Neuweiler brewery hsr final 051112

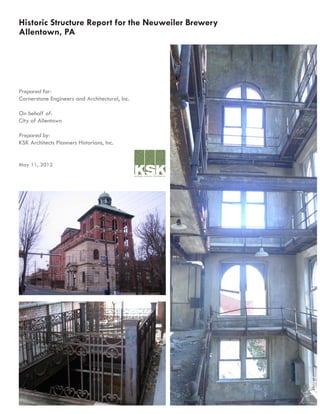

- 1. Historic Structure Report for the Neuweiler Brewery Allentown, PA Prepared for: Cornerstone Engineers and Architectural, Inc. On behalf of: City of Allentown Prepared by: KSK Architects Planners Historians, Inc. May 11, 2012 architects planners historians inc

- 2. 1 TABLE OF CONTENTS Introduction Part I: Developmental History Historical Overview................................................................................................................................................5 Character Defining Features.................................................................................................................................9 Physical Description..............................................................................................................................................9 Condition Assessment........................................................................................................................................72 Part 2: Treatment and Work Recommendations Summary of Significance....................................................................................................................................85 Treatment Philosophy..........................................................................................................................................85 Levels of Treatment.............................................................................................................................................85 Work Recommendations.....................................................................................................................................87 Appendices A. Historical Plans, c. 1950 B: Photo Key Plans C: Bibliography D: Vitae

- 3. 2

- 4. 3 INTRODUCTION The former Neuweiler Brewery is a landmark feature of the Allentown landscape. The smokestack from the on- site boiler house, featuring the name “Neuweiler” down its length, was visible for miles until its recent demolition, and the copper cupola of the six-story Brew House is similarly iconic. Situated near the Lehigh River, the brewery was part of the industrial character between the river and the neighborhoods (Figure 1). The Neuweiler Brewery is listed in the National Register of Historic Places. As part of an effort to plan for the future of the waterfront along the Lehigh River, the City of Allentown commissioned a team led by Cornerstone Engineers and Architectural, Inc. to prepare a reuse plan for the brewery complex, which is a major redevelopment opportunity in the waterfront area. KSK Architects Planners Historians, Inc. (KSK) was part of Cornerstone’s team for the project, tasked with preparing a Historic Structure Report (HSR) as one component of the reuse study. The reuse of historic buildings is a common sense strategy to fulfill multiple aims: conserve fiscal resources; conserve landfill capacity; maintain the “embodied energy” of existing buildings and capitalize on existing materials of proven quality and longevity; and – last but not least – retain essential elements of the community’s cultural heritage. The City’s goal for the reuse of the former Neuweiler Brewery is to re-integrate this landmark community asset into the economic and cultural life of the city by developing a feasible reuse plan that A) preserves the character defining features of the property, B) identifies feasible reuse scenarios that take into account the varied issues of the building and site, and C) provides a baseline of data for developers, politicians, funders, and other stakeholders to take the next steps in project development. KSK’s approach for the HSR was to provide the essential information needed for future stewards of the site to understand the significance of the property, know the character-defining features that should be preserved in any reuse scenario, and grasp the range of preservation options available. The National Park Service’s guidance for the preparation of HSRs, Preservation Brief #43 (“The Preservation and Use of Historic Structure Reports”), is intentionally broad and flexible to allow for the variety of project needs and funding levels. This HSR adheres to the general content and organization laid out in Brief #43, while being mindful of the project budget, schedule, and the essential information needed to complete the reuse study. Importantly, the reuse study considers the potential use of federal historic rehabilitation tax credits to help fund the redevelopment of the property. This HSR responds to that scenario by providing guidance regarding the important features of the property to save and where there is more flexibility to carry out proposed alterations. The copper canopy at the Neuweiler Brewery Bottling House, 1979. Note the copper bottles along the edge. (HAER PA-152. National Park Service. Photography by Jet Lowe.)

- 5. 4 Figure 1. Location Map. (Source: Google.com, accessed March 14, 2012.) LehighRiver 0 200 400 scale in feet N

- 6. 5 PART 1: DEVELOPMENTAL HISTORY The purpose of this section of the report is to provide baselinedataonthecurrentphysicalstatusoftheNeuweiler Brewery complex and its historical significance. It includes a historical summary and assessment of significance, physical description, and a general assessment of conditions. The Brewery’s character-defining features are also identified; these are features that significantly contribute to the physical character of the resource and that are essential to its National Register listing. Note that not all interior spaces were accessible to the team due to compromised floors or stairs. HISTORICAL OVERVIEW The Neuweiler Brewery is significant as a relatively intact example of an early 20th-century brewery, and also as a representative of the important brewing traditions in the Lehigh Valley. The plant was state-of-the-art when it opened in 1913, and continued to manufacture and distribute traditional German-style beer, porter, and ale in the Mid-Atlantic region through the mid-20th century. The years of expansion, exemplified in the brewery’s building campaigns, as well as its demise in the 1960s illustrate the arc of local breweries in the Lehigh Valley and beyond. The construction of the Neuweiler Brewery in the early 20th century was the culmination of years of brewing experience in the Neuweiler family. Louis F. Neuweiler, born into a family of brewers in 1848, emigrated from Germany in the late 19th century (Whelan). He spent time in Philadelphia, working at the Charles Theis Lager Beer Brewery in a neighborhood now known as Brewerytown owing to the dense concentration of breweries in the area along the Schuylkill River. As of 1890, Neuweiler was the Superintendent at the Theis brewery (Hexamer, 1890). In 1891, he became a partner with Benedict Nuding at the Nuding-Neuweiler Brewing Company in Allentown. Then located behind the Germania Hotel on South 7th Street, Nuding’s brewery, also known as the Germania, had been in operation since 1878 (Hojsak). During this period, there were many small breweries throughout the commonwealth, primarily serving local consumers. In Allentown alone, there were at least four breweries in 1901 (Western Brewer). UndertheleadershipofNeuweilerandNuding,theirbrewery expanded from producing 4,000 barrels of beer in 1891 to 20,000 barrels in 1900, for customers as far away as Wilkes Barre (Whelan). The partnership lasted until 1901 when Neuweiler bought out Nuding’s share in the business and changed its name to Nuding-Neuweiler Brewing. The company became a family endeavor in 1906 when eldest son Charles F. became a full partner; the company then became known as L.F. Neuweiler & Son (Whelan). The Neuweilers decided to expand their operations, no doubt based on increasing demand and corporate aspirations. Given the lack of room for expansion on 7th Street, the company embarked upon a major project to build an entirely new facility at Gordon and Front Streets beginning in 1911. The 4.5-acre site had direct access to a major road (Front Street) as well as the mainline of the Lehigh Valley Railroad. The plant was to be independent of public utilities, using water drawn from a subterranean lake and generating power in its own power plant. The company hired the Philadelphia architectural firm of Peukert and Wunder to design the new facility. While little is currently known about this firm, they did appear in Philadelphia city directories as “brewers’ engineers and architects;” they may have designed a similar facility in Baltimore (Hojsak). Sanborn maps for Allentown in 1911 depict the brewery based on plans for the facility, as it was not yet built (Figure 2; Figure 3 shows a recent “birds eye” photograph of the site). The map shows the current Office, Brew House, Machine House, Boiler House, Stock House, and Wash House. No connection between the Brew House and Stock House is shown above the rail siding. A basement level was built below the rail siding, with a scale for weighing incoming materials, among other uses. Though not shown on the 1911 map, a date on the building indicates that the original portion of the Bottling House was built in 1912. The facility maintains a vertical brewing configuration popular in the late 19th century, while incorporating up- to-date equipment and facilities to create one of the most modern breweries in the country at the time (Preservation Pennsylvania). By all accounts, the new brewery reflected the exacting nature of Louis F. Neuweiler, Sr., who expected the highest quality materials and operational efficiencies. According to the National Register nomination, Neuweiler insisted on building the brewery on a “floating form” foundation, with footers 90 feet deep, to avoid problems stemming from the presence of the subterranean lake (Hojsak). Finer details, such as the copper cupola on the Brew House, the Neuweiler “N” on the façade and name on the smoke stack, and fine materials on the office façade, are attributed to the senior Neuweiler’s fine standards. The year 1913 marked the beginning of production at the new brewery, as well as a change in ownership. Son Louis P. Neuweiler joined the firm, and the company changed to the name it would have until 1965: Louis F. Neuweiler & Sons. Once brewing began at Front Street, the former Germania plant on 7th Street was abandoned (Whelan). As predicted, the brewery continued to expand. In 1914,

