California Wool Mill Feasibility Study

- 1. The California Wool Mill: A New Model for Making Fabric

- 2. The Study Team: • Amber Bieg, MBA – Green-Ideas • Dustin Kahn - Fibershed • Rebecca Burgess - Fibershed Funders: • Lorene Arey, Clara Fund • Don Shaffer, at Rudolf Steiner Foundation • John Wick and Peggy Rathmann • Heather Blackie, Blackie Foundation Research Support: • Key Contributors: Lydia Wendt, Marcia de Longe, Jenny Kassan, and Erin Axlerod • Processing: Dan Rhodes of Gaston College, Amaury De La Forcade of NSC, Lynda Grose of California College of the Arts • Supply: Mike Corn of Roswell Wool, California sheepherds and rangers, farmers, shearers and everyone who answered the surveys • Demand: Designers and apparel brands who answered our survey and interviews

- 3. Outline Introduction Supply Analysis/Inventory Demand Analysis Mill Operations and Site Feasibility Mill Financial and Environmental Performance Economic and Community Impact Analysis Conclusion and Recommendations

- 4. INTRODUCTION

- 6. Synthetic garment fibers are the greatest source of plastic pollution on the world’s beaches (NY Times, 2011)

- 7. 20% of global water pollution is from textile dyeing and treatment (World Bank, 2013

- 8. Child labor and forced labor still are problems in the textile supply chain

- 9. Culture of Sheepherding at Risk

- 10. It’s time for a new model . . . Sheep to Chic

- 12. SUPPLY ANALYSIS

- 13. CA Wool Inventory Quantity Total inventory = 1.4 million lbs. of wool, 44.8% of total CA supply

- 14. CA Wool Inventory Quality 79% is fine enough to wear next to skin!

- 15. CA Wool Inventory Color and Usability Breeding needs to be optimized for fineness and color diversity!

- 16. Flock Size and Wool Quality

- 17. DEMAND ANALYSIS

- 18. Consumers want local and domestic 0 100 200 300 400 500 600 700 Support ag and local economy Perceived Safety and Quality Env. Benefits from farms Reduce fossil fuel use Willingness to pay 25% or more price markup for local Source: Iowa State University, Allan Ortiz 2010 In a NY Times Survey, 68% of respondents preferred products made in the U.S. and were willing to pay more!

- 19. Re-shoring is already happening are employing far fewer workers. (Clifford, 2013).” This advantage is particularly true in the production of wool knits. The cost of raw material is the same, the labor is minimal and the cost of transportation is less, making a more cost efficient product. Bayard W inthrop, the founder of the sweatshirt and clothing company American Giant said: “ Now it is cheaper to shop in the United States,” (Clifford, 2013). Figure 19: How much it costs to make a hoodie. Representative wholesale costs, according to Bayard W inthrop, the founder of American Giant. Source: New York Times, September 19, 2013. How much it costs to make a hoodie. Representative wholesale costs, according to Bayard Winthrop, the founder of American Giant. Source: New York Times, September 19, 2013. “LA’s Single brand can turn around 800 silk print dresses for Neiman Marcus and Lord & Taylor in as little as two weeks, now that 90% of its production is done at home with only a $1/dress price difference, with quality control and timing much better (Los Angeles Times, 2011).”

- 20. Recommended Products 4.5 oz. knit fabric, 60" wide on bolt 8 oz. knit fabric, 60" wide on bolt 12 oz. knit fabric, 60" wide on bolt 4.5 oz. seamless garment 8 oz. seamless garment 20 oz. knit fabric, 60" wide on bolt

- 21. Addressable Market Consumers LOHAS Brands Total Addressable market = $14.7 billion $331 billion US Apparel Market $290 billion LOHAS market $36 billion in CA textile/apparel market $14.7 billion CA brands textile market

- 22. Potential Customer Research “Made in California taps into our original roots. As a company based out of Berkeley and tied very closely with California culture, we believe that Made in California will mean a lot to our customers.” – KRYSTLE MOODY, THE NORTH FACE “Localized production is important. I would love to see regional textiles from Northern California.” – SCOTT LEONARD, INDIGENOUS “We pride ourselves on quality: quality of fiber, yarn and fabric. We source from the best of the best. We would be interested in sourcing from California, especially if we can lower our footprint, without lowering our environmental and quality standards.” – RYAN THOMPSON, PATAGONIA

