to initiate the momentum transferring jump up procedure, and an LQI state feedback controller to actively balance the system on a corner. 2.2 Functional Specifications To aid in a successful project, the following quantitative functional specifications were set as target goals for the final prototype. 5

- 6. Table 1: Functional Specifications Jump up success rate >95 % Maximum recovery angle >7◦ Total mass <1 kg Recovery overshoot <75 % Recovery settling time <3 s Steady state error <1◦ 2.3 Design approach The main considerations for the prototype design were scope and performance. Firstly, the scope of this project was limited to a two-dimensional Cubli system to allow for full completion within the two quarter timeline. This led to prioritizing simplicity where possible, such as in the braking system and flywheel design. With additional time and resources, the final prototype presented in this report can be easily extrapolated to build a full three-dimensional Cubli system without much additional effort, since the de- sign and control for a single rotational degree of freedom has already been achieved. Secondly, the prototype was designed to meet or exceed the functional specifications listed above. One key consid- eration to accomplish this was the sizing of the system and the various components used. The mass of the system was limited to less than one kilogram as to require less angular velocity and torque from the motor to effectively jump up to the corner and correct for disturbances. So the system was sized accordingly to accomplish this. Furthermore, re- liability was a major consideration while developing the final prototype. A jump up success rate greater than 95% was desired, so the design for the final prototype was based mainly on minimizing weight and maximizing reliability. 3 Dynamic Model 3.1 Non-Linear Model The dynamic model of the cubli is based on the deriva- tions presented in [2] and [3]. The equations of motion for the system are derived from the free body diagrams of the cubli body and flywheel shown in Figures 1 and 2 re- spectively, and the parameters used in this derivation are summarized in Table 2. The flywheel is supported directly by the cubli body, which can rotate independently of the flywheel, so it is necessary to specify the angle of the wheel with respect to the angle of the body for this derivation, as shown in Figure 2. The cubli body is subjected to external torques from gravity and the motor as well as damping torques from the motor and pivot bearings. In the reference frame of the Table 2: List of Symbols Symbol Definition Units θb Body angle rad θ̇b Body angular velocity rad s θ̈b Body angular acceleration rad s2 θ̇w Wheel angular velocity rad s θ̈w Wheel angular acceleration rad s2 Bb Body damping N·m·s rad Bw Wheel damping N·m·s rad mb Body mass kg mw Wheel mass kg lw Pivot to wheel center m lb Pivot to center of mass m τm Motor torque N · m Iw Wheel inertia kg · m2 Ib Body inertia kg · m2 KKm Motor Constant Nm A cubli body, the flywheel is subjected to equal and opposite bearing and motor torques as well as an external force of gravity that causes a torque on the body. Figure 1: Cubli Body Free Body Diagram The equation of motion for the cubli body is summarized in (1). Rewriting the torque terms in this equation to be in terms of the body angle, body angular velocity, and wheel angular velocity yields an expression for the angular acceleration of the body, shown in (2). 6

- 7. Figure 2: Cubli Wheel Free Body Diagram (Ib + mwlw 2 )θ̈b = τBb + τg + τBw − τm (1) θ̈b = −Bbθ̇b + (mblb + mwlw)g · sin(θb) + Bwθ̇w − τm Ib + mwlw 2 (2) The equation for the angular acceleration of the flywheel is shown in (3), which directly depends on the angular acceleration of the cubli body due to the flywheel angle dependency on the angle of the body. From (2) and (3), the nonlinear block diagram of the cubli body is derived and shown in Figure 3. This model is set up as a single input multiple output system, since our strategy to control this system during balancing is based on the principles of full state control, thus requiring all state variables of the system as outputs. θ̈w = τm − Bwθ̇w − ¨ θb Iw (3) 3.2 Linearized Model Next, the nonlinear cubli plant model can be linearized about the operating point of θb = 0 using a small angle approximation so that sin(θb) ≈ θb. This removes the sin term from the plant model and allows for the derivation of a state space representation of our model in the form shown in (4) that is used in designing the balancing controller. Here the state vector of this system, x, is composed the angle of the cubli body, θb, the angular velocity of the body, θ̇b, and the angular velocity of the flywheel, θ̇w. The single Figure 3: Nonlinear Cubli Plant Model input to this system, u, is the current delivered to the motor. These expressions are summarized in (5). Finally, the A and B matrices are derived from the cubli plant model and shown in (6) and (7). ẋ = Ax + Bu, y = x (4) x = θb θ̇b θ̇w , u = h im i (5) A = 0 1 0 (mblb+mwlw)g Ib+mwlw 2 − Bb Ib+mwlw 2 Bw Ib+mwlw 2 −(mblb+mwlw)g Ib+mwlw 2 Bb Ib+mwlw 2 − Bw(Ib+Iw+mwlw 2 ) Iw(Ib+mwlw 2) (6) B = 0 − Km Ib+mwlw 2 Km(Ib+Iw+mwlw 2 ) Iw(Ib+mwlw 2) (7) 4 Control Overview Two separate controllers were used to control the Cubli prototype. A proportional-integral (PI) controller was de- veloped to control the angular velocity of the flywheel to a desired speed prior to braking. A linear quadratic integral controller (LQI) was developed to control all three state variables of the system simultaneously to achieve robust balancing performance. For both controllers, the output of the controller is a current sent directly to the motor 7

- 8. controller operating in current controller mode. This al- lows for direct control of the torque applied to the motor in both cases. 4.1 PI Controller Figure 4: PI Control Loop The control loop for the PI speed controller is shown above in Figure 4. Here, the controller is only controlling the angular velocity of the flywheel, θ̇w, and not the other state variables. This controller is the same controller used in Lab 7 of ME 477 at the University of Washington, which is used to control the speed of a DC motor and inertial load. It is based on the continuous PI controller transfer function shown in the left box of Figure 4. This continuous controller transfer function was discretized using Tustin’s method and implemented with a linear difference equation using the function cascade() in the C control code. The final values of the proportional gain and integral gain terms in this transfer function are Kp = 0.25 Ki = 0.125. These were selected through iteration to achieve a fast speed up from 0 RPM to the desired angular ve- locity with minimal overshoot. To further minimize the overshoot of the speed up process, the function sramps() was implemented to create an angular velocity trajectory as the reference input, rather than a large step change. 4.2 Linear Quadratic Integral Controller Figure 5: LQI Control Loop The control loop for the Linear Quadratic Integral (LQI) feedback controller is shown above in Figure 5. This type of controller is similar to a linear quadratic regulator (LQR) that minimizes a cost function J to find the optimal gain matrix, K, given a set of system and power costs. The key difference between these control types is that the LQI con- troller augments the original state space representation of the Cubli system with an additional state z = R t 0 (r−y)dτ, representing the integral of the error signal for the wheel angular velocity, θw. This helps to drive the steady state error of the system to zero if there are errors between the dynamic model and real prototype parameters. The result- ing augmented state space model is shown below in equa- tion 8, where C = [ 0, 0, 1 ]. This type of controller was selected because of its ease of use and implementation and suitability for controlling a system in state space form. ẋ ż = A 0 −C 0 x z + B 0 u + 0 I r (8) Parameters such as performance (e.g. how quickly re- sponse returns to desired state) and effort (e.g. actuation effort) are optimized by the user defined matrices Q and R. These cost matrices were first selected using Bryson’s rule, where (xi)max and (ui)max are the largest reasonable input magnitudes for each state and input variable respec- tively, arranged along the diagonal of each matrix raised to the power of negative 2. These values were then tuned iteratively to achieve the best balancing performance, and the final cost matrices used are shown in 9 and 10. Q = (1)−2 0 0 0 0 (5)−2 0 0 0 0 (2.7)−2 0 0 0 0 (15)−2 (9) R = (0.92)−2 (10) The lqi() function in MATLAB was then used to cal- culate the optimal gain matrix, K, by minimizing the quadratic cost function J in (11) with the defined cost ma- trices Q and R. This gain matrix can be represented by K = [ Kp, Ki ], where the Kp terms represent the LQR gain matrix, and the Ki term represents the gain for the integral state. The optimal gain matrix used in the final prototype is shown in 12. The controller was then imple- mented into the C control code following the control loop in Figure 5. J = Z ∞ 0 ( h xT zT i Q x z # + uT Ru dt (11) K = −144.4222 −19.8352 −0.3611 0.0613 (12) 5 Simulation Design A Simulink model in conjunction with a MATLAB script was developed to predict the dynamic performance of the system and speed/balance controllers used in the final pro- totype. The Simulink model is composed of the Cubli plant 8

