Srac4302 oyster hatchery_techniques_wallace_2008

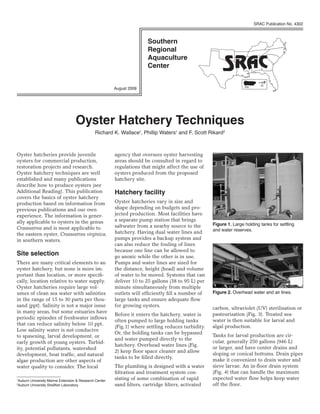

- 1. SRAC Publication No. 4302 VI August 2008 PR Oyster Hatchery Techniques Richard K. Wallace1, Phillip Waters1 and F. Scott Rikard2 Oyster hatcheries provide juvenile agency that oversees oyster harvesting oysters for commercial production, areas should be consulted in regard to restoration projects and research. regulations that might affect the use of Oyster hatchery techniques are well oysters produced from the proposed established and many publications hatchery site. describe how to produce oysters (see Additional Reading). This publication Hatchery facility covers the basics of oyster hatchery production based on information from Oyster hatcheries vary in size and previous publications and our own shape depending on budgets and pro- experience. The information is gener- jected production. Most facilities have ally applicable to oysters in the genus a separate pump station that brings saltwater from a nearby source to the Figure 1. Large holding tanks for settling Crassostrea and is most applicable to and water reserves. the eastern oyster, Crassostrea virginica, hatchery. Having dual water lines and in southern waters. pumps provides a backup system and can also reduce the fouling of lines because one line can be allowed to Site selection go anoxic while the other is in use. There are many critical elements to an Pumps and water lines are sized for oyster hatchery, but none is more im- the distance, height (head) and volume portant than location, or more specifi- of water to be moved. Systems that can cally, location relative to water supply. deliver 10 to 25 gallons (38 to 95 L) per Oyster hatcheries require large vol- minute simultaneously from multiple umes of clean sea water with salinities outlets will efficiently fill a number of Figure 2. Overhead water and air lines. in the range of 15 to 30 parts per thou- large tanks and ensure adequate flow sand (ppt). Salinity is not a major issue for growing oysters. carbon, ultraviolet (UV) sterilization or in many areas, but some estuaries have Before it enters the hatchery, water is pasteurization (Fig. 3). Treated sea- periodic episodes of freshwater inflows often pumped to large holding tanks water is then suitable for larval and that can reduce salinity below 10 ppt. (Fig.1) where settling reduces turbidity. algal production. Low salinity water is not conducive Or, the holding tanks can be bypassed to spawning, larval development, or Tanks for larval production are cir- and water pumped directly to the early growth of young oysters. Turbid- cular, generally 250 gallons (946 L) hatchery. Overhead water lines (Fig. ity, potential pollutants, watershed or larger, and have center drains and 2) keep floor space cleaner and allow development, boat traffic, and natural sloping or conical bottoms. Drain pipes tanks to be filled directly. algae production are other aspects of make it convenient to drain water and water quality to consider. The local The plumbing is designed with a water sieve larvae. An in-floor drain system filtration and treatment system con- (Fig. 4) that can handle the maximum Auburn University Marine Extension & Research Center 1 sisting of some combination of rapid expected water flow helps keep water Auburn University Shellfish Laboratory 2 sand filters, cartridge filters, activated off the floor.

