A.M. McLeod - CV 2015

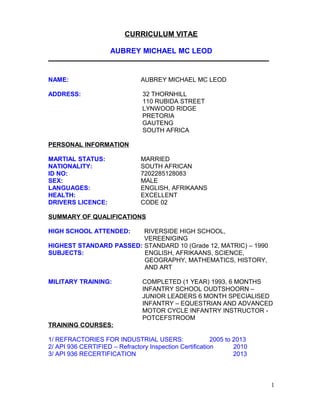

- 1. CURRICULUM VITAE AUBREY MICHAEL MC LEOD _____________________________________________________________________ NAME: AUBREY MICHAEL MC LEOD ADDRESS: 32 THORNHILL 110 RUBIDA STREET LYNWOOD RIDGE PRETORIA GAUTENG SOUTH AFRICA PERSONAL INFORMATION MARTIAL STATUS: MARRIED NATIONALITY: SOUTH AFRICAN ID NO: 7202285128083 SEX: MALE LANGUAGES: ENGLISH, AFRIKAANS HEALTH: EXCELLENT DRIVERS LICENCE: CODE 02 SUMMARY OF QUALIFICATIONS HIGH SCHOOL ATTENDED: RIVERSIDE HIGH SCHOOL, VEREENIGING HIGHEST STANDARD PASSED: STANDARD 10 (Grade 12, MATRIC) – 1990 SUBJECTS: ENGLISH, AFRIKAANS, SCIENCE, GEOGRAPHY, MATHEMATICS, HISTORY, AND ART MILITARY TRAINING: COMPLETED (1 YEAR) 1993, 6 MONTHS INFANTRY SCHOOL OUDTSHOORN – JUNIOR LEADERS 6 MONTH SPECIALISED INFANTRY – EQUESTRIAN AND ADVANCED MOTOR CYCLE INFANTRY INSTRUCTOR - POTCEFSTROOM TRAINING COURSES: 1/ REFRACTORIES FOR INDUSTRIAL USERS: 2005 to 2013 2/ API 936 CERTIFIED – Refractory Inspection Certification 2010 3/ API 936 RECERTIFICATION 2013 1

- 2. WORK HISTORY IN REFRACTORY INDUSTRY – C&H GROUP Mr. Aubrey McLeod has gained extensive site experience in the Refinery; GTL & Petrochem Industry during Maintenance Shutdowns; T&I and New Projects. This has been attributed to his excellent communication skills on site. REFRACTORY INSPECTION AND QA AT CHB 2004 – current SUMMARY MY WORK EXPERIENCE ON SHUTDOWNS; T & I; MAINTINACE SUTDOWNS; FAILURE ANALYSIS AND NEW PROJECTS INCLUDES EQUIPMENTS AND LININGS NAMELY: BRICK / CASTABLE AND RAMMED LININGS ZINCOR ROASTER RE-LINES PRIMARY REFORMERS SECONDARY REFORMERS HYDROGEN REFORMERS SRU COMBUSTION CHAMBERS WASTE HEAT BOILERS INCINERATORS KILNS AUXILLARY HEATERS BOILERS MCC STACKS ETHYLENE CRACKING FURNACES CASTABLE / GUNNED LININGS (INCLUDING RAMMED LININGS) HEATERS / FURNACES BOILERS FCCU GASIFIERS FLEXICOKERS CATALYST COOLER INCINERATORS REACTORS DRUMS SALPHUR PLANT / PIT STACKS TRANSFER LINES CERAMIC FIBRE & CALCIUM SILICATE BOARD HEATERS FURNACES 2