- 9. model shown in Figure 3, along with a LQI balance con- troller, PI speed controller, braking system, and logic to control the transitions between initiating the momentum transfer for the jump up and the balancing control. De- tailed images of these various block diagrams can be found in Figures 38 - 42 in Appendix A. 5.1 Parameter Estimation The parameters used in the Simulink model and MAT- LAB script were based on the actual parameters of the final prototype, which were determined in two ways. Firstly, the mass of the body, mb, and the mass of the wheel, mw, were measured directly after full prototype assembly, along with the length from the pivot to the center of the wheel, lw. Since precision bearings were used for both the body and wheel, the respective damping coefficients were very small and assumed to be zero. The remaining parameters were based on Solidworks inertia analysis on the final updated CAD model after adjusting the masses to match what was measured directly. The resulting parameters are shown in Table 3 below, which were used in all simulation results presented in this report. Table 3: List of Parameters Symbol Value Units mw 0.2201 kg lw 0.0955 m Iw 7.221 × 10−4 kg · m2 Bw 0 N·m·s rad mb 0.6123 kg lb 0.0934 m Ib 0.0119 kg · m2 Bb 0 N·m·s rad 5.2 Linear vs Non-Linear Model Figure 6 presents a simulated comparison between the non-linear dynamic model and linearized state space model for an initial condition response of θb = 5◦ . This response has no external torque input from the motor, so the re- sponse is expected to be unstable about θb = 0◦ and stable about θb = 180◦ , which is the exact behavior predicted by the simulation. Comparing the nonlinear initial condition simulation to the linearized approximation reveals that the linear ap- proximation for all state variables is extremely close to the nonlinear behavior up to an angle of θb ≈ 45◦ at t ≈ 0.3 sec. This indicates that the body angle range where the linear model closely approximates the non-linear model is much larger than the target control range for the LQI con- troller. The full range of motion of the final prototype is limited to ±45◦ , and the LQI is only intended to operate over a portion of this range, so the performance of the lin- earized LQI controller should not be severely affected by deviation from the target angle of 0◦ . Figure 6: Comparison of Linear and Nonlinear Systems 5.3 Jump-up Modeling Figure 7: Simulated Jump Up Response The jump-up procedure for the two-dimensional Cubli 9

- 10. is achieved by increasing the velocity of the flywheel to a specified angular speed and rapidly braking the wheel along the outer edge. The braking mechanism is fixed to the body so that upon initiation of the braking, the mo- mentum of the wheel is transferred to the body via the friction force between the brake pads and the wheel sur- face. The Simulink model for the braking system is split into two sections. The first section simulates a supporting force on the body while the system is stationary. In real life, the body would be resting on a table surface prior to initiating the jump up procedure, which limits the body angle to ± 45◦ and prevents the body from moving as the wheel ac- celerates. This behavior is not captured by the differential equations, so to model this, all active accelerations signals were identified and fed back into the system as negative signals. This allows the simulation to accelerate the fly- wheel to the desired speed while maintaining the angle of the body at 45◦ . The next section in the braking model is used to slow down the wheel and transfer momentum to the body. This is achieved by introducing equal and opposite external torques to the body and wheel that represent the torque applied to the wheel and body by a mechanical braking system. To apply the torques appropriately, a group of logic operators were implemented to the Simulink model that check if enough momentum is transferred to the body to lift it off the table. The logic operators then turn off all table support signals and keep the momentum transfer signal active. Once the angle of the body reaches a speci- fied angle, the LQI controller is activated and the system is balanced. This Simulink model was used to accurately compute the minimum angular velocity of the flywheel required for some specified final jump-up angle based on an approx- imate impulse in the braking force applied to the wheel. The approximate impulse function was applied using a step pulse with an extremely small width and large amplitude, to simulate the conditions of a perfect impulse. The model developed was compared against theoretical speeds that were calculated using (13), which is derived from a per- fectly inelastic momentum transfer between the wheel and body [3]. ω2 w = (2 − √ 2) Iw + Ib + mwl2 w I2 w (mblb + mwlw) ge (13) Equation 12 predicts a wheel velocity of θ̇w = -1073.6 RPM to bring the body from an initial angle of 45◦ ex- actly to 0◦ . Our simulation results predict θ̇w ≈ -1090 RPM to bring the body angle from an initial angle of 45◦ to nearly 0◦ , which is extremely close to that of the perfect momentum transfer as well as the actual jump up speed selected for the final prototype of -1080 RPM. The sim- ulation plots of the state variable jump up and balance response are shown in Figure 7. 5.4 Current Step Disturbance Figure 8: Simulated current disturbance state variable re- sponse Figures 8 and 9 presents a simulated current disturbance response. In this, an external current disturbance of 5A is added to the LQI controller current output that is sent to the non-linear Cubli plant model. The simulation then predicts the state variable responses to this current dis- turbance as well as the controller current output, current sent to the motor, and resulting motor torque. Note that the controller current output settles at a value of -5A to exactly cancel with the 5A disturbance, resulting in zero current and zero torque sent to the motor in steady state. 5.5 Recovery Angle Figure 10 shows a simulated 2◦ recovery angle balancing response for each state variable. In this, the initial body angle was set to θb = 2◦ , and the initial body and wheel velocities were set to zero. This imitates the LQI controller response to a 2◦ step change in the reference angle. 10