- 23. Customer Needs “We are interested in sourcing from California for quicker turn-around time.” – JUICY COUTURE

- 24. MILL OPERATIONS AND SITE FEASIBILITY

- 25. The Greasy Wool to Garment Process Wool Aggregation Cutting and Sewing Wool fabric milling

- 27. Areas of Research and Development Enzymatic Superwash Natural Dyes Bast Fiber Blends Colored Wool Blends

- 28. Production Volumes Yield Post-ScouringBased on current wool supply and growth projections BATCH SIZES

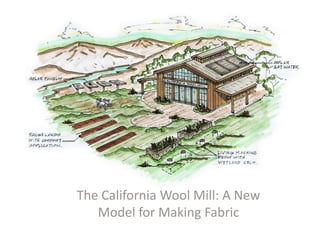

- 29. Conceptual Design 85,000 square feet, 97% renewable energy, 100% water recycling Facility

- 30. Closed Loop Milling System

- 31. Water Use

- 34. Heat and Cooling Systems Solar Hot Water Heater Geothermal Heat Pump System

- 35. Waste

- 36. MILL FINANCIAL AND ENVIRONMENTAL PERFORMANCE

- 37. Profitability

- 38. Profitability

- 39. Revenue

- 40. Capital Costs and Expenses 86%

- 41. Per Unit Margin

- 43. Life Cycle Analysis Scenarios • 1. Conventional realistic • 2. Conventional optimistic • 3. Fibershed Soil Neutral • 4. Fibershed geothermal mix • 5. Fibershed geothermal • 5. Fibershed solar • 7. Fibershed Compost and Solar

- 45. Multi-Stakeholder Coop & DPO The nonprofit Fibershed Ranchers (producers) Designers and artisans (consumers) The mill workers Mission-aligned supporters (investors)

- 46. Initial Funding Start-up financing from foundations and impact investors USDA grant funding Co-op member equity contributions Direct public offering (DPO) of preferred stock

- 47. What are the next steps? Prototype & Test Market Viability Mill Business Plan Design and Build Mill

- 48. Step #1 Prototype • Use existing US milling facilities to produce fabric using California wool. Test Market Viability • Sell the prototype fabric.

- 49. Thank You For questions or comments, please email Amber Bieg amber (at) californiacloth.com

- 50. BIBLIOGRAPHY

Hinweis der Redaktion

- And everyone else who has answered our questions or supported this project!

- Textiles have evolved as part of human culture - Prior to the industrial revolution, they were handmade, from natural fiber and dyes, coming from the soil of a particular bio-region and community . . . And when the fabric reached the end of its life, it would be returned to the soil. Synthetic textiles changed this relationship.

- The New York Times published an article citing a report from Environment Science and Technology saying that synthetic garment fibers, released through laundry-based sewage run-off, account for the greatest share of plastic pollutants on the world’s beaches (Browne, 2011)

- Textile manufacturing is the second largest source of fresh water pollution (from dyeing and treatment), accounting for 20% of global water contamination (The World Bank, 2013).

- While the garment industry is starting to get attention with the recent incidences in Bangladesh, the textile supply chain still has a number of instances of human rights abuses, slavery and child labor.

- Due to price competition from synthetic fibers we have been losing the culture of shepherding. This is an important way of life that has co-evolved with humanity, stewarding the land and providing us food and fiber.

- It’s time for a new model . . . One that is connected to the earth, humans and culture.

- The visionary R. Buckminster (Bucky) Fuller once said: “To change something, build a new model that makes the existing model obsolete.” The aim of this project is to build a new model for textile manufacturing; one that is based on the resources of a particular bioregion and accounts for the entire life cycle of a garment. This model is a soil-to-soil model, where all the impacts from the raw materials to processing and waste are accounted for.

- The next question is . . . Can we build this model?

- The Study Team inventoried 1.408 millionpounds (44.8% of the total wool in California) ofraw fiber for its quality (micron count) and quantity.The farmers that produce this particular supplyeither responded to the Fibershed survey or they sell wool through Roswell Wool auctions. This supply is immediately available for purchase. California produces 3.1 million pounds of wool annually, making it the largest wool producing state in the U.S. (National Agricultural Statistics Board, NASS, 2013). Like the rest of the country, California has seen a steep decline in sheep populations since 1945, however, interestingly this decline California has slowed since 2000 (National Research Council, 2008). This slowing of the decline can be attributed to an increase in demand for lamb from the fast- growing Asian immigrant population, moving here for the tech boom (Fagan, 2013), as well as resurgence in textile manufacturing in the US, with the increased popularity of ‘American Made.’