- 3. INCINERATORS ETHYLENE CRACKING FURNACES RECENT WORK EXPERIENCE IN: MAJOR REFINERIES & THE PETROCHEMICAL [NDUSTRY 2014 1) SPRC (CHEVRON) THAILAND 2014 FERUARY TO APRIL RFCCU RE- VAMP PROJECT AND T&I THIRD PARTY INSPECTORATE & QUALITY ASSURANCE. INSPECTION & RECOMMENDED REPAIRS; REPORTS AND DATA PACK. EQUIPMENT INCLUDES: COMPLETE RFCCU-REGENERATOR AND REACTOR INCLUDING EXTERNAL CYCLONES. REVIEW CONTRACTORS QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT AND MATERIALS & INSTALLATION TECHNIQUES I.E. GUNITE; CASTING & HAND PACK OF ABRASION RESISTANT MATERIALS. MATERIAL REVIEW AND TESTING AS PER API936, ASTM STANDARDS & CLIENT SPECIFICATION. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 2) SHELL PULAU BUKOM F10000 & F20000 ETHYLENE CRACKING FURNACE RE-LINE. SINGAPORE REFRACTORY SPECIALIST, QA / QC FOR INDUSTRIAL SERVICES. EQUIPMENT INCLUDES: 2X ETHYLENE CRACKING FURNACES - RADIANT 3

- 4. SECTION; ARCH ROOF; PLENUM & RADIANT FLOOR. REVIEW CONTRACTORS QCP, METHOD STATEMENT AND ITP. DESIGN REVIEW & IMPROVEMENTS DAILY STAUS REPORTS & MEETINGS. INSTALLATION TECHNIQUES ADVISOR MATERIAL REVIEW AND TESTING AS PER API936, ASTM STANDARDS & CLIENT SPECIFICATION. RECORDS AND REPORTS FOR DATA PACK. FINAL APPROVAL AND HANDOVER. 3) ENGEN (PETRONAS) JULY / AUGUST 2014 FCCU (COMBO) SHUTDOWN DURBAN THIRD PARTY INSPECTORATE & QUALITY ASSURANCE. INSPECTION & RECOMMENDED REPAIRS REPORTS. EQUIPMENT INCLUDES: REACTOR CYCLONES; REACTOR SIDE WALLS; REACTOR CROSSOVER; ORIFICE CHAMBERS - REGENERATOR SIDE WALLS. REVIEW CONTRACTORS QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT AND MATERIALS & INSTALLATION TECHNIQUES I.E. GUNITE; CASTING & HAND PACK OF ABRASION RESISTANT MATERIALS. MATERIAL REVIEW AND TESTING AS PER API936, ASTM STANDARDS & CLIENT SPECIFICATION. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 4

- 5. 1) SASOL 2 & 3 SEPTEMBER / OCTOBER 2014 SHUTDOWN THIRD PARTY INSPECTION AND QUALITY ASSURANCE TO SASOL. INSPECTION REPORTS AND RECOMMENDED REPAIRS ON ALL EQUIPMENT, REVIEW OF QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT & MATERIALS & TECHNIQUES I.E. GUNITE; CASTING, BRICKWORK AND HAND PACK OF ABRASION RESISTANT MATERIALS. EQUIPMENTS INCLUDE: WHB / TUBE SHEETS, PRIMARY AND SECONDARY REFORMERS. RELINING OF CRUDE AND GAS FURNACES, COAL BUNKERS (50) SRU AND SULPHUR PIT, ROTARY KILN. MATERIAL REVIEW AND TESTING AS PER API936 & ASTM STANDARDS. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 2013 1) ENGEN (PETRONAS) 2013 JANUARY / FEBRUARY FCCU SHUTDOWN THIRD PARTY INSPECTORATE & QUALITY ASSURANCE. INSPECTION & RECOMMENDED REPAIRS REPORTS. EQUIPMENT INCLUDES: REACTOR CYCLONES – THIN LAYER ABRASION RESISTANT LINING / HEXMESH. REACTOR SIDE WALLS – MED. WEIGHT INSULATING CASTABLE (RESCO). REACTOR CROSSOVER – ABRASION RESISTANT CASTABLE –HAND PACK ON TO “V” ANCHORS. ORIFICE CHAMBERS - THIN LAYER ABRASION RESISTANT LINING / HEXMESH (RESCO). REGENERATOR SIDE WALLS - MED. WEIGHT INSULATING CASTABLE (RESCO) VISBREAKER – 25m2 GUNITE 5

