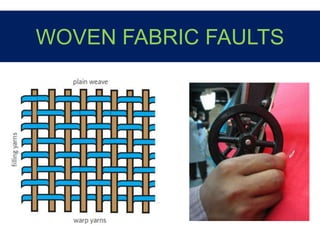

Woven fabric faults

- 2. Prepared By : Mazadul Hasan sheshir ID: 2010000400008 13th Batch (session 2009-2013) Department : Wet Processing Technology Email: mazadulhasan@yahoo.com Blog : www. Textilelab.blogspot.com (visit) Southeast University Department Of Textile Engineering I/A 251,252 Tejgaon Dhaka Bangladesh Prepared By :

- 3. STARTING MARK WARP YARN HEALD SHAFT FIG: LEVELLING STATE OF WARP YARN IN LOOM FIG: SHEDDING STATE OF WARP YARN REASON: THE MAIN REASON OF STARTING MARK IS THE EXTENSION OF WARP YARN DUE TO THE TENSION THAT CREATS ON IT. REMEDIES: TO SOLVE THIS PROBLEM WE HAVE TO MOVE THE BACK REST IN THE BACKWARD POSITION.

- 4. 2. LOOSE WARP IN FABRIC REASONS: a. IF THE TENSION OF WARP YARN IS LOW IN WARPING, THEN THIS FAULT APPEARS. b. IF THE BEAM CONTAIN BROKEN WARP YARN. REMIDIES: a. THE WARP TENSION IN WARPING SHOULD BE EQUAL AND UNIFORM. b. WE HAVE TO MOTIVATE THE WORKER TO TAKE CARE OF THE FABRIC.

- 5. 3. DOUBLE END REASON: a. AFTER SIZING IF THE TWO ENDS OF WARP STICKS TOGATHER. AND IF THE WORKER DON’T OBSERVE THAT PROPERLY THAN THOSE ENDS CAN GO TOGATHER THROUGH THE SAME HEALD EYE AND CAN CREATE THIS PROBLEM. REMEDIE: WORKER HAVE TO BE VERY CARE FULL ABOUT THIS MATTERS.

- 6. BROKEN WARP REASON: IF A WARP YARN BREAKS AND IF THE DROPPER DON’T FALL ON THE DROPPER BAR , THEN THIS FAULT ARISE. REMEDIES: 1. OPERATOR SHOULD WALK AROUND THE MACHINE TO OBSERVE THIS SORTS OF PROBLEM. 2. IF THE PROBLEM IS IN THE DROPPER BAR THEN, WE HAVE TO CHANGE THAT BAR.

- 7. TIGHT END REASON: IF THE TENSION OF A WARP YARN IS MORE THAN THE OTHER ENDS PRESENT IN THE LOOM THEN THIS PROBLEM ARISE. THIS OVER TENSION PRODUCED ON WARP DURING WARPING AND WEAVING. REMEDIES: TO SOLVE THIS PROBLEM WE HAVE TO FIND THESE ENDS AND HAVE TO ADJUST THE TENSION.

- 8. FLOAT OF WARP REASON : IF SOMEONE PULL THE FABRIC TOWARDS THE CLOTH ROLLER INTENTIONALY OR UNTENTIONALY THEN WE CAN HAVE THIS FAULT. REMEDIES: WORKER HAVE TO BE VERY CAREFULL ABOUT THE BUTTON WHICH CAUSES THE FABRIC TO COME FORWARD.

- 9. WRONG END COLOUR REASON: IT HAPPENS DUE TO THE WRONG DRAWING OF COLOUR YARN. REMEDIES: 1. WORKER HAVE TO BE VERY CAREFULL DURING DOING THE JOB OF DRWING. 2. AFTER FINDING THE FAULTS WE HAVE TO REMOVE THE FAULTY COLOUR YARN AND PLACE A CORRECT COLOUR YARN.

