Vnx.su nsx_часть3

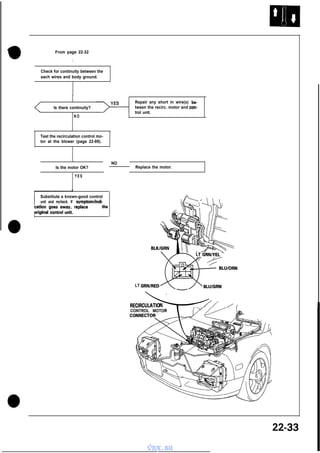

- 1. From page 22-32 I Check for continuity between the each wires and body ground. Repair any short in wire(s) between the recirc. motor and control unit. Is there continuity? NO Test the recirculation control motor at the blower (page 22-89). NO Is the motor OK? Replace the motor. YES Substitute a known-good control unit and recheck. If symptomlindi- /;;t$;ac!gcooenstr~;gfirwlace the LT RECIRCULATIO CONTROL MOTOR 22-33 vnx.su

- 2. Troubleshooting - Vent Door Control Motor Self-diagnosis indicator light I comes on: Indicates a problem in the vent door control motor circuit. Use a digital multimeter (KS-AHM32-03) to check it. The vent door control motor regulates the vent door according to output from the control unit. Problem in the vent door control I No.5 Turn the ignition switch OFF. Make sure all wires in the vent door control motor connector are securely attached. Make sure the linkage is free of obstructions. Remove the climate control unit (page 22-84). Leave the wire connected. I Turn the ignition switch ON. Set the temperature control dial at TEMP display 18, then measure battery voltage between No.5 terminal and body ground when turning temperature control dial at TEMP display 32. After, measure battery voltage between No. 19 terminal and body ground when turning temperature control dial at TEMP display 18. No:1 1 I I Substitute a known-good control unit and recheck. If symptom/indi<T* h ~~;a~~;,~.v;q;raplace t e To page 22-35 22-34 vnx.su Fjo.14

- 3. (From page 22-34) J Turn the ignition switch OFF. Disconnect the 6-P connector from the vent door control motor. YEUBLK I GRNl RED Turn the ignition switch ON. Set the temperature control dial at TEMP display 18, then measure battery voltage between the YEL/BLK terminal and body ground when turning the temperature control dial at TEMP display 32. After, measure battery voltage between the YEL/BLU terminal and body ground when turning the temperature control dial at TEMP display 18. Is there battery voltage? YES BLKlGRN YELlWHT R e p a i r open in YEL/BLK or YELlBLU wires between the vent door control motor and control unit. Turn the ignition switch OFF. Disconnect the 14-P connector from the control unit. Check for continuity between YEL/BLK or YEL/BLU terminals and body grond. Is there continuitv? Reoair short in the YELlBLK or YELlBLU wires between the vent 1 tz control motor and control 1 Reconnect the 1,4Pconnector. ] To page 22-36 (cont’d) 22-35 vnx.su

- 4. Troubleshooting - Vent Door Control Motor (cont’d) From page 22-35 From the back of the 14-P connector at the control unit, measure voltage between the No. 11 and body ground. Substitute a known-good control unit and recheck. If symptomlindiYES I Measure voltage between the GRN/RED terminal and body ground. I I Is there approx. 5V NO I Repair open in the GRNlRED wire between the vent door control motor and control unit. YES Turn the ignition switch OFF. Disconnect the 14-P connector p+q Check each wires for continuity: l YEUWHT wire l BLKIGRN wire <*e ffffKLE2xz: vent door control motor and con- To page 22-37 22-36 vnx.su

- 5. From page 22-36 Check for continuity between the GRN/RED, YEL/WHT or BLK/GRN wire(s) and body ground. NO Repair short in the GRNIRED, YELANHT or BLKlGRN wire(s) between the vent door control motor and control unit. Test the vent door control motor at the heater (page 22-W. Replace the vent door control motor. YES Substitute a known-good control unit and recheck. If symptom/indication goes away, replace the original control unit. 22-37 vnx.su

- 6. Troubleshooting - Power Circuits to A/C Control Unit First, check for blown No.33 (7.5A) and No.4 (15A) fuses. No heater and AIC in either manu- Remove the climate control unit (page 22-84). Disconnect the 30-P connector from the climate control unit. Turn the ignition switch ON. Measure voltage between the No.30 (WHT/YEL) terminal and body ground. Repair open in WHTlYEL (No.301 wire between the control unit and No.33 (7.5 A) fuse. YES Measure voltage between: l No.28 (YEL/BLK) terminal and body ground. l No.27 (YEL/BLK) terminal and body ground. , Is there battery voltage? I YES NO I Repair open in YELlBLK (No.27 or No.281 wire between the control unit and No.4 (15A) fuse. To page 22-39 22-38 vnx.su I

- 7. From page 22-38 Check for continuity between: l No.25 (8LK) and body ground. l No.24 (BLK) and body ground. Is there continuity? NO Repair open BLK (No.24 or No.251 wire between the control unit and body ground. If wires are OK, check for poor ground at G401. Substitute a known-good control unit and recheck. If symptomlindi- 22-39 vnx.su

- 8. Troubleshooting - Blower Motor SUB RELAY First, check for blown No.28(30A) and No.4(15A) fuse Blower motor does not run at all. I j r ~mho;m;;m;;vethe cover from sub kelay box A and re- I Turn the ignition switch ON. , Measure voltage between the BLU/WHT wire terminal (+ ) and body ground (- 1. NO, Is there battery voltage? YES Measure voltage between the YELlBLK wire terminal (+I and body ground (- 1. 1 Is there battery voltage? > I -T <’ Repair open in BLWVHT wire between the No.28 (30AI fuse and blower relay. YES To page 22-41 22-40 vnx.su

- 9. From page 22-40 r 1 Test the blower relay: Connect battery power to relay terminal C, then connect terminal D to body ground. There should be continuity between terminals A and B with power connected, no continuity with power disconnected. Replace the blower relay. YES Check for continuity between the BLK wire terminal and body ground Repair open in BLK wire between the blower relay and body ground. If wire is OK, check for poor ground at 0301. YES Turn the ignition switch OFF. I Reinstall the blower relay. Disconnect the 2-P connector from the blower motor. BLOWER MOTOR CONNECTOR Turn the ignition switch ON. I To page 22-42 (cont’d) 22-41 vnx.su

- 10. Troubleshooting Blower Motor (cont’d) BLOWER MOTOR CONNECTOR Measure voltage between the BLURED wire terminal (+I and body ground (- 1. Is there battery voltage? BLUIRED BLKIBLU From page 22-41 Repair open in BLUlRED wire between blower motor and blower relay YES Inspect the blower motor. Does the blower motor run? NOTE: Connect the battery power to the BLWRED wire terminal and connect the BLK/BLU wire terminal to body ground. The blower motor should runs. Replace the blower motor. I YES ; :;ntx?mi;;~h OFF. SUB RELAY Reconnect the connector to the 22-42 vnx.su f. _ e

- 11. From page 22-42 rGizz+ NO Does the blower motor run? Repair open in BLKIBLU wire between blower motor and blower high relay. YES Turn the ignition switch OFF. 1 the BLK/BLU wire terminal and 1 Turn the ignitio; switch ON. Repair open in BLK wire between 1 ~!t~zLJL,,~;~~ Measure voltage between the YEL/BLK wire (+) terminal and body ground. Repair open in YELIBLK wire between ignition switch and blower high relay. YES To page 22-44 ‘j (cont’d) 22-43 vnx.su

- 12. Troubleshooting . Blower Motor kont’d) From page 22-43 Test the blower high relay: Connect battery power to relay terminal C, then connect terminal D to body ground. There should be continuity between terminals A and 6 with power connected, no continuity with power disconnected. Replace the blower high relay. YES I i Turn the ignitio; switch OFF. # Reinstall the blower high relay. Remove the climate control unit (page 22-84). No.1 2 (ORNIWHT) e Disconnect the 30-P connector from the climate control unit. Connect a jumper wire between the ORN/WHT wire terminal and body ground. Turn the ignition switch ON. To page 22-45 a vnx.su

- 13. From page 22-44 Repair open in ORNMfHT wire between blower high relay and climate control unit. Substitute a known-good control unit and recheck. If symptom/indication goes away, replace the original control unit. a a 22-45 vnx.su

- 14. Troubleshooting - Blower Speed Controls Blower motor speed does not change. LT GRNlBLK Open the hood disconnect the 3-P power transistor connector from the blower harness connector. Connect a voltmeter between the YES Turn the FAN switch to the middle of its range. To v B To page 22-47 22-46 vnx.su

- 15. From page 22-46 V B Connect a jumper wire between the BLK/BLU wire terminal and the BLK wire terminal. BLKIBLU 1 S e e troubleshooting, BLUlRED page YES I I Disconnect the 30-P connector from the control unit and the 2-P connector from the blower motor. I Check for continuity BLK/BLU wire. in the NO Is there continuity? 1YES Repar open in the BLK/BLU wire between the blower motor and control unit. Check for continuity between the BLK/BLU terminal and body ground. No.22 (BLKIBLU) Is there continuity? NO Repair short in the BLKlBLU wire between the blower motor and control unit. Replace the power transistor. (dont’d) 22-47 vnx.su

- 16. Troubleshooting - Blower Speed Controls (cont’d) From page 22-46 Remove the climate control unit (page 22-841. ‘...I Disconnect the 30-P connector Check for continuity in the LT GRN/BLK wire. I I Is there continuity? NO Repair open in the LT GRNlBLK wire between the power transistor and control unit. YES Check for continuity between the No.8 (LT GRN/BLK) wire terminal and body ground. 1NO Substitute a known-good control unit and recheck. If symptomlindication goes away, replace the original control unit. vnx.su