- 6. REPAIRS TO CONVECTION ROOF – MED. WEIGHT GUNING GRADE CASTABLE (RESCO). REVIEW CONTRACTORS QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT AND MATERIALS & INSTALLATION TECHNIQUES I.E. GUNITE; CASTING & HAND PACK OF ABRASION RESISTANT MATERIALS. MATERIAL REVIEW AND TESTING AS PER API936, ASTM STANDARDS & CLIENT SPECIFICATION. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 2) EXONNMOBILE (ESSO) 2013 FEBUARY / APRIL FLEXICOKER TA. ROTTERDAM THIRD PARTY INSPECTORATE, QA / QC FOR QUARTIS REFRACTORY INSPECTION. INSPECTION & RECOMMENDED REPAIRS REPORTS. EQUIPMENT INCLUDES: GASIFIER – PARTIAL WRECK & RE-LINE (270m2 )– PUMP CAST. TRANSFER LINES – BORESCOPIC INSPECTIONS & REPAIRS. SLIDE VALVE RE-LINE – ABR MATERIAL / HEXMESH. HEATERS, REACTION FURNACE, CYCLONE RE-LINE & REPLACEMENT. REACTOR, FRACTIONATOR COLUMN. REVIEW CONTRACTORS QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT AND MATERIALS & INSTALLATION TECHNIQUES I.E. GUNITE; CASTING, PUMP CAST & HAND PACK OF ABRASION RESISTANT MATERIALS. MATERIAL REVIEW AND TESTING AS PER API936, ASTM STANDARDS & CLIENT SPECIFICATION. 6

- 7. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 3) SAPREF (SHELL GLOBAL) 2013 MAY / JUNE FCCU SHUTDOWN THIRD PARTY INSPECTORATE & QUALITY ASSURANCE. INSPECTION & RECOMMENDED REPAIRS REPORTS. EQUIPMENT INCLUDES: REACTOR CYCLONES – THIN LAYER ABRASION RESISTANT LINING / HEXMESH (ACTCHEM). REACTOR SIDE WALLS – MED. WEIGHT INSULATING CASTABLE (CALDERYS). C O DUCT – GUNITE ON TO “V” ANCHORS. COMPLETE WRECK AND RE=-LINE OF SECONDARY CYCLONES ACTCHEM / HEXMESH. PARTIAL WRECK & RE-INE OF PRIMARY CYCLONES. AIA APPOINTED BY FLOUR FOR SHELL GLOBAL AS THIRD PARTY INSPECTORATE: FABRICATION OF NEW FORTH STAGE SEPERATOR- HEXMESH /ACTCHEM LININGS. FABRICATION OF NEW CRITICAL FLOW NOZZLES – HEXMESH / ACTCHEM LININGS. REVIEW CONTRACTORS QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT AND MATERIALS & INSTALLATION TECHNIQUES I.E. GUNITE; CASTING & HAND PACK OF ABRASION RESISTANT MATERIALS. MATERIAL REVIEW AND TESTING AS PER API936, ASTM STANDARDS & CLIENT SPECIFICATION. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. 7

- 8. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 4) EXONNMOBILE (ESSO) 2013 AUGUST / OCTOBER FCCU BELGUIM SHUTDOWN. THIRD PARTY INSPECTORATE, QA / QC FOR QUARTIS REFRACTORY INSPECTION. INSPECTION & RECOMMENDED REPAIRS REPORTS. EQUIPMENT INCLUDES: FCCU – LINING ASSESMENTS & RECOMMMENDED REPAIRS. TRANSFER LINES – BORESCOPIC INSPECTIONS & REPAIRS. SLIDE VALVE RE-LINE – ABR. MATERIAL / HEXMESH. HEATERS, REACTION FURNACE, DRUMS & REPLACEMENT. REACTOR, FRACTIONATOR COLUMN. REVIEW CONTRACTORS QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT AND MATERIALS & INSTALLATION TECHNIQUES I.E. GUNITE; CASTING, PUMP CAST & HAND PACK OF ABRASION RESISTANT MATERIALS. MATERIAL REVIEW AND TESTING AS PER API936, ASTM STANDARDS & CLIENT SPECIFICATION. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 8