- 11. Figure 9: Simulated controller current response Figure 10: Simulated 2◦ recovery angle response 6 Prototype Design 6.1 Purpose The main purpose of this prototype was to compare the simulation predictions with a real life prototype to verify both the simulation results and final design. Additionally, the purpose of this prototype was to explore and imple- ment mechatronics concepts in a hands-on context. Creat- ing a physical prototype presented challenges in manufac- turing, assembly, and moving from theoretical concepts to their practical application. This prototype was an oppor- tunity to move beyond the classroom and gain real-world engineering experience. Furthermore, this prototype also served as a proof-of- concept and starting point for development of a full 3D Cubli prototype. The scope of a fully 3D Cubli prototype from scratch is too large to complete in two quarters, so this prototype can be viewed directly as a starting point for developing the full Cubli system. 6.2 Critical Component Selection The final prototype has several critical components that are necessary for proper operation of the two-dimensional Cubli. These include the motor, motor controller, RC servo motor, collet propeller adapter, and inertia measure- ment unit. More detail is provided for each of these com- ponents in the following sections. A useful method used in selecting these final components was examining the choices made by other Cubli projects. Several papers that included detailed lists of which parts were used and why they were selected [1][4][5][2][6], which provided valuable resources to draw ideas from initially. The search was then narrowed to fit the desired functional specifications and ensure compatibility between compo- nents. 6.2.1 Motor The motor for the final prototype is the Maxon EC 45 Flat 70W Brushless DC motor. This motor has built in Hall sensors for commutation and measurement of angular velocity directly, which was a critical aspect for the feed- back control system. An image of the motor and some important specifications are shown below in Figure 11 and Table 4. One difficulty confronted during motor selection is the trade-off between torque and angular velocity. Motors that are geared to have high output torque have low operating speeds and those meant to operate at high speed have low torque output. Further complicating the choice was the need to keep the mass and volume as low as possible for each component. The EC 45 Flat 70W motor has a good combination of high torque and high speeds while minimiz- ing weight, so it was an ideal choice to control the flywheel without adding unnecessary mass or requiring excessive power consumption. 11

- 12. Figure 11: Maxon EC 45 Flat 70W Brushless DC Motor Table 4: EC 45 Flat 70W specifications Parameter Spec Units Nominal Voltage 24 V Nominal speed 4860 rpm Nominal torque 128 mN · m Nominal Current 3.21 A Stall torque 1460 mN · m Torque constant 36.9 mN·m A Speed constant 259 rpm V Mass 141 g Figure 12: ESCON 36/3 EC Motor Controller 6.2.2 Motor Controller The compatible controller to control this motor was the ESCON 36/3 EC 4-quadrant servo controller sourced from Maxon as seen in Figure 12. The driver input for the ES- CON 36/3 EC is an analog voltage input that controls the set value of either the current or desired speed depend- ing on the operating mode, and a digital enable signal to turn the controller on and off. The motor controller can be used as both a speed and current controller with real time monitoring of the actual speed and current values as analog outputs, and comes with a very easy to use setup software making it the optimal choice for this project and motor. The important specifications are listed in Table 5. Table 5: ESCON 36/3 EC Specifications Parameter Spec Unit Nominal Voltage 10 - 36 V Maximum Output Voltage 38.0 V Continuous Output Current 2.7 A Maximum Output Current 9.0 A Weight 36.0 g PWM Frequency 53.6 kHz 6.2.3 Servo The braking system for the final prototype is actuated via the Reefs RC 99 Micro servo motor, which can be seen in Figure 3. The critical characteristic of this servo mo- tor is its very high stall torque and relatively low weight. The rate at which this motor can slow down the flywheel is directly related to the torque provided by the servo mo- tor, so high torque was necessary to ensure reliability. The weight of the Reefs RC 99 Micro was one of the lightest op- tions considered weighing at ≈20 grams. Several additional specifications can be seen detailed in Table 6. The angular position of the servo rotor is controlled by adjusting the duty cycle of a pulse width modulated (PWM) signal sent directly to the motor from the embedded computer. Table 6: Reefs RC 99 Micro Specifications Parameter @ 6.0 V @ 7.4 V @ 8.4 V Unit Nominal Speed 0.110 0.090 0.080 s Nominal Torque 89 99 115 oz · in Stall Current 2.0 2.2 2.4 A 6.2.4 Collet Prop Adapter A challenging aspect of the final prototype design was the connection between the motor shaft and the manufac- tured flywheel. The final solution involves the addition of a propeller collet adapter that simultaneously attaches the motor, flywheel, and frame together. This attachment method was selected so that the concentricity of the mo- tor shaft aligns with the internal diameter of the flywheel, 12

- 13. Figure 13: Reefs RC 99 Micro and so that the forces holding the flywheel on the adapter also clamp the collect onto the motor shaft, providing a ro- bust means of connection. An image of the collet adapter can be seen in Figure 14. The internal diameter of the collet adapter used was slightly larger than the diameter of the motor shaft, so a 1mm thick brass sleeve was in- serted between these components to ensure a tight, highly concentric fit. Figure 14: Collet Prop Adapter 6.2.5 IMU The final Cubli prototype used a SparkFun 9DoF Stick which is a 9 degree of freedom, 0.9”x0.4” IMU that utilizes a LSM9DS1 sensor with an I2C bus. The LSM9DS1 sensor has 3 accelerometers, 3 gyroscopes, and 3 magnetometers which measure 3 degrees of each proper acceleration, an- gular velocity, and magnetic orientation relative to Earth’s magnetic field, respectively. The IMU was mounted onto the frame so that its positive x- and y-axis matched the prototype’s coordinate system. The main reason for using an IMU over an encoder to measure the angle and velocity of the body is to allow the Cubli system to remain balanced regardless of the orienta- tion of the base. With an encoder mounted to the base, the 0◦ desired balance orientation always remains perpendicu- lar to the base. The direction of gravity does not change, so the controller will be unable to balance the system if the angle of the base changes because of this. However, by using an IMU, the 0◦ desired balance orientation is defined with respect to the direction gravity, so adjusting the base angle will have no effect on the system’s ability to balance, which is desirable. Figure 15: SparkFun LSM9DS1 9DOF IMU 6.3 Mechanical Design 6.3.1 Frame and Motor Cantilever The frame was designed with considerations made to minimize mass while ensuring compatible integration be- tween the others parts in the final prototype such as the braking assembly, collet adapter shaft, IMU, and pivot at- tachment. A CAD render of the final design is shown in Figure 16. Additionally, two components that comprise a cantilever attached to the frame were design to hold the motor and motor controller securely to the frame without interfering with the motion of the flywheel. 6.3.2 Flywheel The main factors in designing the flywheel were the bi- axial forces on the motor shaft, weight restrictions, com- patibility with the prop adapter, and enough space for the brakes. The final design shown in Figure 17 accounts for each of these factors and includes high tolerances to mini- mize forces on the motor shaft. Given the maximum radial load on the motor shaft acquired from the specification sheet, the tolerance for the wheel was calculated using ba- sic centrifugal force mechanics based on a range of expected wheel speeds. The maximum eccentricity allowed in the design that would result in a radial force half that of the maximum allowable was determined, which corresponds to a factor of safety of 2. The final product is highly accu- rate and well balanced, minimizing any potential damage 13