- 2. waters with salinities of about 10 to 25 ppt, though they can tolerate lower and higher salinities. Oysters on natural reefs are stimulated to spawn when the water temperature rises in the spring. The release of sperm and eggs into the water further stimulates other oysters to spawn. This results in a mass release of reproductive products. Sperm fertilize eggs in the water column. Fertilized eggs develop and progress through a series of free- swimming larval stages (Fig. 5.) over a period of 14 to 20 days, depending on Figure 6. Veliger larva. water temperature. These stages are referred to as the trochophore, veliger Figure 3. Small cartridge and ultraviolet and pediveliger. The trochophore sterilizer filter system for treating seawater. larvae feed on very small algae as they move through the water column. Trochophore larvae quickly develop into more motile veliger larvae (Fig. 6). Toward the end of the larval cycle, pediveligers (Fig. 7) develop a foot that helps them find a suitable hard substrate on which to attach (set) and transform into small oysters. This stage is also called an “eyed larvae” because of the development of a pig- mented eye spot. Eyed pediveligers settle out of the water column when they are approxi- Figure 7. Pediveliger larva. mately 300 micrometers (µm) and Figure 4. In-floor water drains and nursery may be stimulated to settle by the tanks. presence of adult oysters. Finding a spot. Once settled, they attach and hard substrate (cultch) is essential to transform into small oysters called their survival. The eyed larvae can spat. Spat soon begin feeding on algae Shallow rectangular tanks with drain move only very small distances, once by filtering water through their gills pipes provide nursery space for juve- they settle, in order to find a suitable and a special structure (labial palps) nile oysters. Aeration throughout the located just in front of the mouth. hatchery is supplied by an appropriate Veliger size blower, overhead PVC piping, vi- Basic hatchery procedures nyl tubing, and good quality air stones. Trochophore Pediveliger These are the basic procedures for If algal cultures are to be produced, spawning oysters, raising and setting there must be a clean room with SETTING larvae, and growing spat. No two special lighting for starting cultures. hatcheries operate identically or in Fertilized Another larger space with special light- egg the same environment and there is no ing, separate from the main hatchery, is substitute for experience. needed to grow larger volumes of algae. Early spat Water treatment Good water quality is essential to suc- Oyster biology Unfertilized egg cessful hatchery production (see Site Later spat An oyster hatchery simply creates a SPAWNING (several days old) Selection) but even high-quality water controlled environment for the early must be treated to remove unwanted portions of the oyster life cycle. There- organisms. Water used for spawning, fore, producers must understand oyster mixing eggs and sperm, and growing Adult Oysters biology. Oysters occur naturally in larvae is typically filtered mechanical- dense aggregations, often called reefs Figure 5. Life cycle of the eastern oyster, ly and treated with ultraviolet radia- or beds. Oysters thrive in estuarine Crassostrea virginica. tion. Large-scale operations and “low-

- 3. tech” or “back yard” facilities may treated seawater at the same salinity as fertilized, the egg container is brought forgo UV treatment but will use some the broodstock holding tank. After the up to a standard volume such as 2.6 mechanical filtration. Mechanical oysters have had time to acclimate and gallons (10 L). (Note: It is simpler to filtration is usually done with a pres- open their shells, warm water (general- work in the metric system and the surized sand filter, cartridge filters for ly 9 ºF or 5 ºC above ambient) is intro- metric system is followed for small smaller volumes, or fine-mesh bags. duced into the tank to induce spawn- measures, while the English system is Because of the rich array of organisms ing. Cycling ambient and warm water referred to where possible.) The eggs in Gulf of Mexico waters, mechanical a few times may also stimulate spawn- are gently mixed and a 1-ml sample filtration down to 1 µm with UV treat- ing. If this fails to produce results in a is taken with a pipette. The sample is ment can assist in successful spawn- reasonable time (about an hour), sperm placed on a Sedgwick–Rafter cell (a ing and larval production. stripped from a male can be delivered special microscope slide that holds 1 by pipette to the shell opening of sev- ml of liquid) and the number of fertil- Spawning eral oysters to stimulate spawning. To ized eggs counted. The sample count is Spawning oysters is the first step in the prevent unwanted fertilization, sperm then multiplied by the volume of the production of spat. As a rule, ten aver- used in this procedure can be placed in container, in this case 10,000 ml (there age females produce about 200 million a microwave oven for 20 to 40 seconds are 10,000 ml in 10 L), to get the total eggs. Under good conditions 200 mil- to eliminate viability. These sperm number of fertilized eggs per contain- lion eggs can result in 100 million or should be checked under a microscope er. This figure is used to determine the more early-stage larvae, which require to be sure there is no motility. volume of water containing eggs that 2,600 gallons (10,000 L) of treated wa- is needed to stock the larval tanks. ter. Natural mortality and the need to When oysters begin releasing gametes, thin out the larvae to proper densities the whitish sperm and eggs can be Fertilized eggs are stocked into larval- should leave about 25 million eyed lar- easily seen against the black back- rearing tanks usually 250 gallons (946 vae ready for setting. Approximately ground of the tank. Males release a L) or larger at the rate of 40,000 to 10 million spat can be expected from near constant stream of sperm and 80,000 per gallon or about 10 to 20 the 25 million eyed larvae. females release eggs during periodic eggs per ml. The following formula shell closures. As oysters begin to can be used to determine the volume Spawning is typically undertaken in spawn, males and females should be (ml) from the container of eggs needed the spring when water temperatures placed in separate containers (1 gallon to stock the larval rearing tanks: rise above 77 ºF (25 ºC) in southern or 2.2 L) containing treated sea water waters. The process begins with select- Stocking rate ÷ eggs per ml = ml to prevent uncontrolled fertilization. ing broodstock, which may be oysters from container of eggs to add to When females appear to have finished taken from the wild or oysters bred larval rearing tank spawning, they should be removed and maintained under controlled con- from the containers and the containers Example: If the egg count in the previ- ditions for selective breeding. In either aerated. Within 45 minutes of spawn- ous step revealed 10,000 eggs per ml case, oysters larger than 3 inches (76 ing all the eggs can be sieved on a and the stocking rate for a 250-gallon mm) are selected, although males may 50-µm screen to remove debris. Eggs (946-L) tank is 10 million eggs, then: be smaller, and then a sample is exam- are then combined in one or several ined for reproductive readiness. Expe- 10,000,000 eggs stocking rate aerated containers and fertilized with ÷10,000 eggs/ml = 1,000 ml from rienced hatchery personnel can judge a small volume of sperm (20 to 50 ml) the state of “ripeness” by removing the container of eggs. combined from three or more males. the right or upper shell and noting the After 15 to 20 minutes, eggs should Algae can be added the same day to development of the gonads. Ripening be examined under a microscope to provide food for fast developing tro- gonads have many branching tubules confirm fertilization. If no more than chophore and veliger larvae. or prominent genital canals. Gonads 10 percent of the eggs have a polar may also be cut and scraped and the Larval care body (Fig. 8), more sperm should be material examined under the micro- Tanks are cleaned, disinfected with added. When eggs appear adequately scope for sperm and eggs. Mature eggs sodium hypochlorite (bleach), and are pear shaped, 55 to 75 µm long, and filled with treated sea water before 35 to 55 µm wide. they are stocked with fertilized eggs. Tanks should be gently aerated so that A significant amount of eggs and sperm eggs and subsequent larvae are mixed can be produced by just a few oysters, throughout the tank. From this point but not every oyster may spawn and it until larvae are ready to set, larval is a good practice to have the eggs and care consists of feeding algae, drain- sperm from several oysters. Therefore, ing tanks every 2 days (daily as larvae 20 to 30 large oysters are thoroughly near setting), sieving and counting lar- cleaned and scrubbed, then placed in vae, cleaning and refilling tanks, and a shallow, black tank containing 4 to restocking larvae at the appropriate 6 inches (101 to 153 mm) of filtered, Figure 8. Fertilized egg with first polar body.

- 4. density. Table 1 outlines a schedule Feeding A fourth method is to purchase for draining, the suggested mesh size Oyster larvae feed by filtering small, concentrated algae from commercial for sieving, the larval density, and the single-cell algae from the water. They producers. While often expensive, food density. must be supplied with the right size commercially produced algae may be food at a density that makes the food cost effective depending on the size of Most fertilized eggs develop into easy to encounter. There are several the oyster hatchery. trochophore larvae within 12 to 20 hours. These become veliger larvae methods for supplying algae to larvae. However it is obtained, algae must (also called straight-hinge or D-shaped The simplest is to coarsely filter (10 be added daily to the larval culture larvae) within 20 to 48 hours. The first to 25 µm) natural waters to keep out tanks at concentrations that result in draining and sieving (Fig. 9) is done zooplankton and large algae and then the densities listed in Table 1. Inten- at about 48 hours. Water is drained provide the water directly to the lar- sively cultured algae are very dense slowly through the appropriate size vae. A second method involves filter- and often a diluted subsample must sieve (Table 1) and the retained larvae ing natural water in the same way and be counted. To do this, a drop of are placed in a known volume of then fertilizing it to stimulate algae diluted culture water is placed on a treated seawater (e.g., 10 L). Several growth and reproduction. After a sig- hemacytometer (a special microscope 1-ml samples are taken, the larvae are nificant amount of algae is produced, slide with finely etched squares to aid counted in