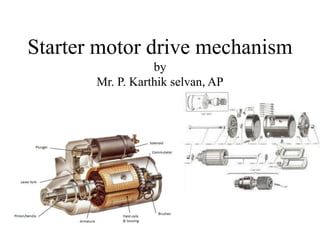

Starter motor drive mechanism

- 1. Starter motor drive mechanism by Mr. P. Karthik selvan, AP

- 2. • The starting motor is located near the flywheel .The drive gear on the starter is arranged so that it can mesh with the teeth on the flywheel (or the ring gear) when the starting switch is closed. • The drive mechanism has two functions: (1) To transmit the turning force to the engine when the starting motor runs and to disconnect the starting motor from the engine immediately after the engine has started and (2) To provide a gear reduction ratio between the starting motor and the engine. (The gear ratio between the driven pinion and the flywheel is usually about 15 to 1. This means that the starting motor rotates 15 times as fast as the engine, or at 1500 rpm to turn the engine at a speed of 100 rpm.)

- 3. • The drive mechanism must disengage the pinion from the flywheel immediately after the engine starts. • After the engine starts, the engine speed may increase rapidly to approximately 1500 rpm. • If the drive pinion were to remain meshed with the flywheel and locked with the shaft of the starting motor, at a normal engine speed (1500 rpm), the shaft would spin at a rapid rate of speed (between 22,500 and 30,000 rpm). At such a rate of speed, the starting motor would be badly damaged.

- 4. Types of starter drives The common kinds of starter drives used are: 1. Bendix drive (Inertia drive) 2. Improved Inertia type 3. Bendix folo-thru type 4. Pre-engagement drive 5. Sliding armature with overrunning type (Axial type) 6. Permanent magnet type. All of these starter drives use a one-way clutch (overrunning clutch) to release the starter drive pinion from the flywheel after the engine has started

- 5. Bendix drive (Inertia drive) • A Bendix drive is a type of engagement mechanism used in a starter motors of internal combustion engines • Inertia type drive works on the principle of inertia of unbalanced weight. In this type, pinion is mounted on threaded sleeve • Engage- When ignition switch pressed, the starter motor begins turning, the inertia of the drive pinion assembly causes it to wound the spring, forcing the length of the spring to change and engage with the ring gear • Disengage- When the engine starts, back drive from the ring gear causes the drive pinion to exceed the rotation speed of the starter, at which point the drive pinion is forced back and out of the mesh with the ring gear • Spring – To pull back the assembly, To avoid hitting of ring gear against the casing

- 7. • Disadvantage • Lots of moving parts cause rapid wearing of teeth • Engagement of pinion is done after starter motor starts To overcome this, pinion must be engaged before starter motor rotating. As a result, pre-engage drive is developed. • Application- old vehicles

- 8. Pre Engagement type • This has a solenoid or magnetic switch which is used to shift the drive pinion magnetically into mesh with the engine flywheel complete the circuit between the battery and self starter • In this arrangement the drive pinion on the starter motor shaft is pushed axially into mesh with the flywheel ring gear before the starter motor is switched ON • When the pinion meshes with flywheel ring gear, the starter motor is switched ON by engagement relay • A solenoid is usually employed to move the lever and close the switch contacts. This method is quite simple and having the advantage not to damage gear teeth

- 9. • Engage- When we turn the key to start solenoid switch ON, the starter motor shifts the pinion with the help of lever for the engagement with ring gear • As the engine is started, it is the time to disengage the pinion form the flywheel • Disengage- This is done by the overrunning clutch which is attached to a pinion overrunning clutch make the pinion free from the starter motor shaft as the engine starts. And motor is saved from the high speed damage Advantage - * A smaller pinion can be utilized for higher reduction * Pinion drive is not so highly stressed * Prolonged cranking life Application – Car and medium size vehicles

- 12. Axial or sliding armature type • The axial starter works on the principle of a sliding armature mechanism • It is similar like pre-engagement drive, In pre engagement type ring gear only moves forward and backward but in this axial armature type whole armature unit will moves forward and backward to produced high starting torque • Here, when the starter switch is operated a solenoid coil is energized. • This completed the circuit of a shunt winding and also of an auxiliary, series field winding • It consists of two winding- one for energizing and another one for moving the armature or sliding

- 13. • The armature is drawn into a central position in addition to rotating because of the magnetic field • As the pinion is attached to the armature shaft, it is moved axially and gets engaged with the flywheel ring gear • After the complete engagement of the pinion with the flywheel ring gear, a catch on the switch is tripped, thereby emerging the main series winding and marking the motor to operate on its full power current supply • A slipping clutch is provided between the pinion and the armature to avoid over speed of the motor

- 15. OVERRUNNING CLUTCH • The overrunning clutch is roller-type clutch that transmits torque in one direction only and freewheels in the other direction • This allows the starter motor to transmit torque to the ring gear but prevents the ring gear from transferring torque to the starter motor • In a typical overrunning type clutch, the clutch housing is internally splined to the starter armature shaft • The drive pinion turns freely on the armature shaft within the clutch housing

- 16. • When torque is transmitted through the armature to the clutch housing, the spring loaded rollers are forced into the small ends of their tapered slots • They are then wedged tightly against the pinion barrel • The pinion barrel and clutch housing are now locked together, torque is transferred through the starter motor to the ring gear and engine • This unloads the clutch rollers and releases the pinion gear to rotate freely around the armature shaft

- 18. SHUNT MOTOR SERIES MOTOR Field winding connected parallel with armature Filed winding connected series with armature Shunt motor are parallel and hence low current Series motor are series so high armature current Shunt DC Motor is used in constant torque application Series DC Motor is used for high starting torque application