- 14. Figure 16: Frame CAD Render to the critical components. Figure 17: Flywheel CAD Render 6.3.3 Braking System Figures 18 and 19 show CAD renders of the final proto- type braking system. This system functions very similarly to sliding caliper braking mechanisms found commonly on cars. The RC servo motor is mounted to the top of the sys- tem via a servo mounting structure attached to the main brake caliper. Actuation of the servo motor turns a plas- tic servo horn extension against a cylindrical Delrin cam, depressing a spring loaded shoulder bolt attached directly to a bicycle brake pad. When this upper brake pad makes contact with the wheel, additional torque provided by the RC servo contributes to lifting the entire caliper assembly off the frame, bringing the bottom brake pad into con- tact with the other side of the flywheel. Additional spring loaded shoulder bolts on the back of the brake caliper aid in releasing the brake pads from the wheel when the servo is disengaged, and also serve to attach the entire braking Figure 18: Braking System CAD Render - Back View system to the frame. Figure 19: Braking System CAD Render - Front View The full mechanism was designed to be lightweight yet sturdy enough to handle the high torque applied by the servo motor. Other considerations were made such as the stiffness of the springs, material of the cylindrical cam, and brake pad material during the designing of this system to facilitate strong and reliable engagement and release of the brake pads from the servo. 6.3.4 CAD Model The final prototype CAD renders are shown in Figures 20 and 21. These photos call out the various mechanical 14

- 15. and electrical components used in the final prototype and show the final assembly configuration. Figure 20: Final Prototype CAD Render Figure 21: Final Prototype CAD Render - Top View 6.3.5 Manufacturing All structural components, including the flywheel, frame, brake caliper/servo mount, and cantilever motor mount were manufactured out of Aluminum stock mate- rial in the ME machine shop using the manual mills, lathes, and the water jet. The remaining components were either externally sourced or acquired through Professor Garbini, Bill Kuykendall, and on campus engineering clubs. Figure 22 shows the reaction wheel being manufactured at the on campus Machine Shop with the manual 2-axis CNC. De- tailed manufacturing drawings can be found in Figures 43 - 48 in Appendix B. 6.4 Electrical Design The following sections outline the major electrical com- ponents of the final prototype other than those already dis- Figure 22: Reaction Wheel Manual CNC Manufacturing cussed. A detailed electrical schematic including all elec- tric connections can be found in Figure 49 in Appendix C. 6.4.1 NI myRio-1900 The embedded computer used for the final prototype is the National Instruments myRIO-1900 embedded com- puter. This is the same computer used for all labs in ME 477, which allowed for easy modification of code developed in that class for this project. The myRIO is used along with a LCD display and numerical keypad connected to connector B. The IMU signals and RC servo PWM signal are connected to connector A, and the AIO of the motor controller is connected to connector C in the final proto- type. 6.4.2 Power Supply The power supply used for the final prototype is the Mean Well SPV-300-24 switching power supply. It pro- vides 24V and up to 12.5A of current output directly to the motor controller, which is higher than the maximum allowable current into the motor controller meaning there is more power available than needed. An image of this power supply is shown in Figure 24. 6.4.3 Servo Battery The power supply chosen to power the RC servo is a 6V, 1600mAh capacity NiMH servo battery made by Dy- namite. The battery provides up to 2A of current output when the servo motor is stalled during braking. This bat- 15

- 16. Figure 23: NI myRio-1900 Embedded Computer Figure 24: 24V Mean Well power supply with 12.5A output tery is connected directly to the RC servo, and the negative terminal is grounded to the DGND pin of connector A on the myRIO-1900. An external charging station is used to recharge the battery after sustained operation. The servo battery used can be seen in Figure 25. Figure 25: 6V 1600mAh RC Servo Battery 6.4.4 Encoder The encoder used in the final prototype to directly mea- sure the angle and speed of the body is the US Digital S2-2000-B Optical Quadrature Encoder. The encoder is only used in the final design to verify the angles and speeds measured by the IMU are accurate to the encoder values after filtering. The complementary filter break frequency was determined using this encoder, which will be discussed in more detail in the Computational design section below. The encoder is connected directly to connector C on the myRIO-1900 via a Quanser terminal board. Figure 26: US Digital S2-2000-B Optical Quadrature En- coder 6.5 Computational Design 6.5.1 Complementary Filter Figure 27: Complementary Filter Block Diagram A complementary filter was implemented to filter the raw IMU angle and velocity measurements, providing a wider frequency range of valid angle measurements.The built in accelerometers of the IMU are used to measure the direction of the gravity vector, allowing for calculation of the angular orientation of the body. However, rapid 16

- 17. accelerations and velocities can introduce error in the di- rection the measured acceleration vector points, skewing the angle results making the accelerometer readings valid only at low frequencies of motion over longer periods of time. The built in rate gyroscopes differ from the accelerome- ters in that they measure the angular velocity of the body directly. This velocity can then be integrated to obtain the angle of the body, which can result in drift in the an- gle over time due to the constant integration, making them only useful at higher frequencies of operation over shorter periods of time. So, the complementary filter combines both the accelerometers and gyroscopes together to filter out the high frequency effects on the accelerometer and low frequency effects on the gyroscopes with a low pass and high pass filter respectively, resulting in clean mea- surements of the body angle over a wider frequency range. A block diagram of the parallel filter combination is shown in Figure 27. Much of the work that goes into creating a complemen- tary filter is in the selection of the filter break frequency. The filters for the two sensors are chosen to have the same break frequency so that the parallel combination of filters has a unity magnitude over all frequencies, as shown in Figure 28. The final break frequency of 1.2566 rad/s was chosen through trial and error with constant examination of how the complementary filtered body angle compared to the body angle measured directly from the encoder. The results of these tests are shown in the Testing section be- low. Both the low pass and high pass filters for this com- plementary filter were discretized using Tustin’s method, converted to a series of second order biquad systems, and implemented in the main C control code using the func- tion cascade() to compute the next value using a linear difference equation. 6.5.2 Finite State Machine To implement the sequence from our prototype’s jump up state, braking state, to the eventual act of balancing the Cubli on its edge, a finite state machine was imple- mented to the C control code utilizing a timer IRQ thread with a 5 ms sample time. Each time through the IRQ assertion loop, the current state variables are measured, and then the current state function is called. The state transitions between each of the five states are triggered by various inputs including the current measurements of the body angle, body velocity, and wheel velocity, button presses on the keypad, and builtin timer variables. These transitions handle the entire functionality of speeding up the flywheel using the PI controller, applying the brake by adjusting the PWM duty cycle, and then balancing the cubli with the LQI controller. Prior to starting the state machine, all necesary initialization for the AIO, DIO, IMU, Figure 28: Complementary Filter Bode Plot Off Speed Up Brake Balance Timer 800 | (|Wheel_Vel| - |Jump_speed|) | 2.42 Timer = 0 Speed_up_on = 0 Speed_up_on != 0 |Wheel_Vel| 5 |Frame_Vel| 5 Go_to_off = 0 PWM Duty Cycle = 63% Timer = 0 Motor Controller = Enabled PI Controller = Enabled Timer 6000 || Go_to_off != 0 Speed_up_on = 0 Timer = 0 Motor Controller = Disabled PI Controller = Disabled PI Controller = Disabled PWM Duty Cycle = 63.5% Brake to Balance Go_to_off != 0 || Frame_Angle -30 || Frame_Angle 30 Speed_up_on = 0 Motor Controller = Disabled LQI Controller = Disabled -2 Frame_Angle 2 LQI Controller = Enabled PWM Duty Cycle = 60% Timer 500 |Frame_Vel| 5 PWM Duty Cycle = 60% Timer = 0 Figure 29: State Transition Diagram and PWM signals is completed. All the corresponding in- put conditions and resulting outputs are discussed in the following sections, and the full transition diagram can be seen in Figure 29. The full C control code along with flow charts for the main and Timer IRQ threads can be found in Appendix D. 17