- 17. 22-49 vnx.su

- 18. Troubleshooting A/C System First, check for blown fuses: NO. 4 (15 A), No. 36 (10 A), No. 37 (10 A), No. 21 (10 A). AK system does not work (cornpressor and condenser fans). Remove the climate control unit (page 22-84). Disconnect the 30-P connector from climate control unit. Turn the ignition switch ON. I 1 Measure voltage between the No. 13 (GRY/BLK) terminal (+ ) and body ground I-). NO To paw I Is there battery voltage? Repair open in one of the two BLK wires between the climate control unit and body ground. If the wires are OK, check for a poor ground at 6401. 22-51 YES Check for continuity between; l No.25 (BLK) terminal and body ground. l No.24 (BLK) terminal and body ground. YES / Substitute a known-good climate control unit and recheck. If symptomlindication goes away, replace original control unit. 22-50 vnx.su

- 19. From page 22-50 1 1 Turn the ignition switch OFF. I Disconnect the 12-P connector from cooling fan control unit. I Substitute a known-good cooling replace the original control unit. 22-51 vnx.su

- 20. -Condenser Fan First, check for blown fuses: NO. 4 (15 A), No.36 (10 A), No. 37 (10 A). One or both condenser fans does 1 z:~:~:::::;e / cover from sub ;elay / box A and re- Using a jumper wire, connect the VV-l~T/~RNwireterminaltobody l Do both condenser fans run? / L-- To page 22-55 YES Connect a jumper wire between the WHT/GRN wire terminal and ELK wire terminal. Do both condenser fans run? YES Turn the ignition switch ON. To page 22-53 22-52 vnx.su

- 21. From page 22-52 Measure the voltage between the YEL/BLK wire terminal (+) and body ground (- 1. NO I YES Repair open in the YELlBLK wire between the No. 4 fuse (15 A) and condenser fan relay. Test the condenser fan relay: Connect battery power to relay terminal C, then connect terminal D to body ground. There should be continuity between terminals A and B with power connected, no continuity with power disconnected. Replace the condenser fan relay. Turn the ignition switch OFF, and reinstall the condenser fan relay. Disconnect the 12-P connector from the cooling fan control unit. Turn the ignition switch ON. To page 22-54 (cont’d) 22-53 vnx.su

- 22. Troubleshooting - Condenser (cont’d) From page 22-53 Measure voltage between the ORN/BLU terminal (+) and body ground t-1. NO Is there battery voltage? , I Repair open in the ORNlBLU wire between the condenser fan relay and cooling fan control unit. fan control unit and recheck. If symptom/indication goes away. replace the original control unit. 22-54 vnx.su

- 23. V From page 22-52 Right side: WHT Left side: WHTIBL A Disconnect the 2-P connector from inoperative condenser fan(s). I I Measure voltage: Right fan: WHT wire terminal and body ground. Left fan: WHT/BLU wire terminal and body ground. I”. Is there battery voltage at terYES Repair open in WHT wire between the No. 37 fuse (10 A) and the right fan, or in the WHTIBLU wire between the No. 36 fuse (IOA) and the left fan. Test both condenser fan motors. Connect battery power to the WHT and WHT/BLU wire terminals and connect the WHT/GRN terminal to body ground. Both fans should run. NO Does the fan motor(s) OK? I YES r between the condenser fan motor Replace the faulty fan motor. 1 22-55 vnx.su

- 24. Troubleshooting - A/C Compressor :irst, check for blown fuses: No. 21 (IO A), No. 4 (15 A). Compressor clutch does not engage. When AIC is turned on with engine running. Remove the compressor clutch relay from sub relay box A. c / Is there battery voltage? ..NW YES , Repair open in the PNKlORN wire between the No. 21 (IO A) fuse and compressor clutch relay. I Turn the ignition switch ON. Measure voltage between the YEL/BLK wire terminal (+I and body ground (- ). NO ’ Is there battery voltage? Repair open in the YELlBLK wire between the No. 4 (16 A) fuse and compressor clutch relay. YES To page 22-57 22-56 vnx.su

- 25. From page 22-56 Test the compressor clutch relay: Connect battery power to relay terminal C, then connect terminal D to body ground. There should be continuity between terminals A and Et with power connected, no power with power disconnected. NO Is the relay OK? YES I 1 Turn the ignition switch OFF. Remstall I Replace the compressor clutch relav. I I 1 the compressor clutch p Remove the panel from behind the passenger seat. Disconnect the 4 connectors from PGM-FI-ECU. Connect teh ECU test harness connectors to the ECU. Turn the ignition switch ON. I--+ ECU TEST HARNESS Measure battery voltage between NO Is there battery voltage? Repair open in the REDlBLU wire between the compressor clutch relay and PGM-FI-ECU. YES To page 22-58 (cont’d) 22-57 vnx.su

- 26. Troubleshooting - A/C Compressor (cont’d) From page 22-57 ECU Start the engine and connect a jumper wire between test harness terminal Al 5 and body ground. ECU TEST HARNESS Al5 I Does compressor clutch engage? I Turn the ignition switch OFF. YES B L7 Using a jumper wire, connect C3 test harness terminal to body ground. To page 22-61 NO Does compressor clutch engage? Substitute a known-good PGM-FIECU and recheck. If symptomiindication goes away, replace the original ECU. YES Turn the ignition switch OFF. ? c3 I A To page 22-59 22-58 vnx.su I

- 27. From page 22-58 Disconnect the test harness, and reconnect the connectors to the BRNlBLK Disconnect the 4-P connector from the pressure switch. BLK YES Check refrigerant pressure. If pressure good, replace AIC pressure switch. NO Repair open in the BLK wire between the pressure switch and body ground or poor ground (0302). Does compressor clutch engage? NO Turn the ignition switch OFF. I Check for continuity between the 8LK wire terminal and body ground. Is there continuity? YES To page 22-60 (cont’d) 22-59 vnx.su

- 28. Troubleshooting I A/C Compressor (cont’d) From page 22-59 connector from the cooling fan Check for continuity of BRN/BLK wire between the cooling fan con/ t r o l u n i t a n d prey” s w i t c h . Repair open in the BRNIBLK wire between the cooling fan control unit and pressure switch. YES 11 Start the enginei NO Does compressor clutch engage YES Repair open in the BLWBLK wire between PGM-F&ECU and cooling fan control unit. Substitute a known-good cooling symptom/indication goes away. replace the original control unit. 22-60 vnx.su

- 29. From page 22-58 B ? Disconnect the connector from compressor. Turn the ignition switch ON. g 1 r o u n d t-1. RED Repair open in the RED wire between the compressor clutch relay and compressor. Is there battery voltage? YES ( Replace the compressor clutch. 1 22-6 1 vnx.su

- 31. -Replacement 1. 2. Remove the spare tire (refer to Owner’s manual). Remove the spare tire holder. 4. * CORROSION RESISTANT BOLT Remove the sub relay box A and the water drair duct. Disconnect the connectors from the blower motor, power transistor and recirculation contra motor. Q CORROSION RESISTANT BOLT 4 6 mm bolt I?r 6 mm bolt DUCT BLOWER, POWER TRANSISTOR, and RECIRC. MOTOR CONNECTORS * 6 mm bolt- 5. 0 Remove the blower mounting bolts, then remove the blower. ~2 CORROSION RESISTANT BOLT 3. Disconnect the battery cables, loosen the hold-down bracket nuts, and remove the hold-down bracket. Then, remove the battery. BATTERY ab 6. Install the blower in the reverse order of removal, then make sure it runs and doesn’t leak any air. BRACKET 22-63 vnx.su

- 32. Recirculation Control Motor - Replacement 1. 2. 4. Remove the blower (previous page). Remove the recirculation control motor cover from the blower (3 screws). REClkCULATlON CONTROL MOTOR COVER 3. Remove the recirculation control motor (I connector and 3 screws). RECIRCULATION CONTROL MOTOR L 22-64 vnx.su Install the recirculation control motor in the reverse order of removal. Apply battery voltage (page 22-89) and watch the door movement. Make sure that the recirculation door moves smoothly without binding. Make sure the motor doesn’t pull the door too far.

- 33. A/C Service Tips and Precautions 1. 2. 3. 4. 5. 6. Always disconnect the negative cable from the battery whenever replacing air conditioner parts. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don’t remove the caps or plugs until just before you reconnect each line. Before connecting any hose or line, apply a few drops of refrigerant oil to the O-ring. When tightening or loosening a fitting, use a second wrench to support the matching fitting. When discharging the system, use a refrigerant recovery system; don’t release refrigerant into the atmosphare. And refrigerant oil after replacing the following parts: Condenser . . . . . . . . . . . . . . . . . . . . . . . . 10 cc (l/3 fl oz) Evaporator . . . . . . . . . . . . . . . . . . . . . . . . 10,cc (l/3 fl OL) Line or hose . . . . . . . . . . . . . . . . . . . . . 20 cc fl oz) (2/3 Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 cc (l/3 fl 02) Compressor.. . . . . . . . . . . . . . . . . . . . . On compressor replacement, subtract the volume of oil drained from the removed compressor from 80 cc (2 2/3 fl 02). and drain the calculated volume of oil from the new compressor: 80 cc (2 2/3 fl OZ)-Volume of oil from removed compressor=Volume to drain from new compressor. Don’t overtighten fittings; you could damage them. Leaks are caused by faulty O-rings, overtightening won’t stop them. ft CORROSION RESISTANT BOLT @ Suction hose and discharge hose to AK lines . . . . . . . . . . . . . . .._..... 22 N’m (2.2 kg-m, 16 lb-ft) @ Discharge line C (both side) . . . .._................. 23 N*m (2.3 kg-m, 17 lb-ft) @ Condenser line A (both side) . . . . . . . . . . . . . . . . . . . . . . . 23 N*m (2.3 kg-m, 17 lb-ft) @ Condenser line C to left side 14 N-m (1.4 kg-m, 10 lb-ft) condenser . . . . . . . . . . . . . . . . . . . . . . . . @ Receiver-dryer . . . . . . . . . . . . . . . . . . 14 N-m (1.4 kg-m, 10 lb-ft) @ @ @ @ @ @ Receiver line and suction line to heater assembly . . . . . . . . . . . . . . . . . . . . . . . . . 22 N-m (2.2 kg-m, 16 lb-ft) Compressor hose mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 N-m (2.2 kg-m, 16 lb-ft) Compressor mounting bolts . . . ..a......................... 25 N-m (2.5 kg-m, 18 lb-ft) Compressor bracket mounting bolts . . . . . . . . . . . . . . . . . 50 N-m (4.5 kg-m, 36 lb-ft) Idler pulley center nut . . . . 45 N.m (4.5 kg-m, 32.5 lb-ft) * 6 mm bolt . . . . . . . . . . . . . . . . . . 10 N’m (1.0 kg-m, 7.2 lb-ft) When handling refrigerant (R-12): 0 Always wear eye protection. l Do not let refrigerant get on your skin or in your eyes. If it does: - Do not rub your eyes or skin. - Splash large quantities of cool water in your eyes or on your skin. - Rush to a physician or hospital for immediate treatment. Do not attempt to treat it yourself. l Keep refrigerant containers (cans of R-12) stored below 40°C (100°F). l Do not handle or discharge refrigerant in an enclosed area near an open flame; it may ignite and produce a poisonous gas. l The ozone is fragile layer surrounding the earth which acts as a shield against the sun’s ultraviolet radiation. Chlorine from chemicals called chlorofluorocarbons (CFCs) destroy the ozone in the stratosphere. Automotive air conditioning systems currently use chlorofluorocarbons as the refrigerant. Auto air conditioning service equipment has been developed to minimize the release of CFCs to the atmosphere. All service procedures should be performed using this equipment and the manufactuer’s instructions. 22-65 vnx.su