a Sedgewick-Rafter cell, it is fed to the oysters. Both of these counting) and the cells within several and the average number is used to cal- methods have worked for hatcheries 1-mm-square areas are counted. The culate the total number of larvae, as in but the results can vary considerably; cell count is divided by the number of the egg count. Larvae are restocked in and, the water can be contaminated 1-mm-square areas counted and then a cleaned and disinfected tank filled by unwanted zooplankton or the multiplied by 10,000 to get the cells with treated seawater at the recom- wrong kinds of algae. per ml. This number is then multi- mended density, five per ml or about plied by the dilution factor. A third method is to separately 20,000 per gallon. This process is culture several species of algae from The volume of culture water needed repeated every 2 days (daily as larvae pure cultures of each desired species. to achieve the desired density in near setting) with appropriate reduc- Algae species that have been used to the larval tanks is determined from tions in larval density (Table 1) until grow oyster larvae include Chaetocerus the calculated density of algae. For larvae are ready to set. gracilis, Isochrysis galbana, Pavlova example, if the hemacytometer count spp., and Nannochloropsis spp. Several shows 100 cells in four 1-mm-square studies have shown that a mix of areas, the number of cells per 1-mm- algae species results in better growth. square area is 25. Multiply by 10,000 Culturing algae can be labor inten- to get 250,000 cells per ml. If the sam- sive, requiring repeated sterilization ple was originally diluted by a factor of glassware as the algae is moved of 10, multiply by 10 to get 2,500,000 through a series of larger containers. cells per ml in the original culture. Several continuous culture methods The desired density of algae at the have been developed that can reduce beginning of larval culture is 25,000 labor and provide larger volumes. See cells per ml. Suppose the larval tank the Additional Reading section for is 250 gallons (946 L). Multiply the sources of more detailed information larval tank volume (946,000 ml) by Figure 9. Sieving oyster larvae. on culturing algae. the desired algae density (25,000 cells/ ml) and divide by the density of cells in the algae culture (2,500,000 cells/ Table 1. Days of larval culture, size of larvae (long axis in µm), sieve size in µm, suggested ml) to get 9,460 ml of plankton culture larval density, and algae density for larval culture tanks (modified from Creswell et al. 1990). to be added to the larval tank. Sieve size is given as one side of a square opening. Number in ( ) is diagonal opening. Days after Larval height Sieve size Larval density Algae density Setting larvae spawn (µm) (µm) (larvae/ml) (cells/ml) Larvae are ready to set when they 0 10 20-25,000 have a well developed eye spot and 2 65 35 (50) 5 20-25,000 are 290 µm or more in length. Lar- 4 100 53 (75) 5 20-25,000 vae that are ready to set are usually 6 140 53 (75) 4-5 30-40,000 selected by sieving them through 8 180 73 (103) 4 50,000 a 180-µm screen (254-µm diagonal opening). Larvae that pass through 10 220 73 (103) 4 50,000 are restocked. The retained larvae 12 260 100 (141) 3 70-80,000 are sieved again on a 210-µm screen 14 290* 118 (166) 2.5 100-150,000 (296-µm diagonal opening). Those that *See text for sieving eyed larvae. pass through are also restocked to a

- 5. separate tank. The retained larvae with fine mesh bottoms (l50- to 180- natural waters off-bottom. The small (larger than 296 µm) are pooled and µm) and a thin layer of microcultch. mesh size of the bags makes regular counted before being transferred The containers, called wellers, are cleaning necessary. As the oysters to setting tanks. This procedure is immersed in shallow tanks containing grow they are sieved through appro- repeated every day until the desired treated seawater (Fig. 10). Contain- priate size meshes (slightly smaller number of eyed larvae is obtained or ers are configured so that water can than the mesh size of the bag they are the number of eyed larvae dwindles to flow up through (upwelling) or down being put into) and the retained oys- the point that it is no longer effective through (downwellng) the mesh bot- ters moved to larger mesh bags. The to continue. toms by routing water through an larger mesh bags also require periodic opening near the top of the container. cleaning and inspection for preda- The large, eyed larvae can be set on a (See SRAC Publication No. 4301 for tors in the bags. An example of mesh variety of materials (cultch) using sev- diagrams). At stocking, the container sizes and stocking densities is given in eral methods. The choice depends on is set for downwelling and the entire Table 2. the desired use of the resulting spat. tank covered with black plastic to The two basic choices are producing encourage more even setting. Algae is single oysters (good for research and/ Table 2. Typical mesh size of oyster-growing added to feed late-setting larvae and or off-bottom farming for the half containers (bags) and suggested stocking early metamorphosed spat. Setting shell market) and producing oyster densities. and metamorphosis usually takes 48 clusters (good for producing a lot of Bag mesh Oysters/bag hours. After metamorphosis is con- oysters for restoration projects and/ firmed, the containers are converted 0.04 in (1 mm) 50,000 or farming aimed at the shucked meat to upwellers using coarsely filtered 0.08 in (2 mm) 10,000 market). (100 µm), flow-through sea water. 