- 18. 6.5.3 Off State In this state, the Cubli system is stationary and at rest with no current sent to the flywheel. This state was imple- mented as a baseline state from which to initiate the jump up and balancing procedures as well as a safety check if the jump up or balancing process fails. All states except the brake state can transition to the off state, but the off state can only transition to the speed up state if the sys- tem is motionless and a button is pressed on the keypad to initiate the speed up of the flywheel. 6.5.4 Speed Up State In this state, the flywheel is accelerated along a refer- ence velocity profile generated by the function sramps() using the PI speed controller until it reaches a target jump up velocity. This state will then hold this velocity for a few seconds before transitioning to the Brake state. If a problem occurs or the speed of the wheel does not reach the target velocity, it will transition back to the off state. 6.5.5 Brake State In this state, the PI speed controller is disabled and the PWM signal sent to the RC servo motor is adjusted to en- gage the braking system. It then immediately transitions to the brake to balance state. 6.5.6 Brake to Balance State This state handles the transition from the brake state to the fully balancing state. When the target angle to start balancing is reached, this state will release the brake and activate the LQI balance controller before transitioning to the balancing state. If the target angle is not reached, it will transition back to the off state. 6.5.7 Balance State This is the final state in which the cubli remains bal- anced from the active LQI balancing controller. The sys- tem will remain balancing in this state as long as the angle of the body stays within ±30◦ . If this condition is broken or a button on the keypad is pressed to move to the off state, it will transition directly to the off state. 6.6 Final Assembly Figure 6.6 shows the final assembly of our prototype in its balancing state, including all mechanical and electric components. Figure 30: Final Assembly 7 Testing 7.1 IMU vs Encoder Provided the break frequency of 1.2566 rad/sec, the fol- lowing graphs as shown in Figure 31 were examined to compare the encoder to the IMU’s reading of the frame angle and the encoder to the gyroscope’s reading for the frame’s angular velocity. From this, it can be seen that the comparative data almost perfectly overlaps with one another under both slow and rapid movement, indicating the selected break frequency results in highly accurate an- gle measurements from the IMU. This helped justify the decision of the final chosen break frequency as well as the full transition to using the IMU over the encoder for angle and velocity measurements of the body. 18

- 19. Figure 31: Encoder vs IMU response 7.2 Current Disturbance Response A current disturbance of 5A was sent to the motor to test the disturbance response of the system. The main goals of this test were to measure the response of the LQI controller during re-balancing of the system and to see how well the simulated disturbance response matches with the actual motion of the system. This is shown in Figure 32 where the simulated and actual frame angle, frame velocity, and wheel velocity are plotted. For the simulation, a 5 A step in current was simply added onto the input current to the motor via a Sum block. Figure 33 shows the response from the controller due to the disturbance. In all these cases, the simulated re- sponse and actual response match very well omitting the noise generated by the sensors, indicating the simulation is a good model of the physical system. The simulated angle of the frame vs the actual angle of the frame during the disturbance has higher error than the other plots, but this can be attributed mostly to a non-zero balancing position of the physical system. The center of mass location as well as the orientation of the wires on the back of the proto- type contribute to slight deviations in the angle at which the system is fully balanced, so the real system balances about a non-zero angle. The simulation assumes a balanc- ing angle of 0◦ , which is likely why there is error between the simulated and measured angle. Figure 32: 5A current disturbance state variable response Figure 33: Controller current response 7.3 Jump Up Response Figure 34 shows the jump up to balancing response. The frame starts at rest at 45◦ with the wheel accelerated up to a velocity of 1080 RPM. After this position is held, the PWM duty cycle of the RC Servo is set to 63.5% which en- 19

- 20. gages the braking system. The angular momentum trans- fer between the wheel and frame causes the frame to jump up near 0◦ where the LQI controller is activated. For both the frame angle and frame velocity responses, the simulated results and actual results align fairly closely indicating that our dynamic model and system parameters are well known. However, the wheel velocity data received from the motor’s Hall sensors does not match well with the simulation prediction or the actual response of the flywheel taken from slow motion video recordings. This is due to an issue with the Hall sensor explained further in the Hall Sensor Issue section of this report, which is the source of the most of the error between the simulated and real jump up procedures. Figure 34: Jump Up to Balancing Response 7.4 Max Recovery Response To better understand the limits of the motor and con- troller, the maximum recovery angle that the Cubli could recover from was iteratively tested. Starting at small an- gles and moving upwards, a maximum angle of 20 degrees was found to be the highest angle above which the system could no longer recover given the current limits on the motor controller. Figure 35 shows the plotted response for each of the three state variables. In almost all cases there was a higher overshoot for the actual response compared to simulation, which may be related to the non-zero balanc- ing position of the prototype as well as interference from the wires. However, the general shape of the actual data is consistent to the simulation in all three cases. Figure 35: Maximum Recovery Angle Response 7.5 Hall Sensor Issue As is explained in the Jump Up Response section, the wheel velocity data received from the motor’s Hall sensors does not match well with simulation results, nor expected results as seen in slow motion video of the wheel velocity when braking occurs. The expected result when braking occurs is for the wheel velocity to quickly drop to zero as seen with the red line in Figure 36. The blue line shows the measured wheel velocity from the Hall sensors, which appears to get ”stuck” at a nonzero value and before cor- recting upon release of the brakes. This discrepancy likely causes the majority of difference seen in the actual vs sim- ulation response shown in the jump up to balancing pro- cedure in Figure 34, and the cause of this issue remains unknown to our group or the manufacturer of the motor. To check to see if the discrepancy between the simu- lated jump up and actual jump up is mainly due to this Hall sensor issue, the Simulink model was adjusted to in- stead use the actual measured wheel velocity data rather than the simulation prediction. This was to see how the model would predict the body angle and velocity response if the simulated wheel data matched closely to the actual data with the Hall sensor issue. Figure 37 shows this mod- ified response. The frame angle and frame velocity match extremely well to the simulation verifying that the Hall sensor issue contributed to the majority of discrepancy in the jump up response, and further verifying the agreement between the simulation results and measured data. This also verifies that the estimated parameters used in these simulations are likely very accurate to the true values. 20