- 34. Heater-Evaporator Unit - Replacement SRS wire harness is routed near the heater. cM!m AllDoSRS wire harnesses and connectors colored yellow. not use electrical test equipment 5. are on Remove all refrigerant from the A/C system with a refrigerant recovery system. (page 22-93). 6. Disconnect the receiver line and the suction line from the evaporator. Cap the open fittings immediately to keep moisture out of the system. these circuits. CAUTION: Be careful not to damage the SRS wire harnesses when servicing the heater. 1. RECEIVER PIPE Remove the blower (page 22-63). 2. When the engine is cool, drain the coolant from the radiator (Section IO). m 0 Do not remove the radiator cap when the engine is hot; the coolant is under pressure and could severely scald you. Keep hands away from the radiator fan. The fan 0 may start automatically without warning and run for up to 30 minutes, even after the engine is turned off. CAUTION: Radiator coolant will damage paint. Quickly rinse any spilled coolant off painted surfaces. 3. Disconnect the heater hoses at the heater. Coolant will run out when the hoses are disconnected, drain it into a clean drip pan. 4. SUCTION PIPE 7. Remove the dashboard (Section 20). 8. Remove the heater duct. Disconnect the heater valve cable from the heater valve. 9. Remove the mounting bolts{41 and disconnect the connectors from control units and evaporator temperature sensor connector from the control unit bracket, then remove the control unit bracket. --75; EVAPORATOR TEMPERATURE HEAiER VALVE CABLE 10. Remove the enclosure woofer. vnx.su .

- 35. 11. Disconnect the connectors from all the actuators and sensors attached to the heater-evaporator. 15. If necessary, adjust the heater valve cable: l Set the air mix control motor at COLD position (page 22-90). 12. Remove the mounting bolts(2-under the dash) and nuts(2-under the hood), then remove the heaterevaporator through the passenger door. l Connect the end of the cable to the heater valve arm. a: CORROSION RESISTANT BOLT HEATER-EVAPORATOR l Gently slide the cable outer housing back from the end enough to take up any slack in the cable, but not enough to make the other end move the arm on the air mix motor. Then snap the clamp down over the cable housing. CLAMP NUTS HEATER VALVE 6x20 10 N-m (1.0 kg-m, 7.2 lb-ft) 13. Install in the reverse order of removal, and: l Apply sealant to the A/C line grommets. l Do not interchange the inlet and outlet heater hoses. Make sure that the hose clamps are tight. 14 Fill the radiator and reservoir tank with the proper coolant mixture. Bleed the air from the cooling system (Section IO). CAUTION: Follow the sequence described in the air bleed procedure. If you don’t, you may leave air in the system which could damage the engine. II HEATER CABLE VALVE 16. Turn the blower on and make sure that there is no air leakage. 17. Charge the system (page 22-93-95) and test Performance (page 22-96). 22-67 vnx.su

- 36. Evaporator Temperature Sensor. Coolant Temperature Sensor - Removal - Removal Disconnect the connector, and remove the coolant temperature sensor clip and the sensor. COOLANT TEMPERATURE SENSOR Give the evaporator temperature sensor a quarter turn and then pull out it. EVAPORATOR / TEMPERATURE SENSOR 22-68 vnx.su

- 37. Vent Door Control Motor Mode Control Motor - Replacement - Replacement 1. Remove the mounting screws, then remove the vent door control motor. 1. WI Remove the mounting screws, then remove thl mode control motor. VENT DOOR CONTROL MOTOR 2 Install the vent door control motor in the reverse order of removal. Then apply battery voltage (page 22-90) and watch the door move. l l Make sure that the vent door moves smoothly without binding. Make sure the motor doesn’t pull the vent door too far. MODE CONTROL MOTOR 2. install the mode control motor in the reverse order of removal. Then apply battery voltage (page 22-91) and watch the doors move. l l Make sure that the HEAT and DEF doors moves smoothly without binding. Make sure the motor doesn’t pull the HEAT and DEF doors too far. 22-69 vnx.su

- 38. Air Mix Control Motor - Replacement 1. Disconnect the heater valve cable from the air mix control motor. 4. HEATER VALVE If necessary, to adjust the heater valve cable; 0 Set the air mix control motor at COLD position (page 22-90). 0 Hold the end of the cable housing against the stop on the cable. Then snap the clamp down over the housing. 0 After adjusting the cable, make sure that the air mix control motor still moves smoothly without binding. STOP CLA AIR MIX CONTROL MOTOR 2. Remove the air mix control motor (3 screws, 1 connector). HEATER VALVE CABLE AIR MIX CONTROL MOTOR 3. AIR MIX CONTROL Install the air mix control motor in the reverse order of removal. Then apply battery voltage (page 22-90) and watch the door move. Make sure that the air mix door moves smoothly without binding. Make sure the motor doesn’t pull the air mix door too far. 22-70 vnx.su

- 39. Heater-Evaporator Unit -Disassembly/Reassembly 1. Remove the heater core cover, remove the pipe clamp, then pull out the heater core. 2. Remove the lower half of the housing, then remove the evaporater. 3. Remove the expansion valve if necessary. HEATER CORE PIPE CLAMP EXPANSION VALVE AIR MIX DOOR 1 TAPE Replace CAPILLARY TUBE must be touching the suction line. LOWER HALF OF THE HOUSING 4. Assemble the heater-evaporator unit in the reverse order of disassembly. Hold the expansion valve capillary tube down against the suction line, and wrap it with tape to hold it there. 22-7 1 vnx.su

- 40. Heater-Evaporator Unit “HEAT” Door Adjustment - “DEF” Door Adjustment :onnect the control rod to he clip. 0 Turn this lever all the way clockwise and hold it there. 0 / Reposition gear 2 so this mark lines up with the mark on gear 1. Loosen this screw in gear 2. 0 GEAR 1 GEAR 2 Turn this Ieve; clockwise and hold it against its stop. a 22-72 vnx.su

- 41. Condenser - Description Dual condensers are mounted behind the right and left side of the front bumper as shown. The cooling efficiency of paralleldual condensers is as good as or better than a single condenser mounted in front of radiator. RECEIVER/ DRYER RIGHT CONDENSER 22-73 vnx.su

- 42. . Condenser Assembly Replacement Disconnect the battery negative terminal. Use a refrigerant recovery system to discharge the refrigerant (page 22-93). 3. Disconnect the discharge line and the condenser lines from the condenser. Cap the open fittings immediately to keep moisture and dirt out of system. 1. 2. (Right 4. Disconnect the connector from the condenser fan motor, remove the mounting belts(2) and nut, then remove the condenser. *: CORROSION RESISTANT BOLT (Right Condenser) Condenser) NUT V RIGHT CONDENSER * MOUNTING BOLTS 10 N-m (1.0 kg-m, 7.21 lb-ft) DISCHARGE LINE C (Left Condenser) NUT / (Left Condenser) CONDENSER Q MOhNTlNG BOLTS 10 N’m (1.0 kg-m, 7.2 lb-ftl 5. CONDENSER LINE A 22-74 vnx.su Install the condenser in the reverse order of removal; l Replace O-rings with new ones each fitting. l Charge the system (page 22-93-95) and test its performance (page 22-96).