- 9. 2012 1) SASOL 2 & 3 2013 SHUTDOWN – THIRD PARTY INSPECTION AND QUALITY ASSURANCE TO SASOL. INSPECTION REPORTS AND RECOMMENDED REPAIRS ON ALL EQUIPMENT, REVIEW OF QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR PERSONEEL, EQUIPMENT & MATERIALS & TECHNIQUES I.E. GUNITE; CASTING, BRICKWORK AND HAND PACK OF ABRASION RESISTANT MATERIALS. EQUIPMENTS INCLUDE: WHB / TUBE SHEETS, PRIMARY AND SECONDARY REFORMERS. RELINING OF CRUDE AND GAS FURNACES, COAL BUNKERS (50) SRU AND SULPHUR PIT, ROTARY KILN. MATERIAL REVIEW AND TESTING AS PER API936 & ASTM STANDARDS. REVIEW & APPROVAL OF DRY OUT CONTRACTORS PROCEDURES. WITNESS REPAIRS & POST CURE INSPECTION & RELEASE FOR SERVICE. SELECTION OF TEST SAMPLES & REGISTER. REVIEW RESULTS OF TESTING. COMPILATION OF SHUTDOWN DATA PACK FOR CLIENT. 1) NATREF (SASOL) 2012 CDU SHUTDOWN – THIRD PARTY INSPECTION AND QUALITY ASSURANCE. INSPECTION REPORTS AND RECOMMENDED REPAIRS ON ALL EQUIPMENT, REVIEW OF QCP AND ITP. PRE-QUALIFICATION OF CONTRACTOR I.E. GUNITE; INSULATION AND ABRASION RESISTANT MATERIALS. WHB, SECONDARY AND PRIMARY REFORMERS. RELINING OF NEW CDU FURNACES (2), FCCU. RE-LINE OF FLARE TIP. 2) SASOL 1 B6990 CRYSALLIC PITCH INCINERATOR – THIRD PARTY INSPECTORATE AND QUALITY ASSURANCE. RECOMMENDED REPAIRS. WITNESS DEMOLITION AND INSTALLATION. REVIEW OF QCP, ITP, TEST CERTIFICATES, PRODUCTION SAMPLE TESTING AND DRY OUT. 9

- 10. APPROVAL AS PER CLIENT SPECIFICATION. COMPLETION OF DATA PACK. 3) PETROSA (GTL) 2010 REFORMING SHUTDOWN - THIRD PARTY INSPECTION AND QUALITY ASSURANCE. INSPECTION REPORTS AND RECOMMENDED REPAIRS ON PRIMARY AND SECONDARY FURNACES; WHB INCLUDING TUBESHEET RE-LINE; SUPER HEATER; DUCTING AND TRANSFER LINE. REVIEW OF QCP / ITP; TEST CERTS. PRE-QUALIFICATION OF CONTRACTOR. CLIENT PRESENTATION IN DAILY MEETINGS. DAILY STATUS REPORTS. REVIEW OF PRODUCTION TEST SAMPLE RESULTS. COMPLETION OF DATA PACK. 4) ADGAS (UAE) OFFSHORE. PLANT 7 2012 APRIL / MAY SHUTDOWN THIRD PARTY INSPECTION & QA FOR RE-LINE OF THE SULPHUR PLANT INCLUDING SULPHUR PIT AND INCINERATOR STACK, MAIN COMBUSTION CHAMBER. REVIEW OF QCP / ITP; TEST CERTS AND DRY OUT CURVE. PRE-QUALIFICATION OF CONTRACTOR (CASTING AND GUNITE). ORDER OF MATERIALS. DAILY STATUS REPORTS AND MEETINGS. REVIEW OF PRODUCTION TEST SAMPLE RESULTS. COMPLETION OF DATA PACK. SUPERVISION DURING COMMISSIONING OF THE PLANT. 5) ADGAS (UAE) OFFSHORE. OCTOBER / NOVEMBER - THIRD PARTY INSPECTION AND QUALITY ASSURANCE. INSPECTION REPORTS AND RECOMMENDED REPAIRS ON WHB; HEATERS; MAIN COMBUSTION CHAMBER TUBESHEET RE-LINE. PRE- QUALIFICATION OF CONTRACTOR (CASTING AND GUNITE). ORDER OF MATERIALS. DAILY STATUS REPORTS AND MEETINGS. REVIEW OF PRODUCTION TEST SAMPLE RESULTS. COMPLETION OF DATA PACK. SUPERVISION DURING COMMISSIONING OF THE PLANT. 10