- 21. Figure 36: Hall Sensor Issue - Actual vs Measured Wheel Velocity Figure 37: Simulated jump up response using recorded wheel data 7.6 Comparison to Functional Specifica- tions The actual functional specifications when compared to the original target parameters resulted in values having met or improved upon the target. One notable improve- ment can be seen with our maximum recovery angle whose actual angle was approximately 20 degrees. When com- pared to its initial 7 degree goal, the actual maximum recovery angle was 185.71% larger, which is mostly due to the much higher current limits sent to the motor con- troller when compared to those of other Cubli projects. Additionally the actual value for percentage overshoot was 57% which by itself is a large overshoot but was found to be a good balance between overshoot and optimizing the setting time so that it was 1.975 seconds. During the de- velopment of the balancing controller, there was a clear tradeoff between the amount of overshoot and the settling time of the system, so the final prototype has a good bal- ance of fast settling and controlled recovery. The rest of our comparison to our initial functional specifications can be found in Table 7. Table 7: Comparison to Functional Specifications Spec Goal Actual Jump up success rate 95% ≈ 99% Disturbance recovery an- gle 7◦ ≈ 20◦ Total mass 1 kg 0.832 kg Recovery overshoot 75% 57% Recovery settling time 3 s 1.975 s Steady state error 1◦ ≈ 0.2◦ 8 Risk and Liability The prototype posed a serious risk of injury to people standing nearby due to the high velocity of the flywheel and rapid acceleration during braking. Any mechanical malfunctions or excessive flywheel speed beyond the de- signed factor of safety could create a dangerous projectile. There are multiple safeguards taken to reduce the risk of injury from the prototype. Firstly, there was a current saturation of ±9A on the motor controller. If this value was exceeded, the controller would turn itself off. Addi- tionally, for early testing, a simple pin wire was used to enable the controller. If anything went wrong this wire could quickly be unplugged to cut all power to the motor. Once the system was determined to work reliably, this re- movable wire was no longer necessary and was replaced with a more permanent connection. Another design deci- sion intended to increase the safety of the prototype was a cutoff condition implemented in the software. If the an- gle of the frame got too far away from the balance point, the finite state machine would enter the off state and cut power to the motor. 21

- 22. In addition to aspects of the design that reduced risk, there were also operation procedures created to further minimize risk. For example, operators doing testing would ensure everyone in the vicinity was aware that the system would be in use. And when no one from the team was on site to monitor the prototype, the system was discon- nected from power and a warning sign was placed at the workstation. 9 Ethical Issues Engineers have a responsibility to be agents of the knowl- edge and skills they possess. For this project, it was paramount to uphold the safety of the team and bystanders prior to the implementation of the final prototype. The system poses the potential to cause injury due to fast mov- ing components, so additional features were added to min- imize these risks and maintain safety above all else. Also, inverted pendulum dynamics are integral in the creation of many popular technology industries such as the Hoverboard industry. This prototype uses many of the same ideas that Hoverboards rely on to actively balance a rider. Some of the ethical implications of the use of Hover- boards include injuries that users can sustain by falling off and fracturing or bruising themselves due to faults in the balancing control system. During a two year study, nearly 27,000 emergency room visits were made due to Hover- board injuries [7]. Special attention should be made in the creation of balancing devices with unstable dynamics and the model should be well understood to promote the safety of nearby users. 10 Impact on Society The biggest impact of this prototype on society is further development and research into optimized control systems for balancing on small scales. The techniques, systems, and models developed for this prototype have the potential to improve safety systems for things that require balance and stability, such as applications like Hoverboards or Segways. Additionally, this prototype develops processes for trans- ferring momentum via control of a reaction wheel, which has direct applications for orbital maneuverability in space systems. Finally, this research, design, and implementa- tion of this project allowed each team member to gain valu- able hands on experience and knowledge that expanded their engineering knowledge and intuition, which will be applied in the future towards other projects and products in society. 11 Impact on the Environment To minimize the environmental footprint of this project, repurposed aluminum was used in manufacturing. Instead of buying new aluminum stock, sufficient material was sourced from the University of Washington machine shop. This was material that might have otherwise gone to waste. While aluminum is highly recyclable, an issue that arises is its high energy requirements. Production of 1 tonne of aluminum requires about 17,000 kWh of electricity [8]. To put that into perspective, the average U.S home uses about 900 kWh per month of energy. Additionally, alu- minum in high concentration is recognized as a toxic agent to freshwater so if not properly recycled can pose a threat to the conservation of aquatic life [9]. Less than 1 kg of aluminum was used in this prototype, so its overall envi- ronmental impact due to metal usage is minimal. When the prototype is no longer needed, the aluminum parts can be disassembled and recycled. Additionally, the number of separate shipments was kept to a minimum. This was accomplished by sourcing mul- tiple components from the same distributors, not placing orders too frequently, and even sourcing some components locally. Reducing the amount of shipments received de- creased the direct carbon footprint from this project. Despite effort to minimize environmental impact, there are still unavoidable external factors for a project like this. This is especially true for the semiconductors required in all of the electronic components. Silicon chip manufactur- ing requires large amounts of energy and water and cre- ates hazardous waste. The electronic components used in this project are high quality and can be reused in future capstone projects or other endeavors at the University of Washington. After their usable lifespan, the components should be disposed of properly. Some of the materials can be recycled but others will create hazardous waste. This is a consequence of any mechatronics project that must be acknowledged. However, the potential for technology to help manage climate change and improve the lives of peo- ple makes it worthwhile to pursue innovation despite the impacts. 12 Cost and Engineering Eco- nomics To minimize the cost of this prototype, many of the com- ponents were manufactured rather than purchased. The purchased components can be found in the table below showing the cost to build final 2D Cubli prototype. The cost was minimized when possible, but some mechanical redesigns throughout the process contributed to sourc- ing components that were not used in the final design, which added to unnecessary expenses. All of the aluminum 22

- 23. stock material used for manufacturing was provided for free through the ME machine shop. Other components such as the myRIO-1900, encoder, power supply, LCD display, and keypad were salvaged from previous projects and labs at the University of Washington, further minimizing the to- tal cost. These components total more than $3,000, so this had a major impact on cost reduction, allowing for sourc- ing of higher quality motor and controller components. Table 8: Purchase list Item Cost Maxon Brushless DC Motor $162.33 ESCON 36/3 EC, 4-Q Controller $213.75 Reefs RC 99micro Servo $59.99 E-flite SR-22T Propeller Adapter $11.98 SparkFun 9DOF Sensor Stick. $17.50 Misc. (wires, bolts, etc.) $270.02 Total $735.57 13 Codes and Standards The relevant codes and standards needed to protect the people in the vicinity of our prototype are those of the motor and motor controller. These standards are already in place on each of these components individually by the manufacturers. This coupled with the high compatibility between the final motor and motor controller used made it so the relevant codes were not a major concern during de- sign and implementation. Communication to the IMU was done with the I2 C serial protocol standard for communi- cation with the myRIO. ASTM standards were considered in the creation and tolerances of the mechanical drawing diagrams used to manufacture many of the components. There are no additional codes or standards on self balanc- ing inverted pendulum systems, so no other considerations were made while designing other than for the functional specification requirements. 14 Conclusions 14.1 Continued development The first step in future development should be to address the aforementioned Hall sensor issue. A simple solution is to add an encoder to the motor to use in tandem with the Hall sensors. This would require minor mechanical and software redesign to integrate into the existing prototype. Fixing this problem would likely result in better agreement between the model and the physical system. It could also make the jump up smoother and more controlled since the controller would have access to more accurate state vari- ables during braking. Additional future work could be done to expand the scope of the project. Given the time constraints of this project, the prototype was a 2D square with one actively controlled degree of freedom. A future team could build off of this work to design a full 3D cube with three ac- tively controlled rotational axes. This would be require some redesign in the mechanical domain in order to make a more compact profile that could fit inside a cube of similar edge length. Namely, the braking system would need to have a slimmer design. In addition to mechani- cal changes, the computational system would need to be expanded to control three flywheels simultaneously. This would require more a complex state space model incorpo- rating 3-dimensional dynamics. 14.2 Final product configuration The final product configuration is shown in Figure 30. All mechanical, electrical, and computational fea- tures were fully implemented and function properly and reliably. There are no major differences between the pre- manufactured design and the final prototype. The software used to control the prototype is reflective of the content covered in the ME 477 Embedded Computing course at the University of Washington. The functional prototype satis- fies all functional specifications for overshoot, settling time, mass, braking reliability, and steady state error. Compar- ison between simulation predictions for the jump up and balance, 5A current disturbance, and maximum recovery angle tests agreed closely with the experimental results. The major discrepancies between the simulation and ac- tual data for the jump up process were attributed mainly to the hall sensor issue giving incorrect wheel velocity data during braking. Overall, all project goals and deliverables were met, and a successful and robust final prototype was developed. References [1] G. Mohanarajah, The cloud, paper planes, and the cube. PhD thesis, ETH Zürich, 2014. [2] B. Kitz, J. Bréhin, M. Sander, N. Skov Vestergaard, and N. Villarmarzon Arruñada, “Cubli: Dynamic con- trol of a reaction wheel inverted pendulum,” bachelor’s thesis, Aalborg University, 2016. [3] M. Gajamohan, M. Merz, I. Thommen, and R. D’Andrea, “The cubli: A cube that can jump up 23