- To our surprise, we discovered that 79% is fine enough to wear next to skin – or suitable for fine garment production.

- Key feasibility study team members consulted with Industry experts in North and South Carolina to assess how to best use California Wool This chart shows the hypothetical use compared to the California Wool Supply.

- The distribution of fine fiber and larger flocks is focused on the central valley.

- “In a survey of 1,300 affluent shoppers conducted by Unity Marketing, the U.S. ranked highest on the scale measuring quality in luxury goods manufacturing. It topped both Italy and France, home to such brands as Louis Vuitton, Prada and Hermes (Los Angeles Times, 2011).” Perhaps the most compelling evidence of this trend is a 2013 New York Times survey, showing that 68 percent of respondents preferred products made in the United States, even if they cost more, and 63 percent believed they were of higher quality (New York Times , 2013)

- Manufacturing in California is becoming very attractive to apparel brands because of speed, quality control and more recently cost-effectiveness. Because of this, some large apparel companies (large = $30 million plus) are finding that they can produce in California with only a minimal price difference passed on to shoppers. “LA’s Single brand can turn around 800 silk print dresses for Neiman Marcus and Lord & Taylor in as little as two weeks, now that 90% of its production is done at home with only a $1/dress price difference,

- These are the recommended products based on wool supply and consumer demand. However, we also think that there is a great opportunity to start developing seamless garments for direct-to-consumer products.

- The addressable market for the sale of fabric in California is 14.7 billion. We expect to capture one tenth of a percent in the first few years . . . Growing to 4.7% by year 10.

- We interviewed a number of brands who all gave us positive feedback. Essentially, if we can produce high-quality fabric at close to market price ($15-$20/yard), brands will buy it.

- This is key in developing new prototypes. The next step in assessing the real demand for a CA Wool Mill is prototyping cloth.

- The raw materials for the California Wool Mill are: wool, detergent, enzymes, and water. Energy is used to convert these materials into a commercially viable product: fabric.

- These are examples of some of the equipment. The equipment is estimated to cost more than $13,000,000 in the first year.

- Currently 75% of machine-washable wool is treated by the Chlorine-Hercosett shrink-proofing process, (Textilchemie Dr. Petry GMBH, 2012) This method guarantees the felt-free superwash standard, and works on the basis of chlorination and subsequent coating of the fiber material with a polyaminoamide. The process uses large amounts of water as well as dangerous substances and leads to significant pollution of wastewater with organic halogen compounds (AOX) (Comyns, 1999). We are looking at developing both a natural dye system that can be scaled and an enzymatic superwash system that doesn’t create water pollution.

- The California Wool Mill will process 1.39 million pounds of greasy wool in year one. This raw material quantity is based upon the 2013 Wool Inventory. Conservative growth projections (15% average annual growth rate) predict that this will grow to approximately 2.4 million pounds of wool by year five and 4.8 million pounds of wool by year ten. While initially the superfine batch is small, the batch sizes will change as California sheep farmers optimize breeding for wool fineness. As the Mill production increases and breeding is optimized, the batch sizes become more evenly distributed.

- The California Wool Mill facility will be designed as a state-of-the-art facility optimized for environmental performance and longevity. The building design should aim to meet the The Living Building ChallengeTM certification criteria, demonstrating this facility as one of the greenest manufacturing plants in the world. The idea is to build an example of what modern manufacturing system can be. This building should also serve as a classroom and education facility to teach other leaders how a sustainable manufacturing system works.

- The wastewater coming off the scouring line feeds into a centrifuge where the lanolin is extracted, and then the dirty water goes to the water recycling system, where 100% of the water is recycled and sent back through the building. The toilets and drains feed into the same system. The energy system is looped into this as well. The water is pre-heated with solar hot water heaters on the roof of the building, and then sent to the scouring line. The heat from the machines is re-captured and used as part of this system. The humidity from the scouring line will be pumped into the spinning room where it will be controlled to maintain the perfect conditions for worsted yarn. These systems are built into the pro forma, so that they can be analyzed for environmental and financial performance.