- 7. 6 1911. Brewery buildings, unbuilt, were drawn from plans. 1950. The bottling plant was expanded in 1934, and later an auto shed built and Building E built west of the Stock House. 1957. The malt hopper was added east of the Boiler House. Figure 2. A series of site plans by the Sanborn Map Company, from their fire insurance maps for Allentown. 1932. The primary buildings of the complex were in place. FRONTSTREET FRONTSTREET LIBERTY STREET LIBERTY STREET GORDON STREET GORDON STREET LIBERTY STREETLIBERTY STREET FRONTSTREET 0 50 100 200 approximate scale in feet N

- 8. 7 Figure 3. Neuweiler Brewery, overall site with buildings labeled. The smoke stack has since been demolished. (Source: Bing.com, accessed March 14, 2012.) J F E B A C H G K D I

- 9. 8 an Auto Repair building (now known as Building K) was constructed east of the Bottling House. Neuweiler had its own fleet of delivery vehicles, making this an investment in in-house services. Also likely built during these early years, and certainly present by 1932, are the Pump House (Building I) at the north end of the Stock House, and the Ale Storage House (Building H). The 1932 Sanborn map (Figure 2) shows all of these buildings in place, as well as the Stock House and roof structure over a portion of the rail siding. The west elevation of Building H is indicated as being open at this time, with a solid brick wall at the north end, and a fully enclosed bay at the south end; its use is coded as “A:” private garage. Existing bumpers at the edges of the pilasters support this use. Based on the Sanborn maps, the bays were enclosed with brick between 1932 and 1950 and converted to use as a fermenting cellar. The southern portion of the two-story section was used as a cooper shop at that time. An open auto shed was also built during this period, likely replacing the parking spaces lost to the expanded fermenting cellar. DuringtheProhibitionyears(1919-1933),Neuweiler&Sons produced carbonated beverages (soda), tonics, and “near beer,” with less than ½% alcohol, to remain in business. The government strictly regulated “near beer,” but this production allowed the company to retain beer on site during Prohibition. When Prohibition was finally repealed, the company had the most beer on-hand of any brewery in the state (Whelan). Over half of the breweries in the U.S. never re-opened after Prohibition; however, Neuweiler’s continuous operations and stock of beer gave this brewery a head start on production (Preservation Pennsylvania). The company expanded the Bottle House in 1934. The $200,000 addition also included the installation of a new bottling system to span both sections of the building, and it is likely that the canopy over the loading area along Front Street was added at this time (Hojsak). The complex then formed a near continuous brick edifice between Gordon and Liberty Streets, and the brewery had a reputation as “one of the most modern, famous and oldest breweries in the eastern U.S.” (Hojsak). Louis F. Neuweiler & Sons continued to pursue capital investments at the plant. In 1935, the brewery was among the first to sell its beer in cans (Hojsak), likely requiring some changes to the bottling operation. Between 1932 and 1950, the one-story Filter House (Building E) was built between the Stock House and Front Street, a one-story warehouse was built east of the Ale Stock House, and a 12-car auto shed was built along the rail line near Gordon Street. In 1941, the brewery published a 50th anniversary souvenir booklet touting the establishment’s history and facilities. At that time, 300,000 barrels of beer were brewed at Neuweiler’s annually, and distributed to 10 states and Washington, DC. The fastidious cleanliness and efficiency of the operation were in full display, both in text and photographs. The brass brew kettle gleamed, and white-suited employees monitored the bottling. Even the Boiler House and Machine House were spotless by any definition. Rows of fermenting tanks filled the Stock Houses, and staff in the laboratory and yeast room kept a close eye on the Neuweiler formula and quality. According to the booklet, visitors were always welcome at Neuweiler’s for an interesting and educational tour (Louis F. Neuweiler’s Sons). As depicted on a plan of the buildings on the property in 1950, the warehouse east of the Ale Stock House was labeled Neuweiler’s Vitamin Yeast, Inc., and the Auto Repair shop is indicated as storage for untaxed cases of bottles and cans (though it is still labeled as “Auto Rep” on the 1957 Sanborn map). At the middle of the 20th century, Louis F. Neuweiler & Sons had reached its physical capacity. Plans prepared in the late 1940s and 1950 provide detailed illustrations of the buildings’ structure and internal workings; all levels of each building are shown, including the tunnel between the Stock House and Bottling House (Appendix A). By the 1960s, changes in the brewing industry were affecting the Neuweiler Brewery. As breweries expanded in the American west, they were able to advertise in larger – and eventually national – markets, taking market share from smaller brewers (Whelan). Additionally, a Pennsylvania statute passed in the 1930s attempted to keep local breweries local by preventing out-of-state breweries from locating here unless the officers, directors, and 51% of stockholders were Pennsylvania residents (Whelan). This prevented the larger out-of-state breweries from acquiring Neuweiler&Sonswhenitwasanoperatingbrewery. Further, the changing tastes of customers began to favor the lighter beers of the Midwest over the heavier traditional German beers offered by Neuweiler & Sons. In 1967, the company filed for bankruptcy protection, hoping for a solution that would allow the company to continue operating. However, with nearly $800,000 in claims against the company and its owners, trustees were unable to resolve the issues. The Louis F. Neuweiler & Sons brewery ceased operations on May 31, 1968 (Hojsak). By 1972, the large Neuweiler sign facing the Lehigh River and Tilghman Street Bridge from the flat north roof of the Bottling House had been removed. The sign had been in place since the 1930s. Since the closure of the brewery, most of the buildings have remained vacant, though some spaces were leased for primarily commercial or warehouse use. The walls of the Stock House were opened to permit the removal of equipment, some of which was repurposed to process