- 43. 1. 2. Disassembly/Reassembly Remove the bolts and nuts (4). Then separate the condenser duct from the shroud, and remove the condenser. Remove the fan mounting screws (31, then remove the fan from the shroud. CONDENSER I CONDENSER DUCT NUT 10 N-m (1.0 kg-m, 7.2 lb-it) SCREW SHROUD SPACER CONDENSE6 FAN 3. Assemble the condenser in the reverse order. Be careful not to damage the tabs on the condenser shroud when you attach it to the air intake duct. 22-75 vnx.su

- 44. Compressor Description This compressor is a Nippondenso piston type. A revolving inclined disc drives the surrounding 10 reciprocating pistons. thus compressing the refrigerant. As the inclined disc revolved, it pushes the pistons, protected by a ceramic shoe, CENTER BOLT 4 PRESSURE PLATE _e 4e SHIMS SNAP RING B PULLEY SNAP RING A FIELD COIL 22-76 vnx.su

- 45. -Replacement 1 1. If the compressor still works, run the engine at idle for a few minutes with the A/C on, then shut the engine off and disconnect the negative cable from the battery. 2. Use a refrigerant recovery system to discharge the refrigerant from the system (page 22-93). 3. Disconnect the compressor connector. 7. Loosen the idler pulley center nut and adjusting bolt, then remove the belt from compressor. ADJUSTING BOLT 12 N-m 11.2 kg-m. COMPRESSOR CONNECTOR IDLER PULLEY CENTER NUT 45 N-m (4.5 kg-m, 32.5 lb-ft) 4. 5. 6. Raise the car on a hoist. Make sure it’s properly supported (Section I). Remove the front beam (Section 5). Disconnect the suction and discharge hoses from the compressor. Cap the open fittings immediately to keep moisture and dirt out of the system. 8. Remove the four compressor mounting bolts and compressor. DISCHARGE HOSE SUCTION f&3 COMPRESSOR MOUNTING BOLTS 25 N-m (2.5 kg-m, 18 lb-ft) (cont’d) 22-77 vnx.su

- 46. Compressor - Replacement (cont’d) 9. If necessary, remove the compressor bracket (4 bolts, plus 1 from the idler pully bracket). 0 Check the idler pulley bearing for play and drag. Replace it with a new one if it’s noisy or has excessive play or drag. o- 10x65 50 N*m 15.0 kg-m, 36 lb-ft) IDLER PULLEY BRACKET BOLT / I 0 12 N.m (1.2 kg-m, 8.7 lb-ftt 10x50 50 N-m (5.0 kg-m, 36 lb-ft) 4 5 N*m (4.5 kg-m, 36 lb-ft) COMPRESSOR BRACKET IO. If necessary remove the idler pulley (2 more bolts). 11. Install in the reverse order of removal. If you’re installing a new compressor, drain all the refrigerant oil out of the old compressor and measure its volume. Subtract the volume of old oil from 80 CC (2 l/3 floz); the result is the amount of oil you should drain from the new compressor (through the suction fitting). 12. Adjust the compressor belt (page 22-79). After adjusting the belt, tighten the pully center nut. Then tighten the adjusting bolt securely. 13. Charge the system (page 22-93-96). 14. Test system performance (page 22-961. IDLEk PULLY ASSEMBLY 22-78 vnx.su

- 47. - Compressor Belt Adjustment “New belt” refers to a belt which has been used less than 5 minutes on a running engine. 0 “Used belt“ refers to a belt which has been used or+&+ ;..l- s‘.: ;, a running engine for 5 minutes or more. L*:;,+, “d ,. NOTE: Check for belt damage. If necessary, replace-’ the belt. l ADJUSTING BOLT 12 N-m (1.2 kg-m, 8.7 lb-ft) PULLEY CENTER NUT 45 N-m 14.5 kg-m, 32.5 lb-ft) 22-79 vnx.su

- 48. Compressor Clutch 1. Inspection Check pulley bearing play and drag by rotating the pulley by hand. Replace the pulley with a new one if it is noisy or has excessive play/drag. 3. Measure the clearance between the pulley and pressure plate all the way around. If the clearance is not within specified limits, the pressure plate must be removed and shims added or removed as required, following the procedure on the next page. CLEARANCE: 0.5 -+ 0.15 (0.020 _+ 0.006 in) NOTE: The shims are available in three sizes: 0.1 mm, 0.2 mm and 0.5 mm of thickness. PULLEY / 2. Check resistance of the field coil: Field Coil Resistance: 3.6f0.2 ohm at 2o”c (68OF) If resistance is not within specifications, replace the 22-80 vnx.su

- 49. Clutch Overhaul 0 3. 1. Remove the center bolt. Use circlip pliers to remove snap ring B, then remove the pulley. CENTER BOLT 12 N-m (1.2 kg-m, 9 lb-ft) SNAP RING B PULLEY P/N 10204 2. Remove the pressure plate and shim(s) not to lose the shims. taking care PRESSURE PLATE SHIMS (cont’d) 22-81 vnx.su

- 50. Compressor Relief Valve Replacement Overhaul (cont’d) 4. 1. Remove snap ring A and the field coil. Remove the relief valve and O-ring. Don’t let any compressor oil run out. SNAP RING A FIELD COIL O-RING RELIEF VALVE 13.5 N*m (I .35 kg-m, 9.8 lb-ft) RE;EF VALVE CAP 2. Install parts in the reverse order of removal, and: 3. Apply compressor oil to the O-ring. 0 Install the field coil with the wire side facing UP (see above). 4. Install and tighten the relief valve. 5. 5. Clean off the mating surface. Charge the system and check for leaks, then push the cap into the valve. 0 Clean the pulley and compressor sliding surfaces with non-petroleum solvent. l Check the pulley bearings for excessive play. 0 Make sure the circlip fits in its groove properly. l Apply locking agent to the threads on the center bolt. l Make sure that the pulley turns smoothly, after it’s reassembled. 22-82 vnx.su I) -

- 51. 22-83 vnx.su

- 52. Component Removal/Replacement - Climate Control Unit SRS wire harness is routed near the console. 4. rmmi Remove the ashtray (lift up on the door to pop it out), then remove the 2 screws behind it. All SRS wire harnesses and connectors are colored yellow. Do not use electrical test equipment on these circuits. ASHTRAY CAUTION: Be careful not to damage the SRS wire harnesses when servicing the console. 1. Carefully pry the clock out of the dash and disconnect it. CAUTION: Be careful not to damage the center console panel and the dashboard. 2. Remove the center dash vent (2 screws). 3. Remove the 2 screws from the top of the console panel. CLOCK 5. Remove the console storage box (lift out the bottom panel and remove 4 screws). 6. Remove the screw from the end of the console panel. IFNT 22-84 vnx.su

- 53. - In-car Temperature Sensor 7. Pull the parking brake handle all the way up, iift the panel and disconnect the 2 connectors from it, then carefully lift the panel off past the shift lever. Remove the center console panel. The in-car temperature sensor assembly includes a small fan (aspirator fan) to draw air past the sensor. SRS wire harness is routed near the console. m All SRS wire harnesses and connectors are colored yellow. Do not use electrical test equipment on these circuit. CENTER CONSOLE PANEL CAUTION: Be careful not to damage the SRS wire harnesses when servicing the console. I 1. 2. 8. Remove the center console panel as described in step 1 - 7 in the first column (Climate Control Unit). Remove the mounting screws 12) and remove the in-car temperature sensor from the under side of the console panel. Be careful not to damage the console panel. Remove the screws (41, then pull out the control unit, disconnect its connectors and remove it from the dashboard. IN-CAR TEMPERATURE SENSOR UNDER SIDE bF CENTER CONSOLE PANEL / CLIMATE CONTROL. UNIT SRS CONTROL UNIT 22-85 vnx.su

- 54. Component Removal/Replacement -Ambient Temperature Sensor Remove the screw, disconnect the wire harness and then remove the ambient temperature sensor. Be careful not to damage the front grille and front bumper. - Sunlight Sensor With a small screwdriver, carefully pry the sunlight sensor out of the dashboard and disconnect its wire harness. Protect the dashboard; cover it with a shop towel before you pry against it. SUNLIGHT SENSOR AMilENT TEMPERATURE SENSOR 22-86 vnx.su

- 55. Component Tests In-car Temperature Sensor Ambient Temperature Sensor - Compare the resistance reading between No. 1 and No. 2 terminals of the in-car temperature sensor with specifications shown in the following graph: It should be within specification. Compare the resistance reading between terminals of the ambient temperature sensor with specificatoins shown in the following graph: It should be within specification. o“F oc a - 32 (0) 50 (IO) 66 (20) .86 104 122 OF (30) (40) OC (-10) (50) 35 32 5 0 6 8 86 104 122 (0) (IO) 120) 130) (40) i501 TEMPERATUER TEMPERATUER CAUTION: The sensor uses a thermistor which can be damaged if high current is applied to it during testing. Therefore, use a circuit tester that puts out a measuring current of 1 mA or less. CAUTION: The sensor uses a thermistor which can be damaged if high current is applied to it during testing. Therefore, use a circuit tester that puts out a measuring current of 1 mA or less. 22-87 vnx.su

- 56. Component Tests Coolant Temperature sensor Evaporator Temperature Sensor - Compare the resistance reading between terminals of the coolant temperature sensor with specifications shown in the following graph: It should be within specification. Compare the resistance reading between terminals of the evaporator temperature sensor with specification shown in the following graph: It should be within specification. 20 16 10 6 0 6 F 32 Oc (0) C ~0)(10)(20)~80)~40~~601~60~~70~~80~ 50 (IO) 68 (201 86 (301 TEMPERATURE TEMPERATURE CAUTION: The sensor uses a thermistor which can be damaged if high current is applied to it during testing. Therefore, use a circuit tester that puts out a measuring current of 1 mA or less. CAUTION: The sensor uses a thermistor which can be damaged if high current is applied to it during testing. Therefore, use a circuit tester that puts out a measuring current of 1 mA or less. 22-88 vnx.su

- 57. - Recirculation Control Motor - Sunlight Sensor Measure the voltage between the terminals with the sensor out of direct sunlight. l With the connector connected (probe the back of it): 1.420.2 V l With the connector disconnected: 0.1 - 0.2 V 1. Connect battery power to No. 1 terminal of the recirculation control motor, and connect to the No. 2 terminal to ground. The motor should run. If it doesn’t, reverse the connections; the motor should then run. 2. Check for continuity between the terminals of the recirculation control motor according to this table. 22-89 vnx.su