- According to the California Department of Water Resources, “Climate change is having a profound impact on California water resources, as evidenced by changes in snowpack, sea level, and river flows. These changes are expected to continue in the future and more of our precipitation will likely fall as rain instead of snow. This potential change in weather patterns will exacerbate flood risks and add additional challenges for water supply reliability.” (California Dept. of Water Resources)As wool scouring is a very water-intensive operation, requiring approximately 1.2 gallons of water for every pound of greasy wool, the Mill will have to be very conservative in water use. The mill not only has scouring water requirements, but human and irrigation water needs as well. The chart below illustrates the water needs by use. Only a small portion of the water needs are potable needs. Most of the water required for scouring, toilets and irrigation could be greywater. This allows for the possibility of water recycling and rainwater catchment to meet a significant portion of the total Mill water demand.The four locations considered for this study all have a Mediterranean climate distinguished by warm, wet winters and dry, hot summers. Firebaugh receives an average of only 11 inches of rain per year. Marysville and Woodland both receive an average of 21 inches of rain per year. Santa Rosa receives the most rain of the four locations, with an average of 30 inches per year. (Western Regional Climate Center)

- Rather than take an averaged 3 million gallons of water per year for wool scouring and other facility needs from either municipal sources or well water at the mill location, the Study Team proposes to use a technology called the Living Machine® that will constantly clean the water from scouring, toilets and faucets in the building, and recycle 100% of it back into the plumbing for non-potable reuse in the scouring line, toilets, and irrigation.

- The energy requirements for the Mill steadily increase as Mill production increases. Machine use is the primary energy consumer for the Mill, with scouring as the secondary energy consumer. While costly, the PV system can provide 100% of the Mill’s electricity needs. The total cost of Solar PV in the first year is $1.5 million, assuming 100% of the Mill’s electricity needs are met by solar. Additional panels can be added as demand for energy increases with Mill production. In comparing the cost solar versus grid, the variable is set at 50% solar and 50% grid. Overa ten-year time frame and using the current price of solar photovoltaic panels and grid electricity, solar pv outperforms on cost and on greenhouse gas emissions, making a clear choice for the use of 100% solar.

- Most off the energy required for scouring is for heating water. 70% of the scouring energy required can be met by solar hot water, the rest must come from a boiler heated by natural gas. Most solar water-heating systems for buildings have two main parts: a solar collector and a storage tank. The most common collector used in solar hot water systems is the flat-plate collector. Solar water heaters use the sun to heat water, which is then held in the storage tank ready for use, with a conventional system providing additional heating as necessary (Meline Engineering). An economical solar water heating polymer array and storage system by Fafco would cost $48,500 and provide $11,000 dollars in operating savings per year.A geothermal heat pump, also known as a ground source heat pump or Geoexchange, taps the energy stored in the earth to provide energy-efficient heating, cooling and hot water for buildings. The technology uses the constant temperature of the earth as the medium of heat exchange instead of outside air temperature. This heat dump could preheat some of the water going to the scouring line, and the remainder would be re-injected into an injection well. The cooling efficiency would be good, and better than with a chiller/tower, although permitting may be a challenge. A rough estimate of cost is $650,000.00 for this type of system.According to Meline Engineering’s report to Fibershed, a heat recovery unit can simultaneously remove heat from return space cooling water and transfer this heat to incoming scouring line water. This transfer is at very low operating costs (two loads, heating and cooling, essentially served by one compressor circuit).

- The Study Team has identified that an aerobic windrow compost pile process using thermophilic microorganisms is the most appropriate method to turn the waste into rich,nutritious compost to be distributed to Fibershedranchers. Will Bakx, owner of the locally-ownedcompany, Sonoma Compost, and acclaimed soilscientist, and Jeff Creque, Mill Operations Supervisorfor McEvoy Ranch, who received a PhD in rangelandecology, have advised the Study Team in the mosteffective composting methods.

- The Mill can be profitable within the first year of operations given the demand for wool fabric. The charts show a conservative 15 percent annual average growth rate over ten years. Realistic demand growth is much higher, based on the growth of brands such as Smartwool and Ibex, which are in the ranges of 30 – 50 percent per year. Supply growth is also significantly higher. Based on interviews with wool producers, flocks can double in size nearly every year. To be conservative, the Study Team used 15 percent as the growth rate. The margins steadily increase as mill throughput increases.

- Profits grow quickly as production volumes start to reach economies of scale.

