Overview of 3 day Lean & Kaizen Course Content

•Download as PPT, PDF•

8 likes•4,893 views

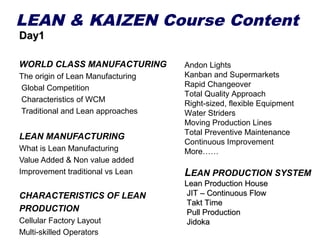

This document outlines the content of a 3-day Lean & Kaizen course. Day 1 covers topics like Lean Manufacturing principles, characteristics of Lean production including cellular layouts and Kanban systems. Day 2 focuses on standard work including takt time and pull production. Day 3 covers tools for standard work, Total Productive Maintenance (TPM), and Kaizen workshops which use small group projects to drive continuous improvement. The workshop method involves planning, implementing improvements on the production floor for a week, and follow up meetings to sustain results.

Report

Share

Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Viewers also liked

Viewers also liked (19)

5S Techniques by Operational Excellence Consulting

5S Techniques by Operational Excellence Consulting

Similar to Overview of 3 day Lean & Kaizen Course Content

Similar to Overview of 3 day Lean & Kaizen Course Content (20)

LEAN - What Does Kaizen Mean.ppt based on lean manufacturing

LEAN - What Does Kaizen Mean.ppt based on lean manufacturing

Proven Methods to Abnormality Management and Error Proofing

Proven Methods to Abnormality Management and Error Proofing

Kanban India 2023 | Renjith Achuthanunni and Anoop Kadur Vijayakumar | DevOps...

Kanban India 2023 | Renjith Achuthanunni and Anoop Kadur Vijayakumar | DevOps...

More from Timothy Wooi

More from Timothy Wooi (20)

Story of The Soldier Son Portrait who died to save others

Story of The Soldier Son Portrait who died to save others

SEAIETI Online Educational Administration Practices with TQM

SEAIETI Online Educational Administration Practices with TQM

Innovative Leadership in Education for the New Normal

Innovative Leadership in Education for the New Normal

Leadership and the teaching and learning culture in the new normal

Leadership and the teaching and learning culture in the new normal

Communication & Interpersonal Skills at Multi Cultural Workplace

Communication & Interpersonal Skills at Multi Cultural Workplace

The Seven Habits of Highly Effective People by Steven Covey

The Seven Habits of Highly Effective People by Steven Covey

Touraride Penang Downing Street to London Downing Street

Touraride Penang Downing Street to London Downing Street

Disruptive Pandemic School Leadership Management Shift

Disruptive Pandemic School Leadership Management Shift

Recently uploaded

Saudi Arabia [ Abortion pills) Jeddah/riaydh/dammam/++918133066128☎️] cytotec tablets uses abortion pills 💊💊 How effective is the abortion pill? 💊💊 +918133066128) "Abortion pills in Jeddah" how to get cytotec tablets in Riyadh " Abortion pills in dammam*💊💊 The abortion pill is very effective. If you’re taking mifepristone and misoprostol, it depends on how far along the pregnancy is, and how many doses of medicine you take:💊💊 +918133066128) how to buy cytotec pills

At 8 weeks pregnant or less, it works about 94-98% of the time. +918133066128[ 💊💊💊 At 8-9 weeks pregnant, it works about 94-96% of the time. +918133066128) At 9-10 weeks pregnant, it works about 91-93% of the time. +918133066128)💊💊 If you take an extra dose of misoprostol, it works about 99% of the time. At 10-11 weeks pregnant, it works about 87% of the time. +918133066128) If you take an extra dose of misoprostol, it works about 98% of the time. In general, taking both mifepristone and+918133066128 misoprostol works a bit better than taking misoprostol only. +918133066128 Taking misoprostol alone works to end the+918133066128 pregnancy about 85-95% of the time — depending on how far along the+918133066128 pregnancy is and how you take the medicine. +918133066128 The abortion pill usually works, but if it doesn’t, you can take more medicine or have an in-clinic abortion. +918133066128 When can I take the abortion pill?+918133066128 In general, you can have a medication abortion up to 77 days (11 weeks)+918133066128 after the first day of your last period. If it’s been 78 days or more since the first day of your last+918133066128 period, you can have an in-clinic abortion to end your pregnancy.+918133066128