- 10. 9 apple juice and store water (Whelan). Central Motorramp Garage Co. bought the property from the trustees in 1969, intending to use the buildings for cold, frozen, and dry storage, and a cab facility. The property was purchased in the late 1970s by George Hanna of Hanna Construction Company, with the hope of redeveloping the property. As of 1980, Mack Trucks, Inc. used the Bottling House (Building J) for storage, and the one-story cold storage addition was built on the east side of the Ale Stock House (Building H) and was being used by Rozak Produce. By 2005 the warehouse identified as Neuweiler’s Vitamin Yeast, Inc. was demolished. In recent years, the former Auto Repair building (Building K) housed a roofing company. Period of Significance The period of significance on the National Register nomination indicates 1911-1913, corresponding to the original construction campaign at the Neuweiler Brewery. However, given the longevity of the enterprise and its importance as an illustration of the evolution of the brewing industry of the period, we believe that the period of significance should encompass the Neuweiler site’s history up to its closure in 1968. Typically, the Pennsylvania Historical and Museum Commission ends the period of significance at the 50-year evaluation standard for the National Register, which at this point is 1962. Because all buildings currently on the site were present during this period and contributed to the operation of the brewery and its significance, all buildings are contributing elements of the National Register listed Neuweiler Brewery. National Register Boundary The historic resource boundary as described in the National Register nomination extends along Front Street from Gordon to Liberty Street, then east along Liberty to the railroad tracks, then south along the railroad tracks to Gordon Street, then Gordon Street back to the beginning point. This includes the residences along the west side of Liberty Street. While one graphic in a Morning Call article indicates the brick northern residences as the brew master’s house, additional historical research would be necessary to confirm the buildings’ association with the brewery and determine whether they belong within the National Register boundary. CHARACTER-DEFINING FEATURES Character-defining features are those distinctive qualities or characteristics of a historic resource that contribute significantly to its physical character. At the Neuweiler Brewery, the exterior features define the public character of the property. Important features include the brick, limestone, granite, and terra cotta materials and definition of bays and stories on its exterior elevations; the nature of the window and door openings (and the blind windows), including arches, sills, mullion details, window configurations, large loading doors, and fenestration pattern; the copper roof elements (Brew House roof and cupola, cornices, awning frieze at the Bottling House loading dock); the use of rooftop clerestory windows and skylights; and the variety of decorative features, such as pediments, carvings (the Neuweiler “N”), the lion head awning anchors at the Bottling House, and others. Interior features also make important contributions to the physical character of the property. These include the floor cut-outs in the Brew House, industrial lighting fixtures, the volcanic pumice insulation and insulated doors at the Stock House, the sanitary concrete and tile floors and bases, and the woodwork and decorative plasters in the Office. Remaining brewing equipment (tanks, conveyors, overhead beer lines between buildings, etc.) is also central to the identity of the Neuweiler Brewery. Several site features also contribute to the physical character of the property. Because the site is below street level at Front Street, fences were needed to keep pedestrians from veering off the Front Street sidewalk and stairs provided access to the property. A metal diamond- pattern fence remains along Front Street, and stairs are located west of the Brew House, accessing the property from Gordon Street. The brick pavers in the courtyard area allowed for a smooth, stable driving surface for Neuweiler’s delivery fleet; some of the pavers have been removed or covered with asphalt or cement. PHYSICAL DESCRIPTION The Neuweiler Brewery complex is located near the west bank of the Lehigh River in Allentown, Pennsylvania. The site is generally bounded by Front Street, to the west, Gordon Street (also known as Pump Place) to the south, Liberty Street to the north, and the former Lehigh Valley Railroad tracks to the east (Figure 1). The complex consists of eleven buildings, several of which are physically connected to form a roughly L-shaped operation along Gordon and Front Streets (Photo 1); the facades are along Front Street. Buildings H and K are separated from the others, to the east (Photos 2 and 3). See Figure 2 for a labeled site plan. The site is depressed below Front Street, but buildings open onto both Front Street on the west and the lower level courtyard to the east. The site slopes down toward the river. The buildings are generally brick with terra cotta trim except the Office, the west façade and south side of which

- 11. 10 are clad in limestone. The complex generally exhibits a restrained Italian Renaissance style, with the rusticated street level masonry, pilasters, dentiled cornice, arched windows, and classical columns at the main (Office) entry. The initial design of the complex exhibited an ordered simplicity and consistency that was honored in subsequent alterations and additions. The complex reads as a unified composition. Common features include terra cotta and limestone belt courses, cornices, and similar fenestration that unify the contiguous buildings, concrete floors, exposed ceilings, and bumpers at many corners and large door openings to prevent damage from vehicles. Dates incorporated into decorative pediments on some buildings record the construction dates. According to historic Sanborn maps, all construction was intended to be fireproof, except for exposed steel roofing members.1 On plans from 1950, the buildings are labeled as follows: 1 Sanborn Map Company, Allentown, 1911 (New York: San- born Fire Insurance Map Company, 1911), plate 68, accessed from Proquest, Inc., http://sanborn1.proquest.com/map. php?m=510189, March 5, 2011. Building A: Office Building B: Brew House Building C: Machine House Building D: Boiler House Building E: Filter Room Building F: Stock House Building G: Wash House Building H: Ale Stock House Building I: Pump House Building J: Bottling House Building K: Storage Site features include fencing, paving materials, retaining walls, and site access features. A set of concrete stairs descend to access the side of the Brew House from Gordon Street. Vehicles can access the property from driveways off Liberty Street (east of Building J) and Gordon Street (east of Building D). A rail siding extends from the railroad mainline into the property, ending between the Brew House and Stock House (see Figure 2). Much of the open area on the site is paved with bricks, except the Photo 1. Neuweiler Brewery along Front and Gordon Streets, view north. Buildings A, B, E, F, and J extend along Front Street to the left, and Buildings B and C extend along Gordon Street to the right.

- 12. 11 Photo 2. Building H, view northwest. Photo 3. Building K, view north.

- 13. 12 area near the railroad line, which is grass (see Figure 1). A metal diamond-pattern fence is located along the edge of the property at the Front Street sidewalk (Photo 4). A gate in this fence near the southern end of Building J once accessed stairs down to the property. A chain link fence has been erected to separate recently leased spaces and prevent access to the abandoned buildings. Each building is described individually below. For the purposes of this document, the first story is considered the ground-level story as it relates to the site. The first/ground level is below street level at Front Street. Basements are below ground level; however, these were not accessed during the site visit. Building A: Office (c. 1911) Exterior: Building A is a three-story, three-bay brick Italian Renaissance-style building with a flat roof and limestone cladding on the west (Front Street) and south (Gordon Street) elevations. This building functioned as the main office of the brewery, and included the laboratory. The building has been referred to as the brewery’s bank, but so far this use has not been identified in the documentation. The building is roughly 51 feet long (along Front Street) and 26 feet deep (along Gordon Street), and its first story is below the level of Front Street. It is offset approximately 20 feet to the south of the buildings behind (B, C, and D). On the façade along Front Street, the foundation is granite and the façade is limestone, which is rusticated at the second story (at street level). A limestone entablature belt course is between the second and third stories, and a dentiled entablature with a broad frieze band forms the cornice (Photo 5). The central entrance on the façade is defined by a projecting pedimented entry with polished granite columns with Corinthian capitals and a frieze carved with “Neuweiler” above. The double doors, accessed by three granite stairs, have an arched, fluted surround. The arched transom and the southern door are covered with plywood. The exposed northern door has a window opening covered in plywood and a panel below. Two pairs of jack arched windows flank the central entry; each pair shares a limestone sill. Arched windows at the third story are similarly paired. On the limestone clad south elevation, two windows at each story are not paired, but are jack arched at the second story (street level) and round arched at the third story, similar to the façade (Photo 6). The base, belt course, and cornice on the façade continue around the side and rear elevations. The east (rear) elevation is brick, with boarded-up brick jack arched window openings at the second story and round arched one-over-one windows at the third story (Photo 7). The northern window opening at the second story is bricked-in; this appears to be a historical condition. The second-story limestone masonry coursing at the west and south elevations is reflected in the brick relief of the rear elevation, and continues on the Brew House. Because the site slopes downward to the east, the brick first story is exposed on the rear elevation. Two-over- two wood windows are present below the limestone belt course, which continues from the base of the side (south) elevation. The north (side) elevation is also brick, with similar trim and window openings (Photo 8). The window openings here are symmetrically placed, three at each story. However, the western windows at each floor are infilled with recessed brick with limestone sills. Window openings at the first story are covered with plywood. Interior: Doors with transoms at the second and third stories, on the east elevation near the north end, internally connect the Office Building to the Brew House to the rear. Paneled wood reveals extend the depth of the masonry wall (Photos 9 and 10). Adjacent interior windows are one-over-one double-hung sash. Walls are plastered throughout, except for later partitions, unless the plaster has failed. At the second floor, several historic features remain, including wood private office enclosures, some stair newels and balustrades (though the stairs themselves have been compromised), wood window surrounds and the decorative plaster ceiling (Photos 11 thru 13). Some exterior windows remain beneath the paneling, and are visible on the interior. At the third story, flooring is wood, there are wood window and door surrounds, and some partitions are beaded board (Photo 14). There are also plaster ceilings at this floor, although some have failed. Photo 4. The historic diamond-shaped metal fence behind the chain link fence along Front Street, view southeast.