- 10. BROKEN PICK REASONS: 1. IF THE SPEED OF THE MACHINE IS TOO HIGH, THEN BEAT FORCE OF THE REED TO WEFT YARN WILL BE TOO HIGH. 2. IF THE PRESSURE OF THE RELAY NOZZLE AND ELCA IS TOO HIGH. REMEDIES: 1. WE HAVE TO REDUCE SPEED OF THE MACHINE. 2. WE HAVE TO REDUCE THE PREESURE OF RELAY NOZZLE OR ELCA.

- 11. MISS PICK REASONS: IF A WORKER START A STOPPED MACHINE WITHOUT PICKING THE BROKEN WEFT FROM THE SHED THEN THIS TYPE OF FAULT ARISE. REMEDY: WE HAVE TO MOTIVATE THE WORKER TO DO JOB PROPERLY DURING TIME OF PICK FINDING.

- 12. DOUBLE PICK REASON: IF THE CUTTER DON’T WORK PROPERLY. REMEDY: THE ANGLE OF THE CUTTER SHOULD BE CHANGED OR IT’S BLADE SHOULD BE CHANGED.

- 13. SNARL OR LOOSE WEFT REASON: IT HAPPENS DUE TO THE MALFUNCTIONING OF THE PFT OR DUE TO LOOSENESS OF THE FILLING YARN OR THE WRONG ALIGNMENT OF PRE-WINDER TO FIXED NOZZLE. REMEDIES: 1. THE DEGREE OF THE PFT HAVE TO BE PERFECT. 2. THE PRESSURE OF THE MAIN VALVE, RELAY VALVE AND RELAY NOZZLE SHOULD BE PERFECT. 3. THE ALIGNMENT OF THE PREWINDER SHOULD UNIFORM AND STRAIGHT.

- 14. WEFT BAR REASONS: IF COUNT OF YARN VARY FROM CONE TO CONE OR WITHIN THE CONE THEN A BAR OF WEFT WILL APPEARED IN FABRIC AFTER WEAVING. REMEDY: TO SOLVE THIS PROBLEM WE NEED TO BUY YARN WITH UNIFORM THICKNESS.

- 15. BALL REASON: IF THE WARP IS TOO MUCH HAIRY . THEN THE REED WILL CREATE BALL IN WARP YARN IN- BETWEEN HEALD SHAFT AND REED . IF THE BALL IS SMALL ENOUGH TO PASS TROUGH THE DENT OF REED THEN THEY WILL FORM THE BALL IN FABRIC. REMEDY: TO SOLVE THIS PROBLEM WE HAVE TO CHANGE THE REED, OR REDUCE THE TENSION OF THE WRAP YARN.

- 16. HOLES 1. IF WE TRY TO CUT THE BALLS OF THE FABRIC WHICH MAKES THE LOOK OF THE FABRIC POOR THEN IT WILL BE CUT ALONG WITH THE WARP. THIS WILL CREATE HOLE IN THE FABRIC. THIS HOLES BECOME BIGGER AFTER THE FINISHING PROCESS. 2. IT CAN BE HAPPEN DUE TO THE CLASH BETWEEN FABRIC AND SHARP EDGE OF MACHINE PARTS. REMEDIES: 1. IF WE CONTROL THE BALL WE CAN CONTROL HOLE. 2. WORKER HAVE TO CAREFULL DURING THE TRANSPORTATION OF FABRIC FROM ONE FLOOR TO ANOTHER TO AVOID SHARP POINT TINGLE WITH FABRIC.

- 17. OIL SPOT REASON: OIL SPOT ON THE FABRICS ARE CAUSED BY TOO MUCH OILING ON LOOM PARTS FROM OTHER SOURCES. REMEDY: THIS STAINS ARE REMOVED SCOURING.

- 18. TAILS OUT REASON: IF THE CUTTER DON’T WORK PROPERLY THEN THIS KIND FAULTS ARISE. REMEDY: TO SOLVE THIOS PROBLEM EITHER WE HAVE CHANGE THE DEGREE OF CUTTER OR WE HAVE TO CHANGE THE CUTTER BLADE.

- 19. TEMPLE MARK REASON: IF THE PLACEMENT OF RING IN THE TEMPLE BAR IS WRONG OR THE PRESSURE OF TEMPLE TO THE FABRIC IS TOO HIGH. REMEDY: THE SETTING OF TEMPLE SHOULD BE PERFECT. AND THE BRISTLE SHOULD BE SHARP AND EASY GOING.