Why do people choose the abortion pill? Which kind of abortion you choose all depends on your personal+918133066128 preference and situation. With+918133066128 medication+918133066128 abortion, some people like that you don’t need to have a procedure in a doctor’s office. You can have your medication abortion on your own+918133066128 schedule, at home or in another comfortable place that you choose.+918133066128 You get to decide who you want to be with during your abortion, or you can go it alone. Because+918133066128 medication abortion is similar to a miscarriage, many people feel like it’s more “natural” and less invasive. And some+918133066128 people may not have an in-clinic abortion provider close by, so abortion pills are more available to+918133066128 them. +918133066128 Your doctor, nurse, or health center staff can help you decide which kind of abortion is best for you. +918133066128 More questions from patients: Saudi Arabia+918133066128 CYTOTEC Misoprostol Tablets. Misoprostol is a medication that can prevent stomach ulcers if you also take NSAID medications. It reduces the amount of acid in your stomach, which protects your stomach lining. The brand name of this medication is Cytotec®.+918133066128) Unwanted Kit is a combination of two medicines, ounwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE Abudhabi![unwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE Abudhabi](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![unwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE Abudhabi](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

unwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE AbudhabiAbortion pills in Kuwait Cytotec pills in Kuwait

Saudi Arabia [ Abortion pills) Jeddah/riaydh/dammam/++918133066128☎️] cytotec tablets uses abortion pills 💊💊 How effective is the abortion pill? 💊💊 +918133066128) "Abortion pills in Jeddah" how to get cytotec tablets in Riyadh " Abortion pills in dammam*💊💊 The abortion pill is very effective. If you’re taking mifepristone and misoprostol, it depends on how far along the pregnancy is, and how many doses of medicine you take:💊💊 +918133066128) how to buy cytotec pills

At 8 weeks pregnant or less, it works about 94-98% of the time. +918133066128[ 💊💊💊 At 8-9 weeks pregnant, it works about 94-96% of the time. +918133066128) At 9-10 weeks pregnant, it works about 91-93% of the time. +918133066128)💊💊 If you take an extra dose of misoprostol, it works about 99% of the time. At 10-11 weeks pregnant, it works about 87% of the time. +918133066128) If you take an extra dose of misoprostol, it works about 98% of the time. In general, taking both mifepristone and+918133066128 misoprostol works a bit better than taking misoprostol only. +918133066128 Taking misoprostol alone works to end the+918133066128 pregnancy about 85-95% of the time — depending on how far along the+918133066128 pregnancy is and how you take the medicine. +918133066128 The abortion pill usually works, but if it doesn’t, you can take more medicine or have an in-clinic abortion. +918133066128 When can I take the abortion pill?+918133066128 In general, you can have a medication abortion up to 77 days (11 weeks)+918133066128 after the first day of your last period. If it’s been 78 days or more since the first day of your last+918133066128 period, you can have an in-clinic abortion to end your pregnancy.+918133066128

Why do people choose the abortion pill? Which kind of abortion you choose all depends on your personal+918133066128 preference and situation. With+918133066128 medication+918133066128 abortion, some people like that you don’t need to have a procedure in a doctor’s office. You can have your medication abortion on your own+918133066128 schedule, at home or in another comfortable place that you choose.+918133066128 You get to decide who you want to be with during your abortion, or you can go it alone. Because+918133066128 medication abortion is similar to a miscarriage, many people feel like it’s more “natural” and less invasive. And some+918133066128 people may not have an in-clinic abortion provider close by, so abortion pills are more available to+918133066128 them. +918133066128 Your doctor, nurse, or health center staff can help you decide which kind of abortion is best for you. +918133066128 More questions from patients: Saudi Arabia+918133066128 CYTOTEC Misoprostol Tablets. Misoprostol is a medication that can prevent stomach ulcers if you also take NSAID medications. It reduces the amount of acid in your stomach, which protects your stomach lining. The brand name of this medication is Cytotec®.+918133066128) Unwanted Kit Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pills

Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pillsAbortion pills in Kuwait Cytotec pills in Kuwait

Falcon stands out as a top-tier P2P Invoice Discounting platform in India, bridging esteemed blue-chip companies and eager investors. Our goal is to transform the investment landscape in India by establishing a comprehensive destination for borrowers and investors with diverse profiles and needs, all while minimizing risk. What sets Falcon apart is the elimination of intermediaries such as commercial banks and depository institutions, allowing investors to enjoy higher yields.Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...

Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...Falcon Invoice Discounting

Falcon stands out as a top-tier P2P Invoice Discounting platform in India, bridging esteemed blue-chip companies and eager investors. Our goal is to transform the investment landscape in India by establishing a comprehensive destination for borrowers and investors with diverse profiles and needs, all while minimizing risk. What sets Falcon apart is the elimination of intermediaries such as commercial banks and depository institutions, allowing investors to enjoy higher yields.Falcon Invoice Discounting: The best investment platform in india for investors

Falcon Invoice Discounting: The best investment platform in india for investorsFalcon Invoice Discounting

Recently uploaded (20)

Falcon Invoice Discounting: Aviate Your Cash Flow Challenges

Falcon Invoice Discounting: Aviate Your Cash Flow Challenges

unwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE Abudhabi![unwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE Abudhabi](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![unwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE Abudhabi](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

unwanted pregnancy Kit [+918133066128] Abortion Pills IN Dubai UAE Abudhabi

Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pills

Mifty kit IN Salmiya (+918133066128) Abortion pills IN Salmiyah Cytotec pills

Al Mizhar Dubai Escorts +971561403006 Escorts Service In Al Mizhar

Al Mizhar Dubai Escorts +971561403006 Escorts Service In Al Mizhar

The Abortion pills for sale in Qatar@Doha [+27737758557] []Deira Dubai Kuwait![The Abortion pills for sale in Qatar@Doha [+27737758557] []Deira Dubai Kuwait](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![The Abortion pills for sale in Qatar@Doha [+27737758557] []Deira Dubai Kuwait](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

The Abortion pills for sale in Qatar@Doha [+27737758557] []Deira Dubai Kuwait

Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...

Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...

Falcon Invoice Discounting: Unlock Your Business Potential

Falcon Invoice Discounting: Unlock Your Business Potential

TVB_The Vietnam Believer Newsletter_May 6th, 2024_ENVol. 006.pdf

TVB_The Vietnam Believer Newsletter_May 6th, 2024_ENVol. 006.pdf

Falcon Invoice Discounting: Empowering Your Business Growth

Falcon Invoice Discounting: Empowering Your Business Growth

How to Get Started in Social Media for Art League City

How to Get Started in Social Media for Art League City

Power point presentation on enterprise performance management

Power point presentation on enterprise performance management

Falcon Invoice Discounting: The best investment platform in india for investors

Falcon Invoice Discounting: The best investment platform in india for investors

Jual Obat Aborsi ( Asli No.1 ) 085657271886 Obat Penggugur Kandungan Cytotec

Jual Obat Aborsi ( Asli No.1 ) 085657271886 Obat Penggugur Kandungan Cytotec

Overview of 3 day Lean & Kaizen Course Content

- 1. LEAN & KAIZEN Course Content Day1 WORLD CLASS MANUFACTURING The origin of Lean Manufacturing Global Competition Characteristics of WCM Traditional and Lean approaches LEAN MANUFACTURING What is Lean Manufacturing Value Added & Non value added Improvement traditional vs Lean CHARACTERISTICS OF LEAN PRODUCTION Cellular Factory Layout Multi-skilled Operators Andon Lights Kanban and Supermarkets Rapid Changeover Total Quality Approach Right-sized, flexible Equipment Water Striders Moving Production Lines Total Preventive Maintenance Continuous Improvement More…… LEAN PRODUCTION SYSTEM Lean Production House JIT – Continuous Flow Takt Time Pull Production Jidoka

- 2. LEAN & KAIZEN Content Day 2 Day3 STANDARD WORK & 3Ts Element 1: Takt time Element 2: Standard work sequence Element 3: Line Balancing Element 4: Standard work in Process (SWIP) 3Ts – Takt Time, Cycle Time & Lead time PULL PRODUCTION & KANBAN Overproduction Continuous flow Push vs Pull system Kanban system STANDARD OPERATION REVIEW (Exercises) STANDARD OPERATION TOOLS Kaizen Target and Scope Standard work sheet Time observation sheet Percent loading chart Standard combination sheet Progress Result Report Kaizen Newspaper TOTAL PRODUCTIVE MAINTENANCE (TPM) KAIZEN WORKSHOP