- 24. and balance,” in IEEE International Conference on In- telligent Robots and System, (Vilamoura, Algarve, Por- tugal), IEEE. [4] E. Bjerke and B. Pehrsson, “Development of a nonlin- ear mechatronic cube,” Master’s thesis, Chalmers Uni- versity of Technology, 2016. [5] D. Posada, “Design and control of an inertia wheel cube 2d prototype with a reaction wheel,” bachelor’s thesis, Universidad de los Andes, 2017. [6] P. Brevik, “Two-axis reaction wheel inverted pendu- lum,” Master’s thesis, Norwegian University of Science and Technology, 2017. [7] T. Korioth, “Hoverboard injuries send thousands of kids to emergency rooms,” 2018. [8] B. Bushman-Roisin and B. Cremonini, Data, Statistics, and Useful Numbers for Environmental Sustainability. Elsevier, 2021. [9] R. BO, E. TD, and S. M, “Environmental effects of aluminum,” 1990. 24

- 25. 15 Appendix 15.A Simulink Block Diagrams Figure 38: Full Simulink Block Diagram 25

- 26. Figure 39: Cubli Plant Simulink Model 26

- 27. Figure 40: Simulink Braking System Figure 41: Simulink PI Speed Controller 27

- 28. Figure 42: Simulink LQI Balance Controller 28

- 29. 15.B Manufacturing Drawings Figure 43: Frame Drawing File 29

- 30. Figure 44: Cantilever Base Drawing File 30

- 31. Figure 45: Cantilever Motor Mount Drawing File 31

- 32. Figure 46: Flywheel Drawing File 32

- 33. Figure 47: Caliper Drawing File 33

- 34. Figure 48: Servo Mount Drawing File 34

- 35. 15.C Wiring Diagram Figure 49: Wiring Diagram 35

- 36. 15.D Code 15.D.1 Main Thread Diagram Start Open mRIO myRIO Opened? End Initialize AIO, DIO, PWM, IMU, Sramps Register Timer IRQ Thread Register Successful? Create Timer thread Call ctable2 table editor function End and Unregister Timer IRQ Thread Close myRIO session No No Yes Yes Figure 50: Main Thread Flowchart 36

- 37. 15.D.2 IRQ Timer Thread Diagram While IRQ Thread is ready to run Poll sensors for current state variables Complementary Filter IRQ Asserted Start Save Data To Buffers Call Current State Function Write Saved Buffers to .mat file Write zero voltage to motor Disable Motor Controller End Wait for assertion Writes timeout value Writes Boolean Value Yes No Figure 51: Timer IRQ Thread Flowchart 37

- 38. 15.E Component Specification Sheets 15.E.1 Motor Specifications 38

- 39. maxon EC motor 267 267 maxon flat motor 397172 402685 402686 402687 411812 411814 411815 411816 24 30 36 48 6110 6230 6330 3440 234 194 166 48.1 4860 4990 5080 2540 128 112 108 134 3.21 2.36 1.93 0.936 1460 1170 1100 915 39.5 25.8 20.7 6.97 85 84 83 84 0.608 1.16 1.74 6.89 0.463 0.691 0.966 5.85 36.9 45.1 53.3 131 259 212 179 72.7 4.26 5.44 5.85 3.82 8.07 10.3 11.1 7.24 181 181 181 181 M 1:2 397172 70 W 25 50 75 125 150 1.0 2.0 3.0 4.0 3.56 K/W 4.1 K/W 29.6 s 178 s -40 ... +100°C +125°C 4.0 N 0 mm 4.0 N 0.14 mm 3.8 N 50 N 1000 N 21 N 8 3 141 g ESCON 36/3 EC 445 ESCON Mod. 50/4 EC-S 445 ESCON Module 50/5 445 ESCON 50/5 447 DEC Module 50/5 449 EPOS4 50/5 453 EPOS4 Mod./Comp. 50/5 453 EPOS2 P 24/5 464 MAXPOS 50/5 468 May 2018 edition / subject to change maxon EC motor Stock program Standard program Special program (on request) Part Numbers Specifications Operating Range Comments n [rpm] Continuous operation In observation of above listed thermal resistance (lines 17 and 18) the maximum permissible wind- ing temperature will be reached during continuous operation at 25°C ambient. = Thermal limit. Short term operation The motor may be briefly overloaded (recurring). Assigned power rating maxon Modular System Overview on page 28–36 EC 45 flat ∅42.8 mm, brushless, 70 Watt Motor Data (provisional) Values at nominal voltage 1 Nominal voltage V 2 No load speed rpm 3 No load current mA 4 Nominal speed rpm 5 Nominal torque (max. continuous torque) mNm 6 Nominal current (max. continuous current) A 7 Stall torque1 mNm 8 Stall current A 9 Max. efficiency % Characteristics 10 Terminal resistance phase to phase W 11 Terminal inductance phase to phase mH 12 Torque constant mNm / A 13 Speed constant rpm / V 14 Speed / torque gradient rpm / mNm 15 Mechanical time constant ms 16 Rotor inertia gcm2 Thermal data 17 Thermal resistance housing-ambient 18 Thermal resistance winding-housing 19 Thermal time constant winding 20 Thermal time constant motor 21 Ambient temperature 22 Max. winding temperature Mechanical data (preloaded ball bearings) 23 Max. speed 10 000 rpm 24 Axial play at axial load 25 Radial play preloaded 26 Max. axial load (dynamic) 27 Max. force for press fits (static) (static, shaft supported) 28 Max. radial load, 5 mm from flange Other specifications 29 Number of pole pairs 30 Number of phases 31 Weight of motor Values listed in the table are nominal. Connection V1 V2 (AWG 24 ) Pin 1 Hall sensor 1* Motor winding 1 Pin 2 Hall sensor 2* Motor winding 2 Pin 3 VHall 4.5 ... 18 VDC Motor winding 3 Pin 4 Motor winding 3 VHall 4.5 ... 18 VDC Pin 5 Hall sensor 3* GND Pin 6 GND Hall sensor 1* Pin 7 Motor winding 1 Hall sensor 2* Pin 8 Motor winding 2 Hall sensor 3* *Internal pull-up (7 … 13 kW) on Vhall Wiring diagram for Hall sensors see p. 43 Cable for V1 Connection cable Universal, L = 500 mm 339380 Connection cable to EPOS, L = 500 mm 354045 V2 21 Ambient temperature -20 ... +100°C 1 Calculation does not include saturation effect (p. 53/164) Recommended Electronics: Notes Page 32 V1 with Hall sensors V2 with Hall sensors and cables Planetary Gearhead ∅42 mm 3 - 15 Nm Page 356 Spur Gearhead ∅45 mm 0.5 - 2.0 Nm Page 358 Connector: 8 pole 2.5 mm z.B. WCON WF2512-HXX Encoder MILE 256 - 2048 CPT, 2 channels Page 402