- 58. Component Tests t Air Mix Control Motor - Vent Door Control Motor 0 Connect battery power to the No. 1 terminal of the air mix control motor, and connect to the No. 2 terminal to ground; the air mix control motor should run, and stop at HOT. If it doesn’t, reverse the connections: then the motor should run, and stop at COLD. 0 Apply 5 V between the No. 3 terminal and the No. 5 terminal, then measure the voltage between the No. 3 terminal and the No. 4 terminal. The reading should be; 4.7 kO.7 V at HOT position. 0.3 kO.7 V at COLD pcosition. 1. 2. Connect battery power to the No. 1 terminal of the vent door control motor, and connect to the No. 2 terminal to ground; the vent door control motor should run, and stop at CLOSE. If it doesn’t, reverse the connections; then the motor should run, and stop at OPEN. Apply 5 V between the No. 3 terminal and the No. 5 terminal, then measure the voltage between the No. 4 and the No. 5 terminals. The reading should be; 4.7 kO.7 V at OPEN position. 0.3 kO.7 V at CLOSE positon. - I vnx.su I

- 59. - Mode Control Motor 1. - Aspirator Fan Connect battery power to the No. 1 terminal of the mode control motor, and connect to the No. 2 terminal to ground. The motor should run, and stop at VENT. If it doesn’t reverse the connectinos; the motor should run, and stop at DEF. Connect battery power to the BRN/YEL terminal of the connector, and connect the BLK terminal to ground. The fan should run. BLK 2. Plug the connector back in to the motor. Then operate the MODE switch on the control panel, and in each mode probe the back of the connector to check for continuity between terminals according to the table. 22-9 1 vnx.su

- 60. Control Unit Adjustment Component Tests IRelay There should be continuity between the A and B terminals when the battery is connected to the C and D terminals. There should be no continuity when the battery is disconnected. The calibration switch can raise or lower the set temperature by f3OF (1.5OC) in relation to the digitallydisplayed temperature. Calibration switch 5~ 3OF (+ 1.53=’ A C E v v B D 22-92 vnx.su

- 61. A/C System Service - Evacuation - Discharge 1. 0 Keep away from open flames. The refrigerant, although nonflammable, will produce a poisonous gas if burned. _ l Work in a well-ventilated area. Refrigerant evaporates quickly, and can force all the air out of a small enclosed area. 1. Connect a Refrigerant Recovery System to the A/C system. 2. Operate the Refrigerant Recovery System according to the manufacturer’s instractions. IMPORTANT: Do not vent refrigerant to the atmosphere. The chlorofluorocarbons (CFCs) used in conventional refrigerant (R-12) may damage the earth’s ozone layer. Always use UL-listed, refrigerant recovery/recycling equipment to extract the refrigerant before you open an A/C system to make repairs. Follow the equipment manufacturer’s instructions. Refrigerant Recovery/Recycling System. vnx.su When an A/C System has been opened to the atmosphere, such as during installation or repair, it must be evacuated using a vacuum pump. (If the system has been open for several days, the receiver/dryer should be replaced). 2. Attach an Air Conditioning Service Station as shown. Follow the equipment manufacturer’s instructions. NOTE: If low pressure does not reach more than 700 mm hg (27 in-Hg) in 15 minutes, there is probably a leak in the system. Partially charge the system and check for leaks (see Leak Test).

- 62. A/C System Service - Leak Test mlm When handling refrigerant (R-l 2): Always wear eye protection. 0 Do not let refrigerant get on your skin or in your eyes. If it does: - Do not rub your eyes or skin. - Splash large quantities of cool water in your eyes or on your skin. - Rush to a physician or hospital for immediate treatment. Do not attempt to treat it yourself. l Keep away from open flame. Refrigerant, although non-flammable, will produce poisonous gas if burned. l Work in well-ventilated area. Refrigerant evaporates quickly, and can force all the air out of a small, enclosed area. l IMPORTANT: Do not vent refrigerant to the atmosphere. The chlorofluorocarbons (CFCs) used in conventional refrigerant (R-12) may damage the earth’s ozone layer. Always use UL listed, refrigerant recovery/recycling equipment to extract the refrigerant before you open an A/C system to make repairs. Follow the equipment manufacturer’s instructions. 1. Attach an Air Conditioning Service Station as shown. 2. Open high pressure valve to charge the system to about 100 kPa (14 psi), then close the supply valve. 3. Check the system for leaks using a leak detector. 4. If you find leaks that require the system to be opened (to repair or replace hoses, fittings, etc.), discharge the system according to the Discharge Procedure on page 22-93. 5. After checking and repairing leaks, the system must be evacuated (see System Evacuation on page 22-93). vnx.su I HIGH-SIDE ADAPTER Kent-Moors: P/N J26499 Snap-on: P/N ACT 135

- 63. Charging Procedures Refrigerant capacity: 900-950 g (32-34 02) m Always wear eye protection when charging the system. CAUTION: Do not overcharge the system; the compressor will be damaged. Attach an Air Conditioning Service Station as shown. Follow the equipment manufacturer’s instructions. HIGH-SIDE ADAPTER Kent-Moors: P/N J25499 P/N ACT135 22-95 vnx.su

- 64. Performance Test The performance test will help determine if the air conditioning system is operating within specifications. 1. Connect the hoses as shown. 2. Insert a thermometer in the vent outlet. Determine the relative humidity and air temperature by calling the local weather information line. 3. Test conditions: l Avoid direct sunlight. 1 0 Open engine cover. 0 Open front doors. l Set the temperature control dial to max cold and push the VENT and fresh air buttons. 0 Turn the fan switch to MAX. 0 Run the engine at 1,500 RPM. l No driver or passengers in vehicle. ‘4. After running the air conditioning for 10 minutes under the above conditions, read the delivery temperature from the thermometer in the dash vent and the high and low system pressure from the AK gauges. 5. To complete the charts: 0 Mark the delivery temperature along the vertical line. 0 Mark the intake temperature fair temperature) along the bottom line. 0 Draw a line straight up from the air temperature to the humidity. 0 Mark a point one line above and one line below the humidity level. (I 0% above and 10% below the humidity level) 0 From each point, draw a horizontal line across to the delivery temperature. l The delivery temperature should fall between the two lines. 0 Complete the low side pressure test and high side pressure test in the same way. 22-96 vnx.su HIGH-SIDE ADAPTER Kent-Moors: P/N J25499 Snap-on: PIN ACT 135

- 65. (Without fog lamp) (With fog lamp) HUMIDITY 80% kPa z =) kPa HUMIDITY 80% 25001 w 2500 5 1 8 u 2000 E * K.CM t (PSI) (501- kPa 3 lilw 4 0 0 a n1000 (Psi) ,,“.C 1 kPa (50) 400 (40) 3 0 0 I Mol. 300 (3Ol- 200 (2017 (lo)- 0 EMPERATURE 32 68 77 86 85 104 120) (251 130) (351 MO) (0) (20) (26) (30) (35) MO) INTAKE TEMPERATURE INTAKE TEMPERATURE 22-97 vnx.su I f ; 100 2 TEMPERATURE (0) I i

- 66. Pressure Test NOTE: Performance Test on page 22-96. TFCT RF91 II l-C 1 RFI ATFD IL”, 11~~-~11 * .__. . . SYMPTOMS -...- PROBABLE CAUSE -- -. . REMEDY After stopping compressor, pressure drops to about 196 kPa (28 psi) quickly, and then falls gradually Air in system No bubbles in sight glass when condenser is cooled by water Discharge (high) pressure abnormally high Evacuate system: then recharge Evacuation: page 22-93 Recharging: page 22-95 Excessive refrigerant in system Discharge refrigerant as necessary Reduced or no air flow through condenser. l l Clogged condenser or radiater fins Condenser or radiator fan not working properly Line to condenser is excessively hot Discharge pressure abnormally low Restricted flow of refrigerant in system Excessive bubbles in sight glass; condenser is not hot High and low pressures are balanced soon after stopping compressor insufficient refrigerant in system l Clean l Check voltage and fan rpm Expansion valve l l Check for leak Charge system l Outlet of expansion valve is not frosted, low pressure gauge indicates vacuum Faulty expansion valve Excessive bubbles in sight glass; condenser is not hot Insufficient refrigerant Expansion valve is not frosted and low pressure line is not cold. Low pressure gauge indicates vacuum l Frozen evaporator Run the fan with compressor off then check capillary tube. Expansion valve frosted Clogged expansion valve Clean or Replace Receiver dryer is cool (should be warm during operation) Suction pressure abnormally high l Discharge temperature is low and the air flow from vents is restricted Suction flow) pressure abnormally low Faulty compressor discharge or inlet valve Faulty compressor seal Clogged receiver dryer Replace l l Low pressure hose and check joint are cooler than around evaporator l l Suction pressure is lowered when condenser is cooled by water Expansion valve open too long Loose expansion valve Excessive refrigerant in system High and low pressure are equalized as soon as the compressor is stopped Suction and discharge pressures abnormally high Frozen expansion valve Faulty expansion valve l Reduced air flow through condenser l l l l Replace compressor Replace Check for leaks. Charge as required. Replace expansion valve Repair or Replace. Discharge refrigerant as necessary Faulty gasket Faulty high pressure valve Foreign particle stuck in high pressure vlave Replace compressor Clogged condenser or radiator fins Condenser or radiator fan not working properly l l Clean condenser and radiator Check voltage and fan rpm No bubbles in sight glass when condenser is cooled by water Excessive refrigerant in system Discharge refrigerant as necessary. Suction and discharge pressure abnormally low Low pressure hose and metal end areas are cooler than evaporator Clogged or kinked low pressure hose parts Repair or Replace Temperature around expansion valve is too low compared with that around receiver-dryer Clogged high pressure line Repair or Replace Refrigerant leaks Compressor clutch is dirty Compressor shaft seal leaking Replace compressor Compressor bolt(s) are dirty Leaking around bolt(s) Tighten bolt(s) or replace compressor Compressor gasket is wet with oil Gasket leaking Replace compressor 22-98 vnx.su e