- 3. Day1 WORLD CLASS MANUFACTURING Class outlines: The origin of Lean Manufacturing Global Competition Characteristics of WCM Traditional and Lean approaches

- 4. Day1 LEAN MANUFACTURING Class outlines: What is Lean Manufacturing Value Added & Non value added Improvement traditional vs Lean

- 5. Day1 CHARACTERISTICS OF LEAN PRODUCTION Tools and practices commonly associated Lean Production System Cellular Factory Layout Multi-skilled Operators 5s and Visual Control Andon Lights Kanban and Supermarkets Rapid Changeover Total Quality Approach Right-sized, flexible Equipment Water Striders Moving Production Lines Total Preventive Maintenance Continuous Improvement More……

- 6. Day1 LEAN PRODUCTION SYSTEM Class Outlines: Lean Production House JIT – Continuous Flow Takt Time Pull Production Jidoka

- 7. Day2 STANDARD OPERATION Class Outlines: Element 1: Takt time Element 2: Standard work sequence Element 3: Line Balancing Element 4: Standard work in Process (SWIP) 3Ts – Takt Time, Cycle Time & Lead time

- 8. Day2 PULL SYSTEM & KANBAN Class Outlines: Overproduction Continuous flow Push vs Pull system Kanban system

- 9. Day2 Standard Operations Exercise Example 1 of Exercise Data 1 shift (8 hours) 2 - 15 minute breaks 1 - 15 minute crew meeting Requirements 290 per month 20 days per month WIP 26 Heads 5

- 10. Day3 STANDARD OPERATION TOOLS Class outlines: Tools used in Standard Operation Kaizen Target and Scope Standard work sheet Time observation sheet Percent loading chart Standard combination sheet Progress Result Report Kaizen Newspaper

- 11. Day3 Total Productive Maintenance Class Outlines:

- 12. Day3 KAIZEN WORKSHOP Class Outlines: What is Kaizen? Roles and benefit of Kaizen events Key roles for Successful Kaizen Events Phase 1: Planning & prepare for Kaizen Event Phase 2: Implementation – the event itself Phase 3: Follow up

- 13. What is Kaizen? KAIZEN = CONTINOUS IMPROVEMENT IMPROVEMENT WITHOUT ENDING In Japanese KAI ZEN Change Good KAI ZEN = Change for better The small, gradual, incremental changes applied over a long period can be add up for a major impact on business in the future.

- 14. The spirit of Kaizen Throw all your concrete head 10 people’s ideas is better than 1 Kaizen with LESS COST or NO COST Think how it would work NOT won’t Improvement has NO limits Don’t accept excuses Don’t seek for perfection Correct the mistake the moment you found Ask WHY 5 times Problem gives your brain a chance to work

- 15. Why Kaizen? To continuously eliminate waste without removing the value added activities in the process Waiting Processing Inventory Transportation Take all FOUR Movement I need ONE! MUDA Defects Over Production

- 16. Why Kaizen? Benefits to the Company Eliminates hidden cost – 11 wastes Improve value added – Quality, Cost & Delivery Benefits to YOU Improved work place – eliminate unnecessary movement & delay Improve the best methods YOU HELP THE COMPANY TO MEET QCD

- 17. Key roles for a Successful Kaizen event Upper Management The initiation MUST come from Upper Management Build the culture of continuous improvement Additional training on the concept of cell design, one piece flow, Pull production, TPM, 5s’ Kaizen is not about eliminating people but eliminate waste for better work place

- 18. Production Manager Work with KPO Choose areas Identify problems Identify leaders To guide and support the Kaizen team Lean principles

- 19. Phase 1: Planning and preparation STEP 1: Select area STEP 2: Identify problems Eliminate waste Eliminate bottleneck Implement 5s Implement Cell Design, Line Balancing or Kanban STEP 3: Select leader STEP 4: Select Team Train the team STEP 5: Walk and document the process STEP 6: Prepare the area Advanced production Required material, equipment & Support people