- 11. 2011 1) SHAW (HOUSTON TEXAS) FEBRUARY TO MAY - THIRD PARTY INSPECTOR AND SHAW REPRESENTATIVE FOR TAKREER PROJECT (RUWAIS). FABRICATION OF NEW RISER SEPARATION SYSTEM (RSS) AT HYUNDAI HEAVY INDUSTRIES (ULSAN, S. KOREA). REVIEW ITP; IAL; QCP; TEST CERTS AND DRAWINGS FOR APPROVAL. INSPECTION OF HEXMESH LINING DURING INSTALLATION. CO- ORDINATE DAILY MEETINGS. PRE- QUALIFICATION OF CONTRACTOR AND MATERIALS (RESCO AA-22). WITNESS ALL TESTING OF SAMPLES AT INDEPENDENT LABORATORY (KTR) SOUTH KOREA ADVICE ON INSTALLATION TECHNIQUES AND TRAINING. SUPERVISE CONTRACTORS DAILY ACTIVITIES. STATUS REPORTS. COMPLETION OF DATA PACK. AUGUST TO DECEMBER - THIRD PARTY INSPECTOR AND SHAW REPRESENTATIVE FOR TAKREER PROJECT (RUWAIS). FABRICATION OF CATALYST COOLER AT DOOSAN ENGINEERING (CHANGWON, S. KOREA). REVIEW ITP; IAL; QCP; TEST CERTS. AND DRAWINGS FOR APPROVAL. INSPECTION OF VARIOUS ANCHOR SYSTEMS DURING INSTALLATION. CO- ORDINATE DAILY MEETINGS. PRE- QUALIFICATION OF CONTRACTOR AND MATERIALS (GUNITE, VIBRO-CASTING AND PLACEMENT OF ABRASION RESISTANT MATERIALS (RESSCO). WITNESS ALL TESTING OF SAMPLES AT INDEPENDENT LABORATORY (KTR). ADVICE ON INSTALLATION TECHNIQUES AND TRAINING. SUPERVISE CONTRACTORS DAILY ACTIVITIES. DAILY STATUS REPORTS AND COMMUNICATIONS BETWEEN CLIENT, CONTRACTOR AND OTHER INSPECTION 11

- 12. DISCIPLINES. DRY OUT PROCEDURES. COMPLETION OF DATA PACK. 2010 1) ENGEN (PETRONAS) SAFOR SHUTDOWN – THIRD PARTY QA, RECOMMENDED REPAIRS, LEAD INSPECTOR FOR STATUS MEETINGS. COMPLETE RELINE OF 2 CRUDE HEATERS, PARTIAL RE-LINE OF ONE CRUDE HEAT. COMPLETION OF DATA PACK FCCU SHUTDOWN – THIRD PARTY INSPECTOR AND QA, QC AND ADVICE FOR HEXMESH AND ABRASION RESISTANT INSTALLATIONS (ACTCHEM), RECOMMENDED REPAIRS FOR COMPLETE FCCU INCLUDING: REGENERATOR CYCLONES, RISER LINE, AIR GRID, FIRED HEATERS, BOILERS, OFF TAKE DUCTS, GOGGLE VALVE, CO BOILERS. COMPLETION OF DATA PACK. 2) CHEVRON (CALTEX) FCCU SHUTDOWN – THIRD PARTY INSPECTOR AND QA, QC AND ADVICE FOR HEXMESH AND ABRASION RESISTANT INSTALLATIONS (ACTCHEM), RECOMMENDED REPAIRS FOR COMPLETE FCCU INCLUDING REGENERATOR CYCLONES, RISER LINE, AIR GRID, FIRED HEATERS, BOILERS, OFF TAKE DUCTS, GOGGLE VALVE, CO BOILERS, COMMON STACK. COMPLETION OF DATA PACK. SRU COMPLETE RELINE THIRD PARTY INSPECTOR AND QA, MATERIAL QC, PRE-QUALIFICATION OF CONTRACTOR, QCP APPROVAL, SUPERVISION OF CONTRACTOR DAILY ACTIVITIES. COMPLETION OF DATA PACK. 2) SASOL 2 AND 3 PETROCHEMICAL PLANT SHUTDOWN THIRD PARTY INSPECTOR AND QUALITY ASSURANCE, PROJECT COORDINATOR, QUALITY CONTROL AND ADVICE, REPAIRS RECOMMENDATION REFORMERS, BOILERS, SYNTHOL, HEATERS, 12