- 14. 13 Photo 5. Building A, the Office Building, view east. Photo 6. Building A, south side elevation, view northwest.

- 15. 14 Photo 7. Building A, south (side) and east (rear) elevations, view northwest. Photo 8. Building A, north (side) elevation, view south. The Brew House is visible to the left, and the retaining wall and fence along Front Street to the right.

- 16. 15 Photo 9. Building A, doorway and window between the first floor Brew House and Office Building, view south from the Brew House. Photo 10. Building A, doorway between the third floor Brew House and Office Building, view south from the Brew House.

- 17. 16 Photo 11. Building A, 2nd floor, view south. Note the remaining woodwork, and plaster fallen from the ceiling. Photo 12. Building A, 2nd floor, view west. Window surrounds and other woodwork are visible, as well as the collapsed stair.

- 18. 17 Photo 13. Building A, view of the decorative plaster that survives on the second floor ceiling, view west. Photo 14. Building A, collapsed plaster ceiling and windows remaining behind the exterior plywood, third floor, view southeast.

- 19. 18 Building B – Brew House (c. 1911) Exterior: The Brew House, where the grain was mixed and the beer was brewed, is a six-story brick building with a basement level and a penthouse, measuring roughly 49 feet deep by 76 feet wide.2 The building abuts the east (rear) elevation of the Office Building, and is offset to the north approximately 28 feet. It is set back from Front Street approximately 25 feet. The building is comprised of two masses divided by a single steel framed partition wall: the roughly 38’ wide by 48’ deep, six-story southern portion (Photo 15), and the roughly 38’ wide by 57’ deep, five-story northern portion (Photo 16). The first level of the northern portion begins at the second level of the southern portion, leaving clearance for rail cars at grade. While the massing, fenestration, and roofing differ, the segments are treated as a unified whole with the same brickwork, belt courses, and copper cornice, which carry onto the adjacent Building F (Photo 17). The importance of the Brew House’s southern portion is emphasized by the consistent treatment of its brickwork, copper cornice, large arched window openings, and terra cotta trim on each elevation. On the west elevation, facing Front Street, the southern portion of the Brew House has two bays, each defined by brick pilasters with terra cotta capitals and bases. The southern bay at the first through third stories is obscured by the Office Building (see Photo 15). A granite belt course above the first story, and terra cotta belt courses above the second and third stories, continues those at corresponding levels of the Office Building. Another entablature-like belt course is located above the fifth story of the Brew House. Each bay contains a pair of wood windows with a common limestone sill. At the first story (below street level), the limestone belt course forms the lintel for the window openings, which have been covered with plywood. At the second story, these windows are rectangular one-over-one units with brick jack arches and limestone keystones. At the third story, these windows are framed by limestone lintels and sills. At the fourth through sixth stories, the windows are capped by arched transoms, divided by a fluted mullion, within a brick arched opening with scrolled terra cotta keystones (Photo 18). The pyramidal roof is clad in copper sheets, has a heavy, dentiled copper cornice, and is capped by a domed copper cupola. The cupola has operable nine- pane pivot windows and a tall flagpole at the top. The fenestration of the southern elevation is similar to that of the west, with double-hung windows with arched transoms in arched brick openings (Photo 19). The fourth through sixth stories have the scrolled terra cotta keystones. A paneled wood spandrel separates the windows of the 2 This measurement is at the second story, at the building’s full dimension. The building is only about 57 feet on the first floor, leaving clearance for the rail siding. third and fourth stories, which are contained within the same brick arched opening. At the second story, the brick arches are plain, but the brick pilasters separating them are laid in a pattern mimicking the limestone on the Office Building. At the first level, flat arched door and window openings are covered with plywood. The northern section of the Brew House is also six stories, but only the southern bay touches the ground; the northern bays begin above the first story to allow for rail cars at grade (see Photo 16). The horizontal division of the western façade by belt courses and vertical division by brick pilasters continue the pattern and material from the southern portion of the Brew House. The copper cornice is similarly consistent, except that it is at a lower level. In the southern bay of this section, windows are similar to those on the southern portion of the Brew House, except that there are no arched window openings at the upper stories; instead, these are paired one-over-one windows with brick jack arches and simple terra cotta keystones. Fifth-story windows have single-light transoms, and windows at the sixth story have no discernible decorative lintel as they are capped by the copper cornice. The lower, dentiled portion of the cornice is missing. The northern bay has a carved limestone entablature above the rail car opening that reads “Neuweiler and Son,” though the northernmost portion of the entablature is obscured by the later Building E (Photo 20). A slide mechanism indicates a former sliding door across this opening. The windows above are small compared to those of the southern portion of the Brew House. At the second story, there are four narrow single casement windows with limestone sills and tall brick jack arches. One is a two-light window, and others are one-light, though a muntin may just be missing in these sashes. Similar windows at the third story have terra cotta keystones in their lintels. Instead of windows at the fourth and fifth stories, there is a large limestone relief with what appears to be a sort of Neuweiler crest. The letter “N” is in an oval shield, which is capped by a lion’s head and surrounded by what appear to be the grains of the family trade. At the sixth story, there are two, two-over-two double-hung wood windows. The east (rear) elevation has six-over-six wood windows, though the bottom sash is not always present (Photo 21). A corrugated metal penthouse, which contains grain elevator equipment, is located on the flat roof, as is a stucco covered wood frame structure that contains the elevator equipment and the stair access to the penthouse (Photos 22 and 23). The roof of the sixth story, accessed from the elevator housing structure, is partially covered with trees and grass as a result of ineffective drainage. Interior: As the brewing process was literally a “top-

- 20. 19 Photo 16. Building B, five-story northern end, with rail siding below and penthouse at the roof, view northeast. Photo 15. Building B, six-story southern section (one story is below grade) extends behind Building A (Office), view east.

- 21. 20 Photo 17. Building B, southern section upper windows, detail, view northeast. Note the fluted mullions, remaining window frames, and projecting terra cotta keystones. Photo 18. Building B, southern section, third and fourth-story windows, detail, view northeast. Note the fluted mullions.

- 22. 21 Photo 19. Building B, south elevation, view northwest. Photo 20. Building B, detail of “Neuweiler and Son” entablature above the rail siding, view northeast. Note the open casement window frames above. The entrance to Building E is just out of frame to the left.

- 23. 22 Photo 22. Building B, corrugated metal machinery penthouse on the roof of the northern section, view north. Photo 21. The rear (east) elevation of Buildings B is visible between the side of Building D (at left) and Building F, attached to the right, view southwest.