- 67. ‘, Electrical Special Tools ......................................... 23-2 How to Use This Section Troubleshooting Precautions .................... Five-step Troubleshooting ....................... Schematic Symbols ................................ Wire Color Codes ................................... Relays and Control Unit Locations Front Compartment ............................ Dashboard ......................................... Dashboard, Door and Floor .................. Rear Bulkhead .................................... Engine Compartment .......................... 23-3 23-8 23-9 23-9 23- 10 23-11 23-12 23-l 3 23-14 Index to Circuits and Systems a h Air Conditioner .................................. Section 2 1 Alternator .............................................. 23-100 Antenna, Power ..................................... 23-235 Anti-Lock Brake System (AL61 ............ Section 19 Automatic Transmission Control System ............................. Section 14 Battery ................................................. 23-67 Blower Controls ............................... Sectiion 21 Charging system .................................... 23-99 Cigarette. Lighter .................................... 23-226 : Clock ... t. ................................................. 23-224 :‘A CoolingYFan Control ................................ 23-l 12 * Cruise Control ....................................... 23-290 Defogger, Rear Window .......................... 23-274 Fuel Pump ........................................ Section 11 + Fuse Box ............................................... 23-47 Fuel Injection Sysrwm ....................... Section 11 * Gauges Circuit Diagram .................................. 23-l 24 Coolant Temperature Gauge ........................................... 23-136 Fuel Gauge ........................................ 23-134 Oil Pressure Gauge ............................. 23-l 37 Speedometer ..................................... 23-l 23 Tachometer ....................................... 23-123 Grounds Distribution ....................................... 23-67 Locations .......................................... 23-15 * Heater Controls ................................. Section 21 * Horns ................................................... 23-239 * Ignition Switch ...................................... 23-72 Ignition System ...................................... 23-88 Ignition Timing Control ........................... 2 3 - 9 1 Indicator * High Beam Indicator ........................... 23-l 30 *Safety Indicator ..................................... 23-145 * Shift Lever Position Indicator ............... 23-152 * Turn Signal Indicator .......................... 23-209 Integrated Control Unit ........................... 23-l 58 Interlock System .................................... 23-140 Lights, Exterior Back-up Lights ................................... 23-200 Brake Lights ...................................... 23-203 Daytime Running Lights (CANADA) ...... 23-190 Front Side Marker Lights ..................... 23-191 Hazard Lights .................................... 23-209 Headlights ......................................... 23-187 Brake Lights ...................................... 23-203 License Plate Lights ............................ 23-193 Position Lights ................................... 23-191 Rear Side Marker Lights ...................... 23-193 Taillights ........................................... 23-l 92 Turn Signal Lights .............................. 23-191 Lights, Interior Courtesy Lights ................................. 23-195 Dashlight Brightness Control .................................... .: ... 23-216 Dome Light ....................................... 23-195 Entry Light Timer ............................... 23-22 1 Glove Box Light ................................. 23-194 Trunk Light ....................................... 23-195 + Lighting System ..................................... 23-168 Locks, Power ...... . .................................. 23-253 Mirrors, Power ....................................... 23-248 Opener, Trunk ................. . ..................... 23-245 Power Distribution .................................. 23-50 Electrical Power Steering.&PSj ........... Section 11 Main Relay 80x . . .. . .... . ........................ . 23-47 . . . Relay Locations ........ ’............................. 23-10 c Seats, Power ................ . ........................ 23-270 Security Alarm System ..................... . ..... 23-304 Spark Plugs ........................................... 23-96 Starting System ..................................... ‘.23-75 * Stereo Sound System ............................. 23-229 Side Marker/Turn Signal/Hazard Flasher System .................................. 23-209 Washer, Windshield ................................ 23-28 1 ,I Windows, Power .................................... 23-261 . Wipers, Windshield .................... ;;;:z;rs-. ... 23-281 * Wires, Harnesses and Connectors Wire Color Codes ............................... 23-9 Wire Harness Routing ......................... 23-15 Wiring Diagrams ................................ 23-360 vnx.su ;I’ ; ,;;L’.: > “$~!,;s”.:y , .Qy?~>,~, ~ :i .,:f:$~ >,i ,; ‘g** ‘: ” 1,.9% 8’‘T: b

- 68. Special Tools Ref. No. 0 0 0 0 0 0 0 Tool Number 07JAA-001 OOOB 07MAi!-SL00500 07LAZ-SL40200 07LAZ-SL40300 07LAZ-SL40400 07HAZ-SG00500 KS-AHM-32-003 Discription Antenna Nut Wrench SRS Test Harness-A SRS Test Harness B SRS Test Harness C SRS Test Harness D Deployment Tool Digital Multimeter 23-2 vnx.su O’ty Page Reference 1 1 1 1 1 1 1 23-236 23-329 23-33 1 23-334 23-33 1 23-340 23-78

- 69. Troubleshooting -Troubleshooting Precautions 0 Push the locking tab to disconnect. Before Troubleshooting 0 Check the main fuse and the fuse box. 0 Check the battery for damage, ‘state of charge, and clean and tight connections. 0 Check the alternator belt tension. CAUTION: 0 Do not quick-charge a battery unless the battery ground cable has been disconnected, or you will damage the alternator diodes. 0 Do not attempt to crank the engine with the battery ground cable connected incompletely or you will severely damage the wiring. While You’re Working l Make sure connectors are clean, and have no loose pins or receptacles. 0 Make sure multiple pin connectors are packed with grease (except watertight connectors). LOCKING TABS Since new type connectors are used, connection and disconnection of them should be done paying attention to the following precautions. 0 Because all the connectors except terminal of 1-P are equipped with push-down type locks, unlock them first before disconnecting the connectors. 0 On the connectors installed on the bracket a pull type lock is equipped between the bracket and the connector. Some connectors of this type can not’ be disconnected unless they are removed from their brackets. ,’ When disconnecting, check their shapes. 0 On the bracket mounted connector with dual locks, remove the connector from the bracket before disconnecting. (cont’d) 23-3 vnx.su

- 70. Troubleshooting -Troubleshooting Precautions (cont’d) 0 Pull the locking tab to remove the connector from the bracket. 0 Place the plastic cover over the mating connector after reconnecting. Also check that the cover is not distorted. NO GOOD x CONNECTdR &ACKET 0 When disconnecting locks, first press in the connector tightly (to provide clearance to the locking device), then operate the tab fully and remove the connector in the designated manner. . 0 Before connecting connectors, check to see that the terminals are in place and not bent or distorted. NO GOOD LOCKING PAWL GOOD 0 When disconnecting a connector, pull it off from the mating connector by holding on both connectors. 0 Check for loose retainer and rubber seals. The illustration shows examples of terminal and seal abnormality. 0 Never try to disconnect connectors by pulling on their wires. GOOD NO GOOD 0 / 0 Example of waterproof connector: x NO GOOD RUBBER B/AL 23-4 vnx.su RETAINER I RUBBER SEAL /

- 71. + rl e l For the connector which uses insulation grease, clean the connector then apply grease if the grease is insufficient or contaminated. 0 Before connecting, check each connector cover for damage. Also make sure that the female connector is tight and not loosened from the previous use. 0 Insert male connectors into the female connectors fully until they will no longer go. l 0 Insert the connector tightly and make sure it is securely locked. 0 Position the wires so that the open end of the cover faces down. 0 Check all the wire harnesses are connected. 0 There are two types of locking tab: one that you have to push and the other you should not touch when connecting the connector. Check the shape of the locking tab before connecting. l e l Be sure that plastic cover is placed over the connection. The locking tab having a taper end should not be touched when connecting. The locking tab with an angle end should be pushed when connecting. x 0 GOOD 0 Secure wires and wire harness to the frame with their respective wire bands at the designated locations. Position the wiring in the bands so that only the insulated surfaces contact the wires or harnesses. 0 Remove with care not to damage the lock. 0 Insert connectors fully until they will no longer go. 0 The connectors must be aligned and engaged securely. 0 Do not use wire harnesses with a loose wire or connector. NO GOOD x nnnn 23-5 vnx.su

- 72. Troubleshooting rroubleshooting GOOD Precautions (cont’d) NO GOOD 0 Do not bring wire harnesses in direct contact with sharp edges or corners. 0 Also avoid contact with the projected ends of bolts, screws and other fasteners. NO GOOD GOOD x NO GOOD ’ 0 Route harnesses so they are not pulled taut or slackened excessively. After clamping, check each harness to be certain that it is not interfering with any moving or sliding parts of the vehicle. / x NO GOOD 1Keep wire harnesses away from the exhaust pipes and other hot parts. GOOD 0 Protect wires and harnesses with a tape or a tube if they are in contact with a sharp edge or corner. GOOD B Always keep a safe distance between wire harnesses and any heated parts. NO GOOD 0 Clean the attaching surface thoroughly if an adhesive is used. First, wipe with solvent or alcohol if necessary. x GOOD Keep sufficient distance1 0 0 GOOD 23-6 vnx.su NO GOOD x

- 73. + rl a l 0 Seat grommets in their grooves properly. When using the Service Tester, follow the manufacturer’s instructions and those described in the Shop Manual. l Always insert the probe of the tester from the wire harness side (except waterproof connector). 0 Do not damage the insulation when connecting a wire. 0 Do not use wires or harnesses with a broken insulation. Repair by wrapping with protective tape or replace with new ones if necessary. 0 After installing parts, make sure that wire harnesses are not pinched. 0 Make sure to use the probe with a tapered tip. 0 s GOOD NO GOOD 0 Do not drop parts. NO GOOD 0 After routing, check that the wire harnesses are not twisted or kinked. @ x 0 Wire harnesses should be routed so that they are not pulled taut, slackened excessively, pinched, or interfering with adjacent or surrounding parts in all steering positions. 23-7 vnx.su

- 74. Troubleshooting - Five-Step Troubleshooting 1. Verify The Complaint Turn on all the components in the problem circuit to verify the customer complaint. Note the symptoms. Do not begin disassembly or testing until you have narrowed down the problem area. 2. 4. Fix The Problem Once the specific problem is identified, make the repair. Be sure to use proper tools and safe procedures. Analyze The Schematic Look up the schematic for the problem circuit. Determine how the circuit is supposed to work by tracing the current paths from the power feed through the circuit components to ground. If several circuits fail at the same time, the fuse or ground is a likely cause. 5. Based on the symptoms and your understanding of the circuit operation, identify one or more possible causes of the problem. 3. Isolate The Problem By Testing The Circuit Make circuit tests to check the diagnosis you made in step 2. Keep in mind that a logical, simple procedure is the key to efficient troubleshooting. Test for the most likely cause of failure first. Try to make tests at points that are easily accessible. 23-8 vnx.su Make Sure The Circuit Works Turn on all components in the repaired circuit in all modes to make sure you’ve fixed the entire problem. If the problem was a blown fuse, be sure to test all of the circuits on that fuse. Make sure no new problems turn up and the original problem does not recur.