- 13. COMBUSTION CHAMBERS, REACTOR UNITS, ASH CHANNELS, TRANSFER LINES AND ROTARY KILN. COMPLETION OF DATA PACK. 3) PETRO SA (GTL) 2010 REFORMING SHUTDOWN THIRD PARTY INSPECTION AND . QUALITY ASSURANCE RECOMMENDED REPAIRS ON FURNACES, WHB (CAST BRICK SHAPES), PRIMARY AND SECONDARY REFORMERS. 4) ENGEN (PETRONAS) THIRD PARTY INSPECTOR FOR COMPLETE RE-LINE OF PRE-HEATER FURNACE (GUNITE). APPROVAL OF MATERIALS. PRE-QUALIFICATION OF CONTRACTOR AND APPROVAL OF QCP. COMPLETION AND HAND OVER OF DATA PACK. 2009 1) CHEVRON (CALTEX) FCCU SHUTDOWN – THIRD PARTY QA, QC AND ADVISOR FOR HEXMESH AND ABRASION RESISTANT INSTALLATIONS (ACTCHEM). REVIEW AND APPROVAL OF CONTRACTOR QCP AND INSTALLATION METHODOLOGY, ISSUE OF RECOMMENDED REPAIRS REPORTS FOR ALL EQUIPMENT’S OF FCCU INCLUDING REGENERATOR CYCLONES, RISER LINE, AIR GRID, FIRED HEATERS, BOILERS, OFF TAKE DUCTS, GOGGLE VALVE, CO BOILERS, COMMON STACK. COMPLETION OF SHUTDOWN DATA PACK FOR CLIENT; REVIEW OF TEST SAMPLE RESULTS. 2) NATREF (SASOL) 2009 HYDROCRACKER SHUTDOWN THIRD PARTY INSPECTION AND QUALITY ASSURANCE. RECOMMENDED REPAIRS ON FURNACES, WHB, SECONDARY AND PRIMARY REFORMERS. RELINING OF PRIMARY REFORMER USING CERAMIC FIBRE 13

- 14. MODULES. RELINE OF SRU INCL. TUBE SHEET. 3) SAPREF (SHELL GLOBAL) FCCU RE-VAMP OF THE NEW REACTOR, HOT AND COLD WALL RISER LINE, PRIMARY AND SECONDARY CYCLONES, DIP LEGS AND AIR GRID – THIRD PARTY QA AND PROJECT COORDINATOR. INSPECTION OF HEXMESH INSTALLATIONS AND ABRASION RESISTANT LININGS (ACTCHEM) IN ACCORDANCE TO SHELL SPECIFICATIONS. 4) SASOL 2 SCC SHUTDOWN – THIRD PARTY INSPECTION, QUALITY ASSURANCE, ADVICE AND QUALITY CONTROL. NEW RISER LINE PROJECT – PROJECT COORDINATOR. THIRD PARTY INSPECTION AND QUALITY ASSURANCE. INSTALLATION ADVICE ON RESCO SUREFLOW 17E AND 88 SELF FLOW ABRASION RESISTANT MATERIALS. 30M RISER PIPE CAST IN 10M SECTIONAL POURS. FIELD JOINT REFRACTORY INS 5) PETRO SA (GTL) 2009 SHUTDOWN THIRD PARTY INSPECTION AND QUALITY ASSURANCE. RECOMMENDED REPAIRS ON FURNACES, WHB, SECONDARY AND PRIMARY REFORMERS. 6) QP REFINERY (QATAR) THIRD PARTY INSPECTION AND RECOMMENDED REPAIRS TO REFINERY 1 AND REFINERY 2 HEATERS. 2008 1) RASGAS (QATAR) REFRACTORY INSPECTION AND 2008 SHUTDOWN, RECOMMENDED REPAIRS ON HEATERS, TURBINE STACK, INCINERATORS AND COMBUSTION CHAMBERS AND SRU. WRECK AND 14