- 24. 23 down” operation, raw materials were loaded to the top of the building via grain and malt elevators, and proceeded downward through the brewing process. The northern portion of the Brew House primarily stored malt in various large tanks and hoppers until it was fed into the brewing process. The actual beer production took place via a system of tanks, tubs, and kettles in the southern portion of the building. Cutouts in the floors contained multi-story tanks and the brew kettle and related pipes, and allowed for viewing the multiple-story operation and provided access to the tank exteriors. Cutouts include a section encompassing most of the southern end of the floor from the fourth to sixth stories (Photos 24 and 25). Each end of the building has its own internal steel stairs with stamped steel treads and steel pipe railing (Photo 26), and a single elevator is located near the center of the eastern elevation. Floors are concrete and tile, with a tile base along the walls for easy cleaning (Photo 27). Ceilings are shallow barrel vaulted concrete between the steel beams (Photo 28). Walls are plastered (though some plaster has fallen away), and wood moldings surround the doorways. Interior structural steel columns are exposed. Brewing equipment has largely been removed from the southern portion of the Brew House, but several tanks and other equipment remain in the northern portion. There is a doorway at the northeast corner of each story, except the first and fifth stories, to connect the Brew House with the adjacent Building F – the Stock House (Photo 29). The interior of the northern section of the Brew House is characterized by its relatively small windows, concrete floors, and the tanks, hoppers, and other equipment (Photos 30 thru 33). At the second story, there is a large steel framed opening in the central partition between the north and south segments of the building, with an opening to the first floor below surrounded by pipe railing (see Photo 30, at the left of the frame). A raised steel platform in the northeast corner at the fourth story provides access to the upper portion of the massive malt hopper. The interior of the southern portion of the Brew House is more distinguished with its large windows, tiled floors, decorated balustrades, floor openings at the second and third stories, and substantial rectangular open section between the fourth, fifth, and sixth stories (see Photos 24 thru 28). These floor openings allowed for large tanks and associated pipes, rendered the brewing process somewhat visible, and allowed for continuous monitoring and easy communication among the floors. Other typical views are shown in Photos 34 thru 37. A five-panel wood sliding door is located near the west end of the central partition on the fifth floor; portions of steel catwalks that wrapped around the tanks are detached and hanging from the ceiling (Photo 38). Some railings around the openings in the floors are partially detached. Above the sixth floor, the concrete ceiling is supported by an exposed steel framing system (Photo 39). Photo 23. Building B, elevator housing penthouse on the roof of the northern section, view southeast.

- 25. 24 Photo 24. Building B, southern section, floor cutout at the second story, view south. Photo 25. Building B, southern section, multi-story floor cutout spanning the fourth through sixth stories, view east.

- 26. 25 Photo 26. Building B, southern section, open stair at the third story (typical), view southwest. Photo 27. Building B, southern section, floor cutout for the brew kettle at the third floor, view east.

- 27. 26 Photo 28. Building B, northern section, second floor, open stair at the third story (typical), view west. Note the vaulted ceiling. Photo 29. Building B, northern section, doorway between Buildings B (Brew House) and F (Stock House), view north.

- 28. 27 Photo 30. Building B, northern section, second floor, showing the floor cutout (at left) adjacent to the partition, view west. Photo 31. Building B, northern section, malt storage tanks remaining in the Brew House, view west. Note the exposed steel framing.

- 29. 28 Photo 32. Building B, northern section, sixth floor, pipes that distributed grain to the malt storage hoppers, view east. Photo 33. Building B, third-floor doorway between the north and south sections of the Brew House, view south. Note the transition in flooring materials and the intact door surround.

- 30. 29 Photo 34. Building B, southern section, second floor, view northeast. Photo 35. Building B, southern section, third floor, view north.

- 31. 30 Photo 36. Building B, southern section, fifth floor, view south. Photo 37. Building B, southern section, fifth floor, looking up, view south.

- 32. 31 Photo 38. Building B, southern section, fifth floor, view west. Note the paneled sliding door to the northern section to the right, and the disconnected balcony and stair railings in the left portion of the image. Photo 39. Building B, southern section, fifth floor, looking up to the steel-supported concrete ceiling, view north.

- 33. 32 The interior of the elevator penthouse is parged, and the door to the roof has a flat wood surround (Photo 40). There are two paired windows, one on the west elevation and one on the north elevation. The corrugated metal penthouse space contains grain elevator equipment and piping (Photo 41). Building C – Machine House (c. 1911) Exterior: The two-story brick Machine House, adjacent to the east wall of the Brew House, is approximately 38’ wide by 61’ deep (Photo 42). The flat roof has a brick parapet with terra cotta coping, and a central gable-roofed clerestory (Photo 43). Clerestory windows are six-light metal horizontal pivot windows. Only two elevations are visible. On the four-bay south elevation, fenestration is consistent with that of the Brew House (Photo 42). At the first story, flat arched window openings have been filled in. Brick panel spandrels separate these from the arched window openings at the second story, the window and transoms of which have been filled in with painted plywood. Sills are brick. The eastern window opening at the second story is open; no window frame exists here currently. Mullions here are not fluted like those of the Brew House. The north elevation is divided by a later roof that covers the rail siding adjacent to this building. A wood framed door opening provides access to the building from the exterior in the western bay. Other large door openings are boarded over and cover wood roll-up doors with paired six-light transom widows, which are visible on the interior; not all windows survive (Photo 44). Second story windows are paired wood windows with concrete sills and exposed steel lintels (Photo 45). Interior: The interior has exposed brick walls, concrete floors, and tile base along the walls. Each story is a single room. Internal doors provide access between the Machine House and the Boiler House to the east and Brew House to the west; a doorway on the first floor provides the only access to the Boiler House (Photo 46). Internal steel stairs are located on the west wall; the balustrade is missing (Photo 47). At the first story, the brick walls are painted white. Exposed steel beams support the concrete floor of the second floor above. A door to the Brew House on the west elevation has a six-pane transom window (see Photo 46). At the second story, “compressor room,” the original stair balustrade remains, as does a similar railing system around an opening in the floor near the east wall. The single room has a concrete floor and concrete ceiling with exposed steel roof trusses. There is a central concrete floor platform in the floor with a raised border. More recent two-by-four framing surrounds a portion of the platform (Photos 48 and 49). There are four arched window openings on the east wall looking into the Boiler House, similar to the exterior window openings, with wood pivot windows capped by arched transoms; the beaded center mullion is also present here, as well as at the interior of other windows at this level. The single pivoting window sash reads as two three-light casement windows (though only one muntin survives) separated by the fluted mullion (Photo 50). Building D – Boiler House (c. 1911) Exterior: The two-story brick Boiler House, adjacent to the east wall of the Machine House, is approximately 52’ wide by 53’ deep. The steel framed gable roof has a shallow brick parapet with terra cotta coping, and a central gable- roofed clerestory. While the belt course and cornice are similar in material and design to those elsewhere, the differing height of the stories required non-contiguous placement on the building (Photos 51 thru 53). On the south elevation, all window openings have brick arches (see Photo 51). At the second story, only one one- over-one wood window remains, though it appears that the windows were likely in the same configuration as those on the Brew House, including the fluted mullions. Wood windows and frames remain at the lower level. The east elevation has corbelled brick belt courses that define each story (Photo 54). Windows at the second story have wood double-hung sash with four-light upper sashes, limestone sills, and exposed steel lintels. Lower window sashes are missing. The metal chute to the former chimney stack remains, though the stack has been demolished. Some rubble from the stack remains at the site. The north elevation has paired six-over-six light windows with concrete sills and exposed steel lintels (see Photo 52). First story windows are boarded over, but portions of the windows are present behind the boards. The western window sill and bricks below have been removed, likely to provide access for the removal of large boiler equipment (visible on the interior). The windows and frame are missing entirely from the second story east window opening. Interior: The interior is a single full-height space encompassing the first and second stories, with exposed brick walls and a concrete floor (Photos 55 thru 57). The ceiling is concrete, supported by steel trusses. A door opening with exposed steel lintel is located on the west wall, providing access to the Machine House to the west. Steel stairs with pipe railings adjacent to this wall descend

- 34. 33 Photo 40. Building B, northern section, roof-level elevator housing, view southeast. Photo 41. Building B, northern section, grain elevator equipment in the corrugated metal penthouse, view northeast.

- 35. 34 Photo 42. Building C, Machine House, south elevation, view northwest. Photo 43. Building C, view of the roof from the fourth floor of the Brew House, view southeast. Note the steel pivot clerestory windows.

- 36. 35 Photo 44. Building C, first floor, view northeast. The wood overhead garage door and three-light transom are visible on the interior. (Courtesy of Cornerstone Engineers & Architectural, Inc.) Photo 45. Building C, north elevation, second story, view from the Brew House, view southeast. Note the trees growing from the base of the parapet wall.