- Revenue from the Mill is diversified among seven products. A significant portion of the revenue in the first year comes from the sale of 12 oz. wool knit fabric. This is an ideal weight for mid-weight garments. The other major revenue streams come from 8 oz. wool knits and 8 oz. seamless garments (for private label production). As the demand for seamless garment and direct to consumer products grow, a greater portion of the Mill’s revenue will come from 8 oz. and 4 oz. seamless garment production. The Mill will eventually grow it’s own direct to consumer brand and offer the high quality goods to consumers, featuring up-and-coming designers.

- The California Wool Mill’s operating expenses are mostly variable expenses, which change as the volume of wool moving through the mill changes. This indicates a low overhead for the operations of the mill, suggesting that the mill can weather fluctuations supply of raw material and demand for fabric. The break-even point production averages at about 14% estimated production volume. The other costs are based on current market price, rising with predicted change in the consumer price index, estimated at an average annual rate of 3%.

- The Mill’s most significant variable expense is wool. The model was built to assume that the mill will pay more than the current price of wool for the finest quality, $6 per pound rather than $2. With the current price of finished fabric, the per-unit margin on the product utilizing the fine wool is negative. Other products, such as seamless garments and other grade wool fabrics subsidize the cost of wool for this particular product. The value of producing this product at a loss is to continue to drive demand for this particular product until market prices can support the cost of production.

- The Mill performance varies depending on the site specified. Santa Rosa has a lower Return on investment primarily due to the high price of real estate in that area compared to the other locations. Below is a chart comparing the performance of the Mill for each site location. While the financial performance is best in Firebaugh, the greenhouse gas footprint is best in Woodland. The financial return generated by a financial model suggests Firebaugh to be the optimal place for the California Wool Mill, however there are other factors to consider, such as proximity to a design hub, readiness of the local municipality, support from local government, proximity to the wool supply, and greenhouse gas performance. Another important factor to consider is the Economic Multiplier effect, which is highest in Santa Rosa due to the higher expenses.

- One of the objectives of this study is to provide the first-ever greenhouse gas based ‘Soil to Soil’ life cycle assessment (LCA) for all future cloth and garments produced by the California Wool Mill. The existing LCA research within the textile industry has been primarily conducted and paid for by industry members who stand to profit from the results (Tobassian, 2013). In contrast, we developed an in-depth systemic analysis to-date of textile creation through a collaboration with UC Berkeley’s Silver lab and Dr. Marcia DeLonge. She developed a series of scenarios that were based on some initial pro-forma assumptions that were later changed (such as the average amount of fabric used per garment, etc.). The later changes actually improved the greenhouse has performance on a per-garment basis for scenario #7. This improvement reached a -151kg of ghge per garment.

- This is the breakdown of the LCA for the entire Mill over a ten-year time-frame. Comparison: The annual emissions from one coal fired powerplant = 3,535,557 metric tons of CO2e per year.

- Our proposed vision rests on a model of community-ownership that has the potential to create healthier working conditions and improve quality of life for the mill’s workers, local sheep ranchers, and dye farmers, while lowering unemployment and combating inequality throughout the region. This transformative idea of ownership creates an economic landscape where environmental enforcement is not restricted to a single enforcement body. Instead, stewardship of the environment is decentralized into the hands of all shareholders in the community-owned companies, who are by design also stakeholders with an interest in preserving the environmental services of the region they live in. In short, place matters.

- It is expected that start-up financing will primarily be in the form of loans. Co-op member equity contributions are likely to be minimal since there will not be a large number of initial members and California securities law requires more onerous compliance for member capital contributions greater than $300. Thus a relatively large portion of the start up capital could be raised in a DPO.

- Each step in this process requires capital. The prototyping process will require a few hundred thousand in funding in order to meet minimum quantities to run through a processing line in the Carolinas. This early stage of the California Wool Mill venture will require a small, but highly knowledgeable team familiar with this project and the supply chain in the Carolinas. In order for the next step to move forward, early stage funding will be essential.The exciting part of this venture is that it is truly a new model utilizing new technology, but built upon old ideas and ancient processes. The California Wool Mill model demonstrates that old systems can be updated to create sustainable solutions. Society can learn from ancient crafts and practices in order to reinvent new systems for today’s most pressing challenges. The California Soil-To-Soil Wool Mill is truly a new model that makes the existing model obsolete.