- 15. RE-LINE OF INCINERATOR BRICK LINING, INCLUDING AIR WALL. 2) PETRO SA (GTL) THIRD PARTY INSPECTION AND QUALITY ASSURANCE. HEXMESH AND ACTCHEM INSTALLATION. INSPECTION AND RECOMMENDED REPAIRS FOR WASTE HEAT BOILERS, PRIMARY REFORMERS AND SECONDARY REFORMERS. 3) NATREF (SASOL) FCCU SHUTDOWN. THIRD PARTY QA ON HEXMESH INSTALLATION AND REFRACTORY IN REACTOR, REGEN, RISER AND ORIFICE CHAMBER. COMPILATION OF DATA PACK 4) SAPREF (SHELL GLOBAL) THIRD PARTY QA ON FCCU FABRICATION FOR REVAMP: FABRICATION OF NEW CYCLONES FOR REGEN. FABRICATION OF NEW COLD WALL VIBRO-CAST RISER LINE.FABRICATION OF NEW HOT WALL (HEX) RISER LINE. 5) EXXARO (STEEL INDUSTRY) RE-LINE OF ROASTERS 1&2 – THIRD PARTY QA 6) ENGEN (PETRONAS) INSPECTION, FAILURE ANALYSIS AND REPORT ON SULPHUR RECOVERY UNIT. 7) NPC (CEMENT INDUSTRY) ROTARY KILN AND COOLER, EMERGENCY SHUTDOWN AND FAILURE ANALYSIS INSPECTION AND REPORT. RECOMMENDED REPAIRS AND THIRD PARTY QA. 15

- 16. 2007 1) SINOPEC (CHINA) QA INSPECTOR DURING INSTALLATION. TRAINING PERSONNEL ON INSTALLATION OF THE ABRASION RESISTANT REFRACTORY LINING. DRAFTING RECOMMENDED INSTALLATION PROCEDURES. 2) RASGAS (QATAR) REFRACTORY INSPECTION AND RECOMMENDATIONS, REPAIRS ON HEATERS, INCINERATORS, SRU AND COMBUSTION CHAMBERS. 3) PETRO SA (GTL) INSPECTION AND RECOMMENDED REPAIRS FOR WASTE HEAT BOILERS, PRIMARY REFORMERS AND SECONDARY REFORMERS. REVIEW OF IR (INFRARED) AND RECOMMENDATION REPORTS. 4) SASOL 1 FAILURE ANALYSIS ON REGENERATOR LINING AND THIRD PARTY INSPECTION AND QA FOR REPAIRS. 5) NATREF (SASOL) THIRD PARTY INSPECTION AND RECOMMENDED REPAIRS FOR HEATERS AND INCINERATORS DURING SHUTDOWN.IR SCANNING. 6) SASOL 1 THIRD PARTY INSPECTION ON METHANE REFORMER AND WASTE HEAT BOILER. 7) METSEP (IR SCAN) INFRA-RED SCANNING OF REACTOR 2 AND RECOMMENDATION REPORT. 8) ADGAS (UAE) THIRD PARTY INSPECTION & QA FOR RELINE OF THE SULPHUR PLANT, MAIN COMBUSTION CHAMBER. SUPERVISION DURING COMMISSIONING OF THE PLANT. IR VIDEO ANALYSIS 16