- 37. 36 Photo 46. Building C, first floor, view northeast. The wood overhead garage doors are visible to the left, and the doorway to the Boiler House is visible in the distance. (Courtesy of Cornerstone Engineers & Architectural, Inc.) Photo 47. Building C, first floor, view southwest.

- 38. 37 Photo 48. Building C, second floor, view southwest. Photo 49. Building C, second floor, view east. The windows on the far elevation look into the Boiler House to the east.

- 39. 38 Photo 50. Building C, second floor, east elevation window detail, view east. Note the pivot sash and the fluted mullion. Photo 51. Building D, Boiler House, view northwest.

- 40. 39 Photo 52. Building D, north elevation, view southeast. Photo 53. Building D, rooftop, from the Brew House, view northeast.

- 41. 40 Photo 54. Building D, east elevation, view southwest. Photo 55. Building D, interior, view down from the second floor of the Machine House, view northeast.

- 42. 41 Photo 56. Building D, interior, view across from the second floor of the Machine House, view northeast. Photo 57. Building D, interior, view up from the second floor of the Machine House, view northeast.

- 43. 42 to the basement below. Steel framing and double-height brickwork that enclosed the boilers remain in place. A portion of the steel catwalk below the second story windows remains along the east and south walls. Building E – Filter House (between 1932-1950) Exterior: The Filter House is a one-story brick building located adjacent to the west wall of Building F and the east side of Front Street (Photo 58). A single metal roll- up garage door, accessed from a concrete platform, is located on the south elevation; it appears that this opening has been altered, as concrete blocks now surround the modern door rather than brick (Photo 59). The western brick elevation, with cast stone cap, entablature, and base, forms a wall located directly along Front Street along this building. The brick is laid in a pattern mimicking the horizontal masonry joints of this level of adjacent buildings. The north elevation is a plain brick wall. The interior was not accessible for survey. Building F – Stock House (1911) Exterior: The Stock House is a six-story, nine-bay brick building, contiguous with the Brew House (Building B) to the south (see Photo 58). The horizontal division of the façade by belt courses and vertical division by brick pilasters continue the pattern and material from the Brew House. The copper cornice is similarly consistent. The second story, at street level, maintains the brick banding evident at the Brew House and Office Building (east and north elevations). Generally, there are window openings in every other bay on the façade. However, many of these are blind openings, filled with recessed brick. All of these openings have brick jack arches with limestone keystones and sills. The windows that are present are paired three-light wood casements with fluted center mullions, except those at the sixth story, which are paired two-light casements. Sixth story windows have no discernible decorative lintel as they are capped by the copper cornice. The southern three bays correspond to the levels of the Brew House, attached to the south (Photo 60). The top two stories of the northern six bays are slightly higher, though with the same cornice line, creating a short interior for the sixth story here (Photo 61). Windows at the sixth story are two-over-two double-hung sash. A one-story brick gabled penthouse rises above the southern three bays, and has a copper cornice (a portion of which is missing) and gabled clerestory. A terra cotta pediment notes the date of construction as 1911 (Photo 62). There are arched blind window openings in each bay. The east (rear) elevation has brick pilasters dividing the brick bays, with a corbelled brick belt course above the fifth story and a shallow sixth story above (Photo 63). The gabled brick penthouse rises above the top story. Windows on this elevation are generally blind – recessed brick in arched brick openings with brick sills, with the exception of the sixth northern bays at the sixth-story and some other windows, mostly in the southern half, at other stories. Sixth-story windows are paired two-light wood casements, and others are paired three-light wood casements, where muntins survive. Penthouse windows are wood double- hung sash in arched brick openings, with two lights in the top sash and missing bottom sashes (Photo 64). A surviving transom has two lights. A door to the loading platform near the north end of the east elevation has been infilled, and the adjacent brick arched window opening with a concrete sill is covered with plywood. The north elevation has three large brick arched openings in the center of the second, third, and fourth stories (Photo 65). No sills are evident, as brick has been damaged. The lower opening is partially infilled with concrete block. These openings appear to have been incorporated when the building was built, perhaps for loading, with multi-row brick arches defining the top of each opening (Photo 66). The remnants of a lifting beam and pulley system are evident at the roof. Flanking windows are paired three-light wood casements with brick jack arches and concrete sills. Fifth story window openings are brick blind niches, and sixth floor windows are paired two-light wood casements. Not all windows survive, and two openings are covered with plywood. The south elevation of the penthouse is parged, and there are four six-light horizontal pivot windows near the east end, as well as glass block in the clerestory window openings (Photo 67). Interior: The interior of the Stock House is largely comprised of a series of large, open spaces with exposed steel frame ceilings with concrete vaults, and brick walls lined with volcanic pumice panels for insulation (Photos 68 thru 79). At the fifth floor, there is an enclosed room with a tile interior (see Photo 74). This was the yeast room. An enclosed plastered brick stair tower, separate from the insulated spaces, is located at the southeast corner of the building; above the fifth story, the stairs are not enclosed. Rather, the door from the Brew House is insulated. Stairs are steel, open stairs with pressed treads and pipe railings (Photo 80). Thick, layered wood doors access the main spaces from the stairwell (Photo 81). Building G – Wash House (c. 1911) Exterior: The Wash House is a one and a half-story brick building attached to the east side of the Stock House (see Photo 63). The gabled concrete roof has a brick parapet

- 44. 43 Photo 58. Buildings I, F, E, B, and A (left to right) along Front Street, view southeast. The Pump House is visible at the extreme left, and the west wall and parapet of Building E (Filter Room) forms the wall along Front Street. Photo 59. Building E (Filter Room), at left, view northeast. The garage door visible at left accesses the Filter Room.

- 45. 44 Photo 60. Building F (Stock House), southern portion, along Front Street, view southeast. Photo 61. Building F (Stock House), northern portion, along Front Street, view southeast.

- 46. 45 Photo 62. Building F, copper cornices (with sections missing) and terra cotta pediment with date of construction, view northeast. Photo 63. Building F, east (rear) elevation, view southwest.

- 47. 46 Photo 65. Building F, north elevation, view southwest. Building G is at the left. Photo 64. Building F, east (rear) elevation, penthouse level, view southwest.

- 48. 47 Photo 67. Building F, south elevation, penthouse level, view northwest. Photo 66. Building F, north elevation, detail, view southwest. Note the brick arches above the large central openings, and a few intact casement windows.

- 49. 48 Photo 69. Building F, interior, second floor, view southeast. Photo 68. Building F, interior, second floor, view northwest. This room has suffered fire damage.

- 50. 49 Photo 71. Building F, interior, third floor, view southeast. Photo 70. Building F, interior, third floor, view southeast. Note the remaining volcanic pumice panels on the wall.

- 51. 50 Photo 73. Building F, interior, fifth floor, northern mezzanine level, view northwest. Photo 72. Building F, interior, fifth floor, view northwest. Note the stairs to the mezzanine level.

- 52. 51 Photo 75. Building F, interior, sixth floor, view northwest. Photo 74. Building F, interior, fifth floor mezzanine level, view northwest. This fully tiled room was the yeast room.

- 53. 52 Photo 77. Building F, interior, sixth floor, view southwest. Photo 76. Building F, interior, sixth floor, short northern end, view northwest.

- 54. 53 Photo 79. Building F, interior, penthouse, view northeast. Photo 78. Building F, interior, penthouse, view southwest.

- 55. 54 Photo 81. Building F, interior, second floor, typical insulated door to a fermenting room, view southwest. Photo 80. Building F, interior, penthouse, typical stair, view south.