- 75. + rl How to Use This Section 1 r- Schematic Symbols 0 FUSE GROUND BATTERY Ground terminal RESISTOR MOTOR PUMP i 7 IGNITION SWITCH 1 VARIABLE RESISTOR :lRCUlT BREAKEF 0 Mast HORN I Q P TRANSISTOR CIGARETTE LIGHTER I $ : Component ground I I I I 1 d Y- 1 COIL. SOLENOID (Tr) Window HEATER BULB DIODE SPEAKER, i BUZZER D -Wire Color Codes The following abbreviations are used to identify wire colors in the circuit schematics. i IlIt RELAY (In Normal open relay I I -a-yi normal condition) 1Normal closed relay I I Y3 Input DIODE (LCC White Yellow Black Blue Green Red Orange Pink Borwn Gray Purple Light Blue Light Green Wire insulator has one color or one color with another color stripe. The second color is the stripe. BLK- Q CONNECTOR REED SWITCH ; output I e .UMlNOUS lormal closed switch I Q CONNECTION 1 T I SWITCH (In normal condition) Normal open switch CONDENSER WHT ......... YEL ........... BLK ........... BLU ........... GRN .......... RED ........... ORN .......... PNK .......... BRN .......... GRY .......... PUP ........... LT BLU ...... LT GRN ..... I --+--Male Femalc -a- 0 23-9 vnx.su

- 76. Relay and Control Unit Locations - Front compartment WINDSHIELD WIPER LOW RELAY HORN RELAY I INTERMITTENT WIPER RELAY /RIGHT RETRACTOR CUT RELAY RADIATOR FAN LOW RELAY -. -...-- RADIATOR FAN HIGH RELAY ULUWtK ALB REAR FAIL-SAFE RELAY / RELAY ALB FRONT FAI ICI nv CONDENSER FAN RE WER HIGH RELAY POWER WINDOW RELAY . TAILLIGHT RELAY ’ ALB MOTOR RELAY Y LlGHTlNd RELAY MAIN RELAY BOX ’ LEFT RETRACTOR RELAY 23-10 vnx.su

- 77. . Dashboard AUTOMATIC CLIMATE CONTROL STARTER warning system) INTEGRATED CONTROL UNIT DASH FUSE BOX vnx.su

- 78. Relay and Control Unit Locations - Dashboard, Door and Floor DRIVER’S DOOR INNER PANEL I I -’ ,, ANTI-LOCK BRAKE CONTROL UNIT I POWER DOOR LOCK CONTROL UNIT CONTROL UNIT ME RUNNING CONTROL CAhlAnd 1 SriCURlTY CONTROL UNIT SRS CONTkOL UNIT FOOT WELL BASk SPEAKER .,i .’ 2 3 - 1 2 vnx.su RIGHT F~~NT FLOOR PANEL

- 79. + rl - Rear Bulkhead PG PGM-FI MAIN RELAY RETRACTABLE HEADLIGHT INTERLOCK CONTROL UNIT aQcoNTRoLuNiT FUEL PUMP RELAY Ll”” I TNESS 9OL TCS CONTROL UNIT TCS FAIL-SAFE RELAY 23-13 vnx.su

- 80. Relay and Control Unit Locations - Engine Compartment ENGINE COMPARTMENT FAN RELA’! , REAR WINDOW DEFOGGER IGNITER UNIT 23-14 vnx.su

- 81. + rl Connector and Wire Harness Routing How to Identify Connectors: Identifying numbers have been assigned to all connectors. The number is preceded by the letter “C” for connectors, “G” for ground terminals or “T” for non-ground terminals. Location Harness Engine Compartment Starter Cable Battery Ground Wire Dashboard Others (Floor, Door, Trunk, Roof, Side) T2 and @ Tl and T3 Engine Ground Wire A Front compartment T5 G2 T6 G2 Engine Ground Wire B 0 Gl T7 G4 EPS Ground Wire Engine Wire Harness Knock Sensor Sub Harness Front Compartment Wire Harness Cl01 thru Cl61 TlOl and T103 GIOI thru G103 Cl71 thru Cl73 C201 thru C222 C225 thru C250 C301 thru C321 T201 thru T20B G201 and G202 G301 and G302 Right Retractor Sub Harness Left Retractor Sub Harness Floor Wire Harness C281 thru C283 C381 thru C383 C401 thru C471 G401 and G402 Side Wire Harness Rear Wire Harness Trunk Wire Harness Trunk Sub Wire Harness Driver’s Door Wire Harness Passenger’s Door Wire Harness SRS Main Wire Harness Roof Wire Fuel Tank Wires Driver’s Power Seat Wire Harness Passenger’s Power Seat Wire Harness Hatch Wires Rear Window Deffoger Wire Main Fuse Box Dash Fuse Box Main Relay Box C472 G403 C521 C551 G551 C581 C591 C601 C651 C701 G701 C751 C771 C781 C791 C801 G801 C811 thru thru thru thru C508 G405 C545 C564 and C582 and C592 thru C615 thru C660 thru C706 and C752 thru C773 thru C786 thru C795 thru C803 and C812 c921 C901 thru C907 C910 thru C913 C934 thru C941 23-l 5 vnx.su

- 82. Connector and Wire Harness Routing starter Cable Connector or Terminal Number Number of pins Where the Wires Go Location Left side of engine compartment Right side of front compartment area Right side of engine compartment To Main fuse box Battery To Battery positive terminal Gl Middle of front compartment area To Body ground, via battery ground wire 0 Battery To Battery negative terminal T5 Middle of engine compartment To G2 Left side of engine compartment To Body ground, via engine ground wire A To Main relay box To Starter motor Battery Ground Wire Engine Ground Wire A Transmission housing Engine Ground Wire B T6 G3 Right front corner of engine compartment To Front head cover Right front corner of engine compartment To Body ground, via engine ground wire B Center front compartment ander area To EPS Gearbox Center front compartment ander area To Body ground, via EPS ground wire EPS Ground Wire T7 G4 23-l 6 vnx.su Remark

- 83. &&JND WIRE . . EN&NE GROUND WIRE B vnx.su

- 84. Connector and Wire Harness Routing Engine Wire Harness Connector or rerminal Number Number of pins Cl01 14 Cl01 6 Cl02 2 Cl03 Cl04 Cl05 Cl06 Cl07 Cl08 Cl09 Cl10 Cl11 Cl12 Cl13 Cl14 Cl15 Cl16 Cl17 Cl18 Cl19 Cl20 Cl21 Cl22 Cl23 Cl24 Cl25 Cl26 Cl27 Cl28 Cl29 1 2 1 2 2 2 1 2 3 2 3 2 3 3 2 8 3 2 2 2 8 2 2 2 2 2 2 TIOI G103 Where the Wires Go Location Left side of engine compartment Left side of engine compartment Left side of engine compartment Engine compartment Engine compartment Engine compartment Engine Engine compartment Engine Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine compartment Engine Engine Engine Engine Engine Engine Engine Engine Remark To Side wire harness (C530) A/T To Side wire harness (C530) M/T To Side wire harness (C531) To Starter solenoid To Engine oil pressure sensor To Radio noise condenser To Front oil pressure switch B To Front spool solenoid valve To Coolant temperature sensor (TW) To Coolant temperature gauge sender To Back-up light switch To NM speed pulser To Lock-up control solenoid valve To Neutral switch To Shift control solenoid valve To Linear solenoid valve To Accel pedal sensor To Radiator coolant temperature sensor UWI To Jumper connector To Speed sensor To NC speed pulser To Rear spool solenoid valve To Rear engine oil pressure switch B To Igniter To No.1 Ignition coil To No.2 Ignition coil To No.3 Ignition coil To No.4 Ignition coil To No.5 Ignition coil To No.6 Ignition coil Left side of engine compartment To Main fuse box Engine compartment To Engine ground via engine wire harness 23-l 8 vnx.su MiT A/T A/T M/T A/T A/T A/T Rear