- 17. 2006 1) ADGAS (UAE) THIRD PARTY INSPECTION & QA FOR RELINE OF THE SULPHUR PLANT, MAIN COMBUSTION CHAMBER. SUPERVISION DURING COMMISSIONING OF THE PLANT. 2) SAPREF (SHELL GLOBAL) FCCU – 3RD PARTY QA FOR REPAIRS TO +100M2 OF HEXMESH IN FCCU REACTOR. INSPECTION OF FITTING OF HEXMESH AND QA DURING THE INSTALLATION OF ACTCHEM. ON SITE PRE-QUALIFICATION OF INSTALLATION PERSONNEL. 3) SASOL THIRD PARTY INSPECTION ON METHANE REFORMER AND WASTE HEAT BOILER 4) PETRO SA (GTL) THIRD PARTY INSPECTION AND QUALITY ASSURANCE. HEXMESH AND ACTCHEM INSTALLATION. INSPECTION AND RECOMMENDED REPAIRS FOR WASTE HEAT BOILERS, PRIMARY REFORMERS AND SECONDARY REFORMERS. 5) QP REFINERY (QATAR) THIRD PARTY INSPECTION AND RECOMMENDED REPAIRS FOR THE FCCU, HEATERS AND WASTE HEAT BOILERS DURING THE UNPLANNED SHUTDOWN. 6) RASGAS (QATAR GTL) REFRACTORY INSPECTION AND QA. RECOMMENDED REPAIRS ON HEATERS, INCINERATORS AND COMBUSTION CHAMBERS. PROJECT CO-ORDINATION. ADVISE AND ORDERING OF MATERIALS. LEAD DAILY MEETINGS. APPROVAL OF QCP. PRE- QUALIFICATION OF CONTRACTOR AND MATERIALS. STATUS REPORTS. COMPLETION OF DATA PACK. 17

- 18. 2005 1) PETROSA (GTL) THIRD PARTY INSPECTIONS AND QA ON WASTE HEAT BOILERS, METHANE REFORMERS. THIRD PARTY INSPECTION AND QUALITY ASSURANCE. HEXMESH AND ACTCHEM INSTALLATION. 2) ADGAS (UAE) THIRD PARTY INSPECTION & QA FOR RELINE OF SRU MCC. 3) SAPREF (SHELL GLOBAL) INSPECTION AND RECOMMENDED REPAIR PROCEDURES FOR FIRED HEATERS. 4) SASOL 1 THIRD PARTY INSPECTION ON METHANE REFORMER AND WASTE HEAT BOILER 2004 1) SAPREF (SHELL GLOBAL) CDU SHUTDOWN AND REVAMP THIRD PARTY INSPECTION AND QUALITY ASSURANCE IN FURNANCES, SULPHUR RECOVERY UNIT AND WASTE HEATR BOILERS ON-SITE TESTING OF PRODUCTION SAMPLES. 2) NATREF (SASOL) FCCU SHUTDOWN. THIRD PARTY QA ON HEXMESH AND ACTCHEM INSTALLATION 3) PETROSA (GTL) THIRD PARTY INSPECTION AND QUALITY ASSURANCE ON WASTE HEAT BOILER REPAIRS AND METHANE REFORMERS. THIRD PARTY QA ON HEXMESH AND ACTCHEM INSTALLATION IN SYNTHOL. 18

- 19. 4) ADGAS (UAE) THIRD PARTY INSPECTION & QA FOR RELINE OF THE SUPLHUR PLANT, MAIN COMBUSTION CHAMBER 5) PETROSA (GTL) THIRD PARTY QA ON SYNTHOL PLANT FOR HEXMESH & REFRACTORY MAINTENANCE REPAIRS. ONSITE TESTING OF SAMPLES WITH MOBILE LABORATORY. 5) HEURTY PETROCHEM THIRD PARTY QA ON TWO NEW CERAMIC FIBRE HEATERS FOR SASOL Should you require further information please contact our offices at : Tel: +27 16 971 2678 / e-mail:chlabs@mweb.co.za or dcbiggs@mweb.co.za 19