- 56. 55 door openings on the western block have been infilled with brick; the pedestrian door opening in the western bay has been infilled with brick and a small single-light window. A modern pedestrian door is located in the eastern bay. The west elevation of the one-story western portion of the building is seven bays, each separated by brick pilasters. It appears that each bay was originally open, and has since been infilled with brick. A gable roofed shed is located in front of the second bay from the south end of the building, near a historic insulated wood door into the building (Photo 92). The western elevation of the two-story central block has six symmetrically placed arched niches filled with brick. A brick one-story bay, the stair enclosure, projects from the third bay from the south. The north elevation has a double-width insulated door in the western block, accessed by a concrete ramp (Photo 93). A wood panel door is located at the western bay of the central block, accessed by concrete stairs with pipe railing. A metal emergency stair provides access to a second-story door above. The cornice on the central block is terra cotta. Window openings at the east bay of the first and second stories of the central block are blind niches with brick jack arches and concrete sills. The east elevation of the one-story eastern block is stucco, with an overhead garage door in the southern bay. A one-story concrete paneled addition extends to the north (Photo 94). Both of these structures rest atop a concrete foundation. The western elevation of the two-story central block has six symmetrically placed arched niches filled with brick at the second story. There is a large patch of concrete block infill in the southern bay. There are similar blind niches at the first story, though somewhat smaller and more numerous (Photo 95). A corbelled brick and metal cornice defines the roofline. Interior: The interior spaces are generally characterized by concrete floors, painted masonry walls, and open ceilings. The central block contains two main rooms at the first floor and a single room at the second floor. On the first floor, the front (south) portion contains a concrete block room with two doors (Photos 96 and 97). A double-width insulated door provides access to the larger rear section (Photo 98). The second story is a single room with a tiled floor with perimeter gutters and an open ceiling exposing the roof trusses. Metal studs line the walls (Photo 99). The western block is open on the interior, with insulated exterior walls (north, south, and west) (Photo 100). An internal brick enclosed stair tower is located on the east wall. Large doors provide egress on the north and south and a large gabled clerestory, with six-light pivot windows, several of which are covered with plywood (Photo 82). A broad wood and corrugated metal awning supported by cantilever metal brackets and trusses overhangs the platform (Photos 83 and 84). At the southern end, the awning extends to meet the north elevation of the Boiler House, providing cover for the rail siding (Photos 85 and 86). There are symmetrically placed square window openings at the mezzanine level, with six-light wood windows in brick arched openings with brick sills; these are directly below the exterior awning, and some are covered with plywood. Brick arched window openings with brick sills at the first story are covered with plywood. There are paired double-hung sash windows at the center of the south gable end with four-light top sashes windows (bottom sash are missing) and exposed steel lintels (Photo 87). To the west of this is a similar pair of smaller windows. Several regularly spaced doorways on each elevation access a wood timber loading platform on steel piers that encircles the building on the east, south, and north elevations. Most door openings are covered with plywood. The wood panel door at the east end of the south elevation remains, as does a large panel door at the north elevation. Interior: The interior of the Wash House is largely a single room with exposed steel roof trusses and a steel and concrete mezzanine around three sides of the building (Photos 88 thru 90). The floor is concrete. One small room with brick walls is located at the southeast corner of the building, and a similar room is located at the northwest corner. A large pipe hangs from the center of the ceiling. Building H – Ale Stock House (by 1932) Exterior: The Ale Stock House is a south facing building with a two-story central section flanked by one-story sections, built between 1911 and 1932 (Photo 91; see also Photo 2). Each section is distinguished by its design, size, and material. The two-story brick central section and one-story western one-story brick section were present by 1932, and the eastern one-story stuccoed concrete block section was added after 1972. The central 2-story section has a flat roof with a pedimented brick parapet, capped by metal coping. A dentiled terra cotta cornice is located below the parapet on the north, west and south elevations of the central and western blocks. The western brick section has a shed roof, with a stepped parapet abutting the central block. The (south) façade has two modern overhead garage doors for loading in the central block; the first floor around these doorways appears to have been altered. Similar overhead loading doors are located on the eastern block, as well as a modern pedestrian door in the western bay. Former

- 57. 56 Photo 83. Building G, north elevation, view east. Note the broad awning over the loading platform. Windows are somewhat visible below the awning. Photo 82. Building G (Wash House), clerestory on the gable roof, view northeast.

- 58. 57 Photo 85. Building C, B, F, and G (left to right), east elevation, view southwest. Note the broad awning extending over the rail siding to Building C. Photo 84. Building G, east elevation, along the loading dock, view northwest.

- 59. 58 Photo 87. Building G, south elevation, gable end, view northwest from the second floor of the Machine House. Photo 86. Roof over the rail siding with skylight, view northeast.

- 60. 59 Photo 89. Building G, interior, view northwest. Photo 88. Building G, interior, view northeast.

- 61. 60 Photo 91. Building H, view northeast from the fifth story of the Brew House. Photo 90. Building G, interior, view southwest. Note the balcony that encircles the room below the clerestory.

- 62. 61 Photo 93. Building H, north (rear) elevation, view south. Photo 92. Building H, west (side) elevation (southern end), view southeast.

- 63. 62 Photo 95. Building H, east (side) elevation, northern portion, view southwest. Photo 94. Building H, east (side) elevation, southern portion, view southwest. The one-story additions were present by 2005. The concrete base of the chain link fence is the foundation for the former auto shed on the site.

- 64. 63 Photo 97. Building H, interior, view southwest. Photo 96. Building H, interior, view toward cooler, view northeast.

- 65. 64 Photo 99. Building H, interior, second floor, view northwest. Note the tile floor with perimeter gutter and drain. Photo 98. Building H, interior, first floor of the two-story block, view toward cooler, view northwest.

- 66. 65 elevations, though the south door opening is covered. The later eastern block is a metal-lined refrigerated room with an exposed steel structure and a plastic fringe door opening (Photo 101). Building I – Pump House (by 1932) Exterior: This small one-story brick building, measuring 18’ by 24 ½’, with a concrete foundation attached to the west end of the north elevation of the Stock House (Building F) (Photo 102). The flat roof is surrounded by a brick parapet with terra cotta coping, and has a steel framed clerestory with a hipped glass roof and four-light pivot windows in the side walls (Photo 103). A terra cotta entablature cornice caps the first story on the north and west elevations. Three symmetrical window openings on the east elevation have a three-row brick header arches and concrete sills. No windows or frames remain here, and the central window opening is covered with plywood. The arched portions of the openings are filled in with brick. Arched openings on the west elevation contain four-over-four windows (some sash missing), and are covered with plywood. On the north elevation, tall stretcher bond brick window arches have terra cotta keystones. The north window is a wood four-over-four double-hung sash. There is a large door opening on the north elevation, with no door. Interior: The interior is a single room with a concrete foundation and exposed brick walls. The floor is filled with debris. It historically contained brine pumps and a gas engine to power the pumps that moved various fluids throughout the complex. Building J – Bottling House (1912, 1934) Exterior: This three-story, ten-bay brick building on a concrete foundation was built in two sections: the southern section was built in 1912, and the northern section in 1934 (Photos 104 and 105). Each section has a central terra cotta pediment with the construction date (Photo 106). The roof of the southern section has a clerestory, which has been closed up except for a central vent; the northern roof is flat (Photo 107). The west façade is unified by an awning extending over the length of the wood and steel loading dock, featuring a copper frieze along the edge. At one time, the copper included bottle shapes in the design; however, these have been removed. The awning is secured by iron chains fastened to the building through the mouths of iron lion heads on the façade (see Photo 106). Similar to the Stock House, the bays are articulated by brick pilasters with terra cotta capitals and Photo 100. Building H, interior, western block, view southeast.

- 67. 66 Photo 101. Building H, interior, cooler addition, view southwest. Photo 102. Building I, Pump House, view southwest. Note the remaining windows.

- 68. 67 Photo 103. Building I, view of the roof from Building J, view southwest. The north wall and roof of Building E are somewhat visible in the background to the right. Photo 104. Building J, Bottling House, view southeast.

- 69. 68 Photo 105. Building J, northern section, view north. Photo 106. Building J, terra cotta pediment with the date of construction of the northern addition (1934), view east.