- 85. + lzl A ENGINE W I R E H A R N E S S / / -// / (cont’d) 23-l 9 vnx.su

- 86. Connector and Wiew Harness Routing Engine Wire Harness (Cont’d) Connector or ‘erminai Number Number of pins Cl30 Cl31 3 6 Cl32 Cl33 Cl34 Cl35 Cl36 Cl37 Cl38 Cl39 Cl40 Cl41 Cl42 Cl43 Cl44 Cl45 Cl46 Cl47 3 2 2 2 2 2 2 2 2 3 4 6 4 1 8 4 Cl48 4 Cl49 8 Cl50 2 Cl51 2 Cl52 Cl53 Cl54 2 20 26 Cl55 16 Cl56 12 Cl57 22 Cl58 Cl59 Cl60 Cl61 16 8 18 20 Where the Wires Go Location Left side of engine compartment Left side of engine compartment Left side of engine compartment Middle of engine Middle of engine Middle of engine Middle of engine Middle of engine Middle of engine Middle of engine Middle of engine Middle of engine Middle of engine Middle of engine Right corner of front engine Right corner of front engine Middle of engine Right side of engine compartment Right corner rear engine compartment Right side of engine compartment Right side of engine compartment Right side of engine compartment Right front engine compartment Right bulkhead Middle of behind middle of bulkhead Middle of behind middle of bulkhead Middle of behind middle of bulkhead Middle of behind middle of bulkhead Behind right side of bulkhead Behind right side of bulkhead Behind right side of bulkhead Behind right side of bulkhead Remark To Throttle angle sensor To Throttle motor To Knock sensor sub harness (C 171) To EACV To No.1 Fuel injector To No.2 Fuel injector To No.3 Fuel injector To No.4 Fuel injector To No.5 Fuel injector To No.6 Fuel injector To intake air temperature sensor To EGR valve lift sensor To Voltage regulator To igniter To Front oxygen sensor To A/C compresor clutch To CRANKICYL sensor Front To Engine compartment fan relay To Rear oxygen sensor To Engine compartment fan resister To Engine compartment fan To ignition Ne service connector To Fuel pump resister To Junction connector To PGM-Fi ECU To PGM-FI ECU To PGM-Fi ECU To PGM-Fi ECU To Floor wire harness (C476) To Floor wire harness (C475) To Floor wire harness (C477) To Floor wire harness (C478) T102 T103 Middle of engine compartment To Alternator Engine rear cylinder head To Oil pressure switch cover GIOI G102 Right middle of engine Right side of engine compartment To Engine ground, via engine wire harness Middle of engine Middle of engine Middle of engine To Engine wire harness (Cl321 To Front knock sensor To Rear knock sensor To Body ground, via engine wire harness Knock Sensor Sub Harness Cl71 Cl72 Cl73 3 2 2 23-20 vnx.su 0

- 88. Connector and Wire Harness Routing Front Compartment Wire Herness Connector or Number rerminal Number of pins c201 2 c202 C203 C204 c205 C206 2 2 2 2 2 C207 3 C206 14 c209 c210 c211 c212 C213 C214 c215 C216 C217 C218 c219 c220 c221 6 6 4 4 4 4 5 4 4 6 2 3 2 c222 5 G201 G202 Location Where the Wires Go Right front corner of front compartment area Behind Right front bumper Behind Right front bumper Behind Right front bumper Behind Right front bumper Front end of front compartment area Front end of front compartment area Right side of front compartment area Behind Right headlight Behind Right headlight Sub relay box B Sub relay box B Sub relay box B Sub relay box 6 Sub relay box B Sub relay box B Sub relay box B Behind spare tire Behind spare tire Behind spare tire Right front compartment area Under air scoop Right side of front compartment area Right side of front compartment area Remark To R. Front side marker To R. Condenser fan motor To R. Front position light To.R. Front turn signal light To. R. Horn To Radiator fan motor To Radiator fan resister To R. Retractor sub harness (C281) To R. Retractor relay To L. Retractor relay To Power amplifier relay To Anti-lock brake Front fail-safe relay To Washer motor relay To Anti-lock brake Rear fail-safe relay To Intermittent wiper relay To Windshield wiper high relay To Windshield wiper low relay To Recirculation control motor To Blower motor To Power transistor To R. Front anti-lock brake speed sensor To Windshild wiper rpotor To Body ground, via front compartment wire harness To Body ground, via front compartment wire harness e 23-22 vnx.su

- 90. Connector and Wire Harness Routing Front Compartment Wire Harness (Cont’dl Connector or ‘erminal Number Number of pins C225 C226 C227 C228 c229 C230 C231 C232 C233 C234 C235 4 4 4 4 4 4 4 4 4 4 4 C236 6 C237 C238 C239 C240 C241 C242 C243 C244 C245 C246 C247 C248 C249 C250 T201 T202 T203 T204 L T205 T206 T207 T208 20 14 6 20 18 18 12 20 1 8 16 14 12 10 7 Location Where the Wires Go box A box A box A box A box A Sub relay box A Sub relay box A Sub relay box A Sub relay box A Sub relay box A Rear under front compartment area Rear under front compartment area Behind right kick panel Right front floor Right under dash Right under dash Right under dash Right under dash Right under dash Behind right kick panel Behind right kick panel Behind right kick panel Behind right kick panel Behind right kick panel Behind right kick panel Behind right kick panel To Junction connector To Radiator fan low relay To A/C compressor clutch relay To Radiator fan high relay To Horn relay To Condenser fan relay To L. Retractor cut relay To Blower high relay To R. Retractor cut relay To Blower relay Battery Rear under front compartment area Rear under front compartment area Rear under front compartment area Right front floor Right front floor Right front floor Right front floor Remark Sub Sub Sub Sub Sub relay relay relay relay relay To EPS Tach generator EPS To EPS Torque sensor To Jaunction connector To Power unit To Anti-lock brake inspection connector To Anti-lock brake control unit To Anti-lock brake control unit To EPS control unit To EPS control unit To Floor wire harness (C468) To Floor wire harness (C469) To Floor wire harness (C470) To Floor wire harness (C466) To Floor wire harness (C465) To Floor wire harness (C464) To Floor wire harness (C467) EPS To Battery negative terminal EPS To Gearbox EPS To Gearbox EPS . To To To To To 23-24 vnx.su Gearbox Power unit Power unit Power unit Power unit EPS EPS EPS EPS EPS EPS

- 91. + rl SUB RELAY BOX A (cont’d) 23-25 vnx.su

- 92. .: Connector and Wire Harness Routing Front Comoartment Wire Harness (Cont’d) Connector and ‘erminal Number Number of pins c301 C302 c303 c 304 c305 C306 2 2 2 2 2 2 c307 2 C308 2 c309 c310 c311 C312 c313 c314 c315 C316 c317 C318 c319 3 3 2 3 3 14 4 2 2 4 1 C320 1 C321 2 Where the Wires Go Location Left front compartment area Left behind front bumper Left behind front bumper Left behind front bumper Left behind front bumper Behind middle of front bumper Behind middle of front bumper Middle of front compartment area Left front compartment area Left front compartment area Lefr f ront compartment area Left front compartment area Left front compartment area Left front compartment area Left front compartment area Left front compartment area Left front compartment area Left front compartment area Left rear front compartment area Left rear front compartment area Left rear front compartment area G301 Left front compartment area G302 Left front compartment area To To To To To L. Front side marker L. Condenser fan motor L. Front position light L. Front turn signal light L. Horn To Front washer motor To Ambient sensor To To To To To To To To To To To Hood switch Anti-lock brake left front solenoid Anti-lock brake left rear solenoid Anti-lock brake motor Anti-lock brake right front solenoid Anti-lock brake right rear solenoid Retractor sub harness (C381) Auto cruise actuator Security horn Anti-lock brake pressure switch A/C pressure switch To Brake fluid level switch ( + 1 To Brake fluid level switch (- 1 To L. Front anti-lock brake speed sensor To Body ground, via front compartment harness To Body ground, via front compartment harness 23-26 vnx.su Remark

- 94. Connector and Wire Harness Routing Right Retractor Sub Harness Where the Wires Go To Front compartment wire harness (C208) To Right headlight To Right retractor motor Left Retractor Sub Harness C381 14 C382 C383 6 6 Left front compartment area Behind Left headlight Left front compartment area To Front compartment wire harness (C314) To Left headlight To Left retractor motor 23-28 vnx.su Remark

- 95. e RIGHT RETRACTOR SUB HARNESS LEFT RETRACTOR SUB HARNESS I I vnx.su

- 96. Connector and Wire Harness Routing Floor Wire Harness Connector or Number rerminal Number of pins Where the Wires Go Location c401 C402 c403 c404 c405 C406 c407 C408 c409 c410 c411 16 12 14 16 5 16 20 2 18 14 10 Behind Behind Behind Behind Behind Behind Behind Behind Behind Behind Behind C412 c413 c414 c415 C416 c417 C418 c419 C420 C421 C422 C423 C424 C425 C426 C427 C428 c429 c430 c431 C432 c433 c434 c435 C436 c437 30 2 2 6 16 20 14 30 16 2 4 2 2 12 3 4 3 4 2 2 7 6 2 6 5 30 Behind gauge Left under dash Left under dash Left under dash Left under dash Behind gauge Under middle of dash Under middle of dash Under middle of dash Under middle of dash Under center console Under center console Under center console Under center console Under center console Under middle of dash Under middle of dash Under right dash Under right dash Behind glove box Right under dash Under middle of dash Under middle of dash Under middle of dash Behind instrument panel Behind gauges G401 G404 left kick panel left kick panel left kick panel left kick panel left kick panel left kick panel left kick panel left kick panel left kick panel left kick panel instrument kick panel Behind left kick panel Middle of floor Remark To Integrated control unit To Dash fuse box (C904) To Dash fuse box (C901) To Dash fuse box (C902) To Dash fuse box (C905) To Dash fuse box PC9031 To Side wire harness (C523) To Side wire harness (C524) To Driver’s door wire harness (C601) To Driver’s door wire harness (C602) To Retractor switch/Dashiight brightness controller To Gauge assembly To Foot light To Chime (lights-on warning) To Turn signal/Hazard relay To Combination switch (lighting & turn) To Junction connector To Automatic climate control unit To Automatic climate control unit To Stereo radio/cassette player To Cigarette lighter relay To Shift position console light To Shift position console switch To Shift position console switch To Shift lock solenoid To In car temperature sensor To Cigarette lighter To SRS main wire harness (C701) To Glove box light To Trunk opener main switch To Function contol motor To Air mix motor To Evaporator temperature sensor To Ventilation control motor To TCS off switch To Gauge assembly To Body ground, via floor wire harness To Body ground, via floor wire harness 23-30 vnx.su A/T AIT AK AIT A/C A/C A/C A/C AIC

- 97. FLOOR WIRE HARNESS I Lx C4b5 c&2 I C416 / I LEFT KICK PANEL I I C425 C424 C426 c422 C423 I 6701 0404 kont’d) 23-31 vnx.su