- 40. 15.E.2 Motor Controller Specifications 40

- 41. Specifications Technical Data maxon motor control ESCON Servo Controller Document ID: rel7132 2-7 ESCON 36/3 EC Hardware Reference Edition: November 2018 © 2018 maxon motor. Subject to change without prior notice. 2 Specifications 2.1 Technical Data ESCON 36/3 EC (414533) Electrical Rating Nominal operating voltage +VCC 10…36 VDC Absolute operating voltage +VCC min / +VCC max 8 VDC / 38 VDC Output voltage (max.) 0.98 x +VCC Output current Icont / Imax (4 s) 2.7 A / 9 A Pulse Width Modulation frequency 53.6 kHz Sampling rate PI current controller 53.6 kHz Sampling rate PI speed controller 5.36 kHz Max. efficiency 95% Max. speed 150'000 rpm (1 pole pair) Built-in motor chokes 3 x 47 μH; 2.7 A Inputs Outputs Analog Input 1 Analog Input 2 resolution 12-bit; −10…+10 V; differential Analog Output 1 Analog Output 2 resolution 12-bit; −4…+4 V; referenced to GND Digital Input 1 Digital Input 2 +2.4…+36 VDC (Ri = 38.5 kΩ) Digital Input/Output 3 Digital Input/Output 4 +2.4…+36 VDC (Ri = 38.5 kΩ) / max. 36 VDC (IL 500 mA) Hall sensor signals H1, H2, H3 Voltage Outputs Auxiliary output voltage +5 VDC (IL ≤80 mA) Hall sensor supply voltage +5 VDC (IL ≤30 mA) Potentiometer Potentiometer P1 (on board) 210°; linear Motor Connections EC motor Motor winding 1, Motor winding 2, Motor winding 3 Interface USB 2.0 / USB 3.0 full speed Status Indicators Operation green LED Error red LED Physical Weight approx. 36 g Dimensions (L x W x H) 55 x 40 x 19.8 mm Mounting holes for M2.5 screws (max. tightening torque 0.16 Nm)

- 42. Specifications Technical Data maxon motor control 2-8 Document ID: rel7132 ESCON Servo Controller Edition: November 2018 ESCON 36/3 EC Hardware Reference © 2018 maxon motor. Subject to change without prior notice. Table 2-4 Technical Data Figure 2-1 Derating Output Current Table 2-5 Limitations Environmental Conditions Temperature Operation −30…+45 °C Extended range *1) +45…+78 °C Derating Figure 2-1 Storage −40…+85 °C Altitude *2) Operation 0…6’000 m MSL Extended range *1) 6’000…10’000 m MSL Derating Figure 2-1 Humidity 5…90% (condensation not permitted) *1) Operation within the extended range (temperature and altitude) is permitted. However, a respective derating (declina- tion of output current Icont) as to the stated values will apply. *2) Operating altitude in meters above Mean Sea Level, MSL. ESCON 36/3 EC (414533) Protection functionality Switch-off threshold Recovery threshold Undervoltage 7.2 V 7.4 V Overvoltage 43 V 41 V Overcurrent 13.5 A — Thermal overload 95 °C 85 °C

- 43. Setup Connections maxon motor control 3-14 Document ID: rel7132 ESCON Servo Controller Edition: November 2018 ESCON 36/3 EC Hardware Reference © 2018 maxon motor. Subject to change without prior notice. 3.4 Connections The actual connection will depend on the overall configuration of your drive system and the type of motor you will be using. Some connections must be established in a given way, while for motor/Hall sen- sor (J2/J2A alternative plug-in locations can be chosen from. Follow the description in given order and choose the connection scheme that suits the respective com- ponents you are using. For corresponding wiring diagrams chapter “4 Wiring” on page 4-31. 3.4.1 Power (J1) Figure 3-3 Power Socket J1 Table 3-8 Power Socket J1 – Pin Assignment Cabling Table 3-9 Power Cable J1 Head A Prefab Cable Head B Signal Description Pin Color Pin 1 white − Power_GND Ground of supply voltage 2 brown + +VCC Power supply voltage (+10…+36 VDC) Power Cable (403957) Cable cross-section 2 x 0.34 mm2 Length 1.5 m Head A Suitable plugs Suitable contacts Hirose DF3-2S-2C Hirose DF3-22SC… Head B Cable end sleeves 0.34 mm2

- 44. Setup Connections maxon motor control 3-16 Document ID: rel7132 ESCON Servo Controller Edition: November 2018 ESCON 36/3 EC Hardware Reference © 2018 maxon motor. Subject to change without prior notice. SOCKET J2A Figure 3-5 Motor / Hall Sensor Socket J2A Table 3-12 Motor / Hall Sensor Socket J2A – Pin Assignment Cabling Table 3-13 Motor / Hall Sensor Socket J2A – Specification Accessories J2 Head A Prefab Cable Head B Signal Description Pin Color Pin 1 Motor winding 1 EC motor: Winding 1 2 Motor winding 2 EC motor: Winding 2 3 Motor winding 3 EC motor: Winding 3 4 +5 VDC Hall sensor supply voltage (+5 VDC; IL ≤30 mA) 5 GND Ground 6 Hall sensor 1 Hall sensor 1 input 7 Hall sensor 2 Hall sensor 2 input 8 Hall sensor 3 Hall sensor 3 input Specification / Accessories Type Spring-loaded contacts, 8 poles, pitch 2.5 mm Suitable cables Rigid 0.14…0.5 mm2, AWG 26-20 / wire stripping length 6 mm Flexible 0.2…0.5 mm2, AWG 24-20 / wire stripping length 6 mm 0.25…0.5 mm2, AWG 24-20 / wire stripping length 6 mm, cable end sleeves Suitable tools Miniature screwdriver, size “00”