- 20. KICKOFF MEETING Team leader provides welcome and quick introduction Sub-team leaders introduce area “as is” via standard work charts These slides are mandatory: 1. 2. 3. 4. 5. Target & Scope – Problem statement, target to the week, team member & scope Target sheet – Narrow key target for the week Standard work sheet – product flow ie process map & people flow and wip Percent Loading Chart – Takt time against cycle time Standard work combination sheet – the major process

- 21. Phase 2: Implementation Walk and document the process – gather data prior to the Kaizen event Data that represent a study on: Process flow People Travel Product travel Operator cycle time Cycle time against Takt time Quality issues Identifying CLOSEMIDTTS Fill out Standard Operation Tools

- 22. GEMBA KAIZEN Start day working on shop floor. Gather together for lunch (no report) and at end of day for daily report out. Go and have fun!!!! Afternoon bring down key management to see progress made in work area.

- 23. Kaizen REPORT OUT DAILY REPORT OUT Team leader prepare for end of day 10 mins report out in afternoon Review the progress through: Target sheet Used any combination of charts – Standard work sheet, Percent Loading, Std Combination or Kaizen Cartoon , Progress Result Report . Standard Work Sheet Percent Loading Chart (Bar Chart) Process Name: Find Core Remnant Scope Of Operation Process Name: Mohd Noor Model Number: 777 Cutting Core From: Core Store Model Name: 777 To: Core Area Standard Work Combination Sheet To: Core Area Team Leader: Mohd Noor Wait CTT RACK REMNANT RACK 140 TIME (Sec) DOWNDRAFT TABLE B REMNANT RACK A Target 100 sec CTT RACK CUTTING REMNANT RACK 100 DOWNDRAFT TABLE 3 QA TABLE 80 QA TABLE 2 40 CHAMFER SAW 20 163 ft 51 ft 0 BEFORE KAIZEN DAY 1 DAY 2 DAY 3 DAY DAY 4 DAY 5 REMNANT RACK CUTTING SANDING CUTTING TABLE REMNANT RACK REMNANT RACK B REMNANT RACK 60 CHAMFER SAW C C PEOPLE TRAVEL CUTTING PRODUCT TRAVEL 8 CUTTING CTT RACK A)REMNANT BEHIND TORRIT BOOTH B)REMNANT AT CORE AREA C)REMNANT UNDER TABLE # Operation/Process 1 Target and scope Hazli 2 Progress report out Sommat 3 Kanban system Hazli 4 Work instruction for block saw machine Bashri 5 5S practice Osnizal 6 Process improvement cartoon Fauzi 7 Kaizen Newspaper Hazli 9 CHAMFER SAW CHAMFER SAW 10 Quality Check Safety Precaution Standard Work in Process # of pieces of Std. Work-in-Process Takt Time Operator Number 19 Area: CORE AREA Team Leader: MOHD HAZLI Time Step 1 Takt Time: 1200 SEC Process: potting area CYCLE TIME TO FIND CORE REMNANT Requirements: 1 Product: CORE BLOCK SAW LAYUP ROOM 160 Manual Automatic Walking Manager: Ku Mohd Soffi Before kaizen 120 Date: 8 - 12 JUL 2002 From: Core Store Model Name: Boeing Area: Core Area Date: 31/3/2003 - 4/4/2003 Scope of Operations Model Number: 737/747/767/777 Date: 31/3/03 - 4/4/03 Manual 2 2 4 2 2 3 4 Mach 1 Walk 2 3 Ope. Time 6 7 8 9 10

- 24. Phase 3: Follow up The event should NEVER end. Result MUST be monitored and improvements continually made

- 25. Monthly Followup REPORT OUT •Team reports completed implementation actions for the week/month • Prepare final report out with key personals. • All team members are involved, use standard work combination sheet to set sub-team agenda and to allocate time to each member.

Editor's Notes

- {"5":"When you see visit lean factories you may notice they have many common traits. All lean manufacturers use a set of common tools to implement their lean production system. The methods of application may vary, but a good lean facility will practice all these techniques and more.\n","13":"Kaizen event is as much as important as other activities because it is the builiding block of all LEAN Prod. Methology.\nLean production is founded on the idea of KAIZEN or Continous Improvement\n","14":"Kaizen event is as much as important as other activities because it is the builiding block of all LEAN Prod. Methology.\nLean production is founded on the idea of KAIZEN or Continous Improvement\n"}