- 20. TEMPLE PIERCED HOLE REASON: IF THE RING OF THE TEMPLE IS DAMAGED THEN WE WILL HAVE THIS FAULT. REMEDY: THE BRISTLE OF THE TEMPLE SHOULD BE SHARP AND EASY GOING.

- 21. CUT, TORN SELVEDGE REASON: IF THE CUTTER DON’T CUT THE EDGE THE OF THE FABRIC PROPERLY OR IF THE WEAVE IN THE EDGE OF THE FABRIC IS NOT PROPER. THEN WE WILL HAVE THIS FAULT. REMEDIES: 1. WE CAN SOLVE THIS PROBLEM BY CHANGING THE BLADE OF THE CUTTER. 2. BY CHANGING THE DEGREE OF THE CUTTER. 3. BY APPLYING SUITABLE WEAVE SYSTEM IN THE EDGE OF THE FABRIC.

- 22. REED MARK REASON: IF THE DENT OF THE REED IS DAMAGED THEN WE WILL HAVE THIS KIND OF FAULTS. REMEDY: THE REED HAVE TO BE CHANGED

- 23. SLUB REASON: IF THE YARN CONTAIN UNEXPECTED SLUB IN IT, THEN THOSE SLUB WILL BE APPEARED IN THE FABRIC AS A FAULT. REMEDY: THE QUALITY CONTROLER HAVE TO BE VERY CAREFULL ABOUT THE ABOUT QUALITY OF THE YARN.

- 24. FOREIGN MATERIAL REASON: IF THE YARN CONTAIN FOREIGN MATERIAL IN IT LIKE PLASTIC, SEED E.T.C THEN WE WILL HAVE THIS KIND OF FAULT. REMEDY: THE YARN HAVE TO BE CHECKED BY DURING THE TIME OF PROCUREMENT TO AVOID THESE FAULTS.

- 25. HAIRY FABRIC REASONS: THIS TYPE OF FABRIC FAULT COMES DUE TO THE HAIRINESS OF THE YARN. REMEDY: THE YARN HAVE TO BE CHECKED BY DURING THE TIME OF PROCUREMENT TO AVOID THESE FAULTS. WE NEED TO BUY GOOD YARN.

- 26. THICK AND THIN PLACES REASONS: THIS COMES DUE TO THE THICK, THIN PLACES THAT PRESENTS IN THE FABRIC. REMEDY: THE YARN HAVE TO BE CHECKED BY QC DURING THE TIME OF PROCUREMENT TO AVOID THESE FAULTS

- 27. HIGH TWISTED YARN REASONS: IF THE TPI OF YARN HIGHER,THEN WE WILL HAVE THE GIVEN LOOK OF THE FABRIC. REMEDY: YARN WITH SUITABLE TPI SHOULD BE BOUGHT BY US.

- 28. OIL STAINED YARN REASON: IF THE YARN CONTAIN OIL STAIN THEN THEN THESE STAIN WILL BE APPEARED IN THE FABRIC. REMEDY: TO AVOID THESE FAULTS WE HAVE TO BE VERY CAREFULL DURING THE TIME OF PROCUREMENT OF YARN.

- 32. 1. Yarn Manufacturing Technology Link : http://www.facebook.com/pages/Yarn-Manufacturing-Technology/485014954866808 2. Fabric Manufacturing Technology Link : http://www.facebook.com/pages/Fabric-Manufacturing-Technology/459520217425605 3. Garments Manufacturing Technology Link : http://www.facebook.com/pages/Garments-Manufacturing- Technology/472364799463126 3. Wet processing Technology Link : http://www.facebook.com/pages/Wet-Processing-Technology-Dyeing-/468645219825404 4. Fashion-Design-and-Technology Link : http://www.facebook.com/pages/Fashion-Design-and- Technology/587655294583875?ref=ts&fref=ts My Facebook Textile related Pages http://www.textilelab.blogspot.com (Visit My Blog for more Info )