0.13 in (3.3 mm) 4,000 Single oysters can be obtained by 0.25 in (6.4 mm) 1,500 The bottom mesh on the upwellers setting larvae on microcultch, very 0.50 in (12.7 mm) 500 should be cleaned daily. As the spat smooth and slippery surfaces, or by 0.75 in (19 mm) 250 grow they are graded on different chemical induction. Microcultch is mesh size sieves and the larger spat usually made of finely ground oyster moved to upwellers with larger mesh Given the labor costs of growing shell sieved to produce shell pieces bottom screens to enhance water flow single oysters, it is very tempting to 250 to 300 µm in diameter. A single and growth. Growth is highly depen- release single oysters onto suitable larva sets on each particle. Oyster dent on the density of spat, water bottoms at a small size. However, sev- larvae also can be set on a slippery, flow, and the abundance of natural eral studies have shown that the mor- flexible surface such as Mylar® sheets. food in the water supply. Food can be tality of small, single oysters is quite After larvae have metamorphosed supplemented with algae as in larval high when they are not protected in to spat they can be popped off the feeding. bags or some kind of container. sheet. Chemical induction involves treating larvae with chemicals such Setting on large cultch as epinephrine or norepinephrine at Setting on whole shell or other large very low concentrations to induce cultch can be done by placing the metamorphosis without the need for a cultch in large mesh bags and the bags substrate. into tanks with treated seawater. Eyed Cluster oysters are the result of setting larvae are introduced at the rate of larvae on large cultch, usually whole 100 per shell, with a goal of obtaining oyster shell. This results in a product 10 to 30 early spat per shell. Gentle similar to what occurs in nature— aeration is applied, algae added, and a shell with many spat. Over time, the tank covered. After several days, natural attrition results in two to four the tanks are supplied with a continu- adult oysters per shell. Almost any Figure 10. Upweller/downweller. ous flow of coarsely filtered sea water. non-metallic, hard surface could func- Bags of cultch should be washed tion as cultch for cluster oysters. All occasionally and tanks drained to types of cultch should be clean and Single oyster nursery remove wastes. To reduce hatchery “aged” in seawater for several days to The major drawback to single oyster costs, bags can be moved after 1 to 2 establish a “biofilm” on the cultch that production is the amount of labor weeks to protected waters with firm will enhance setting. required to maintain oysters until substrate and a history of growing they reach the desired size. The initial oysters. When oysters reach a size that Single oyster setting upweller culture continues until protects them somewhat from preda- Single oysters are produced by intro- oysters are large enough to be placed tion, and before they grow through ducing eyed larvae (250 larvae per in the smallest mesh size nursery bag. the bags, they can be removed from square inch or 100 per square cm of These bags can be kept in the hatch- the bags and spread on suitable bot- bottom surface area) into containers ery under high water flow or placed in tom substrates.

- 6. Significance Crassostrea virginica, in Florida. Hadley, N.H. and J.M. Whetstone. Harbor Branch Oceanographic 2007. Hard clam hatchery and Oysters are an important component Institution, Inc., Fort Pierce, FL. nursery production. Southern Re- of seafood production and provide gional Aquaculture Center Publi- widely appreciated ecological services. FAO. 1990. Artificial propagation of cation No. 4301. Oyster hatcheries can produce oysters bivalves: techniques and methods. for commercial culture operations, res- FAO Corporate Document Re- Supan, J. 2002. Extensive Culture of toration projects, and a variety of basic pository. http://www.fao.org/docrep/ Crassostrea virginica in the Gulf of and applied research projects. Oyster field/003/AB739E/AB739E05.htm Mexico Region. Southern Regional hatcheries have played an important Aquaculture Center Publication Hadley, N.H., J.J. Manzi, A.G. Ever- role in breeding disease-resistant No. 4300. oysters, triploid and tetraploid oysters, sole, R.T. Dillon, C.E. Battey and and faster growing oysters. N.M. Peacock. 1977. A manual Wallace, R.K. 2001. Cultivating the for the culture of the hard clam Eastern Oyster, Crassostrea virgini- Mercenaria spp. in South Carolina. ca. Southern Regional Aquaculture Additional reading South Carolina Marine Resources Center Publication No. 432. Creswell, R.L., D.E. Vaughan and L. Contribution No. 356. (available Sturmer. 1990. Manual for the from the South Carolina Sea Grant cultivation of the American oyster, Consortium, Charleston, SC.) SRAC fact sheets are reviewed annually by the Publications, Videos and Computer Software Steering Committee. Fact sheets are revised as new knowledge becomes available. Fact sheets that have not been revised are considered to reflect the current state of knowledge. The work reported in this publication was supported in part by the Southern Regional Aquaculture Center through Grant No. 2006-38500- 16977 from the United States Department of Agriculture, Cooperative State Research, Education, and Extension Service.