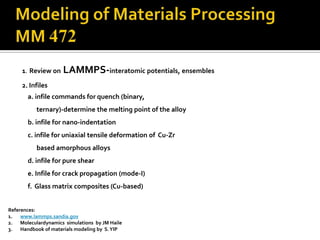

Modeling of materials processing

- 1. 1. Review on LAMMPS-interatomic potentials, ensembles 2. Infiles a. infile commands for quench (binary, ternary)-determine the melting point of the alloy b. infile for nano-indentation c. infile for uniaxial tensile deformation of Cu-Zr based amorphous alloys d. infile for pure shear e. Infile for crack propagation (mode-I) f. Glass matrix composites (Cu-based) References: 1. www.lammps.sandia.gov 2. Moleculardynamics simulations by JM Haile 3. Handbook of materials modeling by S. YIP

- 2. 1. Introduction to Fluent 2. Applications of Fluent 3. How to solve a problem using fluent

- 3. Group leaders Group A: chirag; nachiket (14,40,37,45,43) Group B: divyaranjan; arindam(7,16,51,41,50) Group C: somi, hari (38,56,47,19,42,57) Group D: mukul; swayambhu(36,15,35,30,52) Group E: rajesh; priya(32,58,39,21,22) Group F:raja;satnarayan (26,6,24,44,3,49,31)

- 4. Experiment-1 validate the interatomic potential a. create random solid soultion of Cu50Zr50 alloy (50 Å x 50 Å x 50 Å; 50 Å x 50 Å x 100 Å) b. melt the binary alloy at three different temperatures (1500 K, 2000 K, 1000 K). Use 20000 iterations to reach the above tempe c. compare the temperatures with the experimental observed from the phase diagram d. Use RDF plot to judge the liquid structure e. Quench the alloy (1014 K/s, 1012 K/s, 1010K/s) f. Plot volume vs. temperature during heating, holding and quenching. g. Determine the glass transition temperature and the effect of cooling rate on the transition temperature. h. create ternary Cu47Zr47Al6 amorphous alloy

- 5. Experiment-2 Calculating the diffusivity of Cu in amorphous Cu50Zr50 and Cu47Zr47Al6 alloys 1. Use compute MSD (mean square displacement) to calculate the diffusivities of Cu, Zr and Al 2. Use NPT ensemble Tstart and Tend at 300 K, run the simulation for 50000 iterations, plot MSD values vs time step 3. Slope in diffuse regime gives the diffusivity 4. Study the effect of temperature(300 K, 500 K, 700 K) on the diffusivity. Calculate activation energy. 5. Compare the diffusivities with experimental values (ref: Materials Science and engineering by Raghavan; Calister)

- 6. Experiment-3 Effect of loading rate on the strength of amorphous Cu50Zr50 and Cu47 Zr47Al6 thin film during nano-indentation 1. Indenter diameter 30 Å (50 Å x 50 Å x 50 Å box size) 2. Indenter velocity 2 Å/ps, 5 Å/ps, 7 Å/ps 3. Run for 1000 iterations 4. Plot load vs displcement 5. Contour plots for stress analysis

- 7. Experiment-4 Length scale effect on the deformation behavior of Cu50Zr50 and Cu47Zr47Al6 amorphous alloys 1. Uniaxial tensile deformation at strain rate 109 s-1 2. Deform the two sizes 3. Run for 1000 iterations 4. Calculate the MSD values for Cu, Zr, Al 5. What is the effect of Al on the diffusivity of the Cu, Zr? 6. Stress vs. strain plots

- 8. Experiment-5 Theoretical strength of the amorphous Cu50Zr50 and Cu47Zr47Al6 alloys 1. Do pure shear at strain rate 1 x 1011 s-1 for two sizes 2. What is the effect of box size on the stress-strain behavior 3. What is the effect of aluminum on the flow curve

- 9. Experiment-6 Synthesis of glass matrix composites I 1. Binary Cu50Zr50 GMC 2. Ternary Cu47Zr47Al6 GMC 2D and 3D model (100 Å x 100 Å x 3.5 Å) II. Uniaxial tensile deformation of 2D model till fracture to study the bonding at the glass-crystallite interface

- 10. Experiment-7 Crack-I mode fracture behavior of Cu50Zr50 amorphous alloy 1. Create a crack by deleting atoms 2. Take the box size (50 Å x 50 Å x 50 Å) 3. Deform at strain rate 1011 s-1 4. Plot stress vs. strain

- 11. Experiment-8 a. Flow behavior of fluid in a pipe Laminar and turbulent flow b. Solidification of pure metal in a cylindrical mould