- 70. 69 bases. On the western façade, facing Front Street, only the second and third stories are visible. At the second story – at grade here, there are several door and window openings covered in plywood. Window openings have limestone sills and exposed steel common lintels, which the awning largely obscures. Certain smaller openings are no doubt associated with moving beer cases from inside to waiting customers or delivery vehicles. A “Retail Sales” sign projects above one door opening. Third-story windows are one-over-one wood windows in paired brick arched openings with terra cotta keystones. Above the third story, these are capped by a terra cotta entablature with dentils and a broad frieze. A limestone belt course encircles the building above the first story (not visible on the west elevation. A concrete and steel loading dock and ramp was later constructed near the south end of this elevation. The south (side) elevation has a large opening at the central bay of the third story for loading; the remains of an exterior pulley system remain at the roofline (Photo 108). Window openings at the third story are paired brick arches with terra cotta keystones and concrete sills. At the second story, windows have brick jack arches with terra cotta keystones and concrete sills A corrugated metal awning has been added over a loading platform supported by steel beams. A small concrete block addition was recently built in the central bay, on the loading platform. The east (rear) elevation lacks the terra cotta entablature; instead, corbelled bricks articulate the cornice of this elevation (Photos 109 and 110). Windows at the first and second stories are one-over-one wood double-hung sash (where they survive) with brick flat arches and concrete sills. Third-story windows are one-over-one arched double-hung sash in paired arched brick openings with terra cotta keystones. Some openings are infilled with concrete block, brick, or louvered vents, or covered with plywood. One pair of window openings has been combined and infilled with glass block. A pedestrian entry accessed by concrete steps with a brick base and pipe railings is located at the southernmost bay. A raised metal slab door with a brick surround is located in the northernmost bay. There is a garage door bay near the center of this elevation at the first story. The north (side) elevation along Liberty Street has characteristics similar to the façade: terra cotta cornice and frieze, brick pilasters separating the bays, one-over- one wood windows (where they survive), and paired arched window openings at the third story and flat jack arches with terra cotta keystones at the second story (Photos 110 and 111). At the first story, at ground level, security bars cover the window openings. Interior: The interior of this building is mostly characterized by concrete floors and large rooms with steel support Photo 107. Building J, view of the roof from Building F, view northwest.

- 71. 70 Photo 108. Building J, south (side) and east (rear) elevations, view northwest. Photo 109. Building J, east (rear) elevation, view northwest.

- 72. 71 Photo 110. Building J, east (rear) and north (side) elevations, view southwest. Photo 111. Building J, north (side) elevation, view southeast.

- 73. 72 columns (Photos 112 thru 117). There are few ceilings, as most roofs are exposed steel beams supporting the concrete floor above; at the third story, exposed trusses at the southern half of the building support the concrete roof (Photos 117 and 118). Stairs are located at the northeast and southwest corners of the building (Photo 119), and an elevator is located on the west side of the southern end of the building. Bathrooms are located at the northeast corner of the first story. Some bottling machinery and conveyors remain in the first story, below the loading area at the northwestern corner of the building (Photo 120). At the third story, a few areas have drywall partitions associated with more recent uses (see Photo 121). Building K – Storage House (1914) Exterior: The Storage House, originally an auto repair building, is a one-story, seven-bay brick building approximately 62’ wide and 98’ long; its primary façade is oriented to the south (Photo 122). The gable roof has a brick parapet with metal coping; the parapet steps up at the central entry, and forms a gable at the west elevation. The foundation is concrete. Each bay is recessed in a frame of brick pilasters and brick corbelling. A pressed metal cornice wraps around most of the south and west elevations. The seven bays of the façade are symmetrical, and have large openings with brick arches and painted concrete sills. The central entry is a large overhead garage door with a decorative pressed metal pediment above indicating the date of construction (1914) (Photo 123). A pedestrian door has been installed just east of the central garage door. All other openings, except the western bay, are covered with painted plywood. Behind the plywood, some wood windows remain with six lights in the upper sash (the lower sash is covered with plywood). The western bay is clad with a faux stone veneer, and the door has been replaced. The west (side) elevation has five bays, each with a pair of six-over-six replacement vinyl windows in brick arched openings with lug sills (Photo 124). A faux cameo window with terra cotta voussoirs is located in the parapet wall. Theeast(side)elevationhasacentralgaragedooropening, and flanking bays with enclosed window openings similar to those on the façade (Photo 125). Some of these are infilled with concrete block and stucco. This elevation has been covered in stucco. Similar to the west elevation, there is a gabled roofline, with a faux cameo window in the gable end. The north (rear) elevation is brick and has window openings similar to those of the façade; these are infilled with parged concrete block (Photo 126). Interior: The interior is divided into two components. The western end of the building has been subdivided for office use with a bathroom offices, hallway, and reception counter, and was occupied until recently. The remainder of the space is a clear-span room with concrete floor and painted brick walls (Photos 127 thru 129). A small mezzanine is located on the west end of this space. Other The concrete roof over the rail siding east of the Brew House is supported by steel trusses. It has a steel framed skylight and clerestory above, but the glass is missing (see Photo 86). Some windows and doors are detached and stored within the buildings; there are doors lying flat on floors, and several windows and doors are stored at the sixth story of Building F (Photos 130 and 131). CONDITION ASSESSMENT The condition of the Neuweiler Brewery complex is surprisingly good after more than 40 years of neglect in most of the buildings, a testament to the quality materials and craftsmanship of the original builders. Although Buildings J (Bottling House), K (Auto Repair) and H (Ale Stock House) have been used intermittently since the brewery’s closing, much of the rest of the complex has been left to deteriorate. Openings at windows and doors and faulty drainage systems have allowed the elements (weather, animal, and human) to enter the buildings and cause damage. However, according to a previous report by Cornerstone (2011), the complex is generally structurally sound with issues related to drainage, open windows, vegetation, and related water intrusion problems being the primary concerns regarding the structure and safety. Many architectural elements and materials remain in good condition. This assessment provides a broad description of existing conditions found at the site, organized by major building elements. Exterior Walls Exterior walls are overwhelmingly brick, with the exception of limestone on the west and south elevations of the Office. Other materials include terra cotta and limestone belt courses and trim elements, granite columns at Building A, and concrete foundations and sills. The masonry is generally in good condition. There are some areas of missing or deteriorated mortar. The limestone shows atmospheric soiling, and there is efflorescence on some areas of brick. The latter may be the result of poor drainage allowing water to saturate bricks and mortar.

- 74. 7373 Photo 112. Building J, interior, first floor, view northwest. Photo 113. Building J, interior, second floor, view southeast.

- 75. 74 74 Photo 114. Building J, interior, second floor, view northwest. Photo 115. Building J, interior, second floor, later partitioned space (typical), view northeast.

- 76. 7575 Photo 116. Building J, interior, third floor, view northwest. Photo 117. Building J, interior, third floor, view southeast.

- 77. 76 Photo 118. Building J, interior, third floor, closed up clerestory, view southeast. Photo 119. Building J, interior, typical stair, view southeast.

- 78. 77 Photo 120. Building J, interior, first floor, remaining bottling conveyor and beer cases, view northwest. Photo 121. Building J, interior, third floor, partitioned space, view southwest.

- 79. 78 Photo 122. Building K (Auto Repair Building), view northeast from the second story of the Stock House. Photo 123. Building K, central entry, view northeast.

- 80. 79 Photo 124. Building K, west (side) elevation, view north. Note the replacement vinyl windows. Photo 125. Building K, east (side) elevation, view northwest.

- 81. 80 Photo 126. Building K, north (rear) elevation, view southwest Photo 127. Building K, interior, view west.

- 82. 81 Photo 128. Building K, interior, view southeast. Photo 129. Building K, interior, showing windows remaining behind boarded opening, view southwest.